Design Life-Cycle

assess.design.(don't)consume

Joaquin Loayza

Group Members:

Jesse Mon, German Velasco

DES 40A

Professor Cogdell

Raw materials in Bamboo Reinforced Concrete

Bamboo is an eco-friendly, perennial, green, renewable, natural, and fast-rising plant component originating from all parts of the world. It is used as a component in renewable sources and green technology because of its fast regeneration (Archila et al.). Because of its high tensile strength, bamboo is cast off in various ways as a construction component in the worldwide construction sector, majorly in China and India. Bamboo usage in various industrial processes has demonstrated a great opportunity for the creation of cost-effective composite components and materials that may be effectively used for non-structural and structural uses in the construction of buildings and houses. In the construction industry, bamboo has been used as a reinforcing material in concrete. Concrete as a material has been used in construction for a long time and requires reinforcement because of characteristically weak tension, even though it is stronger in compression force. Instead of using steel, bamboo is used in this type of reinforced concrete because it contains low weight and high compression in terms of strength (Archila et al.). Bamboo fits all the necessary characteristics needed to make concrete structures have the ability to contain active structure load (Archila et al.). Even though bamboo reinforced concrete is not widely used in heavy construction of structures and buildings but in light construction, it is necessary to study how it is formed and the materials used during its formation, its importance in the construction industry, and why it is considered a better replacement of steel in concrete reinforcement, and its advantages and disadvantages in concrete reinforcement.

Bamboo reinforced concrete is made using similar techniques used to create conventional reinforced concrete. During construction, there are some factors considered before reinforcement with bamboo is done. The physical aspects of the bamboo are keenly investigated, starting with swelling and shrinkage, bending, elasticity, and fire resistance. Under swelling and shrinkage, bamboo alters its dimensions when it gains or loses water (Sethia and Baradiya). It is hygroscopic in nature, meaning that its moisture content varies with the temperature and relative humidity changes of a particular place. As for bending, bamboo is considered a reinforcement material because of its ability to bend (Sethia and Baradiya). Elasticity is another aspect that makes bamboo great for reinforcing concrete due to its high elasticity. Bamboo's fire resistance capabilities are great when considered a reinforcing material because it can withstand high temperatures due to its high silicate acid content (Sethia and Baradiya). Other factors that affect the usage of bamboo include aspects such as the type of bamboo, the bamboo's position alongside its culm, its age, the diameter of the bamboo used for reinforcement, and the length of the bamboo (Ahmad, Raza and Gupta). However, during the construction phase, a warning is given that green and unseasoned bamboo that is not waterproofed should not be used in the concrete (Ahmad, Raza and Gupta). Also, any bamboo cut in the summer or spring should not be used because it is considered weak due to the augmented moisture content in its fibers. Moreover, whole culms of unseasoned and green bamboo make poor quality choices for concrete reinforcement work (Brink and Rush). When mixing the concrete, the mixing design is altered a little because the difference in reinforcing material used in that water will affect the bamboo rods compared to how it would affect steel rods (Sethia and Baradiya). Essentially, the concrete slump is lowly made to ensure its workability does not have excess water. Excess water would damage the bamboo by making it swell. Also, during the mixing, it is critical to note that the concrete's alkaline ingredients must be addressed to prevent them from absorbing and diluting the bamboo's fat contents. Such dilution is prevented by waterproofing the bamboo's surfaces using synthetic rubber or resin (Terai and Minami). The other raw materials used include cement, water, and aggregates, which can be coarse or natural aggregates. Then the mixing of the ingredients begins with water being gradually added to the mixture to ensure that it does not destroy the bamboo later in case it is in excess.

Moreover, using bamboo as a reinforcing material in construction concrete has recently become popular and important material. Its importance cannot be understated even though water has the ability to negatively impact bamboo considering water's high usage in construction. Bamboo is considered a high-strength and extremely renewable replacement material with strong capabilities, such as steel, and therefore replaces steel during concrete reinforcement (Archila et al.). Bamboo has a higher tensile resistance than compression due to its axial fibers running along the bamboo (Ghavami). On the outside layer, the bamboo is made up of extremely elastic vascular bundles whose tensile strength is very high, making bamboo fibers’ tensile strength higher than the one found in steel. Bamboo-reinforced concrete, therefore, becomes a viable option in low-cost house construction in areas where bamboo is cheaper and more cost-efficient than steel (Moroz et al.). Another important reason bamboo is considered for low-cost, and light construction of structures and buildings is that it is a nonpolluting material and does not consume much energy. In areas where bamboo is in abundance, it makes sense that the construction of concrete would be done through bamboo, which acts as the reinforcer in the concrete, thereby reducing the wastage of renewable resources and any permanent pollution that is typically caused by the production of steel (Ghavami). Due to its high fiber content, bamboo is globally championed to replace hazardous materials such as asbestos cement, leading to the production of environmentally friendly cement that is used with bamboo to produce fiber-reinforced composites (Ghavami). Furthermore, it favorably compares with steel when used in concrete because of reduced stiffness issues and substantial durability, aspects that have a positive impact on the environment because they ensure that there will be little repair and maintenance done on the concrete using non-renewable materials sourced from the environment (Solahuddin). The use of bamboo has protected the environment and its regeneration because there is reduced sourcing of non-renewable materials such as cement and sand used in the construction of concrete.

Consequently, there is a need to understand the advantages and disadvantages of using bamboo as a reinforcing material in concrete. There are various advantages of using bamboo when constructing concrete, and they include an economical advantage whereby bamboos take a short while to grow fully, and within a few years, they typically attain full mechanical resistance. It takes between three to five years for bamboo to attain a high accretion rate that allows them to be logged for any use (Chang et al.). Moreover, compared to steel in terms of carbon IV oxide footprint and embodied energy during their manufacturing. Bamboo has lower rates of embodied energy at 4 to 6MJ/kg compared to steel which is between 29 to 35 MJ/kg (Archila et al.). Steel adds more carbon to the environment at a rate of 2.2 to 2.8 kgCO2/kg compared to bamboo, whose rate is 0.25 kgCO2/kg (Archila et al.). Bamboo is naturally used as a method of cleaning the environment through the absorption of nitrogen as a way of reducing air pollution (Ahmad et al.). In terms of tensile strength, bamboo has a high tensile strength which can reach 370MPa, making it an alternative material to steel when considering tensile loading abilities (Ghavami). This is because bamboo has a ratio of tensile strength to a particular bamboo weight that is six times greater than steel's tensile strength (Ghavami). However, bamboo has various disadvantages, which include its lack of radial fibers making it perpendicularly weak and hence prone to compression failures and failures caused by transverse tension and longitudinal shear (Archila et al.). Another disadvantage is that bamboo is not easily shaped to carry out any optimal mechanical requirement. For it to be optimally shaped, its nature and properties would have to undergo extensive processing to attain the required shape (Archila et al.). Moreover, bamboo as a construction material is still vulnerable to fungi and insect attacks, while any dried bamboo can easily catch fire (Ahmad et al.). Unfortunately, bamboo-reinforced concrete can only be used as an alternative to steel-reinforced concrete to construct low-housing projects. However, it cannot be used in large-scale construction because of its lack of radial fibers and the inability to transfer tension longitudinally (Moroz et al.). Also, untreated bamboo can cause macro or micro-cracks on cured concrete caused by its ability to absorb water because of dimensional variations (Ghavami). Therefore, there is a need to understand the advantages and disadvantages of bamboo-reinforced concrete to gain insight into how sustainable the structure can be when compared to steel-reinforced concrete when all factors are kept constant.

In conclusion, even though bamboo reinforced concrete is not widely used in heavy construction of structures and buildings but in light construction, it was critical to understand how it was formed and the materials used during its formation. Also, the paper showed how bamboo-reinforced concrete was important in construction, why bamboo could make a good replacement for steel in concrete reinforcement, and the advantages and disadvantages of using bamboo as a concrete reinforcer. Bamboo can be a great building component that nay successfully substitutes steel as a concrete reinforcer in construction. To make bamboo more efficient, water absorption and insect and mold infestation are problems that need to be mitigated to ensure that bamboo-reinforced concrete can be more successful in light construction. Bamboo can be procured at affordable costs while not harming the environment when used as a concrete reinforcer. With the sourcing of bamboo for concrete reinforcement, multiple sustainable development goals would be attained globally, and issues like job creation, economic activity stimulation, and improvement of available infrastructure will happen.

Bibliography

Ahmad, Shakeel, Altamash Raza and Hina Gupta. "Mechanical Properties of Bamboo Fibre Reinforced Concrete." 2nd International Conference on Research in Science, Engineering and Technology (ICRSET’2014). Dubai, 2014. Electronic Document.

Archila, Hector, et al. "Bamboo reinforced concrete: a critical review." Materials and Structures 51.102 (2018). Online Article.

Brink, Francis E and Paul J Rush. Bamboo Reinforced Concrete Construction. US Naval Civil Engineering Laboratory Report. Port Hueneme, 1966.

Chang, Fang-Chih, et al. "Environmental benefit of utilizing bamboo material based on life cycle assessment." Journal of Cleaner Production 204 (2018): 60-69.

Ghavami, Khosrow. "Bamboo as reinforcement in structural concrete elements." Cement and Concrete Composites 27.6 (2005). Online Article.

Moroz, J G, S L Lissel and M D Hagel. "Performance of bamboo reinforced concrete masonry shear walls." Construction and Building Materials 61 (2014). Online Article.

Sethia, Arpit and Vijay Baradiya. "Experimental Investigation on Behavior of Bamboo Reinforced Concrete Member." International Journal of Research in Engineering and Technology 3.2 (2014). Electronic Document.

Sjunnesson, Jeannette. "Life Cycle Assessment of Concrete." 2005. Online Article.

Solahuddin, B. "A Review on Structural Performance of Bamboo Reinforced Concrete." Materials Science Forum 1056 (2022).

Terai, Masakazu and Koichi Minami. Research and Development on Bamboo Reinforced Concrete Structure. Reseach Report. Lisboa: 15 WCEE, 2012. Online Document.

Jesse Mon

German Velasco, Joaquin Loayza

DES 40A

Professor Cogdell

Energy Relating to Bamboo Reinforced Concrete

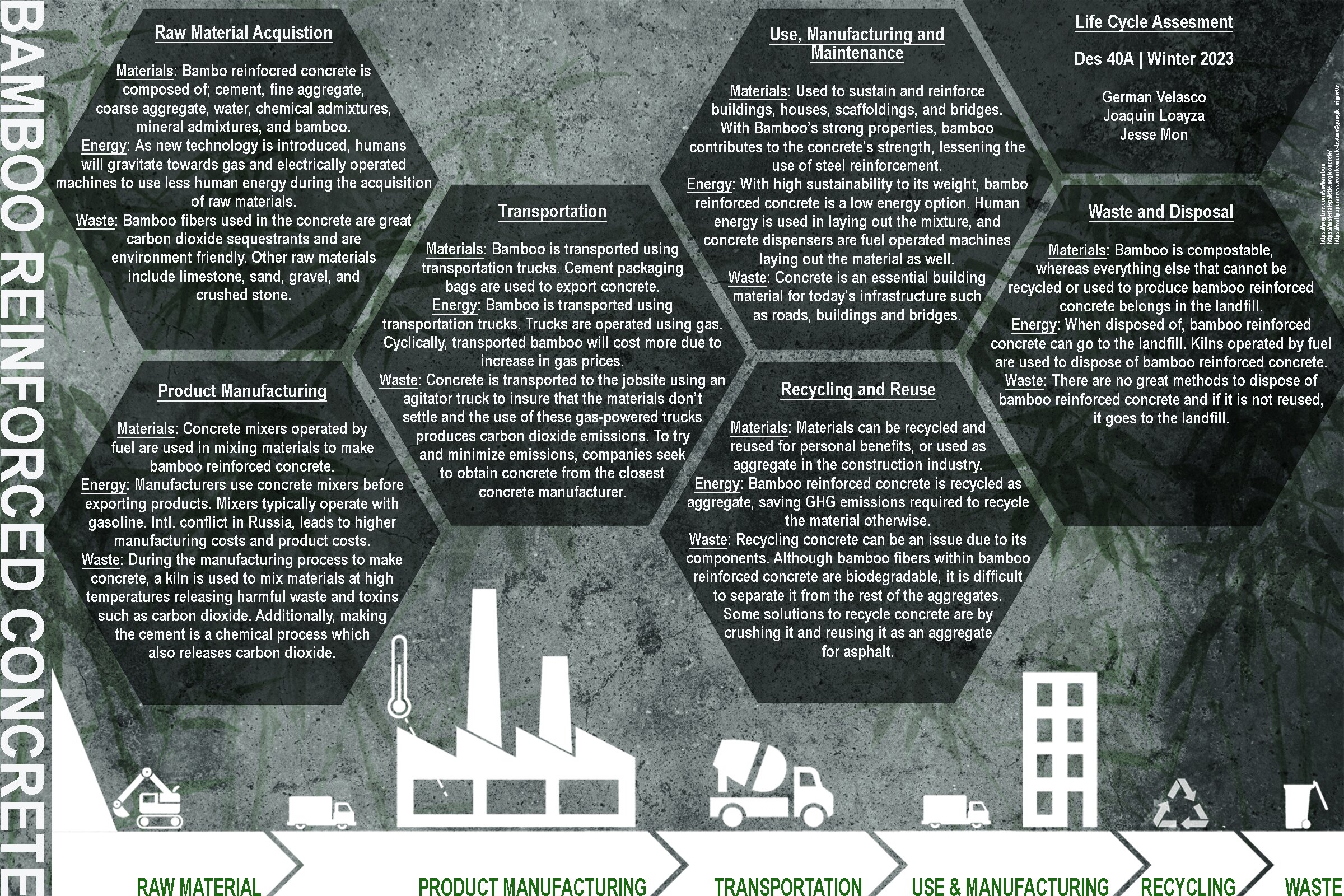

One of the most adaptable plants on the planet, bamboo is employed in several industrial, agricultural, and building applications. Due to its eco-friendliness, durability, and strength, bamboo has attracted a lot of attention in the construction industry over the years. The use of bamboo as reinforcement for concrete structures is one of the most recent developments in bamboo application in the construction sector. Bamboo offers various advantages when used as reinforcement in concrete structures. Energy use in the acquisition of raw materials, product manufacturing, transportation, use, recycling, and disposal will be covered in this essay. Bamboo reinforced concrete is a sustainable alternative to steel supported concrete due to lower needs for energy during raw material acquisition, product manufacturing, transportation, use, and recycling/disposal.

Bamboo is used as reinforcement in concrete to boost its durability and strength. BRC has worked on several building projects around the world, including ones involving residences, bridges, and skyscrapers. There are several advantages to using bamboo as structural reinforcement for concrete as opposed to traditional steel reinforcement. Second, bamboo is a widely distributed, renewable resource that is available all over the world. Bamboo is more eco-friendly and sustainable than steel because steel is a non-renewable resource that is produced using energy-intensive techniques. Second, due to its high tensile strength, bamboo makes a fantastic reinforcement material. Tensile strength of bamboo is equivalent to steel, making it a durable material. Bamboo is much lighter than steel and is abundant and sustainable, making it simpler to transport.

In order to build the BRC, energy is required to produce the concrete and prepare the bamboo. The two types of energy employed in the development of BRC are operational energy and embodied energy. Since BRC materials demand embodied energy during production, BRC structures require operational energy during construction and maintenance.

Bamboo and concrete production both consume energy that is embodied in the production of BRC. Manufacturing cement, aggregate, and water all need a lot of energy, which makes producing concrete a costly endeavor. The majority of the entities in concrete comes from the manufacturing of cement, which is extremely energy-intensive. Although the energy requirements are substantially lower than those of steel reinforcement, bamboo manufacture still requires energy. Traditional agricultural techniques, which mostly involve manual work and little automation, are used to grow and harvest bamboo. Nevertheless, cutting, shaping, and treating the bamboo to stop rot and insect damage are all fuel steps in the processing of bamboo into reinforcement.

Covering the raw materials aspect, bamboo reinforced concrete is a mix of bamboo and concrete to create a concrete form that is more sustainable. In the extraction process of these raw materials, there are many operating energy uses. When gathering bamboo, human energy is used to cut bamboo stems before transporting them for product manufacturing. With new technology, humans can save human energy, utilizing chainsaws to make their extraction process easier. Chain saws typically require fuel, but new research and technology have provided electric chain saws, making extraction costs cheaper. For extracting the minerals/limestone, dynamite is used to break down the rocks into transportable sizes. By mixing liquid nitroglycerin with an inert porous substance like charcoal or diatomaceous earth, dynamite is created. The energy created by igniting dynamite is a form of chemical energy.

Portland cement, the kind most often used in concrete, is made from a combination of a calcareous material (usually limestone) and of silica and alumina found as clay or shale (Advameg Inc, 2023). In order to combine the raw materials listed above to create Portland concrete, the materials are placed into a burning kiln at 1450 degrees. This process is an example of energy used in the “product manufacturing” stages. With kilns requiring fuel, the amount of energy required will stay the same, but the cost of fueling the same energy will be more expensive. When Russia invaded Ukraine, the United States closed trade with Russia, affecting the economy of fuel prices. Russia is responsible for 1 in 10 barrels of gasoline, and impacts of losing trade hinder production costs throughout many industries dependent on fuel. The cost for BRC is likely to go up because of increased prices in fuel. Before the bamboo is mixed, the bamboo is either shredded into tiny pieces, or kept fully in one piece. If shredded, machines allow bamboo to be broken into particles, and this process will require fuel energy. The great amount of fibers held in bamboo create a huge benefit for the sustainability and durability of bamboo reinforced concrete. The energy durability of bamboo allows heavier loads to be held with the usage of BRC.

As for transportation, bamboo reinforced concrete is transported using cement packaging bags, and is distributed and transported using trucks. With bamboo being a lightweight material compared to steel beams, the weight will allow transportation trucks to use less fuel in the process of transporting the goods. As mentioned, political factors relating to the invasion of Ukraine has led to higher fuel prices making transportation costs higher. In relation to this idea, manufacturers may utilize products from geographically closer raw material distributors when assessing the higher transportation costs. In making the cement packaging bags, loads of plastic are layered to create stronger durability, allowing more bamboo reinforced concrete to be moved at once. This process requires human energy and machine operation energy. Moving towards sustainability and autonomy, fully automated electric trucks will lessen the cost of transportation by a ton. With the energy dependent on renewable energy, we will be able to perform the same tasks without using human energy.

BRC is used to sustain and reinforce buildings, houses, scaffoldings, and bridges. With Bamboo’s strong properties, bamboo contributes to the concrete’s strength, lessening the use of steel reinforcement. With high sustainability to its weight, BRC is a low energy, high sustainability option. Less human energy is used in laying out the mixture compared to steel reinforced concrete due to the weight of steel beams. Steel reinforced concrete is far more durable than bamboo reinforced concrete. The reason bamboo reinforced concrete has risen in popularity is because it requires less energy to produce and use in projects. Equipment used to lay concrete are concrete mixers and concrete dispensers. Concrete mixers are operated using fuel, and are responsible for turning the concrete so it wont dry during application processes. The gas provides energy for motors running the concrete mixer. Concrete dispensers allow construction workers to place concrete while limiting the amount of waste. With concrete being so heavy, lifting the tail end of the concrete dispenser barrel requires both renewable and fuel energy.

In the process of recycling bamboo reinforced concrete, concrete drilling tools are used. Concrete drilling tools require fuel for energy, making the process somewhat expensive. With the recycled materials, if the bamboo is in good enough condition after removing it from the concrete, the bamboo can be recycled in thousands of different ways. A way bamboo can produce energy is by turning it into a biofuel. If bamboo is burned and turned into heat, the heat can turn into thermal-energy that can act as energy for anything. As for concrete, when broken down, the pieces can be used as aggregate.

Different ways to dispose of BRC are recycling it, or disposing it in the landfill. The landfill should be the last alternative, given that disposing of it will create waste. In this process, energy is used in transporting the waste to landfills, and trucks will use fuel. Disposing BRC in the landfill will leave the material sitting, requiring no energy to reuse the material.

Bamboo reinforced concrete has been in the market for a long time, establishing itself as a sustainable alternative to steel reinforced concrete. Relative to steel reinforced concrete, bamboo reinforced concrete uses less fuel in its extraction process and manufacturing process. Bamboo reinforced concrete is a sustainable alternative to steel supported concrete due to lower needs for energy during raw material acquisition, product manufacturing, transportation, use, and recycling/disposal. With room for technological improvements, greenhouse gas emissions will lessen, making raw material acquisition, and manufacturing processes eco-friendlier. Bamboo reinforced concrete is here to stay, and has asserted itself as a sustainable alternative in saving energy for future generations.

Bibliography

1) The Constructor. “Bamboo Reinforced Concrete - Mix Proportion, Design and Construction.” The Constructor, 12 Dec. 2016, theconstructor.org/structural-engg/bamboo-reinforced-concrete-mix-design-construction/15054/.

2) “Bamboo Provides Biomass for the Production of Renewable Energy.” Guadua Bamboo, www.guaduabamboo.com/blog/bamboo-provides-biomass-for-the-production-of-renewable-energy#:~:text=Electricity%20can%20be%20generated%20from%20bamboo%20by%20gasification.

3) “Bioenergy Production from Bamboo: Potential Source from Malaysia’s Perspective :: BioResources.” Bioresources.cnr.ncsu.edu, bioresources.cnr.ncsu.edu/resources/bioenergy-production-from-bamboo-potential-source-from-malaysias-perspective/.

4) Nguyen, Quynh. “How Sustainable Is Bamboo “Wood”? Here Are the Facts.” Impactful Ninja, impactful.ninja/how-sustainable-is-bamboo-wood/.

5) “Rebuilding with Recycled Concrete - ASME.” Www.asme.org, www.asme.org/topics-resources/content/rebuilding-with-recycled-concrete#:~:text=The%20recycling%20process%20for%20concrete%20is%20simple%20enough. Accessed 9 Feb. 2023.

6) Sethia, Arpit, and Vijay Baradiya. "Experimental investigation on behavior of bamboo reinforced concrete member." International Journal of research in Engineering and technology, eISSN (2014): 2319-1163.

7) Brink, Francis E., and Paul J. Rush. "Bamboo reinforced concrete construction." US Naval Civil Engineering Laboratory Report, Port Hueneme (1966).

8) Caldas, L., et al. “Dynamic Life Cyle Carbon Assessment of Three Bamboo Bio-Concretes in Brazil.” Academic Journal of Civil Engineering, 26 June 2019, journal.augc.asso.fr/index.php/ajce/article/view/1067.

9) Sjunnesson, Jeannette. "Life cycle assessment of concrete." (2005).

10) “Is Bamboo Recyclable? (and Ways to Dispose Of?) - Conserve Energy Future.” Www.conserve-Energy-Future.com, 1 Nov. 2021, www.conserve-energy-future.com/is-bamboo-recyclable.php.

German Velasco

Joaquin Loayza, Jesse Mon

DES 40A

Professor Cogdell

Bamboo Reinforced Concrete Waste and Emissions

Concrete is one of the most ubiquitous building materials used in the construction industry, but it is also one of the major contributors to creating a carbon footprint. The emissions of concrete worldwide are responsible for roughly 4 billion tonnes of carbon dioxide each year (Ramsden, 2020) . This has put a pressure on the manufacturing industry of concrete to try and find ways to reduce the emissions during the production process. In more recent years, there have been more efforts and research put into trying to find alternatives for the aggregates that go into making concrete mix. One of the proposed solutions is to use bamboo fiber as a reinforcement in concrete instead of its counterpart non-degradable polymeric fibers that are typically used. Bamboo fibers as a concrete reinforcement material have been introduced into the construction world as a means for less waste during the production process of its life cycle in efforts to reduce carbon emissions.

Bamboo reinforced concrete, or BRC for short, is made up of aggregates such as bamboo fibers, limestone, sand, and crushed rock. Bamboo is one of the main materials used as a replacement for the other polymers that emit more carbon dioxide into the environment. Using bamboo as one of the raw materials minimizes waste due to the nature of its extraction and its biodegradability (Caldas, 2020). In other words, this fiber is favored as a sustainable substance due to its low carbon qualities and non-toxic process of acquiring this raw material. Furthermore, bamboo can grow expeditiously and does not require vast amounts of water. In other words, the bamboo fibers used in the concrete mix are environmentally friendly because it is a naturally occuring source that does not need to be concocted through a chemical process. Another key ingredient in concrete is limestone and, unlike bamboo, the extraction of this raw material produces a vast amount of waste. Limestone has to be mined and typically this creates water contamination. These contaminants can look like oil and gas from the equipment used to mine. Once again, this is another reason why bamboo fibers are being implemented into concrete as a replacement for other aggregates: it is amazingly efficient and does not cause tons of waste during its extraction. It is clear that bamboo is one of the most natural and emission free components of bamboo reinforced concrete.

In the concrete manufacturing plants, large amounts of fuel and energy is needed to keep it running. The leading states for production of concrete are California, Florida, Texas, and Missouri. Concrete is conventionally made at a central plant and from there it is distributed to contractors in mixer trucks. Most of the carbon dioxide produced in the life cycle of concrete happens in the manufacturing process. Additionally, around 60% of the concrete industry’s carbon emissions in the state of California is found to be from heating the limestone in the kiln (Lopez, 2022). This statistic agrees with the statement that a large portion of the emissions in the life cycle of concrete come from producing the different ingredients and putting them together. There is also a chemical process to make cement, the main component in manufacturing concrete. During this chemical reaction, carbon dioxide is emitted as a byproduct and released into the atmosphere. The manufacturing process of bamboo reinforced concrete takes up the most energy and energy consumption is generally interconnected with waste and emissions. In this case, it is true that the large amount of energy used to create the concrete is also responsible for all the greenhouse gasses and toxic waste created.

The process of transporting concrete is mainly done through the use of transit mixers. These are trucks that usually have a rotating mixer drum on the back to ensure that the material doesn’t settle. The transit mixers, for the most part, have diesel engines which produce a great deal of carbon dioxide emissions. All methods of transporting the bamboo reinforced concrete to its destination involve the use of a gas-powered vehicle which means there are no current methods of transportation for this material that do not create carbon emissions.

Concrete is an essential building material for our society. Most of the infrastructure seen today involves the use of concrete: bridges, roads, schools, hospitals, etc. Therefore, concrete is one of the highest producers of carbon emissions; although not to be confused, most of the emissions happen during the raw material and production phase. At this point in the life cycle, when bamboo reinforced concrete is actually being used, most of the waste will come from the machinery that lays down the concrete. When laying BRC, companies use a concrete pump truck, or sometimes a boom pump for high-rise buildings, that runs on diesel and releases carbon dioxide into the atmosphere. Additionally, power trowel machines are sometimes used to flatten the concrete and these machines produce exhaust fumes and emit nitrogen oxide. As you can see, not much waste was produced during this part of its life-cycle and by now BRC has gone through most phases that create greenhouse gas emissions.

Some components of bamboo reinforced concrete can be recycled but for the most part there are some materials that are much harder to dispose of. Only about 30% of the components in concrete are recycled to be able to maintain the structural integrity of new concrete (Bentley, 2022). Thus, more than half of the materials in concrete have to go to landfills and are extremely difficult to dispose of. Nonetheless, concrete has a long life because it typically does not need frequent maintenance and is one of the most long lasting construction materials. One of the ways that concrete is reused is through gravel for roads or sometimes as aggregate once again for concrete (Bentley, 2022). By reusing concrete as asphalt for roads, it is eliminating some of the emissions of disposing concrete in landfills and the transportation of it. The parts of concrete that are able to be reused have a diversified application in the construction industry. On top of the two uses mentioned above, old crushed concrete can be used to create retaining walls. Although concrete can be reused, the lifespan of the reused concrete may not last as long because the compounds that were previously used are not as strong as they were the first time.

Currently there are no great ways to dispose of bamboo reinforced concrete. If it is not recycled, then the last resort would be to transport the BRC to a landfill where it sits as waste because it is not biodegradable. Recycling the BRC would save the use of trucks, which in turn would save the amount of gas emissions.

The demand for concrete is not slowing down, so the need to find more sustainable methods during each part of its life-cycle is a pressing matter. Bamboo reinforced concrete has been an attempt to reduce waste during its production and recycling process. Nonetheless, the use of bamboo fibers as an aggregate is still new to the industry and needs more research to be done before it can fully be adapted. As of today, most companies stick to the traditional concrete that has been used and reliable for decades. Needless to say, bamboo concrete is eco-friendlier and still sufficiently better than traditional concrete. It has been proven that BRC produces less emissions during its raw material extraction phase and the manufacturing process. Ultimately, the need for reducing the carbon footprint in the life cycle of concrete will naturally lead to the widespread use of BRC due to its innate ability to mitigate emissions within the construction industry.

Bibliography

Bentley, Dr Peter. “Can We Recycle Concrete?” BBC Science Focus Magazine,BBC Science Focus Magazine, 20 Apr. 2022, www.sciencefocus.com/science/can-we-recycle-concrete/.

Brink, Francis E., and Paul J. Rush. "Bamboo reinforced concrete construction." US Naval Civil Engineering Laboratory Report, Port Hueneme (1966).

Caldas, L., et al. “Dynamic Life Cycle Carbon Assessment of Three Bamboo Bio-Concretes in Brazil.” Academic Journal of Civil Engineering, 26 June 2019, journal.augc.asso.fr/index.php/ajce/article/view/1067.

Caldas, Lucas Rosse, et al. “Bamboo Bio-Concrete as an Alternative for Buildings' Climate Change Mitigation and Adaptation.” Construction and Building Materials, Elsevier, 6 Sept. 2020, www.sciencedirect.com/science/article/pii/S095006182032657X?casa_token=dYxQ1Rk0UyEAAAAA%3AY0XINJCoW64cHYGqmIFQadiDJUORg8iXTEyWbEcHDl-s2YHXp-12avS73LOplvyLIKIMf6w4.

Chang, Fang-Chih, et al. "Environmental benefit of utilizing bamboo material based on life cycle assessment." Journal of Cleaner Production 204 (2018): 60-69.

Greenwood, Tunde. “Concrete Recycling 101 - Can Concrete Be Recycled? .” Iseekplant, Iseekplant.com.au, 8 Apr. 2022, blog.iseekplant.com.au/blog/can-concrete-be-recycled#:~:text=Recycling%20 concrete%20is%20cheaper%20and,the%20economics%20and%20environment%20 factors.

Ikponmwosa, Efe, et al. “Structural Behaviour of Bamboo-Reinforced Foamed Concrete Slab Containing Polyvinyl Wastes (PW) as Partial Replacement of Fine Aggregate.” Journal of King Saud University - Engineering Sciences, Elsevier, 28 June 2015, www.sciencedirect.com/science/article/pii/S1018363915000185.

Kolawole, John, et al. “Blended Cement Binders Containing Bamboo Leaf Ash and Ground Clay Brick Waste for Sustainable Concrete.” Materialia, Elsevier, 23 Feb. 2021, www.sciencedirect.com/science/article/pii/S258915292100048X?casa_token=0vXQAdfxTfAAAAAA%3A14proV_4oxYqmpiTnGFUylF3fPbhwMKbIEzKbYF1uJDJF5Ay9WS5g2RBN4EvpZgOJU2tqmV_.

Lopez, Nadia. “Climate-Friendly Cement? California Takes on a High-Carbon Industry.” CalMatters, 27 June 2022, calmatters.org/environment/2022/06/california-cement-carbon-climate/.

Nguyen, Quynh. “How Sustainable Is Bamboo “Wood”? Here Are the Facts.” Impactful Ninja, impactful.ninja/how-sustainable-is-bamboo-wood/.

Ramsden, Keegan. “Cement and Concrete: The Environmental Impact - PSCI.” Princeton University, The Trustees of Princeton University, 3 Nov. 2020, psci.princeton.edu/tips/2020/11/3/cement-and-concrete-the-environmental-impact.

Sethia, Arpit, and Vijay Baradiya. "Experimental investigation on behavior of bamboo reinforced concrete member." International Journal of research in Engineering and technology, eISSN (2014): 2319-1163.

Terai, Masakazu, and Koichi Minami. "Research and development on bamboo reinforced concrete structure." 15 WCEE (2012)