Design Life-Cycle

assess.design.(don't)consume

Environmental viability of bamboo toothbrushes from a materials standpoint

(By Noah Jones)

Introduction

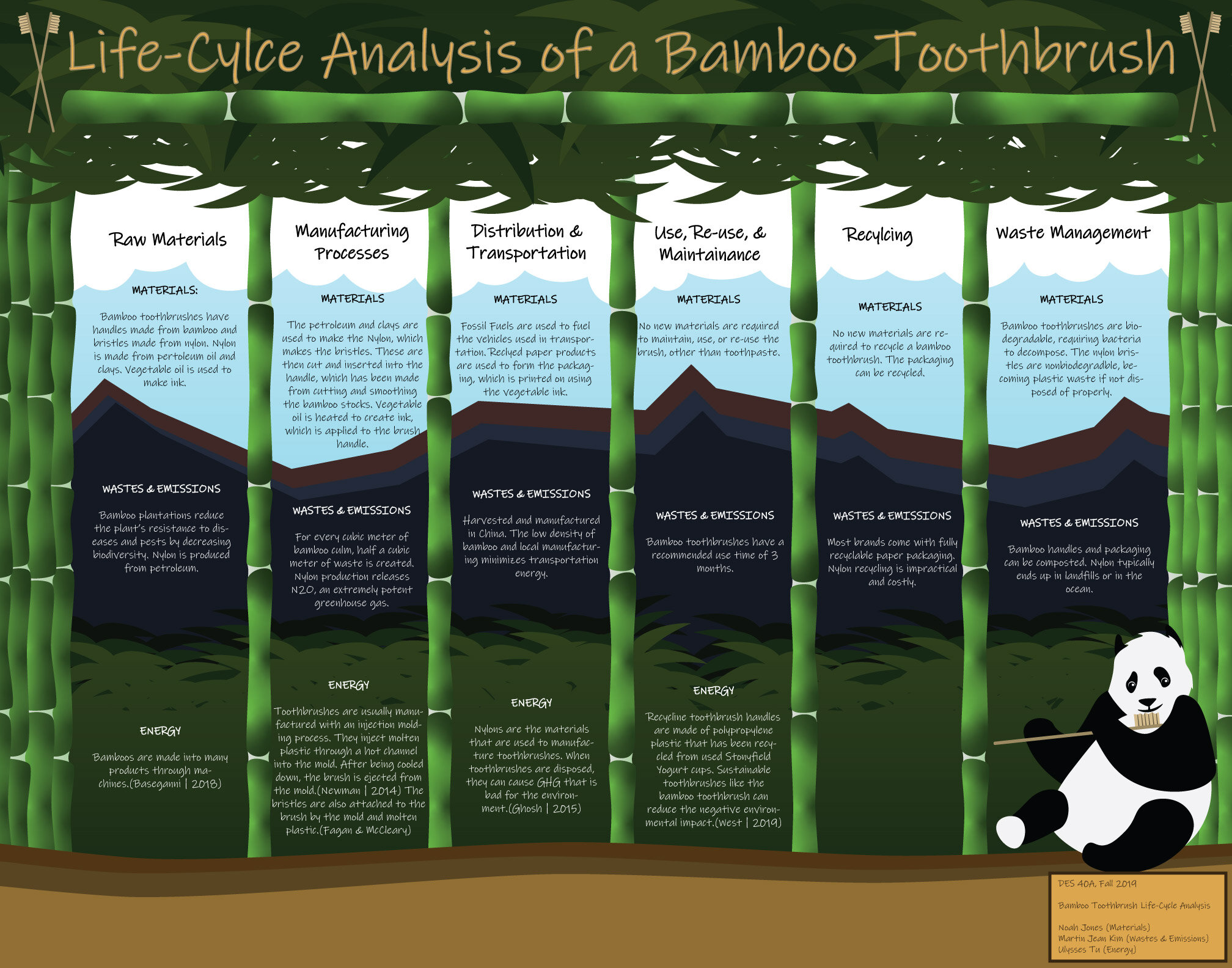

Conventional toothbrushes are made extensively of non-renewable materials like plastic. Of recent advent, bamboo toothbrushes are advertised as an excellent alternative to plastic ones because they are made of renewable materials. Comparison of the cradle-to-grave material requirements between bamboo and plastic toothbrushes reveals that bamboo toothbrushes entail hidden environmental costs. To evaluate the different brushes, one must take a look at them through the processes of material acquisition, manufacturing, disposal, and repurposing. One must consider the materials in all their parts, including the handles, bristles, inks and packaging.

Plastic handle material acquisition

Conventional toothbrush handles are made of the plastics polyethylene and polypropylene (“What Are Toothbrushes Made Of?” Jan 9, 2019). When quantifying energy, the variable MG can be used, signifying a megajoule. Polyethylene releases approximately 1.8 kg of CO2 into the atmosphere per gram produced (Akiyama, et al. Oct 10, 2002). In addition, polypropylene releases approximately 1.9 kg of CO2 into the atmosphere (Akiyama, et al. Oct 10, 2002). Both these polymers are petrochemical-based, which means they come from petroleum oil (Akiyama et. al Oct 10, 2002). Petroleum oil is nonrenewable and can produce 10.3 grams of emissions for every MJ of crude oil collected, with some countries reaching nearly double that amount (Stanford University, Aug 30, 2018). Another plastic, nylon, serves as the bristles in conventional toothbrushes (“What Are Toothbrushes Made Of?” Jan 9, 2019). According to cambridge.org, nylon is a monomer made up of clays and petroleum oils, materials which are nonrenewable (Kojima, et al. May 1993). Clearly, the plastics used conventional toothbrushes have detrimental effects on the environment.

Conventional toothbrushes are packaged in cardboard boxes, often printed on with ink. Others have a transparent plastic viewing window. Cardboard comes from paper, which comes from trees, which are renewable. However, it’s important to know that trees take a long time to grow. Cardboard is also made with fillers, which can include chalks and clays (“How Is Cardboard Made...” Aug 20, 2019). Regarding the viewing windows, as established, plastics are made from oil, which are nonrenewable. Lastly, ink is made from many ingredients like pigments, binders, solvents and additives (“Ink Manufacturing and...” Accessed 26 Nov, 2019). Inks can be based in water, a solvent, ultraviolet beams, and oil (Luminite, May 9, 2019). Due to the endless possibilities for ink formulas, it is unrealistic to do a specific formula analysis without knowledge of the specific formulas used by established toothbrush companies. It’s important to note that while some ingredients in ink are renewable, some are not. Inks can also contain toxins like heavy metals and phthalates (“Environmental Impact Of Printing Inks” Mar 2013). Clearly, the packaging used for conventional toothbrushes has negative environmental impacts.

Bamboo toothbrush material acquisition

Bamboo toothbrushes have the advantage of being renewable. According to barevida.com, bamboo absorbs twice the amount of carbon dioxide as trees, while generating 30% more oxygen than most plants and trees (Simonis, accessed Nov 11, 2019). While producing the plastics used in conventional toothbrushes releases CO2, growing bamboo absorbs it. While bamboo is used in the handle, boar hair, which is renewable, is used in the bristles as a replacement for nylon (Guy, accessed Nov 19, 2019). However, boar hair is used in only a selection of bamboo toothbrushes; upon searching the internet for bamboo toothbrushes for sale, a lot of them use nylon, just like plastic toothbrushes. In addition to the brush itself, it’s important to examine the packaging.

Bamboo toothbrushes often come in packages made from recycled materials. Essentially after paper products are recycled, they are broken down and turned into another form of cardboard. Recycled paper products conserve resources (Jain et al. 2012). In addition, the ink used for bamboo toothbrushes and their packaging comes from vegetable oil (“WooBamboo.” accessed Nov 20, 2019). While vegetable-based ink is renewable, some colors require the use of harmful heavy metals, like cadmium, barium, and copper (Admin, Mar 29, 2015) . Just because an ink is vegetable-oil-based doesn’t mean that it’s completely clean. After looking at the materials involved, it’s important to examine the production processes.

Transportation

Each step of the life-cycle includes some key assumptions. According to eia.gov, petroleum accounted for 89% of the energy required for transportation in the United States in 2018 (“U.S. Energy Information Administration…” updated May 10, 2019). Petroleum is not only nonrenewable, but harmful to the environment (Stanford University, Aug 30, 2018). Transportation also accounted for 29% of the United States’ Greenhouse Gas Emissions in 2017 (“Sources of Greenhouse Gas Emissions.” accessed Dec 3, 2019). Based on these facts, it can be concluded that the transportation of materials is not only harmful to the environment, it is unsustainable because it relies on nonrenewable fuel sources. Because the production of both toothbrushes requires the relocation of materials, they both involve hidden energy and environmental costs.

Plastic toothbrush fabrication processes

The process of creating plastic from hydrocarbon fuels has many negative side effects. Polyethylene and polypropylene become toxic in the manufacturing process (Rogers, May 4, 2016). These plastics go through a process where they are heated and injected into a mold. In addition, the plastics must also be transported from factory to factory, releasing CO2. There are many steps involved in creating nylon bristles. First, the oils and clay must be turned into nylon. While I was unable to find much reading on this process, one can assume that it would require some sort of process where the elements are heated and combined. This process would likely release CO2. In addition, a byproduct of nylon production is nitrous oxide, which is a gas that depletes the molecules in the ozone layer (“Nylon Production Discovered to…” Feb 22, 1991). After the nylon cords are fabricated, they must be cut to a specific size and connected to the handle in some way either through compression or adhesive. Besides the brush itself, it’s important to explore the packaging involved in conventional toothbrushes.

Creating cardboard from wood is an intricate process with its own energy and material requirements. After being broken down into tiny particles known as pulp, it must be processed multiple times, and primed either chemically or physically (“How Is Cardboard Made....”, Aug 20, 2019). In addition, fillers are added, like chalk and clay (“How Is Cardboard Made....”, Aug 20, 2019). To create the plastic used in the viewing window, oil must be chemically processed, which releases toxic emissions. Lastly, inks are created from combining the pigments, binders, solvents and additives, often containing toxic chemicals (“Ink Manufacturing and…” Aug 20, 2019). After exploring the production of plastic toothbrushes, it’s necessary to examine the production of bamboo ones.

Bamboo toothbrush fabrication processes

Bamboo must be cut down and collected, cut to size and shaped into the shape of a toothbrush. This work can be automated through machines, requiring more energy and causing pollution, or done manually, with less energy input and no pollution. I was unable to find specific information about the companies used to fulfill these processes, and therefore it is unknown whether these processes are completed manually or with the aid of machines. However, one can assume that the processing of bamboo more environmentally-friendly than the processing of plastics, simply because bamboo is a primary material, unlike plastics, which must be produced. While working with bamboo doesn’t directly release toxins as plastic does, the factories and machines required in the process still do pollute the environment to some extent. Boar hair bristles simply need to be boiled once harvested to make them straight and sanitary (Guy, accessed Nov 19, 2019). While it may be tedious to harvest the hair of a boar, boar hair is renewable. After assessing the materials that go into the toothbrush, it’s important to explore the packaging.

I was unable to find much information regarding the production process of recycled cardboard. However, I would assume it would begin with a process of accumulating and treating recycled paper products, turning them into a sort of pulp, where they can undergo a similar production process as when the pulp is made directly from wood and fillers. If this is the case, the process of producing recycled packaging would likely have less steps because recycled paper products would probably break down into pulp quicker than wood, requiring less energy than creating non-recycled cardboard. Because there is no remarkable difference between the two toothbrushes as far as usage, one can skip to the effects of discarding them.

Wastes and emissions of plastic toothbrushes

The plastics used in plastic toothbrushes are non-biodegradable (Tokiwa, Aug 26, 2009). This means that they are not capable of being broken down by living organisms, like bacteria, leading to large accumulations of discarded toothbrushes either in landfills, the ocean, or the communities in which people live when they are not disposed of properly (“Nonbiodegradable.”, accessed Nov 19, 2019). According to Sophie Hirsh from greenmatters.com, nonbiodegradable plastics break down into what’s called microplastics, which are tiny particles that are not only hard to filter from water, but harmful to wildlife (Hirsh, Aug 2019). The type of Nylon blend used in toothbrushes, Nylon-6, is also nonbiodegradable (Terry, Dec 8, 2015). The nylon will not decompose naturally, leaving behind little pieces of nylon to pollute the environment. Lastly, both the cardboard and plastic of the packaging are recyclable. Now we’ll look at what happens to bamboo toothbrushes when they’re discarded.

Wastes and emissions of bamboo toothbrushes

Bamboo toothbrushes aren’t entirely biodegradable. While Bamboo is biodegradable, many companies used nylon bristles, which are nonbiodegradable (Lewitin, Mar 18, 2019). However, some companies use boar hair, which is biodegradable (Terry, Dec 8, 2015). In addition, the packaging used in bamboo toothbrushes can be recycled and reused. The brushes can also be repurposed.

Repurposing old toothbrushes

Some consumers may be conscious of the effects of discarding their old toothbrushes, and opt to reuse their brush somehow. If the consumer wants to reuse their plastic brush, they often are limited to the function of brushing, because it can be hard to break down the plastic handle to use it in other capacities. The plastic could theoretically be melted down and reformed in another shape, however this would not only create toxic fumes, but it would also be rather difficult for those without the proper equipment for the task. Bamboo, however, can be manipulated in easier ways than plastic, meaning that consumers have more creative freedom to repurpose their old bamboo toothbrushes. After examining the facts, it’s important to analyze the findings.

Conclusion

Plastic toothbrushes have many downsides. Not only are they made of nonrenewable materials, but their production is very energy intensive. In addition, their production releases toxins, and because they are not biodegradable, they stick around to pollute the environment and harm wildlife when they aren’t disposed of properly. Bamboo toothbrushes have been advertised as a more environmentally-conscious alternative. However, while bamboo toothbrushes use mostly renewable materials, many on the market still use bristles made of nylon, a nonrenewable and harmful material. So, are bamboo toothbrushes as environmentally-friendly as advertised? It depends on the bristles. If a brush is made of boar bristles, yes. However, generally speaking, many of the bamboo toothbrushes aren’t as eco-friendly as they seem because they contain nylon bristles..

Complete Bibliography

Admin. “About Vegetable-Based Ink.” Design Printing - Los Angeles Green Printing Company, 5 Dec. 2016, https://dprintla.com/content/about-vegetable-based-ink.

“Adult Bamboo Toothbrush: Mable.” Natural Beauty Subscription Box, https://shop.beauty-heroes.com/shop/product/2093361407?gclid=Cj0KCQjw0brtBRDOARIsANMDykYM7rO8ZiwCT1T6z8E0GBc41mXGPmSpaxrnzNddyBNm-98gGY2WIcIaAisuEALw_wcB.

Agyekum, Eric Ofori, et al. “Environmental and Social Life Cycle Assessment of Bamboo Bicycle Frames Made in Ghana.” Journal of Cleaner Production, Elsevier, 14 Dec. 2016, https://www.sciencedirect.com/science/article/pii/S0959652616320571.

Akiyama, Minoru, et al. “Environmental Life Cycle Comparison of Polyhydroxyalkanoates Produced from Renewable Carbon Resources by Bacterial Fermentation.” Polymer Degradation and Stability, vol. 80, no. 1, 2003, pp. 183–194. ScienceDirect, https://reader.elsevier.com/reader/sd/pii/S0141391002004007?token=55721E88D49946E5A8D2E4A907CCC6EFFD614A66DA9AA5A0972D8A9935CB0D05BEC193650DFC5D05C149EBEA80130300.

“An Overview of Biodiesel and Petroleum Diesel Life Cycles.” May 1998, https://www.nrel.gov/docs/legosti/fy98/24772.pdf.

“Bamboo Treatment.” Bambooroo, 21 Dec. 2016, http://bambooroo.com/bamboo/bamboo-treatment/.

Chang, Fang-Chih, et al. “Environmental Benefit of Utilizing Bamboo Material Based on Life Cycle Assessment.” Journal of Cleaner Production, Elsevier, 24 Aug. 2018, https://www.sciencedirect.com/science/article/pii/S095965261832599X.

“Environmental Impact Of Printing Inks.” EuPIA, Mar. 2013, pp. 1–12. EuPIA, https://www.eupia.org/fileadmin/FilesAndTradExtx_edm/2013-03-05_EuPIA_Environmental_Impact_of_Printing_Inks_01.pdf.

Erhan, Sevim Z., and Marvin O. Bagby. “Vegetable-Oil-Based Printing Ink Formulation and Degradation.” Industrial Crops and Products, Elsevier, 4 Feb. 2000, https://www.sciencedirect.com/science/article/pii/0926669094000406.

“Fastest Growing Plant.” Guinness World Records, https://www.guinnessworldrecords.com/world-records/fastest-growing-plant/.

Guy, Gaia. “Natural Bristle Bamboo Toothbrush - Totally Biodegradable and Planet-Based 6-Pack.” Amazon.com, https://www.amazon.com/Natural-Bristle-Bamboo-Toothbrush-Biodegradable/dp/B073HCMYPR.

Harding, K.G., et al. “Environmental Analysis of Plastic Production Processes: Comparing Petroleum-Based Polypropylene and Polyethylene with Biologically-Based Poly-β-Hydroxybutyric Acid Using Life Cycle Analysis.” Journal of Biotechnology, Elsevier, 25 Feb. 2007, https://www.sciencedirect.com/science/article/pii/S0168165607001514.

Hirsh, Sophie. “How Plastic Straws Affect the Ocean and Sea Turtles.” Green Matters, Green Matters, 14 Aug. 2019, https://www.greenmatters.com/p/how-plastic-straws-affect-ocean-turtles.

“How Does Bamboo Grow?” Lewis Bamboo, https://lewisbamboo.com/how-bamboo-grows/.

“How Fast Does Bamboo Grow.” The Happy Bamboo, 3 June 2019, https://thehappybamboo.com/how-fast-bamboo-grow/.

“How Is Cardboard Made: Manufacture of Corrugated Board.” GWP Group, 20 Aug. 2019, https://www.gwp.co.uk/guides/how-is-cardboard-made/.

Hydrocarbon Fuels, http://tiki.oneworld.org/questions/energy/1.html.

“Ink Manufacturing and the Dispersion of Pigment into Printing Ink.” Torrey Hills Technologies, LLC, https://www.threerollmill.com/documents/Ink.pdf.

Jain, Seema, et al., “Mechanical Behaviour of Bamboo and Bamboo Composite.” SpringerLink, Kluwer Academic Publishers, https://link.springer.com/article/10.1007/BF01165993.

Kojima, Yoshitsugu, et al. “Mechanical Properties of Nylon 6-Clay Hybrid: Journal of Materials Research.” Cambridge Core, Cambridge University Press, 31 Jan. 2011, https://www.cambridge.org/core/journals/journal-of-materials-research/article/mechanical-properties-of-nylon-6clay-hybrid/E07B017BCFB8C14542AC13E541AAFE7D.

Kramer, Hans.

Lewitin, Joseph. “Bamboo Flooring Really Is Eco-Friendly, in Some Ways.” The Spruce, The Spruce, 18 Mar. 2019, https://www.thespruce.com/is-bamboo-flooring-really-eco-friendly-1314953.

“Nonbiodegradable.” Merriam-Webster, Merriam-Webster, https://www.merriam-webster.com/dictionary/nonbiodegradable.

“Nylon Production Discovered to Represent Major Source of Atmospheric ‘Laughing Gas.’” UC San Diego NEWS RELEASE, 22 Feb. 1991. University Archives, https://library.ucsd.edu/dc/object/bb9762438g/_2.pdf.

“OLAS Bamboo Toothbrush - Case of 12.” OLAS - Goop Shop - Goop Shop, https://shop.goop.com/shop/products/olas-bamboo-toothbrush-case-of-12-1?country=USA&variant_id=37100&utm_source=google&utm_medium=pla&utm_campaign=PLA_ALL_SMART_ALL_MWELLNESS&product=9074-37100&gclid=Cj0KCQjw0brtBRDOARIsANMDykYwRdDV97Ozv-6X67K9tGQQHPmrzuXGu7zFXihGdDD95sS9n5p6GjwaAheVEALw_wcB.

“Order Online: Free Shipping Worldwide.” Bamboo Toothbrush Bam&Boo, https://thebamandboo.com/.

“Recycled Paper.” Recycled Paper - an Overview | ScienceDirect Topics, https://www.sciencedirect.com/topics/earth-and-planetary-sciences/recycled-paper.

Rogers, Tony. “Everything You Need To Know About Polyethylene (PE).” Everything You Need To Know About Polyethylene (PE), https://www.creativemechanisms.com/blog/polyethylene-pe-for-prototypes-3d-printing-and-cnc.

Schröder, Stéphane. “Chemical Bamboo Preservation.” Guadua Bamboo, Guadua Bamboo, 13 Nov. 2012, https://www.guaduabamboo.com/preservation/chemical-bamboo-preservation.

Simonis, Harriet. “5 Reasons Why Bamboo Is Saving Our World.” Bare Vida, Bare Vida, 18 Sept. 2018, https://barevida.com/blogs/news/why-is-bamboo-eco-friendly.

“Sources of Greenhouse Gas Emissions.” EPA, Environmental Protection Agency, 13 Sept. 2019, https://www.epa.gov/ghgemissions/sources-greenhouse-gas-emissions.

Staff, Creative Mechanisms. “Everything You Need To Know About Polypropylene (PP) Plastic.” Everything You Need To Know About Polypropylene (PP) Plastic, https://www.creativemechanisms.com/blog/all-about-polypropylene-pp-plastic.

Stanford University. “Measuring Crude Oil's Carbon Footprint.” Stanford News, 31 Aug. 2018, https://news.stanford.edu/2018/08/30/measuring-crude-oils-carbon-footprint/.

Terry, Beth. “The Truth About Your Biodegradable Bamboo Toothbrush " My Plastic-Free Life.” My Plastic-Free Life, 22 May 2018, https://myplasticfreelife.com/2015/12/the-truth-about-your-biodegradable-bamboo-toothbrush/.

“The Use of Recycled Materials in Manufacturing: Implications for Supply Chain Management and Operations Strategy.” Taylor & Francis, https://www.tandfonline.com/doi/full/10.1080/00207540701440287.

Thompson, Wanda. “How Eco-Friendly Are Bamboo Products?” Household Wonders, https://householdwonders.com/are-bamboo-products-eco-friendly/.

Tokiwa, Yutaka, et al. “Biodegradability of Plastics.” International Journal of Molecular Sciences, Molecular Diversity Preservation International (MDPI), 26 Aug. 2009, https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2769161/.

“U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.” Use of Energy for Transportation - U.S. Energy Information Administration (EIA), https://www.eia.gov/energyexplained/use-of-energy/transportation.php.

Upperlux. “5 Key Benefits Of Using Bamboo Toothbrushes.” Upperlux, 4 May 2018, https://upperluxstore.com/5-key-benefits-of-using-bamboo-toothbrushes/.

“US5122188A - Vegetable Oil-Based Printing Ink.” Google Patents, Google, https://patents.google.com/patent/US5122188A/en.

“What Are Toothbrushes Made Of?” CariFree, 9 Jan. 2019, https://carifree.com/2019/01/09/what-are-toothbrushes-made-of/.

“Where Bamboo Grows.” Where Bamboo Grows - Bamboo Growing, https://www.bamboogrove.com/where-bamboo-grows.html.

“WooBamboo.” EarthHero, https://earthhero.com/brands/woobamboo/.

Zhao-hua, Li, et al. “Growth Behavior of Phyllostachys Nigra Var. Henonis (Bambusoideae) in Central China.” SpringerLink, Northeast Forestry University and Ecological Society of China, https://link.springer.com/article/10.1007/BF02856808#enumeration.

Bamboo Toothbrush Energy

(By Ulysses Tu)

Bamboos are chopped up and used to make all kinds of furniture like chairs and ladders. They are mainly cut by machines with high productivity. It all depends on the size and shape of the blade that results in the size and shape of the bamboo sticks. Cutting blades have different calculations and designs, which make each cutting machine cutting force and power different. This produces bamboo pieces that were used in making furnitures, ladders, tools, baskets, toys, and of course, toothbrushes.(Baseganni | 2018)

Toothbrushes are usually manufactured with an injection molding process. They inject molten plastic through a hot channel into the mold. The toothbrush is then cooled and ejected from the mold. However there are two limitations: one is that the large diameter handles cannot be produced in an efficient manner because the increase on materials costs a lot of money, which results in the cooling time increasing. Another is that the injection molding process requires multiples steps in order to make a multiple-component brush. The main energy that is being used in toothbrushes are the mold and molten plastic that are being used to make them.(Newman | 2014) The mold also create little holes for the bristles to be fastened. Nylon bristles are the most useful for the brushes. During the process, the bristles are folded, attached, and then trimmed through a machine.(Fagan & McCleary)

When benzene are transported to industrial facilities they react with elements to create Adipic Acid. The Adipic Acid then reacts with hexanediamine to create Nylon. Nylon are transported in a container of various vehicles such as car, truck, and van and oversea transportations such as planes and ships, where Nylon is being transported to factories where they are used to assembled with plastic and metal to create toothbrushes. The selling of toothbrushes were not just good for job opportunities, but also for the economy as a whole. When the product is thrown away, they are taken out with the trash and transported to an incinerator. And the transport of these products produce greenhouse gases that have a negative impact on the environment.(Ghosh | 2015)

Recycline toothbrush handles are made of polypropylene plastic that has been recycled from used Stonyfield Yogurt cups. And when they are used up, they are either recycled or sent back to Recycline via envelope. They are reborn again as raw material for a picnic table, deck, boardwalk or other big products. There are also toothbrushes with replaceable heads that can help minimizing the amount of toothbrushes we throw away every once in a while. Once the bristle wears out, consumers can keep the handle and just put a new head onto it. The bamboo toothbrush is a sustainable toothbrush, which is derived from sustainable yield forests. Another type of sustainable toothbrush is an electric toothbrush, which is powered by battery and electricity. With these type of brushes, environmental impact is significantly reduced.(West | 2019)

Bamboo toothbrushes have all kinds of energy. Bamboos are first made into toothbrushes from machines. There are molten mold inside the bristle that were injected when the brushes were first made. Toothbrushes are made from nylon in factories. They are then transported to different shops and stores, which benefited the customers and the economy. However when the brushes are used and thrown away they cause environmental harm due to greenhouse gas affect. So there are certain types of brushes like sustainable toothbrushes, made to make the environment get more and more healthy. So with bamboo toothbrushes, it produces energy that can be good to the environment.

Work Cited Page

Baseganni, Chetan, et al. Design and Analysis of Bamboo Stick Cutting Machine. Jan. 2018, file:///C:/Users/Uly Tu/Downloads/241-Manuscript (Full Article)-780-2-10-20180529.pdf.

Newman, Matthew Lloyd. “Toothbrush Handle Having an Inner Cavity.” Patent Application Publication, 22 May 2014, https://patentimages.storage.googleapis.com/46/45/9d/84119a95a9da99/US20140137349A1.pdf.

“How the Toothbrush Is Made .” The Toothbrush - Fagan & McCleary, https://americasfavoritetool.weebly.com/how-the-toothbrush-is-made.html.

West, Larry. “Recycling Your Toothbrush.” ThoughtCo., 9 Aug. 2019, https://www.thoughtco.com/can-you-recycle-your-toothbrush-1203671.

Ghosh, Rohan. “The Life Cycle of a Toothbrush .” Prezi, 29 May 2015, https://prezi.com/j2nu4budcrhp/the-life-cycle-of-a-toothbrush/.

The Waste and Emissions in the Life Cycle of Bamboo Toothbrushes

(by Martin Jean Kim)

For thousands of years, bamboo has been one of the most important primary materials used in Asia, valued for its flexibility, rapid growth and strength. For environmentally conscious consumers, these qualities make bamboo a convenient replacement for the plastic handles in toothbrushes, leading to a recent rise in popularity of bamboo toothbrushes. Toothbrushes have three components: the handle, bristles and packaging. While both bamboo and plastic toothbrushes use nylon for bristles, the difference in materials used lies in the handle and packaging. Although the differences in environmental impact between bamboo and plastic in toothbrushes may seem trivial, the waste and emissions between the two materials differ considerably due to the complex global systems involved in the production and distribution of each material.

Toothbrushes are indispensable in modern life. Consumers must choose between bamboo and plastic, as most cannot reasonably abandon toothbrushes all together. Thus, the waste and emissions generated in the life cycle of bamboo can only be evaluated when compared to the waste and emissions of plastics. The plastics commonly used in toothbrushes are Polyethylene and Polypropylene, flexible thermoplastics with a distinctive opaque and shell-like quality (Rajendran, S, et al, 2012). The flexibility, water resistance and strength of bamboo makes it a desirable alternative to these plastics. However these similar qualities come from vastly different processes. Bamboo is a fast growing and abundant natural resource that has a life cycle of only 3-6 years, growing up to 25 cm in a day (Lugt, P. Van Der, et al, 2006). Despite a diversity of bamboo species, 80% of bamboo harvested for use is of one species, Moso bamboo (Phyllostachys pubescens), favored for its large volume of culm and fast growth rate. Moso Bamboo plantations and forests cover over 22,000 square miles in the Chinese provinces of Fujian, Jiangxi and Zhenjiang, where bamboo is the main industry (Escamilla, Edwin Zea, and G. Habert, 2014). Harvesting one cubic meter of bamboo culm requires approximately 18.5 square meters of forest land. As a raw material, bamboo produces minimal waste, with an average of half of a cubic meter of leaves and branches for every cubic meter of culm (Escamilla, Edwin Zea, and G. Habert, 2014). Drying is the most energy intensive step in preparing raw bamboo and most farmers use natural gas or incinerate organic waste to heat the bamboo. On the other hand, plastic starts as oil which has been locked in the crust for hundreds of millions of years and requires a massive global infrastructure to extract. Seismic surveying vessels search for oil sites and offshore drilling rigs are installed if oil if found (Johnson, Alissa). The raw material is then brought to a refinery where the hydrocarbon ethylene combines to form polymer pellets. The embodied energy of Polyethylene is around 80 megajoules per kilogram with Polypropylene being slightly higher (Natiove, Mathew H., 2013). Such high embodied energies come largely from carbon dioxide releasing fossil fuel combustion. In addition, plastic production emits harmful chemicals such as dioxins, phthalates, ethylene, BPA and vinyl chlorides (Yamashita, Kyoto, et al.). In theory, the only energy inputs required for harvesting bamboo is the energy needed to cut, dry and transport it. Bamboo, having a relatively low density of 100 kilograms per cubic meter, would not exceed a fourth of the weight capacity of a fully loaded 16 ton truck and is thus fuel efficient to transport (Yu, Dongwei, et al, 2011). Even a truck at full weight capacity requires only 1.82 kilojoules per kilogram to advance one kilometer (Johnson, Alissa). Overall, the embodied energy of bamboo is measured in kilojoules per kilogram compared to the megajoules per kilogram of plastics, the consequence of which is vastly more waste emitted from the globe-spanning production of plastics than the local and regenerative production of bamboo.

The handles of bamboo toothbrushes are considered organic waste and can be composted at the end of its life cycle. If properly disposed, the handle is likely to end up in an industrial composting facility, where organic material is packed into long cylindrical containers and heated. Composting occurs in these cylinders when thermophilic microorganisms convert organic waste into a rich and porous material used to promote growth in crops. A study evaluating the waste and emissions of such a facility in Toronto found that composting converts approximately 14% of organic matter mass into carbon dioxide in a rapid 28 day composting cycle (Day, M., et al, 1998). The amount of volatile and odorous compounds emitted could also be minimized under ideal carbon-nitrogen ratios. With the proper controls, composting bamboo and lumber waste is a very clean process, especially considering that most volatiles originate from food waste. However, the consumer must choose to compost or else the toothbrush may end up in a landfill, where a slower methane releasing biodegradation occurs (Song, Qingbin, et al, 2015). Globally, landfills are the third largest emitters of methane, a greenhouse gas twenty times more potent than carbon dioxide (Semuels, Alana). The biodegradability of bamboo toothbrushes does not equate to reduced use time as both conventional and bamboo toothbrushes boast a recommended use time of 3 months (“The Lifecycle of a Plastic Toothbrush”).

The packaging of bamboo toothbrushes varies by company but is typically made of recyclable paper with no plastic components (Ross, Charley, 2018). Recycled paper is produced from paper waste that is pulped and recombined. The production of recycled paper depends on energy fed from the grid which originates from the burning of fossil fuels. However, the cogeneration process that produces virgin paper burns 76% of the tree for energy as only 23% is used to create raw pulp (“Does It Take More Energy”, 2013). Overall, recycled paper production releases 39% less greenhouse gasses and produces 43% less solid and liquid waste than virgin paper production (“Does It Take More Energy”, 2013). The recycled packaging can then be recycled again up to five times before the fibers are too short to produce new paper (Semuels, Alana). Recycled paper can also be composted.

Nylon is the primary material used for the bristles of bamboo toothbrushes. Nylon is a type of polyester polymer formed from a petroleum derivative called adipic acid. Adipic acid requires 104.2 gigajoules of energy per ton to form (Duuren, J.b.j.h. Van, et al., 2011). The production of Nylon not only requires immense energy inputs, which releases Carbon Dioxide, but also releases significant amounts of Nitrous oxide as a byproduct, a greenhouse gas 300 times more potent than carbon dioxide. Nitrous Oxide, more commonly known as laughing gas, has a similar ozone depleting effect as Chlorofluorocarbons (CFCs) but remains in the atmosphere for 114 years, far longer than any CFCs. Because of these qualities, Nitrous Oxide is considered the third largest greenhouse gas contributor to climate change after Carbon Dioxide and Methane (Chen, Hsiou-Lien, and Leslie Davis Burns, 2006). At the end of its life cycle, nylon waste also presents a challenge due to its nonbiodegradability. Nylon waste represents 10% of the debris in the ocean and is the main source of microplastics, toxic contaminants which can be biomagnified into food chains and seafood. Furthermore, the recycling process for nylon is costly as its melting point is too low to kill certain bacteria, making additional cleaning necessary (Chen, Hsiou-Lien, and Leslie Davis Burns, 2006). Some toothbrush brands advertise bristles made from a variety of nylon called Nylon 4, which is biodegradable but costly to produce (Terry, Beth, 2015). However, a simple lab analysis revealed that 3 out of 4 brands claiming to contain biodegradable Nylon 4 actually contained a large fraction of nonbiodegradable Nylon 6,6 (Terry, Beth, 2015). While these particular brands have since rescinded their claims, many brands still advertise bristles containing Nylon 4 without evidence. Currently, few alternatives exist to nylon bristles. One of them is pig hair, which was the preferred material for toothbrush bristles before the invention of Nylon. Another is a 62% Castor bean oil variation of nylon sold by the company Brush With Bamboo. Although bio-based, this product is not biodegradable (Terry, Beth, 2015). Of the materials used in bamboo toothbrushes, the most problematic in terms of waste and emissions are the bristles.

There exists a strong public consensus that bamboo is an extraordinarily and inherently sustainable material. In reality, the ecological impact of bamboo as a raw material depends heavily on cultivation practices. Contrary to popular belief, most bamboo is not harvested from natural forests but vast monoculture plantations installed in a national afforestation effort by the Chinese government during the seventies (Bowyer, Jim, et al, 2014). Monoculture plantations detrimentally affect ecology by disrupting the interspecies relationships within the natural biodiversity of a forest, leading to the loss of resitence to pests, disease and increased nutrient depletion and soil erosion. While monoculture plantations are advantageous in the short run, in the long run the ecological consequences are unpredictable. There exists a common misconception that bamboo does not require fertilizer, but on the contrary, Moso bamboo plantations require more fertilizer than other species due to its fast growing rate. A hectare of land typically requires 200 kilograms of fertilizer, including energy expensive Potassium and Nitrogen based fertilizers (Bowyer, Jim, et al, 2014). The runoff of these chemicals into streams and the environment is concerning due to the potential ecological and adverse health impacts to the surrounding communities. Due to a combination of consumer misconceptions and lax regulation on the part of the Chinese government, unsustainable cultivation is allowed to continue unchecked. Most bamboo toothbrush companies claim to have sustainably harvested bamboo but currently the only reliable certification available is given by the Forest Stewardship Council, the validity of which has been questioned by experts due to the vague requirements needed in order to qualify (Bowyer, Jim, et al, 2014). Since the process is so opaque, it is almost impossible for toothbrush companies to verify claims about the origins of the bamboo, practices used to harvest it or the labour conditions in manufacturing. However, bamboo toothbrush companies can rely on the environmentally friendly reputation of bamboo to make claims about their product’s waste and emissions without reliable evidence. Of five major bamboo toothbrush brands evaluated, only two had any sort of certification, and only by the aforementioned Forest Stewardship Council. Three companies gave no information as to how and where their product was produced, undoubtedly finding it unnecessary due to the glowering reputation of bamboo.

Bamboo toothbrushes generate far less waste and emissions than plastic toothbrushes due to the drastically different nature of their production. While plastic production spans the globe, bamboo can be locally grown, harvested and manufactured into products. However, lax regulation and consumer preconceptions lead to unsustainable farming practices with largely unknown environmental consequences. Given that most people use toothbrushes on a daily basis, switching to bamboo toothbrushes can offset a considerable amount of waste and emissions, from greenhouses gasses such as Carbon Dioxide and Nitrous Oxide to harmful chemical byproducts of plastics.

Bibliography

Al-Salem, S.M., P. Lettieri, and J. Baeyens. "Recycling And Recovery Routes Of Plastic Solid Waste (PSW): (2009)

Bowyer, Jim, et al. “Bamboo Products and Their Environmental Impacts: Revisited.” Dovetail Partners Inc., 10 Mar. 2014.

Chen, Hsiou-Lien, and Leslie Davis Burns. “Environmental Analysis of Textile Products.” Clothing and Textiles Research Journal, vol. 24, no. 3, 2006, pp. 248–261., doi:10.1177/0887302x06293065.

Day, M., et al. “An Investigation of the Chemical and Physical Changes Occurring During Commercial Composting.” Compost Science & Utilization, vol. 6, no. 2, 1998, pp. 44–66., doi:10.1080/1065657x.1998.10701920.

“Does It Take More Energy to Produce Recycled Paper?” Southern California Shredding, 7 Mar. 2013, ocshredding.com/2013/03/07/does-it-take-more-energy-to-produce-recycled-paper/.

Duuren, J.b.j.h. Van, et al. “A Limited LCA of Bio-Adipic Acid: Manufacturing the Nylon-6,6 Precursor Adipic Acid Using the Benzoic Acid Degradation Pathway from Different Feedstocks.” Biotechnology and Bioengineering, vol. 108, no. 6, 2011, pp. 1298–1306., doi:10.1002/bit.23074.

Escamilla, Edwin Zea, and G. Habert. “Environmental Impacts of Bamboo-Based Construction Materials Representing Global Production Diversity.” Journal of Cleaner Production, vol. 69, 2014, pp. 117–127., doi:10.1016/j.jclepro.2014.01.067.

Johnson, Alissa. “Recycling Energy: An Exploration of Recycling and Embodied Energy.” Penn Sustainability Review, vol. 1, no. 6, 1 May 2016. Energy Policy.

Lugt, P. Van Der, et al. “An Environmental, Economic and Practical Assessment of Bamboo as a Building Material for Supporting Structures.” Construction and Building Materials, vol. 20, no. 9, 2006, pp. 648–656., doi:10.1016/j.conbuildmat.2005.02.023.

Maoyi, Fu, and R.L. Banik. “Bamboo Production Systems and Their Management.” Bamboo, People and The Environment: Propagation and Management, vol. 1, 1996.

Naitove, Matthew H. "Sustainable Injection Molding: Amcor Looks At The Big Picture." Plastics Technology 59.3 (2013): 42-44.

Ross, Charley. “Should You Be Switching Your Plastic Toothbrush For A Bamboo One?” HuffPost UK, HuffPost UK, 23 July 2018, www.huffingtonpost.co.uk/entry/should-you-b e-switching-your-plastic-toothbrush-for-a-bamboo-one_uk_5b5591a2e4b0fd5c73c6e281?guccounter=2.

Semuels, Alana. “Is This the End of Recycling?” The Atlantic, Atlantic Media Company, 6 Mar. 2019, www.theatlantic.com/technology/archive/2019/03/china-has-stopped-accepting- our-trash/584131/.

Song, Qingbin, et al. “Minimizing the Increasing Solid Waste through Zero Waste Strategy.” Journal of Cleaner Production, vol. 104, 2015, pp. 199–210., doi:10.1016/j.jclepro.2014.08.027.

Terry, Beth. “The Truth About Your Biodegradable Bamboo Toothbrush.” My Plastic Free Life, 18 Dec. 2015, myplasticfreelife.com.

“The Lifecycle of a Plastic Toothbrush: The Bristle Blog.” Bristle, Bristle Ltd., 22 Sept. 2019, www.wearebristle.com/2018/02/13/lifecycle-plastic-toothbrush/.

Yamashita, Kyoko, et al. "Compositions Of Volatile Organic Compounds Emitted From Melted Virgin And Waste Plastic Pellets."

Yu, Dongwei, et al. “A Future Bamboo-Structure Residential Building Prototype in China: Life Cycle Assessment of Energy Use and Carbon Emission.” Energy and Buildings, vol. 43, no. 10, 2011, pp. 2638–2646., doi:10.1016/j.enbuild.2011.06.013.