Design Life-Cycle

assess.design.(don't)consume

Max Butcher

Max, Jinyu Zheng, Katelyn Lam

DES 40A

Professor Cogdell

Raw Materials used in the life Cycle of a Security Camera

Introduction

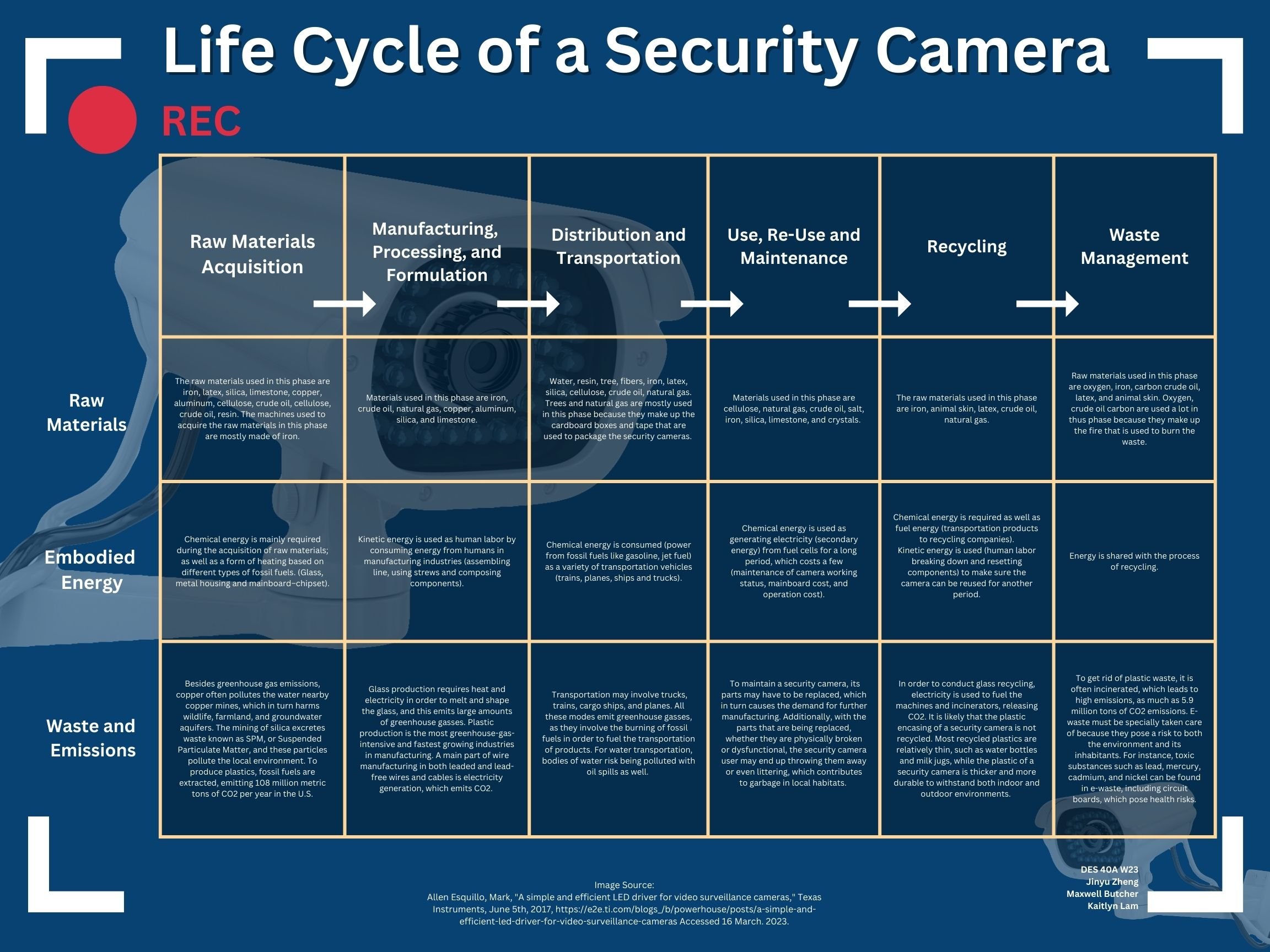

What is a security camera? A security camera is a device that records footage. These little devices are everywhere, you can find them at businesses, people’s houses, banks, schools and more. Why are they used? These devices are used to catch criminals that trespass and break into buildings. Criminals will often choose not to raid a business if they see it has many security cameras. There are many raw materials involved in the production and processing of a security camera. I found through my research that these materials come from many different parts of the world, have interesting characteristics, are very abundant, and can carry some health risks.

There are many raw materials used in the raw materials acquisition phase of a security camera. This is the first phase in the lifecycle of a security camera and it is when the raw materials used to produce a camera are acquired from the earth. The materials used in this phase are: iron, silica, limestone, copper, aluminum, cellulose, crude oil, latex, tree sap, and resin. Iron is perhaps the most used material in this phase, the construction machines that harvest iron ores out of the earth are 90 percent made of iron. Iron is a very abundant material and more than half of the Earth is made up of it. Many of these construction machines have paint that covers their iron components such as the doors and mirrors. It is important that these machines are painted because iron can corrode and rust if exposed to moist weather conditions. The raw materials used to make the paint are resin. Latex is used in this phase to make rubber, and the rubber is used to make the tires that the construction vehicles use to gather the iron ores. Latex is collected by going to a latex tree, slitting the stub with something sharp, and collecting the sap that spills out. The bowls that are used in the process of collecting latex from trees are made of iron.

A. The next phase of the life cycle is the manufacturing, processing and formulation of a security camera. In this phase, the raw materials are processed and assembled to create a security camera. The processing of the raw materials in this phase can cause health issues to the laborers that are involved. For example, metal fume fever is an illness that is caused when someone inhales the fumes or particles of metal (Plymovent). Some of the symptoms include nauseousness, vomiting, difficulty breathing and more. Metal fume fever can lead to death if not treated so it is important that the laborers who are melting and grinding the iron used in a security camera wear respiratory protection. Large amounts of silica are used when creating the glass lens of a security camera. Glass workers could develop a condition called silicosis if they do not wear respirators. Silicosis is a respiratory infection that is caused when someone inhales too much silica dust. According to the American Lung Association, “Approximately 2.3 million U.S. workers are exposed to silica in the workplace, including 2 million in construction and 300,000 in other industries” (American Lung Association). This means that there are at least 2 million people that are at risk for silicosis. Natural gas is a material used in creating the plastic portion of a security camera. It can be dangerous because it is very flammable. The laborers working in plastic manufacturing plants must be careful that they don’t smoke or bring any flammable substances to the plant because one spark could set the whole building ablaze. Also, the burning of raw materials like crude oil and natural gas that are used to make plastic can release carbon monoxide which is very harmful to humans, especially if laborers are exposed to it every day when they go to work.

Distribution and transportation is the next phase of the life cycle. During this phase, the security cameras are boxed and shipped all over the world to consumers who buy the product. Iron is once again heavily used in this phase. Iron makes up nearly all of the transportation vehicles that are used to ship security cameras; cars, boats, planes, cranes, forklifts, and more. The land vehicles used in this phase have rubber tires and these are made out of latex. Every security camera is placed in a cardboard box for shipping. Cardboard boxes are made using wood pulp and fibers from trees. The extraction of these materials is bad for the environment because the process can kill trees and lead to deforestation.

Next is the use and maintenance phase of the life cycle, this is the phase where the security camera is used and gets repaired if it breaks down. Security cameras are usually placed high up on ceilings or building exteriors and in places where people can’t tamper with them. Security cameras have wires that are plugged into a power source that is usually deep in the ground. These wires are housed by a long pvc pipe. Pvc pipe is used rather than copper or metal pipes because it does not corrode at all and is water resistant. The raw materials used to make pvc are cellulose, natural gas, and salt. The wires are composed of copper and aluminum. The footage that the security camera captures is displayed on a remote lcd tv screen in another location, usually in a security room. Lcd tvs are made up of silica, limestone, crystals, cellulose, crude oil, and natural gas. The plastic parts of the tv are made from cellulose, crude oil, and natural gas. The tv screen is composed of silica, limestone and crystal. Crystals are a unique raw material because they’re reflective. According to Rigas, “Light is reflected and refracted on numerous forms of rock crystals from the shiny ores to the clear quartz families” (Rigas). So it makes sense why they’re used in tv screens because they help reflect the light off the screen. Crystals can be found in rocks and deep beneath the surface of the earth.

A. The recycling phase happens towards the end of the life cycle, this phase is when the waste of the security camera is transformed into other materials. Broken security cameras are picked up out of recycling cans by humans and put into recycling trucks. They are then taken to a recycling center where humans separate the materials of each camera; they separate the plastic, the glass, the metal, etc. After being separated, they are washed and sanitized. The materials are then either melted or cut up into little pieces. Lastly, they are sold to manufacturers who use the materials to make new products. The raw materials used in the recycling phase include iron, animal skin, latex, cellulose, and crude oil. Iron is used in the entire structure of the recycling plant, it is used in all the walls, doors, stairways, of the facility. Animal skin is used to make the leather gloves that the recycling employees use to collect and separate the security camera. Gloves made of animal skin are more durable than gloves made of plastic, because they don’t rip easily. However, it is cheaper to create gloves using plastic than animal skin so plastic gloves are preferred.

The very last phase of the life cycle is the waste management phase, this is when the non-recyclable materials of a security camera are disposed of. Materials in a security camera that cannot be recycled are: corroded iron, corroded copper, corroded aluminum, and dirty cardboard packaging. Instead of being recycled, the leftover waste is taken to a trash plant where it is incinerated. Raw materials used in the burning process are oxygen, crude oil, and carbon. Combining and heating these three substances together can create fire. Oxygen is a very abundant raw material, it is created through a process called photosynthesis, which is when plants create oxygen.

Conclusion

There are many raw materials that are used in the life cycle of a security camera. These materials come from all over the world, have unique attributes, are very abundant, and can impact the health of human laborers when processed. Based on my research, I found that the most used materials in the lifecycle of a security camera are iron, cellulose, natural gas, crude oil, and silica.

Bibliography

Wilson, Matt. “American Made Security Cameras.” A1 Security Cameras, 3 Feb. 2023, https://www.a1securitycameras.com/blog/american-security-camera-manufacturers/#All_Pelco_products_are_compliant_with_NDAA.

Plymovent. “Metal Fume Fever. What Is It and How to Prevent It?” Metal Fume Fever, Plymovent, 29 Oct. 2018, https://www.plymovent.com/en/blogs/welding-cutting-fume-removal/metal-fume-fever.

Kanchwala, Hussain. “How Is Glass Made?” Science ABC, 8 July 2022, https://www.scienceabc.com/innovation/how-is-glass-made.html.

Martins, Claudemir. “Why Are There LEDs around a CCTV Camera? - Learn CCTV.Com.” Learn CCTV.Com, https://www.facebook.com/learncctvnow, 14 May 2020, https://learncctv.com/leds-around-a-cctv-camera/.

Editor, Site. “What Are Fiber Optic Cables Made Of? - Leo Network.” LEO Network, Site, 10 Nov. 2021, https://www.leonetworkgroup.com/news/what-are-fiber-optic-cables-made-of.html#:~:text=The%20cables%20are%20made%20up%20of%20thin%20strands,outer%20sheath%20to%20protect%20the%20cable%20from%20damage.

“Silica.” Minerals Education Coalition, 23 Jan. 2018, https://mineralseducationcoalition.org/minerals-database/silica/.

Walker, Robert Donald. “The Metal.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., https://www.britannica.com/technology/iron-processing/The-metal.

Association, American Lung. “Learn About Silicosis.” American Lung Association, https://www.lung.org/lung-health-diseases/lung-disease-lookup/silicosis/learn-about-silicosis.

Karomah, Akhlaqul. “What Raw Materials Are Used to Make Plastic?” AZoM.com, 10 Mar. 2022, https://www.azom.com/article.aspx?ArticleID=21427.

“Other Nonferrous Metals: Material-Specific Data | US EPA.” Environmental Protection Agency, 3 December 2022, https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/other-nonferrous-metals-material-specific. Accessed 9 February 2023.

Rigas, Debra. “Crystals That Reflect Light.” Our Pastimes, 4 May 2021, https://ourpastimes.com/crystals-reflect-light-8212340.html.

Jinyu Zheng

Max Butcher, Kaitlyn Lam

DES 40A

Winter 2023

The Life Cycle Analysis for Security Camera: Energy

As technology developing, more and more products with high technology appear in the human society. With the skyrocketing of digital and electrical innovation, security becomes easier for people to be served. What is known as security camera, one of the most common things we see in daily life, covers most of the households. While the demand of this product is increasing, it’s hard for us to ignore what is happening behind the “screen”. In another word, this kind of product consumes materials, energy and produce waste during its whole life cycle. In this paper, I want to analyze the energy consuming of security camera based on every different stage to have a better understanding the consequence of modern digital products and the balance with environment.

Security camera as a combination product of technology and stability, contains multiple complex processes of production and consumes variety of energy during each stage, from the acquirement of raw materials to the recycling eventually. However, the electricity is not the main consumed energy as using the security camera for a long period. Instead, the chemical energy as well as fuel energy is consumed mainly in the whole life recycle, especially during the material acquisitions and transportations.

First, we need to understand the fundamental things from the nature, which are discovered by human and added process. To do this, lots of energy is required as the approaching to these raw materials. A security camera is mainly composed by glass, metal housing and mainboard. Therefore, the heating process, as well as the chemical energy, becomes inevitable and necessary to gain these materials. When we talk about glass, they are actually made by heating the sand to roughly 1700℃ (3090°F). 73 percent of the energy comes from the burning of natural gas in the industrial smelter, which increases the temperature for better melting. To build the iron housing, a method called blast furnace, uses charcoal, coal and coke to raise the temperature more than 1500℃ (2732°F). This process is also chemical energy as combustion fuels. In addition, a chipset as the mind of the camera, helps conduct the sensor of light into the image for us. Silica is still necessary in this process; to do this, scientists use chemical methods to filter the impurities out to get better silica from sand, which also includes heating them up. Generally, these three main components all require chemical energy to product the materials for a security camera. Although there’s still other energy consumed, they take up fewer space. Now we have the materials we need; these components will be transported into industries for next process stage.

Different materials are coming from all over the world to certain manufacturing industries or companies. Their tasks are to put these components together to form a true security camera. In this process stage, instead of application of machine, human labor becomes a beneficial energy resource to use because they’re cheaper than machine. Employees in industries need utilize various hand tools, and work in the position of assembling line. The action of assembling is called kinetic energy, which generates based on the action of prime mover. On the one hand, each employee focus on a certain process of component, including setting lens or metal housing of the camera. One the other hand, some of the cameras have holes for screws to increase reliability of the product. Compared the kinetic energy with the chemical energy above, we could see that the labor isn’t a high-cost energy form; instead, it plays an important role of making the product all over the world. Once the cameras are all set, all they need to do is to wait the order from the customer.

Since the world has built connection between different continents, it’s convenient for people to buy a product no matter where it’s from originally. The security camera will be packaged and sent to the delivery center, it will be distributed to the destination through variety of transportations. Chemical energy once again, becomes the most used energy for this type of work. According to the resource, gasoline takes up 58 percent of the total United States transportation energy in 2021, followed by distillate fuel around 24 percent and jets fuel of 11 percent. Undeniably, vehicle like cars, trucks, trains, ships, and jets, them all need fuels based on chemical energy to generate power in their inter-combustion machine. From this angle we could see the cost of transportation is huge with this amount of fuels. However, if the energy is calculated based on the quantity of the product, it will be lower because you can’t regard the energy that delivers only one security camera as a whole; the reality situation is more complex. When the camera is on the customer’s hand, it is the time to start work.

We know that one of the most important properties of a security camera is its long-lasting character. It can be 10 years or even longer, but 5 years are enough. During this period, the camera needs to be plugged with electricity cable so that it could maintain its working status. The power of electricity is a typical type of secondary energy, which means that this kind of energy is generated by using energy from other resources, such as the burning of fuels. It is still a type of chemical energy. A security camera use electricity to make its chipset and sensor works; also conducting data and images through cable. What’s surprising is that this product actually cost very little electric power to operate. It uses less than 5 watts, which means it costs less than 1 dollar to operate. Normally, there’s no need to use a camera for 10 years because the upgrading goes fast. This result is against the common mind of human in some ways; but that is the energy cost of a security camera.

What if the customer wants to change a new security camera whether it’s due to the broken of certain components or the individual’s desire. This is something about the recycle part of this product. Kinetic and chemical energy are required during the process of recycling. Unlike other electronic products, there are recycling companies that always receive security cameras. Once they receive the product by transportations, the staff will separate the camera into several components. Then they will check if there’s anything that needs to be replaced or fixed. After the operation of repairing, the security camera is very likely to be reused for future customers. And the whole process consumes labor’s energy and transportation energy, though they are much smaller than other process stage because they have less scales.

It's a undeniable fact that more and more people are using security cameras for their own safety. The long-lasting character of this product makes a wrong though about it; that is security cameras cost very little energy during their whole working life. Oppositely, this high technology costs most of the energy during its production and materials acquisition. It seems like high technology is not absolutely combined with improvement of life recycle, so there is still a lot for human to work on, especially the exploration of producing method.

Bibliography

“What Are CCTV Cameras Made of.” VelaCCTV - Blog, 9 Apr. 2018, https://velacctv.com/blog/what-are-cctv-cameras-made-of/.

“How Glass Is Made | What Is Glass Made of?” Corning | Materials Science Technology and Innovation https://www.corning.com/worldwide/en/innovation/materials-science/glass/how-glass-made.html. Accessed 8 Feb. 2023

“U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.” U.S. Energy Information Administration (EIA), https://www.eia.gov/todayinenergy/detail.php?id=12631#:~:text=Glass%20manufacturing%20is%20an%20energy-intensive%20industry%20mainly%20fueled,lighting%2C%20laboratory%20equipment%2C%20and%20other%20uses%20More%20items.

“What’s the Process of Iron Smelting?” Meetyou Carbide, 8 Jan. 2021, https://www.meetyoucarbide.com/whats-the-process-of-iron-smelting/#:~:text=The%20commonly%20used%20fuel%20is%20mainly%20coke%2C%20anthracite,is%20the%20reduction%20of%20iron%20and%20slagging%20reaction.

Milne, Elizabeth. “How Are Computer Chips Made?” History-Computer, 9 Aug. 2022, https://history-computer.com/how-are-computer-chips-made/#:~:text=Step%20by%20Step%20Guide%201%20Step%201%3A%20Start,...%208%20Step%208%3A%20Layering%20Interconnects%20...%20%E6%9B%B4%E5%A4%9A%E9%A1%B9%E7%9B%AE.

“What Does an Assembler Do: Duties And Responsibilities.” Zippia, 2 Oct. 2020, https://www.zippia.com/assembler-jobs/what-does-an-assembler-do/?survey_step=step2.

“Use of Energy for Transportation.” U.S. Energy Information Administration (EIA), https://www.eia.gov/energyexplained/use-of-energy/transportation.php#:~:text=Gasoline%20is%20the%20dominant%20transportation%20fuel%20in%20the,motor%20gasoline%20includes%20petroleum%20gasoline%20and%20fuel%20ethanol.

Dixon, Thal. “How Long Do Security Cameras Last And Other Security FAQs.” Dixon Security, https://dixonsecurity.com/how-long-do-security-cameras-last-and-other-security-faqs/.

“Do Security Cameras Use a Lot of Electricity? .” Home Security Ops, 11 June 2022, https://homesecurityops.com/do-security-cameras-use-a-lot-of-electricity/#:~:text=In%20general%2C%20however%2C%20it%20is%20safe%20to%20say,the%20type%20of%20security%20camera%20you%20are%20using.

“Security Camera Recycling.” AVA RECYCLING, https://www.avarecycling.com/blog/security-camera-recycling.

Kaitlyn Lam

Jinyu Zheng, Maxwell Butcher

DES 40A

Professor Cogdell

16 March 2023

The Life Cycle of a Security Camera: Wastes and Emissions

The security camera is a universal product that is used in homes, businesses, and public spaces in general. Because of their widespread use, security cameras pose a concern in terms of environmental issues. The life cycle of a security camera begins with the acquisition of raw materials that are later used in the manufacturing process, during which the cameras are made in factories. After production, the security cameras are shipped to businesses or consumers. Eventually after years of usage, security cameras ultimately end up in recycling or waste centers after they are no longer able to properly function. Although security cameras last a relatively long time—from several years to a few decades—this does not mean they are environmentally friendly, as massive amounts of waste and emissions are released into the environment throughout the security camera’s life cycle.

A security camera consists of many parts, of which contain even more raw materials that release wastes and emissions in the acquisition processes. Within the interior of a security camera are electronic components, such as a circuit board and wires. These components are composed of copper, which acts as a conductor for electricity. However, the mining of copper is not exactly an environmentally-friendly process. Copper production “represents approximately 0.2% of global greenhouse emissions” according to the International Copper Association. While these numbers are relatively low, the demand for copper is “expected to double by 2050” (Tikana and Assam 2). Besides greenhouse gas emissions, copper mining can pollute other aspects of the environment. For instance, copper acid often pollutes the water nearby copper mines, which in turn harms wildlife, farmland, and groundwater aquifers. This copper acid pollution is due to the amount of waste that accompanies copper mining: 99 tons of waste is removed for every ton of extracted copper. During extraction, surrounding soil is polluted as well, as underground rocks and boulders may exude radioactive substances and chemicals upon exposure to the atmosphere. Copper mining can even affect humans as well, and not just the physical environment. The toxic chemicals that are released during extraction can “harm people’s skin, eyes and lungs, making breathing difficult,” as “excess [copper] can be fatal” (Federal Metals). Other electronic components of a security camera may include an image sensor, which is composed of a chip that contains silicon. Silicon is derived from silica. The mining of silica excretes waste known as SPM, or Suspended Particulate Matter, and these particles pollute the local environment. For example, SPM may accumulate on the leaves of nearby vegetation, disrupting photosynthesis and respiration processes (Mishra 155). Shifting to the exterior of a security camera, plastics are the main material that encases the interior components. To produce plastics, fossil fuels are extracted, emitting tremendous amounts of greenhouse gasses. In the United States, “108 million metric tons of CO2e per year are attributable to plastic production, mainly from extraction and refining” (Center for International Environmental Law). Aside from greenhouse gasses, the environment is also disturbed when land and forests are cleared for fossil fuel extraction sites. The exterior of a security camera also includes metal parts, such as screws. These parts are often made of steel, which requires iron for production. The mining of iron ore is a “highly capital- and energy-intensive process,” as the estimated greenhouse gas emissions are “11.9 kg CO2e for mining and processing 1 ton of iron ore” (Lu 615). Similar to extractions of the previously described raw materials, iron mining also requires the destruction of land and habitats for extraction sites. While these processes emit considerable amounts of waste, this is only the beginning of the process—the manufacturing of security cameras releases even more pollution into the environment.

A security camera is usually composed of: camera lens, plastic body, metal interior structures, and power cables, all of which emit wastes during production processes. To create the camera lens of a security camera, glass is manufactured, during which greenhouse gasses are released. Glass production requires heat and electricity in order to melt and shape the glass, and this power involves massive amounts of greenhouse gasses that are emitted into the environment. On top of this, the glass production temperatures must be held constant to ensure high quality products. Therefore glass production is a never-ending emission of greenhouse gasses. Additionally, glass melting also “produces fine dust as result of waste gas scrubbing and fine grains,” and this dust cannot be “molten and used for production so far”, or in other words, recycled (Glasstec). Manufacturing the plastic that makes up a security camera also releases wastes into the environment. It produces “significant emissions through the cracking of alkanes into olefins, the polymerization and plasticization of olefins into plastic resins, and other chemical refining processes,” making plastic the “most greenhouse-gas-intensive industries in the manufacturing sector— and the fastest growing,” according to the Center for International Environmental Law. In 2015, global “emissions from cracking to produce ethylene were 184.3–213.0 million metric tons of CO2, as much as 45 million passenger vehicles driven for one year.” The manufacturing of the metal interior components of a security camera is in the steel industry. In 2018, the amount of steel produced was “1.8 billion tons, which equates to about 3.3 billion tons of CO2 emissions,” which makes up 7-9% of all fossil-fuel based CO2 emissions. The average CO2 emissions is about 1.85 tons for every ton of steel (Hall). Although the metal parts of a security camera are rather small in size, the emissions from manufacturing these tiny parts are in extreme amounts. Lastly, the wiring of a security camera also contributes to environmental pollution. A main part of wire manufacturing in both leaded and lead-free wires and cables is electricity generation, which emits CO2. CO2 is the “top contributing material flow for both cables, representing 85% of the impact for the baseline cable and 83% for the leadfree cable” (Socolof et al.) Overall, these production processes of a security camera’s parts emit enormous amounts of waste, particularly greenhouse gasses, into the environment. However, this is not the end of the production process—the assembly of these parts may also release greenhouse gasses, as machinery and factories must be fueled in order to assemble the final product.

On top of the emissions released from the manufacturing stage, the transportation of security camera products to consumers and businesses, and then ultimately landfill and recycling centers, releases waste as well. Modes of transportation may involve trucks, trains, cargo ships, and planes. All these modes emit greenhouse gasses, as they involve the burning of fossil fuels in order to fuel the transportation of products. Particularly for water transportation, bodies of water risk being polluted with oil spills as well. No matter the method, any transportation of a security camera will release waste into the environment.

Even after a security camera finally reaches its users, the usage and maintenance of it still requires the same processes and emissions. To maintain a security camera, its parts may have to be replaced, which in turn causes the demand for further production of the items described above. Additionally, with the parts that are being replaced, whether they are physically broken or dysfunctional, the security camera user may end up throwing them away or even littering, which contributes to garbage in local habitats. Although it may appear that security cameras lack waste emissions during its usage period, the upkeep of the cameras ultimately demands further manufacturing and transportation processes that contribute to environmental pollution.

After a security camera has surpassed functionality, it still contributes to pollution as some parts may end up in recycling centers, where the following processes release emissions. Surprisingly, glass is “100% recyclable,” according to Robert Weisenburger Lipetz, executive director of the Glass Manufacturing Industry Council (GMIC). However, this does not mean that glass recycling is an environmentally-friendly process. In fact, only about a third of glass is recycled in the United States (Jacoby). In this recycling process, glass is “crushed, blended, and melted with sand and other starting materials,” and later molded into other products. In order to conduct these processes, electricity is used to fuel the machines and incinerators, ultimately releasing CO2 into the atmosphere. Like glass, copper is also fully recyclable without any loss of performance. It also undergoes incineration during a melting process and is molded into new products, thus also using electricity and emitting greenhouse gasses during the recycling process. Although copper is fully recyclable, it is not a completely sustainable method that leads to a “circular economy.” This is due to the demand of copper, which “will continue to increase due to population growth, product innovation and economic development,” and additionally, “the growing demand for copper will require a combination of raw materials coming from mines (primary copper), as well as from recycled materials (secondary copper).” As a result, only about 32 percent of annual copper use came from recycled sources in the last decade (Copper Alliance). Similar to copper and glass, plastic can be recycled, however it is not fully recyclable. Whether or not it can be recycled also depends on the type of plastic. Although it is unknown what type of plastic is used to produce security cameras based on online research, it is likely that the plastic encasing of a security camera is not recycled. Most recycled plastics are relatively thin, such as water bottles and milk jugs, while the plastic of a security camera is thicker and more durable to withstand both indoor and outdoor environments. While recycling is undoubtedly a more sustainable method than simply sending security cameras to be incinerated or left in landfills, it is not a waste-free process. Nevertheless, the vast majority of security cameras end up in waste centers, where emissions are released at an even greater rate.

At the last stage of its life cycle, a security camera ultimately ends up in landfills and waste centers, where the breakdown of its parts and the release of pollutants occur. To get rid of plastic waste, it is often incinerated, which leads to high emissions. In fact, incineration is the “primary driver of emissions from plastic waste management.” Plastic incineration in the United States alone accounted for 5.9 million tons of CO2 emissions in 2015 (Center for International Environmental Law). These numbers are extreme, and the use of incineration for plastic waste is expected to grow even further in the future. Since security cameras are a type of electronic product, they are classified as E-waste when disposed of. E-waste must be specially taken care of because they pose a risk to both the environment and its inhabitants. For instance, toxic substances such as lead, mercury, cadmium, and nickel can be found in e-waste, including circuit boards (Bhutta). These substances ultimately pose health threats, including “cancers, miscarriages, neurological damage and diminished IQs” (Environmental Protection Agency). E-waste also undergoes open-air burning, and this combustion not only releases greenhouse gasses, but also creates “fine particulate matter,” which is also correlated with pulmonary and cardiovascular disease (McAllister). E-waste disposal can also affect aquatic systems “via leaching from dumpsites where processed or unprocessed E-waste may have been deposited.” Contaminants also pollute the air via dust containing dioxins, which is a “major exposure pathway for humans through ingestion, inhalation and skin absorption” (Robinson). Overall, E-waste is a unique type of waste that is even more harmful than typical waste products, and security cameras unfortunately belong to this category. At the very end of its life, the security camera emits concerning amounts of waste and emissions, only for the cycle to start over once again as the demand for security camera production will only rise from here on out.

The security camera is an unassuming product—it is meant to be hidden as it keeps watch over its surroundings, and has a relatively long life cycle that spans between several years to decades. However, this reserved nature of the security camera does not mean that it lacks a role in environmental issues in terms of waste. The security camera life cycle emits emissions and wastes throughout each stage, only proving that each product in our surroundings, no matter how insignificant and unassuming they may appear to be, plays a role in harming the environment.

Bibliography

Bhutta, M. Khurrum S., et al. ‘Electronic Waste: A Growing Concern in Today’s Environment’ Economics Research International, vol. 2011, Hindawi

Limited, June 2011, pp. 1–8, https://doi.org10.1155/2011/474230.

Center for International Environmental Law. “Plastic & Climate: The Hidden Costs of a Plastic Planet.” Center for International Environmental Law,

May 2019, https://www.ciel.org/project-update/plastic-climate-the-hidden-costs-of-a-plastic-planet/. Accessed 14 March 2023.

Copper Alliance. “Copper Recycling.” Copper Alliance, 10 February 2022, https://copperalliance.org/resource/copper-recycling/. Accessed 14

March 2023.

Environmental Protection Agency. “Cleaning Up Electronic Waste (E-Waste) | US EPA.”

Environmental Protection Agency, 15 November 2022, https://www.epa.gov/international-cooperation/cleaning-electronic-waste-e-waste.

Accessed 9 February 2023.

Federal Metals. “How Does Copper Mining Affect the Environment? | Calgary.” Federal Metals, 11 August 2022, https://federalmetals.ca/how

does-copper-mining-affect-the-environment/. Accessed 14 March 2023.

Glasstec. “Glass Production and Sustainability | glassonweb.com.” Glass On Web, 7 April 2020, https://www.glassonweb.com/article/glass

production-and-sustainability. Accessed 14 March 2023.

Hall, James. “Cleaning Up The Steel Industry: Reducing CO2 Emissions with CCUS.” Carbon Clean, 28 January 2021,

https://www.carbonclean.com/blog/steel-co2-emissions. Accessed 14 March 2023.

Isa, Hauwa. “The need for waste management in the glass industries: A review.” Scientific Research and Essays, vol. 3, 2008. ResearchGate,

https://www.researchgate.net/publication/237294059_The_need_for_waste_management_in_the_glass_industries_A_review/citation/download. Accessed 14 March 2023.

Jacoby, Mitch. “Why glass recycling in the US is broken.” C&EN, Chemical & Engineering News, 11 February 2019,

https://cen.acs.org/materials/inorganic-chemistry/glass-recycling-US-broken/97/i6. Accessed 14 March 2023.

Lu, Liming, editor. Iron Ore: Mineralogy, Processing and Environmental Sustainability. vol. 66, Elsevier Science, 2015. CSIRO,

https://publications.csiro.au/rpr/pub?pid=csiro:EP1311257. Accessed 14 March 2023.

McAllister, Lucy. ‘The Human and Environmental Effects of E-Waste’. PRB, 4 April 2013,

https://www.prb.org/e-waste/. Accessed 9 Feb 2023.

Mishra, Ashutosh. “Impact of silica mining on environment.” Journal of Geography and Regional Planning, vol. 8, no. 6, 2015, pp. 150-156.

Academic Journals, https://academicjournals.org/journal/JGRP/article-full-text-pdf/915EC0C53587#:~:text=Pollution%3A%20The%20SPM%20(Suspended%20Particulate,the%20photosynthesis%20and%20respiration%20process. Accessed 14 March 2023.

Robinson, Brett H. ‘E-Waste: An Assessment of Global Production and Environmental Impacts’. The Science of the Total Environment, vol. 408, no.

2, Elsevier BV, Dec. 2009, pp.183–191, https://doi.org10.1016/j.scitotenv.2009.09.044.

Singkran, Nuanchan. “Urban product analysis and management of Bangkok Metropolis.” Technology Analysis and Strategic Management, vol.

30, no. 11, 2018, pp. 1269-1282. ResearchGate, https://www.researchgate.net/publication/324221947_Urban_product_analysis_and_management_of_Bangkok_Metropolis. Accessed 14 March 2023.

Socolof, Maria Leet, et al. Wire and Cable Insulation and Jacketing: LifeCycle Assessments for Selected Applications. June 2008. Environmental

Protection Agency, United States Environmental Protection Agency, https://www.epa.gov/sites/default/files/2014-01/documents/wire_lca_summary.pdf. Accessed 14 March 2023. Summary Document.

Tikana, Ladji, and Louise Assam. Carbon Footprint of Copper Production. 1 ed., International Copper Association, 2022. Copper Alliance,

copperalliance.org. Accessed 14 March 2023.