Design Life-Cycle

assess.design.(don't)consume

Julianna, Chan

Group members: Marco Santiago and David Abraham

Des 40A

Professor Cogdel

Raw Materials in the Production of Crocs

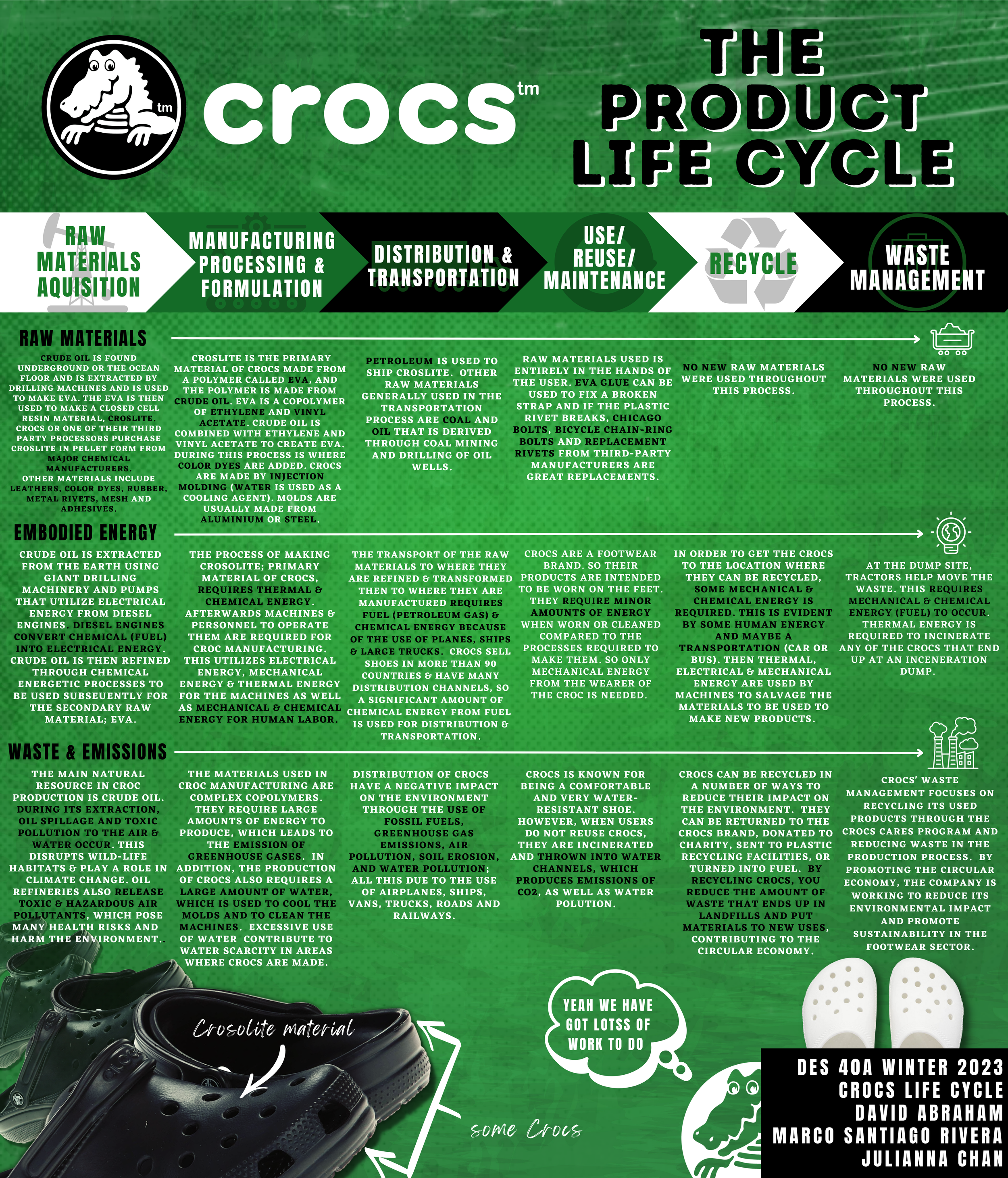

It's no surprise that with more than 100 million pairs of crocs sold each year, and sales increasing each year, they’ve gained global popularity and recognition. Crocs are extremely practical, comfortable, versatile, and affordable. Apart from its utility, Crocs are much more eco-friendly than a great deal of other shoe companies and are conscious of what impacts their materials have on the environment. Most notably, they recycle scrap materials from the manufacturing process; they transitioned to a new bio-based material which drastically reduces their product's carbon footprint; they strive to use minimal packaging during transportation and use sustainable packaging alternatives. It's important for consumers to keep in mind what positive or negative ecological impacts they are making in this world through simply purchasing the products of one’s company.

Throughout the whole product life-cycle process, the primary and secondary raw materials used are ethylene-vinyl acetate, croslite, leathers, color dyes, rubber, metal rivets, mesh, adhesives, aluminum, steel, petroleum, coal, and oil. Being almost entirely made of croslite, crocs require fewer raw materials than other shoe brands, and most materials are organically sourced and constantly recycled throughout the product life cycle.

With that being said, are these raw materials bad for the environment? and what steps can Crocs take to become more environmentally sustainable? The answer isn't as straightforward as you would think.

The primary raw material Crocs is made of is a closed-cell resin material called croslite. It's not plastic or rubber. Resins are unprocessed plastic polymers, and closed-cell foam is foam where the cells are enclosed by walls instead of connecting to other cells. It is denser and firmer than open-cell foam, so it has a higher resistance to substances such as liquids. Croslite is made from a polymer called ethylene-vinyl acetate (EVA), which is sourced from crude oil. Crude oil can be found deep underground or under the sea. Giant drilling machines are used to extract the oil before it is transported to an oil refinery, often through a pipeline or in a tanker. EVA is a copolymer of ethylene and vinyl acetate. Vinyl acetate accounts for 10-40% of the copolymer, and the rest is made up of ethylene. Once the crude oil has been refined, it is then combined with ethylene and vinyl acetate to produce EVA. Crocs acquires croslite by compounding elastomer resins that they or one of their third-party processors purchase in pellet form from major chemical manufacturers such as Dow Chemical. During this process is where they add color dyes.

Crocs are made by injection molding, which requires specific machines and molds for different styles and sizes. Injection molding is a type of manufacturing process typically used to make products out of thermoplastics such as EVA and is especially suited for high-volume manufacturing. With injection molding, the mold has to be made first, which is usually made from aluminum or steel. Aluminum is mined from the Earth's crust as an ore called bauxite before being refined into alumina. Large amounts of electricity are required to smelt alumina into aluminum metal. Steel is made from iron ore which is also mined from Earth's crust (underground). It is then transformed into steel using a blast furnace and an electric arc furnace. Proper cooling is essential for this manufacturing process, so water is primarily used as a cooling agent. There is no evidence that they implement water reduction initiatives. Other materials that go into the manufacturing process include leather, color dyes, rubber, metal rivets, mesh, and adhesives.

Are these materials good or bad for the environment? Formamide, a by-product of manufacture that can be harmful to animals, plants, and soil, has been found to be present in EVA. Although EVA isn't the worst type of plastic for the environment (for instance, vinyl is much worse), it is still a type of plastic. Generally, plastics are not eco-friendly since they are made from non-renewable resources. The non-renewable resource that croslite comes from is crude oil. Collecting and refining crude oil for use can cause environmental concerns such as oil spills and pollution. At the same time, crude oil is 100% organic and therefore is non-toxic. Injection molding is not entirely eco-friendly due to the massive amounts of water and energy used for it. However, injection molding is more eco-friendly than the raw materials acquisition process and formulation since it is a mechanical process. The other materials I mentioned above account for a minuscule amount in the production of crocs, so it has relatively little impact on the environment. Moreover, because crocs are made of only one material and in one mold, they are easy to make and have a low chance of cross-contamination; thus, more resources are conserved.

In order for Crocs to achieve one of its goals to become a net zero brand and reduce its carbon footprint, it prioritized its most used material and developed a more sustainable biobased version of croslite foam in 2021. In collaboration with Dow’s (a global materials science company) technology, the new bio-based croslite reuses sustainably sourced bio-waste and byproducts from other industries to produce the same crocs consumers all know of but with fewer emissions. The new material is made of special resins supplied by Dow Chemical.

In comparison to other shoe brands such as Hunter Boots and Adidas, Crocs modified their existing iconic product instead of creating a separate sustainable line of products.

Moving on from the raw material acquisition and manufacturing process comes the distribution and transportation of crocs. Do crocs reduce, minimize and optimize packaging materials? To what extent does the transportation of goods between crocs and the purchaser have the lowest possible impact on the environment? Petroleum is used to ship croslite from Italy from a manufacturing facility in Canada. Petroleum, like crude oil, is a fossil fuel usually found in underground reservoirs that can be found beneath land or the ocean floor. Other fossil fuels, such as coal and oil, are also generally used in the transportation process. Coal is usually found in sedimentary rock deposits where rock, dead plant, and animal matter are piled up, and oil is extracted from underground reservoirs through drilling and pumping practices. Petroleum, coal, and oil are non-renewable resources; thus, utilizing them contributes to the depletion of finite resources. To avoid logjams at West Coast ports, Crocs has been using air freight instead of cargo (often by sea) transportation to move orders. Research by the United Kingdom government found that airplanes emit 44 times more carbon dioxide than ships do when transporting the same cargo over the same distance. On the bright side, Crocs claims that the majority of their footwear is sold without shoe boxes and that they select recyclable materials for packaging. Since crocs are not recyclable nor are they biodegradable due to the fact that coslite is difficult to recycle, crocs donate unsold Crocs to those in need. According to a statistic from their website, over 250,000 pairs have been saved from landfills in the last five years.

After the products get shipped to their final destination, how are they used, reused, maintained, or recycled? Crocs are shoes, so they don’t require any sort of raw materials to use, reuse, maintain, or recycle. It is entirely in the hands of the user. The closed-cell properties of croslite allow crocs to be resistant to most substances and are highly durable. Crocs typically last between 3 to 5 years with typical wear, and with less frequent wear and proper care, they can last up to 10 years. If used exclusively indoors, it can last even longer than this. A broken strap is one of the most common problems with crocs. An easy way to fix it is simply to repair the strap with a strong EVA glue, a copolymer adhesive. If the strap itself has snapped or if any parts of the crocs are ripped, although very unlikely, EVA glue can melt the material together. Regular CA glues and superglue are not as effective for repairing tears in crocs. Croslite is solely used in crocs, which means that the demand for glue that repairs this material is too small to exist. Crocs can only be repaired with glue that is designed to work for EVA foam. The right type of EVA foam glue creates a chemical reaction that melts the material slightly, allowing it to seal the edges together. No other type of glue will work permanently or effectively for crocs. Every pair of crocs has a set of plastic snap rivets that attach the strap to the main body of the shoe. These rivets are easily broken, and once they come apart, they cannot be reassembled. Instead of disposing of it and buying another pair of crocs, there are a number of possible replacements for the plastic rivets, including chicago bolts, bicycle chain-ring bolts, and replacement rivets from third-party crocs accessory manufacturers. Depending on the manufacturer, the replacement rivets can be non-toxic and made of resin plastic or PVC. Plastic resins are synthetic substances made from organic materials, including coal, natural gas, and crude oil.

Crocs claims that with the inevitable scrap material waste that comes from the production of their shoes, they work with their third-party suppliers to collect and reuse the material. According to their website, they recycle 45% of the scrap that is used to make their croslite. The material is recycled and used to produce more pairs of crocs which reduces the number of raw materials needed for production and minimizes production waste.

The final step of a product's life cycle is its waste management. Crocs, Inc. and Soles4Souls have partnered to create a program where you can recycle your lightly worn Crocs shoes so that they can be used in a "second life." Alternatively, you can donate them. They are relatively high in demand, and you also help raise funds for good causes in the process. To reduce greenhouse gas emissions via vehicle transport, you can take your old shoes to a drop-off location near you. If you have more than five pairs to donate, then you can ship them. Crocs have also done their share of donating; they've donated unsold crocs to people in need and, as a result, saved 20,00 pairs from landfills in 2020 and are looking for more ways to increase the recyclability of their shoes. The only raw material that would be used in this would be for transportation purposes, including fossil fuels, coal, and oil.

If crocs don't get reused or recycled, disposal through landfill or incineration releases greenhouse gasses, contributing to climate change. Improper disposal of crocs harms wildlife and the environment.

In conclusion, crocs, to a large extent, are eco-friendly. Their shoes are great for the environment in the long run as raw materials are constantly being recycled throughout the product life cycle, and a small proportion of their shoes end up in the landfill. As long as crocs are made from EVA, they will not be sustainable or recyclable. Since the crude oil that EVA is sourced from is a non-renewable source, it will eventually run out. Additionally, the collection and refinement of crude oil can cause environmental concerns such as pollution and oil spills. However, what perhaps makes up for this is its durable property that enables crocs to be extremely long-lasting. There is also no evidence that crocs implement water and energy strategies throughout the manufacturing process. Initially, crocs weren't biodegradable due to being made of a plastic material, and plastics do not decompose easily or quickly. However, the implementation of their bio-based croslite makes it possible. The massive usage of fossil fuels for transportation purposes is quite inevitable today as it ensures the success of a business as well as economic productivity, especially for large-scale operations like Crocs. As for the other materials Crocs is made of, including leathers, color dyes, rubber, metal rivets, mesh, and adhesives, Crocs are almost entirely made of croslite, so the impact these materials have in the environment is negligible in comparison. Crocs has taken active steps to become more eco-friendly. In efforts to become a net zero brand, Crocs is targeting a 50 percent reduction in its carbon footprint per pair of crocs by 2030 and have already taken action by introducing their new bio-based croslite into all their shoes. They claim that the new bio-based formula “enhances our ability to explore a circular supply chain in the future.” Moreover, they have reduced the amount of packaging they use to ship their shoes in, as well as switching to more sustainable versions of their packaging. At 3.94 kg CO2 per Per pair of shoes, they have demonstrated a low carbon footprint today.

Some actions Crocs could take to become more environmentally friendly would include changing their mode of transportation, using renewable materials, developing efficient recycling programs, and promoting responsible disposal practices. Even Though air transport is comparably more reliable, safer, and faster than cargo freight, Crocs should switch to cargo freight to reduce environmental impact. To conserve more energy, Crocs could transition to injection molding machines that are powered by electricity. The enormous use of energy and fossil fuels is common practice in large-scale production. Transitioning to options for sustainable shipping is often expensive, not as widely available, and will cause drastic fluctuations in shipping costs and time which will most likely negatively influence profitability and consumer likability.

Bibliography

“Crocs Sustainability: Comfort without Carbon | Crocs.” Crocs, www.crocs.com/comfort-without-carbon.html.

Denton, Elaina. “Crocs: Revolutionizing an Industry's Supply Chain Model For.” Prezi.com, 17 Aug. 2015, https://prezi.com/8ek5vt_2fqxt/crocs-revolutionizing-an-industrys-supply-chain-model-for/.

Eworldtrade. “How Much Does It Cost to Make a Pair of Crocs.” EWorldTrade, 11 Nov. 2021, www.eworldtrade.com/blog/how-much-does-it-cost-to-make-a-pair-of-crocs/.

“Green Comes in Every Color: Crocs Introduces New Bio-Based Croslite™ Material to Lower Carbon Footprint of Its Iconic Footwear.” PR Newswire: Press Release Distribution, Targeting, Monitoring and Marketing, 14 Sept. 2021, www.prnewswire.com/news-releases/green-comes-in-every-color-crocs-introduces-new-bio-based-croslite-material-to-lower-carbon-footprint-of-its-iconic-footwear-301376101.html.

“Investor Relations.” Crocs, Inc. - Overview, Crocs, Inc., 16 Feb. 2023, https://investors.crocs.com/overview/default.aspx.

Lorna. “Crocs Repair Guide: How To Mend Broken Crocs & Strap.” Wearably Weird, https://wearablyweird.com/crocs-repair-guide-how-to-mend-broken-crocs-strap/.

Muzna. “Crocs Croslite, a New Material for Combating Climate Change .” HYBRID RITUALS, 2 Jan. 2023, https://hybrid-rituals.com/discover-crocs-croslite-a-new-material-for-combating-climate-change/.

National Geographic Society. “Fossil Fuels.” Education, 19 May 2022, https://education.nationalgeographic.org/resource/fossil-fuels/.

Schroeder, Benjamin. “Flip Flop Goes Crocs.” Flip Flop Goes Crocs - by Benjamin Schroeder, No Ordinary Strategy, 31 May 2022, www.bcrschroeder.com/p/crocs-business-strategy.

Stanfield, Savanna. “Are Crocs Eco-Friendly? 14 Common Questions Answered (+3 Alternatives).” Citizen Sustainable, https://citizensustainable.com/crocs-eco-friendly/.

Tharwani, Kajal. “Crocs to Introduce Bio-Based Material Croslite Footwear.” OpenGrowth, 15 Nov. 2021, www.opengrowth.com/resources/crocs-to-introduce-bio-based-material-croslite-footwear#:~:text=Therefore%20to%20achieve%20the%20target,from%20byproducts%20or%20sustainable%20waste.

“2021 Crocs ESG Report” Crocs 2021 Comfort Report, https://s22.q4cdn.com/133460125/files/doc_downloads/2021_Crocs_ESG_Report.pdf.

David Abraham

Julianna Chan, Marco Santiago Rivera

DES 40A

Professor Cogdell

Embodied Energy of Crocs

Crocs is a footwear brand that has gained vast popularity since its launch in the early 2000s as a “simple, comfortable boat shoe.” Their shoes are made from a special foam resin material called Croslite™ that makes their footwear lightweight, durable, and odor resistant. Crocs footwear comes in a variety of colors and designs, making them a desired choice for people of all ages and walks of life. Despite their widespread use, many people are unaware of the energy that goes into producing Crocs, this includes the energy required for the acquisition of its raw materials, production of secondary materials, manufacturing processes, transportation, and distribution. This paper aims to explore the embodied energy of Crocs and their need for sustainable alternatives in the future.

The preparatory phase of creating Crocs’ shoes is the procurement of its raw material; Crude Oil. Fossil fuel and a non-renewable resource that is extracted from the Earth using giant drilling machinery and pumps. The energy required for this excavation process is “supplied by diesel engines. Typically these engines use 20–30 m3 diesel fuel per day, depending on the operations performed” (Ipieca). Diesel engines utilize diesel fuel to convert chemical energy into electrical and mechanical energy for drills and pumps to extract more crude oil. Then the oil is refined utilizing many chemical energy processes which account for “slightly over 3 x 10^15 Btu of energy annually - about 4% of yearly U.S energy consumption in oil refineries” (Wang et al.). However, as crude oil extraction and refinement are at the basic foundation of the creation of Crocs shoes, Crocs’ Inc isn’t directly involved with this acquisition process as it is an outsourced material. Crocs’ production and manufacturing processes happen after the polymerization of the chemical components of crude oil to become ethylene vinyl acetate, better known as EVA; a secondary raw material with properties similar to plastic.

The production of Croslite™ occurs after the acquisition of the second raw material; ethylene vinyl acetate or EVA from third parties. This secondary raw material is a “random copolymer, mainly produced by radical chain polymerization between vinyl acetate and ethylene gas at high pressure (up to 30,000 psi)” (Polysciences 1). This process involves the use of chemical energy which tallies with the numerous chemically intensive procedures necessary before Croslite™ is made. The “proprietary closed-cell resin material,” Croslite™, is a patented material and Crocs’ Inc has disclosed no information on what is utilized or required in the process of making this material from EVA. However, the use of chemical energy to make this complex polymer is very likely. Croslite™ is known to be neither plastic, rubber, or foam and some consider it to be all of the above, warranting the need to understand how this extraordinary material is used to make Crocs shoes.

The manufacturing process of Crocs shoes begins with Croslite™, which comes in granule form, based on expandable and cross-linking polyolefin; a type of polymer (Eleonora 56). Initially, the granules are melted and then injected in pre-heated molds which are the “negative” of the shoe shape. The exact method behind the injection phase is mentioned plainly in the journal article Manufacturing and Internationalization The strategic role of manufacturing in a multinational company: The case of Crocs Inc:

The granules are made out of chemicals that once melted and injected, a non-toxic gas is released, forming micro bubbles and forcing the material to expand evenly in the mould, also occupying the small and thin grooves. The result is a closed-cell foam material with a waterproof surface that is highly resistant to wear and deterioration caused by external agents, weathering, and ultraviolet radiation.

After the injection phase, the shoes are warm and left to consolidate on a form that takes the shape of a foot. After cooling, the shoes or better termed “Clogs” are moved to be assembled. “The personnel who work in the injection phase carry out also this phase, the ratio is 1 operator every 8 stations, with a total of 8 employees plus other two for equipment’s upkeep”(Eleonora 59). The injection & consolidation phases require the aid of complex machinery that requires electrical energy as well as human labor to operate these machines and materials. This also requires chemical potential energy converted to mechanical energy. The last phase of producing Crocs shoes is the assembly and packaging phase. This involves the assembly of the clog and strap, removal of imperfections, two quality checks, and application of paper tags. “People in the assembly phase do the packaging and in this two phases are deployed two rotating racks, with a total of 12 people plus other 3 that gather boxes, prepare labels and custom packaging for clients”(Eleonora 60). Scott Seammans, one of the three founders of Crocs mentioned that “for each pair of croc 1.6 kwh of energy is used”. After packaging, the production process to put forth Crocs’ shoes is over, and the products are then distributed and transported all over the world.

Crocs shoes appeal to people all around the globe and are sold in over 90 countries with various distribution mediums some including “traditional footwear retailers, sporting goods and outdoor retailers, department stores, uniform suppliers…”(Reference For Business). With numerous places in the world where Crocs shoes are found, there are also several manufacturing facilities in the United States, Canada, Italy, Mexico, and China. To get to these areas, transportation of the materials for Crocs from one country or region to another requires airplanes, ships, and trucks that burn fossil fuels to do so, depending on how many miles are traveled. The amount of energy required for all these processes is unimaginable; from the transportation of crude oil to where it is refined, down to the facility where they alter its compounds to make EVA & Crosolite, and then finally to the manufacturer that will finally make the Crocs shoes. The transportation required prior to the distribution involves several modes of transportation in large numbers, implying a large reliance on fossil fuels (petroleum) for chemical energy. After the shoes are manufactured, processed, and packaged, they also need to be transported to the various “domestic and international retailers and distributors, and directly to end-user consumers…company-operated retail stores, outlets, webstores, and kiosks” (U.S. SEC). This implies an even greater demand for petroleum gas given the fact that they are sold all over the world in over 2000 locations. Therefore, the transportation of materials and Crocs themselves can have a significant impact on the environment.

The Croslite™ material of Crocs is very similar to plastic in its long-lasting abilities. This allows them to be used continuously over long periods of time without replacement, although there might be some wear and tear. However, using Crocs does not require significant amounts of energy since it is worn on the feet for various purposes and they can be maintained by cleaning with just soap and water. These qualities technically sound great until consumers no longer need or want the pair of Crocs. Then the almost indestructible attributes of the material make them stand out in landfills and pose an issue for the environment. “Crocs are among the items that never decompose. Therefore, the chemical elements used in its manufacture are left in the environment for years. That poses a serious health risk to future generations when the crocs will have flooded the landfill, and humans directly feel its harmful effects” (Omega). This emphasizes the importance of communicating these attributes of Crocs shoes to consumers so that they could be recycled rather than ending up in landfills.

Crocs, Inc. strives to be a more sustainable footwear brand, aiming for “Comfort without carbon”(Crocs). In aims to achieve this goal, they claim to have saved over 250,000 pairs of Crocs from landfills in the last 5 years by donating them to those in need around the globe. Crocs cannot be recycled like any other material, hence why they have programs that allow unwanted shoes to have a second life. A Crocs, Inc. article mentioned that “Crocs, Inc., and Soles4Souls have partnered to provide the opportunity to recycle lightly worn Crocs shoes so that they can be used in a "second life." Once Soles4Souls receives the shoes, they will clean them and donate them to people who need shoes in impoverished nations around the world.” This method for dealing with Crocs shoes prevents them from having an adverse effect on the environment, however, energy from fossil fuels will still be needed to get to designated regions. Energy from human labor & possibly machines will also be needed to clean these Crocs prior to transporting them.

The embodied energy of Crocs shoes involves numerous steps that require energy in the form of electricity, fuel, and chemicals. The process of acquiring raw materials alone requires the use of fossil fuels and the energy used in manufacturing and transportation only adds to the environmental impact. The exact amount of energy consumed during the production of Crocs shoes is not disclosed by Crocs’ Inc, however, it is clear that their manufacturing process is not sustainable. Crocs’ Inc has initiatives towards sustainability as the world becomes more environmentally conscious but there is still a need to consider alternatives to the production of Crocs that are less energy-intensive and less harmful to the environment. In doing so, they can lessen the impact of their choices on the environment, and help limit global warming, and climate change to create a more sustainable future.

Bibliography

Ipieca. “Offshore Drilling Rigs (2013).” Ipieca, www.ipieca.org/resources/energy-efficiency-solutions/offshore-drilling-rigs-2013#:~:text=The%20energy%20needed%20on%20offshore,and%20emissions%20to%20the%20air.

Petroleum. education.nationalgeographic.org/resource/petroleum.

Wang, Michael, et al. “Allocation of Energy Use in Petroleum Refineries to Petroleum Products.” International Journal of Life Cycle Assessment, vol. 9, no. 1, Springer Science+Business Media, Jan. 2004, pp. 34–44. https://doi.org/10.1007/bf02978534.

Dryfoos, Allison Parshall Delaney. “What Crocs Are Made of — and How They’re Changing.” Scienceline, 12 Oct. 2022, scienceline.org/2022/10/crocs-sustainability-plastic/#:~:text=Some%20articles%20call%20them%20rubber,polyethylene%20vinyl%20acetate%2C%20or%20PEVA.

Crocs History | an Unlikely Triumph. www.mastershoe.co.uk/crocs-history.

Da Graça Prediger Da Pieve, Eleonora Maria. “Manufacturing and Internationalization the Strategic Role of Manufacturing in a Multinational Company: The Case of Crocs Inc.” DEPARTMENT OF ECONOMIC AND BUSINESS SCIENCES, Sept. 2016.

Lorna. “Where Are Crocs Made? A Crocs FAQ Guide - Wearably Weird.” Wearably Weird, 18 Feb. 2022, wearablyweird.com/where-are-crocs-made-a-crocs-faq-guide.

Gurtoo, Vitasta. “Crocs Are Stylish but Are They Good for Your Feet?” Travel.Earth, 13 Feb. 2023, travel.earth/crocs-are-stylish-but-are-they-healthy.

---. “What Crocs Are Made of — and How They’re Changing.” Scienceline, 12 Oct. 2022, scienceline.org/2022/10/crocs-sustainability-plastic/#:~:text=Some%20articles%20call%20them%20rubber,polyethylene%20vinyl%20acetate%2C%20or%20PEVA.

Omega, Nashon. “What Are Crocs Made of? Are They Eco-friendly.” Everything Fashion, 21 July 2021, fashionandmash.com/what-are-crocs-made-of.

“Crocs, Inc. - Company Profile, Information, Business Description, History, Background Information on Crocs, Inc.” Reference for Business, www.referenceforbusiness.com/history2/25/Crocs-Inc.html#:~:text=Crocs%2C%20Inc.%2C%20is%20a,resistant%2C%20non%2Dmarking%20sole.

“FORM 10-K: CROCS, INC.” UNITED STATES SECURITIES AND EXCHANGE COMMISSION, www.sec.gov/Archives/edgar/data/1334036/000104746906004382/a2168966z10-k.htm#bg1268_crocs_inc._2005_annual___bg102021.

Crocs. “COMFORT WITHOUT CARBON NET ZERO EMISSIONS BY 2030.” CROCS, www.crocs.com/comfort-without-carbon.html.

Marco Santiago

Waste material and environmental effects

DES40A

03/13/2023

Crocs Waste Materials And Environmental Effects

Crocs is a shoe brand that has become very popular all over the world due to its distinctive design and comfort. Crocs shoes are made from a proprietary foam called Croslite, which is lightweight, water and odor resistant, and molds to the shape of the wearer's foot for a uniquely comfortable feel. However, recently the brand has come under fire for the way it handles materials for its end-of-life products. In particular, Crocs has had problems due to excess materials being wasted during the production process and their disposal; Therefore, as awareness of the importance of sustainability increases, Crocs is forced to address this issue and find more responsible solutions for handling end-of-life products. Since in the process of incineration of Crocs shoes, they release toxic gasses and emit large amounts of carbon emissions, which represents a significant problem for the environment.

It's important to talk about sustainability at Crocs because the need to reduce our impact on the environment and promote more responsible practices in the production and consumption of goods is becoming increasingly evident. Additionally, Crocs shoes have been a bestseller all over the world, which means there are a huge number of them in circulation. If not properly managed at the end of their useful life, they can have a significant impact on the environment. In addition, the production of new shoes also has an impact on natural resources and the emission of greenhouse gasses; Therefore, Crocs must address this issue and find more sustainable solutions for the handling of their products at the end of their useful life. This may include developing new, more sustainable materials and promoting recycling and reuse practices to minimize waste and greenhouse gas emissions.

Crocs is a shoe brand known for its distinctive design and construction with plastic materials, especially a proprietary foam called Croslite. Crocs manufacturing uses various natural resources and can generate waste that affects the environment. The natural resources used for the production of Crocs include primarily petroleum and natural gas. Croslite foam, which is the proprietary material used in most Crocs shoes, is produced from a petroleum-derived thermoplastic polymer resin. To obtain the petroleum, exploration and drilling activities are carried out in areas where there are believed to be oil deposits. Once the oil is located, it is extracted through drilling wells and transported to a refinery for processing. During the refining process, the different components of the oil are separated, including the chemicals used to make Croslite foam. Natural gas, on the other hand, is obtained mainly by drilling and extracting underground reservoirs. The natural gas is then transported to a processing plant, where it is purified and converted into the chemicals needed to produce Croslite foam. In terms of waste, Crocs production generates plastic waste, such as trimmings and leftover materials, which can be difficult to recycle. In the same way, when shoes are discarded, they take many years to decompose; Therefore, they end up contributing to the accumulation of garbage in landfills. The environmental impact of Crocs production depends on several factors, such as the amount of natural resources used, the efficiency of the manufacturing process, and proper waste management.

Furthermore, Crocs manufacturing involves several processes that can have a negative impact on the environment. Some of the environmental impacts associated with the production of Crocs include the Use of Synthetic Materials, as the materials used to make Crocs shoes are synthetic and non-biodegradable. These materials include ethyl vinyl acetate (EVA) and other polymers. The production of these materials can involve the use of toxic chemicals and the consumption of large amounts of energy. Likewise, the production of Crocs involves the use of energy to manufacture the materials and assemble the shoes. This energy comes mainly, as previously mentioned, from non-renewable sources, such as oil and natural gas, which contributes to greenhouse gas emissions. That is, the Croslite production process begins with mixing EVA with other components, such as color pigments and blowing agents. The mixture is heated and poured into molds to give it the desired shape. The material is subjected to high temperatures to activate the blowing agents and cause it to expand and adhere to the mold; However, large amounts of energy and use of fossil fuels are used to reach these high temperatures, therefore this ends up having a negative effect on the environment. Likewise, In the Crocs shoe production process, Once the crostile takes the shape of the mold to create the shoe, the rest of the material is cut away, leaving a large amount of scrap and trim that cannot be reused. These remains of material can be sent to landfills, which increases the volume of solid waste and contributes to environmental pollution.

The transportation of Crocs products can have a significant impact on the environment due to the emission of greenhouse gasses. Most Crocs products are made in Asia and then transported to other countries around the world for sale. This transportation process involves the use of fossil fuels, such as oil, gas, and diesel, to power the engines of ships, planes, trucks, and other vehicles used to transport the products. The combustion of these fossil fuels emits greenhouse gasses, such as carbon dioxide (CO2), which contribute to global warming and climate change. Additionally, transporting Crocs products may require additional packaging and protective materials to ensure shoes arrive undamaged, which can create waste and increase environmental impact.

Crocs production directly and indirectly contributes to air and water pollution in various ways. First, as previously mentioned, Croslite foam manufacturing involves the use of chemicals such as plasticizers and color pigments, which can be toxic to the environment and human health. These chemicals tend to be released into the air and water during production, which can contaminate the air and bodies of water near production plants. Crocs has also been criticized for the way it disposes of materials in its products. defective or unsold. According to the BBC article titled "Crocs: Fashionable, comfortable... and potentially harmful to the environment?" reports that the company has burned thousands of pairs of shoes and other products in the past instead of donating or recycling them, contributing to air and soil pollution. This is because the disposal process for Crocs products at the end of their useful life also contributes to air and water pollution. In other words, Crocs shoes tend to contaminate water if not disposed of properly. By dumping these shoes into landfills or the environment, crostile foam can take hundreds of years to decompose as it is a thermoplastic resin foam, releasing toxic chemicals and microplastics into water, soil and subsoil. In the same way, the pigments and adhesives used during its manufacture, which can leak into the water and contaminate it. These materials may include phthalates, lead, cadmium, and other heavy metals that are harmful to human health and the environment.

Crocs is aware of the effect that the production of its products has on the environment; That is why the company has implemented some recycling programs for its products. One of Crocs' main programs is its recycling program, where customers can send their old Crocs back to the company for recycling. Old Crocs are ground up and turned into a Croslite powder, which is used to make new products, including shoes, insoles, soles, and other accessories.

In addition, Crocs has launched a line of products called "Crocs at Work" that is made with a percentage of recycled Croslite. This line includes work shoes, boots, and other products for healthcare workers, restaurants, and other industries. Crocs has also implemented a program called "Renew," which allows customers to return their used Crocs for recycling or reuse. In return, customers receive a discount on their next Crocs purchase.

In general, the production and distribution of Crocs has a significant impact on the environment. The manufacture of the shoes involves the use of non-biodegradable synthetic materials and the consumption of large amounts of energy, which can lead to greenhouse gas emissions and other environmental impacts. In addition, the transportation of Crocs products can further contribute to greenhouse gas emissions and create additional waste. Regarding waste management, Crocs products are not biodegradable and can take hundreds of years to decompose, which can contribute to the accumulation of waste in landfills and in nature. To reduce its environmental impact, Crocs may consider adopting more sustainable practices at every stage of production, from choosing more sustainable materials to reducing the distance traveled to transport products to promoting more responsible waste management and sustainable.

In conclusion, although Crocs are a popular and useful product, it is important to recognize that their production and distribution have a significant impact on the environment and efforts are needed to minimize this impact and promote greater sustainability in the fashion industry in general; Likewise, it is important that consumers also become aware of the importance of reducing their carbon footprint and support companies that implement sustainable practices in their operations.

Bibliography:

COMFORT REPORT, CROCS. “CROCS 2021 COMFORT REPORT.” COMFORT WITHOUT CARBON, COMFORT FOR OUR COMMUNITIES, COMFORT FOR ALL PEOPLE , Crocs, 2021, https://s22.q4cdn.com/133460125/files/doc_downloads/2021_Crocs_ESG_Report.pdf.

https://thesis.unipd.it/bitstream/20.500.12608/24350/1/Da_Pieve_Marco.pdf

Da Pieve, Marco. "Manufacturing and Internationalization the strategic role of manufacturing in a multinational company: The case of Crocs Inc."

Omega, Author Nashon. “What Are Crocs Made of? Are They Eco-Friendly.” Everything https://www.agro-chemistry.com/news/crocs-to-become-100-plant-based/.

John S. Forrester | Sep 15. “Dow to Supply Sustainable Material to Shoemaker Crocs.” Powderbulksolids.com, 15 Sept. 2021, www.powderbulksolids.com/chemical/dow-supply-sustainable-material-shoemaker-crocs.

“Crocs, Inc. (CROX) Stock Price & News.” Google Finance, Google, https://www.google.com/finance/quote/CROX:NASDAQ.

Lucas High Bizwest Prairie Mountain Media. “Crocs Introduces 'Bio-Based' Shoe Material in Push for Zero Carbon Emissions.” Boulder Daily Camera, Boulder Daily Camera, 14 Sept. 2021,

“Crocs.inc.” Sec.gov, https://www.sec.gov/Archives/edgar/data/1334036/000104746906004382/a2168966z10-k.htm.

.