Design Life-Cycle

assess.design.(don't)consume

Tom Neill

DES 40A

Professor Cogdell

Section A01

12/2/2021

Raw Materials: Air Filters

Air Filter Material Makeup

Air filters are devices composed of layers of porous material with the purpose of removing allergens, dust, bacteria and anything harmful from a certain location. Air filters are crucial elements for any building for a number of reasons. The most familiar purpose of air filters is protecting inhabitants of a building from poor air quality and the harmful health risks associated with breathing unfiltered air. Some of the health risks that can arise from not having air filters or simply not cleaning and replacing ones air filters are: congestion, respiratory diseases, and damage to the immune system. Air filters can also be added to a building's heating, ventilation, or air conditioning system in order to clean and purify the air. The air filtration component of these systems also protects them from debris that can damage and short circuit their systems. Lastly another important reason for using air filters is to protect interior decor and personal belongings from airborne dust related damage. Air filters come in many different forms and with different material makeups, but all share the same common purpose and functions. A MERV rating or Minimum Efficiency Reporting Values is a way of reporting and grading an air filter's ability to capture larger particles between 0.03 and 10 microns. In short a MERV rating grades a filter's effectiveness. The MERV scale is a scale of 1 to 16 with 1 through 4 representing less than twenty percent efficiency and 16 representing 75% or higher efficiency. The three main types of air filters for commercial and household use are the following: pleated, fiberglass, and HEPA filters. A product's material makeup refers to the materials used in the manufacturing process of any specific product both directly and indirectly. There are numerous types of air filters, each with distinctive material makeups, designs, and environmental ramifications.

One of the most common options for both commercial and household air filters are pleated filters. Often used in air conditioning units, these filters are made from pleated layers of filtration sheets. This form of air filter is different from the alternatives because it contains a series of pleats or folds that gives the filter an extra amount of filtration for debris that could damage the air conditioning units that these filters commonly protect. The folds in these filters create more surface area and density while still minimizing the constraint on airflow. Pleated air filters are also more efficient and have a stronger structural design than their counterparts. These filters are broken down into three major components. The first component of their design is its’ frame. The square frame that borders the entire structure is constructed out of cardboard. The second main component of these filters is the filter component themselves. The filtration sheets used in these filters are made from either polyester or cotton fibers and in some cases a combination of the two. Pleated filters constructed with cotton fibers are considered to be the superior filtration method as they can regulate and remove smaller particles. The last major component found in the majority of these filters is a wire mesh for structural support. These are made from tightly strung aluminum wire. Cotton pleated fitters average anywhere from a six to a thirteen on the MERV scale. According to the Environmental Protection Agency, pleated filters can capture microscopic particles. Since they are fitted with a unique synthetic wire media, they are able to filter out dust, mold, pollen, dust mite, and other small bacteria. They are also treated with Polypropylene as the final stage in their construction. Polypropylene, a thermoplastic polymer that is enhanced by the air flow over the filter, makes the filter mildew resistant, reassuring that the filter will not disintegrate over time. In summary the most common materials found in pleated air filters are: polyester, cotton, cardboard, aluminum, and Polypropylene. The material makeup and design of this form of filter makes it extremely durable with a long service life;furthermore, it also allows for the majority of these filters to be fully recyclable. The only negative aspect of pleated air filters is its’ cost efficiency in comparison to some of its alternatives; however, the superior filtration is worth the slight increase in price. Pleated air filters offer a superior filtration system with a simple, yet effective design and material makeup.

Another common form of air filtration systems for commercial and household use are fiberglass air filters. Fiberglass filters are arguably the most frequently used form of air filters due to their cost efficiency. These filters use layers of filtration made up of thin woven fibers of glass. The material makeup of these filters are quite simple: layers of spun glass, and occasionally an additive layer of foam is bonded with a thermosetting resin that strengthens and consolidates the fibers. After a layer of wire mesh is added, these sheets of filtration are then placed into either a cardboard or aluminum frame. Fiberglass filters offer adequate filtration that can easily catch larger debris without constraining airflow for lower prices than the competing options. Fiberglass filters; however, have very flimsy structural designs on top of a limited filtration capacity. It is recommended that fiberglass filters be replaced more often than pleated or Hepa filters, with a service life of thirty days. On top of this, the material made up of fiberglass filters do not allow for them to be recycled. Due to this, using fiberglass air filters creates higher amounts of waste than any other air filter option. In summary the material makeup of fiberglass filters are: fiberglass, foam, cardboard or aluminum, and thermosetting resin. Fiberglass air filters are an affordable and rudimentary option for air filtration systems.

The last commonly used form of air filtration systems are HEPA filters. HEPA does not refer to a specific type of material but instead refers to filters with specifically high MERV ratings. HEPA stands for High Efficiency Particulate Air filter. These filters are used much more diversely than Pleated and fiberglass filters. HEPA filters uses vary from disk drives to medical devices, and even semiconductors. HEPA filters are composed of a mat of randomly arranged fibers, thin fibers of glass, and some level of activated carbon-based material. HEPA filters are rated highest amongst air filters due to their ability to remove high amounts of airborne particles from an environment in comparison to pleated or fiberglass filters. HEPA filters are able to remove at least 99.97% of dust, pollen, mold, bacteria, and any airborne particles with a size of 0.3 microns. HEPA filtration systems are made from a variety of materials. The majority of these filters use fiberglass; however, there are HEPA filters that use synthetic forms of plastic such as polyester instead. These fibers are woven together to provide a highly efficient level of air filtration. HEPA filters on average are rated on the MERV scale anywhere from thirteen to sixteen.

Despite the varying types of air filters the material make up of air filters are relatively similar, with only a few changes in the design and manufacturing process. Air filters share roughly the same material makeup in theory. All air filters use a framework of some degree. Air filters use either cardboard or aluminum for constructing the framework of the filter. For the filtration aspect of all air filters both the materials and design varry. Overall the fibers used for this aspect of the filter are one of the following or a combination of several: woven fiberglass, cotton, plastics more specifically polyester, or foam fibers. The final shared component of most air filtration systems is some chemical process to strengthen or support the fibrous material. The materials used in this process vary from latex bonds, polypropylene, thermosetting resin and other forms of adhesives. It is also important to look at the complete material makeup and environmental effect of the air filter industry from acquiring raw materials, manufacturing, packaging, and shipment of air filtration companies’ products. For air filtration companies most of the raw materials can be easily obtained through large scale suppliers due to the simple nature and availability of these materials needed in this process. This process does require large scale transport systems to bring materials from suppliers to factories where filters are made, therefore: shipping trucks and containers, gasoline, and any other product used in this process are indirect materials needed for the manufacturing process of air filters. Another indirect use of materials is through the packaging and shipping of materials to consumers. Packaging of air filters is usually limited to cardboard and plastic materials. These indirect uses of materials are often overlooked when looking at a specific item's material makeup. The materials used for the manufacturing of air filters is relatively simple in relation to the functionality and effectiveness of this product.

Air filtration systems have become a fundamental element to buildings today, and rightfully so. The benefits of air filtration systems are numerous and likewise are the dangers of lacking proper air filtration. There are countless options in the air filtration market each with different specialties, price points and variables; however, HEPA filters are the superior and most efficient option. Air filtration systems protect individuals from health concerns, protect heating and cooling units from airborne particles and lastly protect individuals’ belongings from dust related damage. The raw materials needed for the manufacturing of air filters are relatively limited in relation to the effectiveness of the product overall. Regardless of the type of air filter used, they are all highly effective for filtering airborne pollutants, allergens, and other irritants that can cause health problems and damage to indoor environments. Overall air filtration systems are an essential element for the modern building that require a simple yet extremely effective material makeup and design.

Bibliography

“Air Filter Guide.” Oransi, https://oransi.com/blogs/blog/air-filter-guide.

TechSci Research, https://www.techsciresearch.com/. “Manufacturing Air Filters.” Manufacturing Air Filters | TechSci Research, https://www.techsciresearch.com/blog/manufacturing-air-filters/93.html.

Claudio, Luz. “INDOOR AIR QUALITY. Planting Healthier Indoor Air.” Environmental Health Perspectives, vol. 119, no. 10, [National Institute of Environmental Health Sciences, Brogan & Partners], 2011, pp. A426–27, http://www.jstor.org/stable/41263034.

Mike McFadden - A/C & Heating Specialist, et al. “Different Types of Materials Used in HVAC Filters: 1431 A/C & Heating.” 1431, 12 July 2021, https://1431ac.com/different-types-of-materials-used-in-hvac-filters/.

Manuel, John. “Indoor Air Quality. HVAC Officemate.” Environmental Health Perspectives, vol. 112, no. 6, [National Institute of Environmental Health Sciences, Brogan & Partners], 2004, pp. A346–A346, http://www.jstor.org/stable/3435976.

Kinesis. “Recycling Hvac Air Filters - How We Dealt with Used Filters.” Reitmeier HVAC Services |, 21 May 2019, https://reitmeiernw.com/reitmeier-is-making-zero-waste-a-reality-hvac-air-filters/.

“Fiberglass Air Filters vs Pleated Air Filters.” Pleated and Fiberglass Air Filters for AC or Furnace, https://www.airfiltersdelivered.com/c/pleated-vs-fiberglass-filters.

“How Pleated Fabric Is Made and Common Types of Pleat.” Number 1 Community and Resource Site For Fashion Students, https://www.thefashionstudenthub.com/blog/the-secrets-to-pleating.

“Why Do Air Filters Have Pleats?” Your Source For All of Your Filter Needs, 6 Aug. 2020, https://www.discountfilters.com/blog/air-filters-pleats/.

Simply The Best AC & Heating, and Simply The Best AC & Heating. “Are Electrostatic Filters Better? See The Pros & Cons: Simply the Best.” Simply the Best Heating Cooling, 24 Sept. 2019, https://www.simplythebestac.com/blog/pros-cons-electrostatic-filters/.

“What Is a HEPA Filter?” EPA, Environmental Protection Agency, https://www.epa.gov/indoor-air-quality-iaq/what-hepa-filter-1.

“What Is a MERV Rating?” EPA, Environmental Protection Agency, https://www.epa.gov/indoor-air-quality-iaq/what-merv-rating-1.

“Pleated Filters: Why They Are so Effective: Bardi Heating.” Bardi Heating, Cooling & Plumbing, 20 Apr. 2021, https://bardi.com/pleated-filters-why-they-are-so-effective/.

Nancy Amador

Professor Christina Cogdell

Des 040A

December 1, 2021

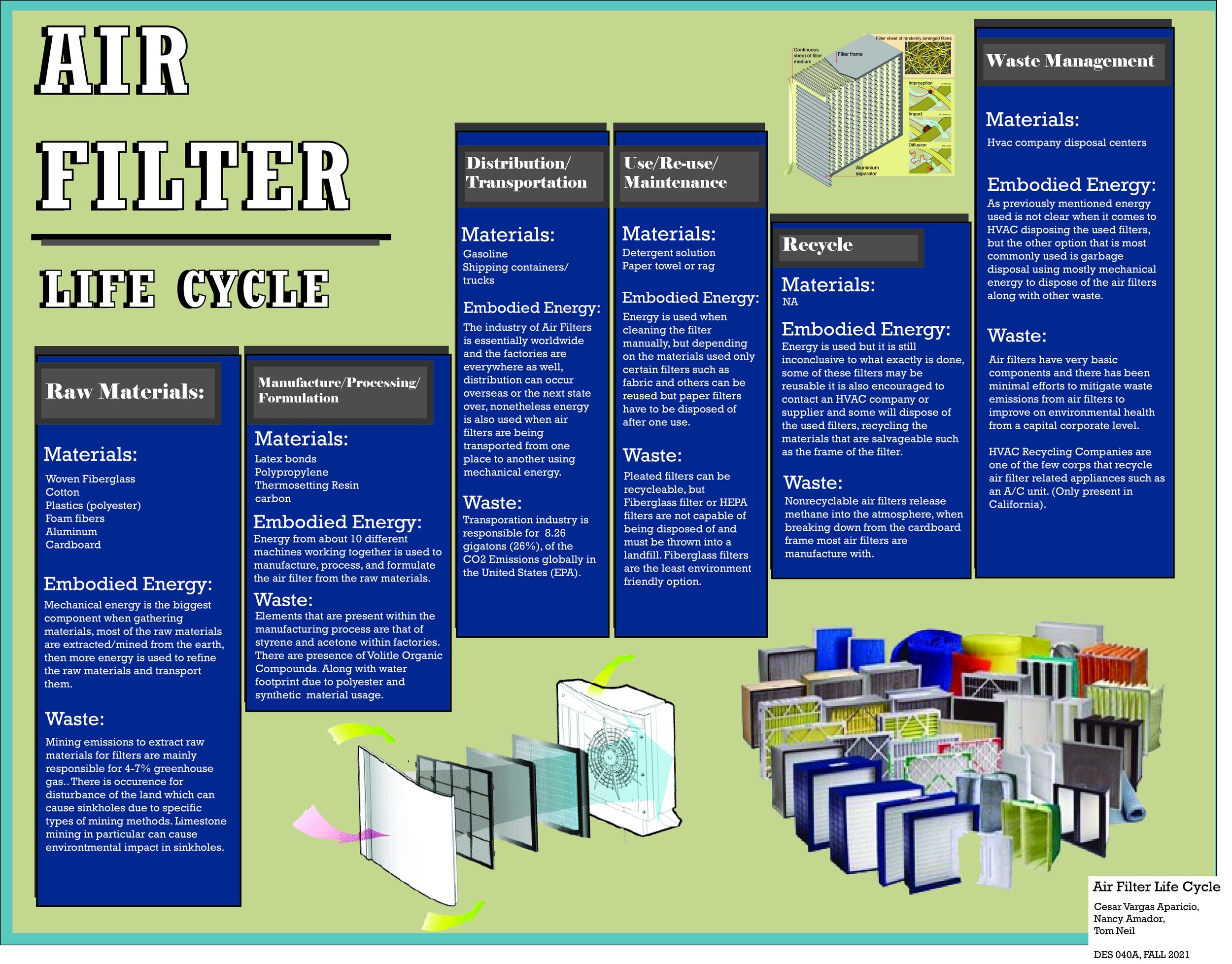

Embodied Energy Of Air Filters

Breathing is essential to live and having clean air is a big part of the longevity of our lives. Nowadays we constantly inhale toxic chemicals in the air, from industries polluting the air daily such as the production of oil, gas, paper, plastic, rubber to name a few. As a solution to improve air quality Air Filters were created. They do exactly what they are called, they filter the air from pollutants, particles, impurities from the air. There are many types of filters, from the efficiency they provide, material of the filter, overall customizable to meet the needs of domestic environments or within industries. The process to manufacture an air filter is simple but complex as well because it’s when the natural and man made materials come together to create this one thing which is the Air Filter. The embodied energy throughout the life cycle of the air filters show that the process can be very energy consuming but the outcome makes up for the energy used and there is hope that it can be replenished in the sustainability of certain air filters.

Everything has a beginning and end, and with Air Filters it isn’t much different. The beginning process starts off with the gathering of materials. The raw materials required for the Air Filter are “CRCA Sheets, Cast Aluminum/Zinc/Plastic components for top and bottom holding rim, Non-Woven fabric, PU foams, fasteners, and filter material” [12]. CRCA (cold rolled close annealed) sheets come from metal that is rolled at a very cold temperature. On the other hand, to create cast aluminum, aluminum has to be heated to an extremely high temperature. The raw material zinc which is a metal at room temperature is mined and refined from the earth. What also comes from the earth and is drilled and mined to obtain it are fossil fuels which make up the plastic components that are materials used in air filters. Non woven fabrics are made up of fibres being bonded together through machines and specialized tech, these fibres can be natural or man made. PU (Polyurethane) Foam is created by reacting di-isocyanates and polyols; at the very root of it, these two products derive from crude oil. Fasteners are made from high-tensile strength metals. Lastly, the filter material all depends on the application it will be used for, filter material can be made out of fabric, paper, metal, plastic, and Active carbon or charcoal. The most sustainable is fabric because it can be used over and over again. But paper based filters are a disposable option and non-reusable. The energy used to acquire these materials are a variety of different forms of energy from machinery to extract the raw materials, packaging them and getting them transported through ships, airplanes, and vehicles so they arrive at their designated destination. After the making and gathering of the materials for the air filter, the manufacturing process for the creation of the air filter is very much straightforward.

When creating the air filters the main component of energy used are machines. The approximate number of machines used are 10. Power Press 100 T, Power Press 10 and 30 T, CR sheet Shearing/perforating machine, Wire mesh/sheet canister rolling machine, Filter paper pleating machine, Spot/ Seam ER welding machine, Riveting machine, Lathe machine, drilling machine, and Filter test bench. The making of air filters are completely dominated by machines and again the energy being used is by machines.

While energy is being used these machines work together to make filters from the raw materials, the most general ones are Pleated, HEPA, and Fiberglass filters. Pleated Filters are made from the cotton/polyester fibres then mechanical energy from machines is used to obtain filtration sheets called pleated layers, this produces a filter that is efficient in air filtration but on the downside it is not as cost efficient as other filters so the other alternative are HEPA filters. HEPA filters have become known to be the most efficient when it comes to filtering air. They are composed of glass fibres or plastic fibers bonded together using energy from machines, these fibers are also known as non woven fabrics as mentioned before, and in most cases active carbon is also used. HEPA filters are favored since the materials used collect finer particles in the air, that also means they need to be replaced more frequently but not as frequently as fiberglass. Fiberglass filters are, as they are called, thin bonded fibres of glass that collect bigger pieces of debri and not so much the tiny particles, because of this it does have to be changed often but it is also the most cost friendly available filter. There are both pros and cons to these three filters, it comes down to deciding which filter one wants to invest more in taking into consideration the cost, efficiency and durability. One additional thing I'd like to add on when deciding which air filter would be the best choice is taking in mind the amount of consumption of energy that takes to produce and dispose of each filter, since the effects of its life cycle process will affect all of us at some point. I could not find much information throughout my research on the exact consumption of energy of each of the filters but if I would have to make a guess on which one based on what I’ve learned, Fiberglass would be the winner. On one hand yes, Fiberglass filters are affordable but they are also the most disposable which means the more that are disposed creates more waste, then another has to be bought and if another has to be bought another has to be produced and the cycle continues over and over. This is not only being conscious about the energy being consumed in production and disposal but it's also about the middle part, not so talked about, that gets the product to its consumers which then energy is again being used in the distribution and transportation of the air filters.

The industry of Air Filters is essentially worldwide and the factories are everywhere as well, distribution can occur overseas or the next state over, nonetheless energy is also used when air filters are being transported from one place to another. After they are transported and distributed to industries using them in factories, families in their homes, or hospitals using the air filters some may be reused and others can’t. Depending on the filter as I said previously they can be a one time use or reusable. Filters using fabric, are reusable, Paper filters are disposable after one use, Metal Filters are durable for a certain amount of time until they have to be replaced, plastic is durable and is used in electrostatic filters which attract dust particles, lastly active carbon or charcoal used in filters are also sustainable until they also have to be replaced like anything else, and this filter type is used in when working with water and helps remove harmful elements from the air. Narrowing down to the three general filters mentioned, HEPA can be reused , Pleated can be recycled, but Fiberglass is the only one from these three that cannot be either reused or recycled. Some HEPA filters can be reused and the energy used when reusing it would be cleaning it manually to be able to reuse it. Pleated filter can be recycled by recycling the materials that it is made out of, not all of the parts are recyclable but most are. Lastly, Fiberglass would go straight to the disposal but there is also another alternative. At this point the energy consumption is very minimal compared to the production at the beginning, but nonetheless energy is still being used by manual work or mechanical energy.

Even though some of these filters may be reusable or recyclable, the parts that aren’t are encouraged to contact an HVAC company or supplier and some will dispose of the used filters. The last option and most common is disposing it out in one’s own trash can. Placing the filter in a trash bag before placing it inside the trash can and then the dumpster company will dispose of it. The process of the waste management company uses the energy of machines to dispose of the trash. Overall, the embodied mechanical energy used throughout the beginning of air filters is a lot I’d have to say, but then having certain filters be a bit sustainable which reduces waste, I see that it balances itself out to a certain extent although it's still damaging. Every step of the way energy is used somehow, now it’s about being conscious that a choice can be made and to choose a more sustainable filter instead of one that is adding on to climate change consistently/ consuming large amounts of energy constantly.

The ending of something is just the beginning of something else. From my point of view and how I saw it at the beginning, air filters had a more positive spotlight in my eyes. Now it’s more towards neutral and I don't really know how to feel about it. Even though air filters are supposed to filter air and have a positive impact the immense amount of energy used during the process and acquisition of materials isn’t that glamorous, since it also adds on the pollution we already have but the air filter is also supposed to help to produce cleaner air. So I am left in the middle ground, and I think the best response I can think of is decreasing the amount of air filters we have that are designed like this and create a more sustainable design, ending these type of air filters and begin with new and more eco friendly air filters that don’t add on to the problem, keeping us going in a circle. We would then use the energy used before to gather materials to create air filters and input the energy into more productive and sustainable designs that would improve the quality of the air naturally over time.

BIBLIOGRAPHY

“Air Purifier.” How Products Are Made, 2021, http://www.madehow.com/Volume-7/Air-Purifier.html.

Albrecht, Wilhelm, et al. Nonwoven Fabrics: Raw Materials, Manufacture, Applications, Characteristics, Testing Processes. Wiley-VCH, 2003.

“Automatic Guided Vehicle Manufacturers, Suppliers and Industry Information.” IQS Directory, https://www.iqsdirectory.com/air-filters/.

Hall, Robert. “Air Filtration: Is Air Filter Recycling for You?” Filtration & Separation, Elsevier Advanced Technology, 4 July 2009, https://www.sciencedirect.com/science/article/pii/S0015188209701600.

Jung, Seojin, and Jooyoun Kim. “Advanced Design of Fiber-Based Particulate Filters: Materials, Morphology, and Construction of Fibrous Assembly.” MDPI, Multidisciplinary Digital Publishing Institute, 30 July 2020, https://www.mdpi.com/2073-4360/12/8/1714/htm.

Muller, Sebastian. “Can HEPA Filters Be Washed and Reused?” Fresh And Breezy, 21 Nov. 2020, https://freshandbreezy.com/can-hepa-filters-be-washed-and-reused/.

Möritz, Martin, et al. “Capability of Air Filters to Retain Airborne Bacteria and Molds in Heating, Ventilating and Air-Conditioning (HVAC) Systems.” International Journal of Hygiene and Environmental Health, Urban & Fischer, 14 Nov. 2004, https://www.sciencedirect.com/science/article/pii/S1438463904700528.

Qin, Xiao-Hong, and Shan-Yuan Wang. “Filtration Properties of Electrospinning Nanofibers.” Wiley Online Library, John Wiley & Sons, Ltd, 28 July 2006, https://onlinelibrary.wiley.com/doi/full/10.1002/app.24361.

“Shop by Size.” Pleated and Fiberglass Air Filters for AC or Furnace, https://www.airfiltersdelivered.com/c/pleated-vs-fiberglass-filters.

Strategix, Digi, and Karan Aklujkar. “Difference between CRCA and HRCA.” JSW MI, 27 Mar. 2021, https://jswmi.in/write-up/difference-between-crca-and-hrca/.

Sun, Christine, PhD. "Delivering Sustainability Promise to HVAC Air Filtration: Part II:

Life Cycle Sustainability of Air Filters." ASHRAE Transactions, vol. 116, 2010, pp. 25-32. ProQuest, https://www.proquest.com/scholarly-journals/delivering-sustainability-promise-hvac-air/docview/854504509/se-2?accountid=14505.

TechSci Research, https://www.techsciresearch.com/. “Manufacturing Air Filters.” Manufacturing Air Filters | TechSci Research, https://www.techsciresearch.com/blog/manufacturing-air-filters/93.html.

“Textiles/Metal–Organic Frameworks Composites as Flexible Air Filters for Efficient Particulate Matter Removal.” ACS Publications, 5 Apr. 2019, https://pubs.acs.org/doi/abs/10.1021/acsami.9b01734.

“Why Choose Recticel Flexible Foams?” Foam Production | Recticel Flexible Foams, https://recticelflexiblefoams.com/about-us/our-expertise/our-technologies/foam-production.html.

Wyon, D. P. “The Effects of Indoor Air Quality on Performance and Productivity.” Wiley Online Library, John Wiley & Sons, Ltd, 25 Aug. 2004, https://onlinelibrary.wiley.com/doi/full/10.1111/j.1600-0668.2004.00278.x.

Yildiz, Ozkan, and Philip D. Bradford. “Aligned Carbon Nanotube Sheet High Efficiency Particulate Air Filters.” Carbon, Pergamon, 30 July 2013, https://www.sciencedirect.com/science/article/pii/S0008622313007008#s0010.

Cesar Vargas Aparicio

Professor Cogdell

DES 040A

25 November 2021

Waste and Emissions: Air Filters

Air Filters come in many forms within society. We have car filters, air filters for A/C units, and filters for humidifiers. The materials within each filter are different for each situation. However, the materials utilized are consistent with that of Fiberglass, Pleated, and now the recent HEPA Filters have shown dominance within the world of air filters. Air filters are highly replaced and have caused outcomes that can potentially be harmful to the environment as much as workers who inhabit air filter factories. Air Filters provide a function within society at the cost of creating airborne wastes, water wastes, chemical releases, and solid wastes that can impact the environmental ecosystem and the health of human beings.

Airborne wastes are present during the production of air filters. Styrene and Acetone are present during fiberglass air filter production in factories and pose harmful effects to factory workers. Working conditions within factories are deemed terrible for workers. Styrene is a chemical most commonly used in the manufacturing of insulation, pipes, automobile parts, printing cartridges, food containers, and carpet backing. Styrene is deemed to be a human carcinogen in its 12th report on Carcinogens (2011) and in 2014 was deemed reasonably a human carcinogen. (NIH, National Institute of Environmental Health Sciences, Styrene). Styrene made up around 47.3 million pounds of emissions to the atmosphere by 1,558 domestic manufacturers and processing facilities in 2006, and accounted for 93% of the estimated total environmental releases from factories required to report to the TRI in 2008. (CDC, Potential For Human Exposure 149). Acetone is created naturally in the environment, but due to industrialized processes the contribution in comparison is immeasurable. Hazards known to be recorded by acetone are possible risk of slight toxicity to aquatic life and the plausibility of membrane damage, and effects in agriculture. However, acetone should not bioaccumulate in plants, animals, or humans. (Acetone, Australian Government). Health issues can arise with acetone with long term exposures and can range with issues from eyes to respiratory system complications which can have a byproduct of possible symptoms such as headaches, light-headedness, confusion, etc. (Acetone, Australian Government).

Some Air filters are responsible for certain emissions more than others. For example, Fiberglass is a non-recyclable material and must be sent to the landfill. Pleated air filters last longer than fiberglass by lasting up to 90 days before necessary replacement. Furthermore, pleated air filters are recyclable depending on the community that allows it. Due to the nature of fiberglass being non-recyclable, the materials of what a fiberglass filter contains are as follows: Fiberglass filters are made with spun glass that is encased in a cardboard frame. (Filter Buy). The quality of the air filter is rather poor and requires constant replacement, resulting in more landfill emissions long term (methane, styrene and acetone traces, etc). Pleated filters tend to be slightly more expensive, but tend to be more eco-friendly due to the production process to put efficiency and biodegradability into consideration when designing the product. Pleated filters are designed and made with sheets of cotton, paper, or polyester which are folded to have more surface area. HEPA filters are to say more improved variants of the fiberglass predecessor. By following a similar form of material and manufacturing, but improving on the lack of surface area from a standard fiberglass filter. Fiberglass filters release a small amount of fiberglass particles into the air when being utilized, HEPA filters are inconclusive whether the release of these particles can be harmful to humans and the environmental ecosystem. According to the excerpt as followed, “many researchers have studied the health impacts of fiberglass on the body, yet there’s still no agreement on whether fibers are harmful or not.” (Smart Air Filters ). Fiberglass particles being released into the air for long periods of time however prove the contrary. “Despite this, other reports have found some evidence of the harm from fibers. The results weren’t conclusive, but the study found there could be an elevated risk of respiratory cancer for people who work with fiberglass on a daily basis.” (Smart Air Filters). Limitations were imposed to combat these long exposures and harsh working conditions for workers who were involved in air filtering manufacturing.

Environmental releases such as Methane and carbon dioxide are present during the disposal of air filters. Methane is present when cardboard is broken down and air filters contain cardboard frames. Methane is considered to be 21 times worse than carbon dioxide if not disposed of properly. Air filters are not normally recyclable and end up in landfills as a result. Specific air filters which are not recyclable are that of HEPA and Fiberglass Filters. Fiberglass Filters have been noted to be replaced frequently in comparison to that of HEPA Filters needing to be replaced every year, and Pleated Filters every 60-90 days. HEPA is mainly made of plastics and glass, and ends up in landfills. Both cardboard and plastic are main culprits when it comes to the footprint of greenhouse gases they will release. However, HEPA and Pleated Filters are replaced less frequently as compared to Fiberglass. Hence, most of the waste in today’s modern emissions within the release of Methane and Carbon Dioxide into the atmosphere would be that of Fiberglass Air filters. As a result, air filters are a culprit to a percentage of greenhouse gas emissions for Methane and Carbon Dioxide due to constant disposal and production to meet public demand with the eventual disposal of nonrenewable materials in our landfills.

Air filters consist of clothes that are made of polyester which is known to be under the same category as Fiberglass within the realm of Synthetic Materials. Synthetic materials are made out of natural gasses which are normally nonrenewable materials. Responsible for 55.8 tons of waste to landfill. (Sustainable Fashion Collection) Synthetic materials have a higher global warming potential due to the nature of synthetic materials being stable and ability to remain present within the environment for ages. Polyester is mainly derived from the usage of petroleum. Top countries of the world that use clothing and textiles that are mainly MMF (man made fibre) were North America 21%, Taiwan 19%, Australia 17% in 2018.

(Semantic Scholar). “In 1 year 70 million barrels of oil are used in the manufacturing of polyester” (Semantic Scholar). Furthermore, synthetic production can emit powerful gasses such as nitrous oxide, evidently nitrous oxide is 300 times more damaging for the earth’s atmospheric ecosystem than that of carbon dioxide and in comparison to methane’s 21 proving to be rather small in the grand scheme of greenhouse gas emissions. (The Conversation). Naturally nitrous oxide has existed within soils of the tropical rainforests, permafrost melting in the Arctic, as well as the microbes in the ocean (Civil Eats). Around ⅓ to ½ of the nitrous oxide released into the atmosphere is caused by human activities (Civil Eats). Nylon and Polyester manufacturing along with the current Agricultural market are responsible for an increased emissions of nitrous oxide to the atmosphere due to the manufacturing of synthetic materials (GreenChoices).

Polyester and Synthetic material manufacturing pollute water and are a major cause for large water footprints that affect the wildlife ecosystem. “On average 200 litres of water is used to make 1kg of textile. Water is used in every aspect of textile making right from cleaning the raw material, till flushing, dyeing, and bleaching, throughout the whole production.” (Fibre2Fashion). Water is not cleansed prior to releasing it into the environment, and as a result chemical traces of the textile materials are exposed to harm wildlife. There is no consideration for treatment to cleanse the used water. The process of polyester requires a huge amount of water to be able to get the dye right for the textiles. “To make the shades in a uniform way, the fabric is dyed and re-dyed several times, which consumes a lot of water.” (Fibre2Fashion). The cost for such a process has not been attempted to be calculated by corporations and this form of water dumping pays a toll on the environment due to such a concentrated dyeing process.

Air filters are heavily used in modern society to give us comfort in our everyday lives. The downsides of air filters is that they are polluted with dangerous and hazardous toxins that prove to be dangerous to the health of human beings and the environment. Methane pollutes the air with inadequate recycling of cardboard, with the issue that most air filters are made with traces of cardboard. Synthetic materials stay in the atmosphere for long periods of time due to the nature of man-made materials. Following the usages of VOCs and multiple carcinogens soon add up as air filters get replaced. Who would have known a commonly used product would have such a nasty background?

Works Cited

“Australian Government, Department of Agriculture, Water and the Environment.” National Pollutant Inventory, www.npi.gov.au/resource/acetone#:~:text=Acetone%20is%20mainly%20emitted%20to,can%20be%20degraded%20within%20days.

“Fiberglass vs Pleated Air Filters.” FilterBuy.com, filterbuy.com/resources/fiberglass-vs-pleated-air-filters/.

Issi. “Environmental Impacts.” Green Choices, Green Choices, 19 Apr. 2018, www.greenchoices.org/green-living/clothes/environmental-impacts.

Jameson, Brett. “Nitrous Oxide, a Powerful Greenhouse Gas, Is on the Rise from Ocean Dead Zones.” The Conversation, 5 July 2021, theconversation.com/nitrous-oxide-a-powerful-greenhouse-gas-is-on-the-rise-from-ocean-dead-zones-162812.

Moazzem, S., et al. “[Pdf] Baseline Scenario of Carbon Footprint of Polyester T-Shirt: Semantic Scholar.” Baseline Scenario of Carbon Footprint of Polyester Moazzem Crossin, 1 Jan. 1970, www.semanticscholar.org/paper/Baseline-Scenario-of-Carbon-Footprint-of-Polyester-Moazzem-Crossin/4a7f619673ee8f59b97586fae8236a74c0a9e6d2.

Potential for Human Exposure. www.atsdr.cdc.gov/toxprofiles/tp53-c6.pdf.

Robertson, Paddy. “Are Fibers From HEPA Filters Harmful to Health?” Smart Air, 5 May 2020, smartairfilters.com/en/blog/hepa-air-filter-fiber-harmful-health/.

Ross, Charlie Bradley. “What Synthetic Materials Are Doing to Our Environment.” The Sustainable Fashion Collective, 11 Apr. 2017, www.the-sustainable-fashion-collective.com/2017/04/11/synthetic-materials-environment/.

“Styrene.” National Institute of Environmental Health Sciences, U.S. Department of Health and Human Services, www.niehs.nih.gov/health/topics/agents/styrene/index.cfm.

Wozniacka, Gosia. “The Greenhouse Gas No One's Talking about: Nitrous Oxide on Farms, Explained.” Civil Eats, 19 Sept. 2019, civileats.com/2019/09/19/the-greenhouse-gas-no-ones-talking-about-nitrous-oxide-on-farms-explained/.

www.fibre2fashion.com. “Textile Wastewater, Polyester Fibres, Recycled Polyester Yarn, Water in Textile Industry, fibre2fashion.” Fibre2Fashion, Mar. 2010, www.fibre2fashion.com/industry-article/4661/textile-wastewater-can-make-a-difference.