Design Life-Cycle

assess.design.(don't)consume

Elena Simeone

Professor Cogdell

DES 40a

12 March 2014

FIJI Water Bottle Materials

The Fiji Water company was found in 1996 by David Gilmour, a Canadian businessman who worked in the mining industry. He also owned a vacation resort on the Pacific island of Fiji, but was tired of the requirement to provide his guests with bottled water that shipped from thousands of miles away. Gilmour wanted to see if there was a solution to be found on the island. With the help of the geologists that worked for his gold-mining business they found an underground aquifer in the Yaqura Valley on one of the main island of Vitu Levu (Myint). This Artesian aquifer is under layers and layer of ancient impermeable volcanic rock. This aquifer was possible because millions of years ago it was a volcano. Once the volcano became dormant the layers of sediment and rock filtered the water from the tropical rainfall. The delivery system from the aquifer is completely sealed from the protected volcanic capsule and is directly placed into plastic bottles.The water that comes out of the aquifer is never touched by man until it is opened by the customer. FIJI Water's operation is sustainable compared to other sources of water in other locations. It is sustainable due to the fact that the Yaqara Valley 's aquifer is replenished faster than the water is drawn out (FIJI Water). The FIJI Water's bottling plant is located on the same island as the aquifer, however Fijians do have access to FIJI Water's aquifer (Lynch). The whole point of starting up the business was to be able to have fresh bottled water for the people on the islands rather than having to import bottle water to Fiji. Now FIJI Water is importing bottled water to other areas of the world; Gilmour did not want to have to import water into Fiji but they are now exporting water bottles out of Fiji.

To make the bottles that hold the FIJI's water you need Polyethylene Terephthalate; the most common polyester fiber on the market. Polyethylene Terephthalate or PET is made out the its rawest materials - natural gas+petroleum and coal-tar distillate. These are also know as primary materials. Natural gas is often found dissolved in oil at the high pressures existing in an oil deposit, and are a complex mixture of hydrocarbons that occur in the Earth in liquid, gaseous, or solid forms. With natural gas and petroleum you are able to obtain Ethylene by heating up natural gases. From Ethylene, Ethylene glycol is created. Ethylene glycol is later used with the byproduct of coal-tar distillate and petroleum. From coal-tar distillate and petroleum, xylene is created or more specifically p-xylene. When xylene is oxidized it makes terephthalic acid, a crystalline solid which is then heated up with the byproduct of the natural gas and petroleum, Ethylene glycol. According to Britannica, a british encyclopedia, PET is then formed into “a molten, viscous mass that can be spun directly to fibers or solidified for later processing as a plastic” (Britannica). The label is made out of a different lower grade plastic. Most water bottle labels are made out of Polyvinyl Chloride (PVC). I could not find any specif evidence stating that FIJI Water does or does not use this type of plastic. Ethylene and chlorine are the rawest material of PVC. First Ethylene and chlorine are combined to produce ethylene dichloride and then is transformed into vinyl chloride. The vinyl chloride molecules are then linked together and from PVC that is in a white powder form. Then other things are blended together to produce the PVC product of your choice. It is usually mixed with elements such as carbon and hydrogen (“How is PVC Made?”).

This bottle is square, not only to have a stylish design, but it is also practical when shipping. The shape creates less space between bottles than does the typical cylindrical bottle (FIJIGreen.com). Funny enough, this was not an idea to create a new design but it was simply more economical for the company. It saves them money, while being more environmentally friendly by minimizing the shrink wrap and cartons required (Myint). Due to the square size 10% less of trucks are needed for transportation. An empty 1 liter FIJI Water bottle weighs around 0.025kg (Päster). As reported by a Sustainability Science class of University of Vermont, “However, this is misleading, because the raw materials are still shipped in from outside sources and some are works-in-process when they reach the Fiji plant” (Lynch).

The PET plastic is said to be made in the Amcor headquarters in San Francisco. The plastic first starts as pellets and this is formed into “blanks”. Blanks are when the bottle is molded into its desired form before given a cap or a label. Those blanks are then shipped to Fiji and made into those iconic square shaped bottles and then filled with water (Wujec). We found information that was in another source stating nothing about PET being made from the company Amcor. It said that the plastic pellets are produced in Thailand and then sent to Fiji to be reformed into bottles (Myint). This source says nothing about Amcor and where the blanks are created. This missing information could mean that the source is incorrect, but we still would like to take it into account. Some of FIJI Water's information is questionable just like any corporate company. The caps are made out of the same PET plastic, but are manufactured in a different location than the bottles. The plastic pellets that is made in the US is then sent to Taiwan to manufacture the caps. Once the caps are made they are then are sent to Fiji to be be added to the bottles; the bottle is then filled with water and then sealed. Fiji's plant makes 50,000 of these bottles per hour on site in their factories (Lenzer). The labels and shrink wrap are manufactured in New Zealand and Australia, which is a 8,700 km journey for the cargo vessel (Lynch). The cardboard used to hold the bottles while being shipped comes from the rainforests of trees in the South Pacific area ("Fiji Water, Energy...”). It is even said that their shipping cartons are made from 100% recycled materials. The cardboard is then sent to Fiji and then the bottles are ready for distribution. In a sustainability report it states that, “FIJI Water still ships to L.A. and then by truck to markets in the Midwest. They use trucks locally to get its product to many other destinations around the globe”. (Lynch). When they are not shipping to areas on the west coast they ship to New York via the Panama Canal, and the trasportaion of the bottles use 55% less greenhouse gas emissions than trucking the bottles all the way from California (Lynch).

To ship these bottles and all of the materials that go into make it produce “exhaust gases-Nitrogen Oxides (NOx), Sulphur Oxides(SOx), Carbon Monoxide (CO), Carbon Dioxide (CO2) and Particulate Matter (PM)” (Nguyen). In Forbes Magazine, an article form 2012 states that the proecess of producing and transporting bottles uses “46 million gallons of fossil fuel, producing approximately 216,000,000 billion pounds of greenhouse gases per year” (Kewalramani). A FIJI Water plant uses diesel fuel to run their factories while having it run 24 hours a day. FIJI Water states that they use PET bottles because they “require 24% less energy to produce, generate 40% less solid waste, and emit 46% less carbon during shipping than glass bottles” (Fiji Water). On the FIJI Water website they say, “Today, over 95% of all waste generated at our plant is sorted and recycled, which leaves less than 5% of largely biodegradable waste such as food destined for a landfill”, but they never talk about what their waste comes from; just that they are decreasing it (FIJI Water).

After a FIJI Water bottle has been used and disposed of by the customer is goes to landfills or to be recycled. PET bottles accounts for only 11% of plastic based materials that ends up in landfills (Saquing). When a FIJI Water bottle is recycled it can reduce the carbon footprint by 30% ("Is it Green?”). To actually reduce the carbon foot print people have to actually the FIJI Water bottle. Post-consumer can use PET forpackaging for detergents, cosmetics, high-quality carpets, foils, car spare parts and fibers in clothing. (“Recycled PET”) Once the bottles are received by post-consumer of PET it is sorted by different colors; uncolored, blue or green. The FIJI Water's bottles are a transparent bottle and is uncolored. Clear bottles are usually more favorable to the recycling companies. The recycling symbol that is on most bottles and recyclable items have a number on the inside of it. That number signifies what type of material was used to make that product and is called the resin identification code. The resin identification code for Polyethylene Terephthalate is 1. After being sorted they are pressed and crushed in cubes, washed and sold to recycling companies or manufactures. Other methods of breaking down the bottle is to put it through a shredder to get PET fragments or “PET flakes” (“PET Bottle Recycling”).

To change the chemical process of PET is done by depolymerization methods and reversing it back to a polymer: glycolysis, methanolysis, hydrolysis, and ammonolysis. The waste of the PET plastic can then be sold as polymers. Glycolysis was the first type of method to depolymerization PET that puts it under pressure and in in temperatures of 180 to 240 degrees and terphthalate (BHET) and polyols is formed. Methanolysis is done by treating PET with heat of 180 to 230 degrees and a pressure of 20 to 40 atm; which then creates dimethyl terephthalate (DMT) and ethylene glycol and is then repolymerized. Hydrolysis allows the polymer chain to break down into terephthalic acid (TPA) and ethylene glycol. This is done by being in temperatures of 25 to 100 degrees and put under atmospheric pressure. It is then treated with sodium hydroxide to allow the TPA to be neutralized and then has a purity level greater than 99%. There is a massive amount of water waste with inorganic salts and sulfuric acid is created and then needs to be disposed of properly. The least use depolymerization method is ammonolysis. PET is reacted with ammonia when put in 70 to 180 degrees with pressure with ethylene glycol. TPA amide is produced and has a purity level of 99%. (Alonso)

In this day and age, the production of plastic bottled water had improved but they are still not to be the best thing for our environment. It is nice to see that Fuji water has made some effort to be conscious of sustainable practices probably more than other bottling companies. FIJI Water's raw materials over all are still not that sustainable. The fact that the production of each part of the bottle coming from different locations uses a lot of fossil fuels. The PET plastic is easily recyclable but there is so much PET plastic that is in the world we really do not need any more plastic bottles laying around in landfills.

Resources

Alonso, José Aguado, and David P. Serrano. Feedstock Recycling of Plastic Wastes. Cambridge, UK: Royal Society of Chemistry, 1999. Print.

"FIJI Water." FIJI Water, 2014. Web. 8 Mar. 2014. <http://fijiwater.sg/>.

"Fiji Water, Energy, and You: Deconstructing a Global Supply Chain." Northisup.com. Adam Hitchcock, 18 Nov. 2008. Web. 20 Feb. 2014. <http://northisup.com/blog/fiji-water-energy-and-you-deconstructing-a-global-supply-chain/>.

"How Is PVC Made?" PVC.org, n.d. Web. 12 Mar. 2014. <http://www.pvc.org/en/p/how-is-pvc-made>.

"IS IT GREEN?: FIJI Bottled Water." Inhabitat. Inhabitat.com, n.d. Web. 20 Feb. 2014. <http://inhabitat.com/is-it-green-fiji-water/fiji-water-bottled-water-fiji-bottled-water-plastic-water-bottles-greenwashing-barbara-chung-plastic-bottles-3/>.

Kewalramani, Devika, and Richard Sobelsohn. ""Greenwashing": Deceptive Business Claims of "Eco-Friendliness"" Forbes. Forbes Magazine, 20 Mar. 2012. Web. 10 Mar. 2014. <http://www.forbes.com/sites/realspin/2012/03/20/greenwashing-deceptive-business-claims-of-eco-friendliness/>.

Lenzer, Anna. "Fiji Water: Spin the Bottle." Mother Jones. Mother Jones and the Foundation for National Progress, 2009. Web. 20 Feb. 2014. <http://www.motherjones.com/politics/2009/09/fiji-spin-bottle>.

Lynch, T., C. Francis, S. Lutter, D. Takase, and B. Buckless. Fiji Water A Sustainability Report (2010): Uvm.edu. University of Vermont, 2010. Web. 26 Feb. 2014. <http://www.uvm.edu/~shali/Fiji.pdf>.

Wujec, Mikayla. "FIJI Water - Behind the Bottle." Word Press, 2009. Web. 20 Feb. 2014. <http://mikaylawujec.files.wordpress.com/2012/08/fiji-water-mikayla-wujec.pdf>.

Myint, Tun. "Commodity Chains and Social Ecological Changes: A Theoretical Inquiry on Human-Environment Interactions." (2009): n. pag. Social Science Research Network. Web. 20 Feb. 2014. <http://papers.ssrn.com/Sol3/papers.cfm?abstract_id=1451839##>.

Nguyen, Tri. "Fiji Water Environmental Nightmare." Slideshare.ne. LinkedIn Corporation, 14 Jan. 2013. Web. 10 Mar. 2014. <http://www.slideshare.net/TRIMI4400/fiji-water-environmental-nightmare>.

Päster, Pablo. "What’s the True Environmental Cost of Fiji Water?" Triple Pundit. Triple Pundit, 5 Feb. 2007. Web. 10 Mar. 2014. <http://www.triplepundit.com/2007/02/whats-the-true-environmental-cost-of-fiji-water/>.

"PET Bottle Recycling." Wikipedia. Wikimedia Foundation, 03 Oct. 2014. Web. 10 Mar. 2014. <http://en.wikipedia.org/wiki/PET_bottle_recycling>.

"Polyethylene Terephthalate (PET or PETE)." Encyclopedia Britannica Online. Encyclopedia Britannica, n.d. Web. 20 Feb. 2014. <http://www.britannica.com/EBchecked/topic/468536/polyethylene-terephthalate-PET-or-PETE>.

"Recycled PET." Kenplas, 2014. Web. 10 Mar. 2014. <http://www.kenplas.com/topic/recyclepet.aspx>.

Saquing, J., C. Saquing, D. Knappe, and M. Barlaz. Impact of Plastics on Fate and Transport of Organic Contaminants in Landfills: Environmental Science Technology, 2010. Print.

Edwin Marquez

Design 40A

March 10, 14

Professor Cogdell

The Energy in the FIJI Water Bottle Life Cycle

As young people, we don’t really pay attention to many materials and objects we use. Unless a person is directly affected with a specific product, they won’t think twice about how something is made or of the energy used to make it. I grew up well into the new millennium. By then plastic water bottles were a normal and every day thing. In my family, all we ever heard is “drink water, drink water, it’s good for you”. And while that is true, I never thought twice about the difference between water we drank from a purified water vending machine, or from a bottled water company. I would just drink it because of the saying that it’s healthy, and way better as opposed to soda. As I got older, I began hearing a lot about plastic water bottles, and the harm they are doing to this world. I would also know that if you “recycle” these plastic bottles, then that helps a lot. So that is what I would do in regards to plastic water bottles. After finding a few decent articles and information on the energy is takes to make plastic water bottles, I found out that water bottles aren’t actually good at all. The only reason they were invented was because soda companies tried to expand their types of drink, and they opted to market a “cleaner” healthy drink. And oh have they marketed these water bottles to perfection. The plastic water bottle has made itself part of everyday life. Too bad it has awful waste problems, “80% of the 28 billion single- serving plastic water bottles used by Americans each year end up in landfills.”{C}[1]{C} For our poster, my group wanted to include a clean image of a FIJI plastic water bottle after seeing that we couldn’t obtain a good one online. So I proposed to go and take a picture of a real one with my DSLR photography camera. The day was hot when I went to go buy it, and on the way back as I drove my car, with various school related thoughts going through my head, I suddenly became thirsty, and picked up the FIJI water bottle, and almost opened it. If I had opened it and drank from it, it wouldn’t be a good photograph since one could probably see that someone drank out of it. That was when I realized the power of a water bottle. I was so close to opening it. While I thought of other things, there was this comfort that came over me knowing that I had a fresh unopened water bottle ready for me to reach, grab, and drink. The influence of a water bottle is great because of the feeling that a person gets when they see or imagine the taste of fresh water, especially in a hot day.

When I began researching this information on the FIJI water bottle life cycle, I was only imagining what the energy cost was because at first, I wasn’t just focusing on the FIJI company by itself, I was researching water bottles in general. There are many plastic water bottle companies out there like Pepsi’s Aquafina, Coca-Cola’s Desani, Nestle’s Pure Life, but the one water bottle company that kept popping up was FIJI Water because of various controversial issues. I won’t really get too much into that because that is not the main focus of this paper. Unfortunately, there weren’t too many articles or actual precise information on the energy used in the life cycle of FIJI water bottles. The best that I was able to find was a study done out of Oakland, CA, where two environmental researchers published their findings on the energy used in the life cycle of three different water bottle type companies, among other decent articles. The three types would be, “local bottled water produced and used in Los Angeles, water bottled in the South Pacific and shipped by cargo ship to Los Angeles, and water bottled in France and shipped in various ways to Los Angeles.”{C}[2]{C} FIJI water bottles would be the one that says the “water bottle in the South Pacific and shipped by cargo ship to Los Angeles”. In this paper, I will state the energy used to create PET, form the bottle, process the water, fill and seal the bottle, transport, and finally, keep the bottles cool and refrigerated.

Many plastic bottles, including FIJI waters, use a type of plastic called Polyethylene Terephthalate, “FIJI Water bottles are made from high-grade PET (polyethylene terephthalate) plastic, which is designated with the #1 code at the bottom of the bottle. The FDA approves PET as safe for contact with food and beverage. PET is also fully recyclable and can be transformed into a number of products such as food and beverage packages, apparel, carpet, automotive parts, and construction materials.”{C}[3]{C} The reason polyethylene terephthalate is used is because, “(PET) is chosen for its durability and the ease in which it can be recycled.”{C}[4]{C} The process of FIJI Water is as follows, “Manufacturing PET bottles requires combining ethylene glycol and terephthalic acid to produce PET resin in the form of small pellets that resemble rice. These pellets are then melted and injected into a mold to produce a ‘preform’, a thick walled test tube with a finished neck and set of cap threads. The preform is then heated, stretched, and blown into the final bottle shape. Some major bottlers blow their own bottles from preforms, though many smaller bottlers purchase pre-blown bottles produced offsite and transported to the bottling plant.”{C}[5]{C} That is how the plastic is derived and turned into what we know as FIJI water bottles.

A regular sized FIJI water bottle mass in grams is 1 liter. Energy is used in many of the life cycle steps, and the first to be analyzed is the creation of a PET bottle; “Energy is embodied in PET material itself, and additional energy is required to turn PET into bottles. This energy is typically supplied by natural gas and petroleum, along with electricity from the local electricity grid. Two comprehensive life-cycle assessments for producing PET and PET bottles have been completed, which indicate that the energy required to produce PET resin is approximately 70–83 MJ (thermal) kg−1 of PET resin. Producing preforms and turning them into bottles requires an additional 20 MJ kg−1 of finished bottle. The total energy used in producing PET bottles, including some transportation energy to move the resin to the point where bottles are produced and then filled, is thus about 100 MJ(th) kg−1 or 100 000 MJ(th)/ton of PET. The mass of PET required per bottle depends on the style, thickness, and size of the bottle.” [6]{C}

Once “preforms” are produced, then comes the formatting of the bottle. As I stated before, FIJI water has a 1 litter bottle. This specific bottle weighs approximately 38 g, and the cap weighs an additional 2 g. One FIJI water bottle costs 4.0 MJ of manufacturing energy. This is stated thoroughly in the following quote, “Combining the estimate of the energy required to make PET and form it into bottles with the average weight-to-volume data results in a manufacturing energy cost of around 4.0 MJ per typical 1 liter PET bottle weighing 38 g. This estimate includes the energy required to convert raw materials into PET resin, energy required to turn resin into bottles ready for filling, and energy to transport PET or bottles to the filling plant.”{C}[7]{C} Bottled water companies have since tried to make their water bottles lighter, and it is estimated that if all companies shifted to lighter bottles, the cost of energy could save around 30% of PET production. Even FIJI waters have talked about making their water bottles lighter. A representative of FIJI waters was interviewed by Adrianne Jeffries from Inhabitat.com, and when questioned about what is being done about lighter weight bottles other companies have worked on, they had no comment, but when asked that if a change to the thickness of the bottle, they responded, “We are in the process of determining how much we can continue to lightweight the bottles, but we will go with the lightest weight possible that still maintains the integrity and quality of our product.”{C}[8]{C} So it seems they are optimistic when it comes to changing the design of their most popular model and at least they are considering it.

The processing of water, even extensive processing, doesn’t use much energy. There are two types of companies that get their water from different sources. FIJI water uses a surface of groundwater system. For the energy used in processing I found that, “Although spring water is not supposed to undergo treatment that substantially changes its chemical composition, it often undergoes some processing at the bottling plant. Treatment processes can include micro or ultrafiltration, ozonation, ultraviolet radiation, and reverse osmosis. Disinfecting water with ultraviolet radiation, for example, requires as little as 10 kWhe/million liters. Energy requirements for reverse osmosis, however, can be as high 1600 kWhe/million liters for source water with a total dissolved solids concentration of 4000 ppm.”{C}[9]{C}

For FIJI water bottles, energy is also used to clean, fill, seal, and label bottles. When it comes to cleaning, the average machine can “clean, fill and seal around 15,000 bottles per hour and requires 0.006 MJ J(th) per bottle.”{C}[10]{C} Only about a third of one percent is used in the embodied energy of a plastic water bottle. It is also interesting to note the little known fact that when a consumer buys a FIJI water bottle, when the bottle is first opened, it lets in oxygen into the bottle for the first time, “At this point, the bottling plant in Fiji has all of the raw materials necessary to make the completed product. The bottling plant uses a sophisticated pumping system to draw the water out of the artesian aquifer and then dispense the contents into newly formed Fiji Water bottles so that the water never touches aboveground oxygen. According the to the website, the entire bottling process is “closed”, so the pristine quality of the water is untouched by aboveground air until the consumer twists off the cap for the first time.”{C}[11]{C}

The energy used to transport FIJI water bottles in its process is the one out of the cycle that uses to most. Heavy water transportation can use one metric ton per cubic meter. One of the biggest energy consuming companies is FIJi water. This following quote is not specific to FIJI water, but it does talk about spring water and transportation, “In contrast, ‘spring’ waters are usually packaged at specific, single sources and transported, sometimes significant distances, to points of demand.”{C}[12]{C} After all of the FIJI waters assembly, and shipped to the US, I found that. “Spring water transported across the Pacific from Fiji to Los Angeles and then delivered locally within 100 km has a total transportation energy cost of 4.0 MJ l−1.”{C}[13]{C} And that isn’t even mentioning the potential energy the bottles then take up when being distributed from Los Angeles to all of the US.

The final energy consuming aspect of FIJI waters is the energy used when being refrigerated. There are two components of water cooling; the energy from refrigerators to make a cold water after originally being room temperature, and the other is the energy used to keep the water cold until it is sold. For the first component, “For the first component, we estimate that bottled water is cooled from a room temperature of around 20.0◦C to a typical refrigerator or cooler temperature of around 3.3◦C. Given that the specific energy of water is around 4.2 kJ kg−1 K−1, we estimate that cooling 1 l of water 17◦C requires 220 kJ, or 0.2 MJ l−1.” For the second component, “The second component depends on the length of time the bottled water is kept cool before consumption and the energy performance of the refrigerator. As of October 2008, more than 1000 refrigerators met the US Energy Star standards for efficiency. These refrigerators had an average volume of 17 cubic feet and used 450 kWh(e) per year or around 8.65 kWh(e) per week. No data are available on the time the average consumer chills bottled water before consuming, but if we assume that a consumer keeps a liter of bottled water cold for a week before consuming it, then the energy required to maintain the cool bottle is another 0.2 MJ l−1.” {C}[14]{C}

I conclusion, because FIJI waters is a long- distance transport company, the energy cost of transport can come close to the energy used to produce the water bottles. The energy cost for processing, bottling, sealing, labeling, and keeping the waters cold and fresh is much smaller.

“For water transported short distances, the energy requirements of bottled water are dominated by the energy to produce the plastic bottles. Long-distance transport, however, can lead to energy costs comparable to, or even larger than, the energy to produce the bottle. Far less energy is needed for processing and treating the water, and cooling bottles for retail sale.” I wasn’t able to find the energy used to recycle or down cycle FIJI plastic bottles because of the fact places do various plastic bottles at the same time. As it turns out, “Combining all of the energy inputs totals, we estimate that producing bottled water requires between 5.6 and 10.2 MJ l−1—as much as 2000 times the energy cost of producing tap water. Given an annual consumption of 33 billion liters of bottled water in the US, we estimate that the annual consumption of bottled water in the US in 2007 required an energy input equivalent to between 32 and 54 million barrels of oil or a third of a per cent of total US primary energy consumption. We estimate that roughly three times this amount was required to satisfy global bottled water demand.”{C}[15]{C}

Bibliography

"FAQs." FIJI Water. N.p., n.d. Web. 7 Mar. 2014. <http://www.fijiwater.com/faqs/>.

"It's Easy to Be Green." It's Easy to Be Green. N.p., n.d. Web. 7 Mar. 2014. <http://lannonline.org/newsletter/article-archive/10-topical/154-its-easy-to-be-green>.

Gleick, PH. Cooley HS. “Energy Implications of Bottled Water”. Environmental Research Letters. N.p., n.d. Web. March 4. 2014 < http://iopscience.iop.org/1748-9326/4/1/014009/pdf/erl9_1_014009.pdf>

Hitchcock, Adam. "Fiji Water, Energy, and You: Deconstructing a Global Supply Chain." Fiji Water, Energy, and You: Deconstructing a Global Supply Chain.

N.p., n.d. Web. 11 Mar. 2014. <http://northisup.com/blog/fiji-water-energy-and-you-deconstructing-a-global-supply-chain/>.

Jeffries, Adrianne. "IS IT GREEN?: FIJI Bottled Water | Inhabitat - Sustainable Design Innovation, Eco Architecture, Green Building." Inhabitat Sustainable Design Innovation Eco Architecture Green Building IS IT GREEN FIJI Bottled Water Comments. N.p., n.d. Web. 4 Mar. 2014. <http://inhabitat.com/is-it-green-fiji-water/>.

Lynch, Ian. Francis, Colin. Lutter, Stefan. Takase, Daichi. Buckless, Brendan. “FIJI Water: A Sustainability Report” Sustainability Science. N.p., n.d. Web. 10 Mar. 2014. <http://www.uvm.edu/~shali/Fiji.pdf>

Wujec, Mikayla. “FIJI Water- Behind the Bottle: The Creation of a Commodity” N.p., n.d. Web. 11 Mar. 2014.<http://mikaylawujec.files.wordpress.com/2012/08/fiji-water-mikayla-wujec.pdf>

Zyga, Liza. "How Much Energy Goes Into Making a Bottle of Water?" How Much Energy Goes Into Making a Bottle of Water? N.p., n.d. Web. 11 Mar. 2014. <http://phys.org/news156506896.html>

[1] "It's Easy to Be Green." It's Easy to Be Green. N.p., n.d. Web. 7 Mar. 2014. <http://lannonline.org/newsletter/article-archive/10-topical/154-its-easy-to-be-green>.

[2] Gleick, PH. Cooley HS. “Energy Implications of Bottled Water”. Environmental Research Letters. Pg. 1. N.p., n.d. Web. March 4. 2014

[3] "FAQs." FIJI Water. N.p., n.d. Web. 7 Mar. 2014.

[4] Hitchcock, Adam. "Fiji Water, Energy, and You: Deconstructing a Global Supply Chain." Fiji Water, Energy, and You: Deconstructing a Global Supply Chain. N.p., n.d. Web. 11 Mar. 2014.

[5] Gleick, PH. Cooley HS. “Energy Implications of Bottled Water”. Environmental Research Letters. Pg. 2. N.p., n.d. Web. March 4. 2014

[6] Gleick, PH. Cooley HS. “Energy Implications of Bottled Water”. Environmental Research Letters. Pg. 2. N.p., n.d. Web. March 4. 2014

[7] Gleick, PH. Cooley HS. “Energy Implications of Bottled Water”. Environmental Research Letters. Pg. 3. N.p., n.d. Web. March 4. 2014

[8] Jeffries, Adrianne. "IS IT GREEN?: FIJI Bottled Water | Inhabitat - Sustainable Design Innovation, Eco Architecture, Green Building." Inhabitat Sustainable Design Innovation Eco Architecture Green Building IS IT GREEN FIJI Bottled Water Comments. N.p., n.d. Web. 4 Mar. 2014.

[9] Gleick, PH. Cooley HS. “Energy Implications of Bottled Water”. Environmental Research Letters. Pg. 4.N.p., n.d. Web. March 4. 2014

[10] Gleick, PH. Cooley HS. “Energy Implications of Bottled Water”. Environmental Research Letters. Pg. 3.N.p., n.d. Web. March 4. 2014

[11] Hitchcock, Adam. "Fiji Water, Energy, and You: Deconstructing a Global Supply Chain." Fiji Water, Energy, and You: Deconstructing a Global Supply Chain. N.p., n.d. Web. 11 Mar. 2014.

[12] Gleick, PH. Cooley HS. “Energy Implications of Bottled Water”. Environmental Research Letters. Pg. 5.N.p., n.d. Web. March 4. 2014

[13] Gleick, PH. Cooley HS. “Energy Implications of Bottled Water”. Environmental Research Letters. Pg. 5.N.p., n.d. Web. March 4. 2014

[14] Gleick, PH. Cooley HS. “Energy Implications of Bottled Water”. Environmental Research Letters. Pg. 5.N.p., n.d. Web. March 4. 2014

[15] Gleick, PH. Cooley HS. “Energy Implications of Bottled Water”. Environmental Research Letters. Pg. 6.N.p., n.d. Web. March 4. 2014.

Elisa Massenzio // DES 40A // Christina Cogdell // Winter 2014

FIJI Water Wastes and Emissions

FIJI Water has been the iconic luxury water bottle brand since its creation in 1996, when founder David Gilmour obtained a 99-year lease for an artesian aquifer in Viti Levu, Fiji (Wujec 2). Though the company won’t release its annual sales, the International Water Bottle Association (IBWA) optimistically declares that the global industry of bottled water was worth over $11B in 2011, selling over 9 billion gallons, or over 29 gallons of bottled water per person. This astounding figure becomes more worrisome after discovering the profound environmental, health and moral issues that surround the industry, especially in terms of the wastes and emissions that are created as a result of water bottle manufacturing. Because it would be too complicated to examine the entire industry and all of the different bottled water brands, this paper will focus on FIJI Water, and will assume that the research done on PET plastic, which is used for FIJI bottles, is relevant to this product. After extensive research, it is obvious that drinking bottled water is morally inexcusable—except in cases of emergency—and that the environmental, and human and animal health problems that arise from the production of bottled water far outweigh the convenience of the product.

Raw Materials Acquisition

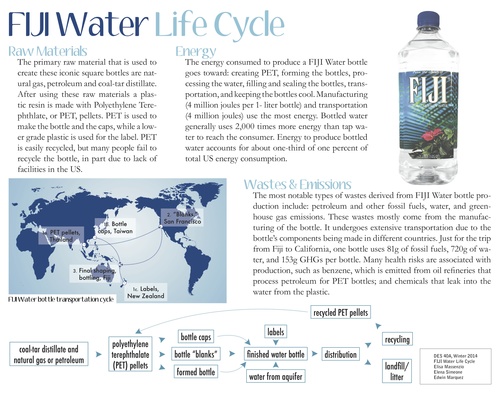

FIJI Water bottles, like most single-serving bottled waters and sodas, are made out of polyethylene terephthalate (PET or PETE), which is a lightweight plastic derived from petroleum. The documentary Tapped claims that “plastic water bottle manufacturing uses 714M gallons of oil every year, [which] is enough to fuel 100,000 cars,” though it is not clear whether this quantity of oil is only the amount used to create the PET for the bottles, or the amount that goes into the entire extraction, manufacturing, and transportation processes. The article “Fiji Water, Energy, and You” also quotes the same figure: 17M barrels of oil. There are 42 gallons in one barrel of oil, so 17M barrels contain 714M gallons. However, another article claims that “producing the PET bottles to satisfy global bottle water demand required [...] the energy equivalent of approximately 50B barrels of oil per year” (Gleick et al. 3). Though this figure differs from the other two, it does also include the entire water bottle creation process, up until the bottles are filled and distributed. Also important to consider is the waste produced to extract petroleum from the earth. It is not possible to gauge exactly how much waste is created in this process, because the petroleum that is extracted may also be used for purposes other than the creation of PET. However, the above figure of 50B barrels does include the waste produced during the entire process.

These outrageous figures clearly show how wasteful bottling water is, even from the very beginning of the process. It is unreasonable to consume such huge amounts of limited natural resources like petroleum to create a product that can easily be replaced by safer, more eco-friendly refillable aluminum bottles and tap water.

Manufacturing, Processing and Formulation

Once the petroleum is processed and the PET pellets are made, they are melted and formed into “blanks,” which can then be molded into the finished water bottle. In the case of FIJI Water, Amcor Plastics makes the pellets and blanks in San Francisco, CA, which are transported to Fiji where the final bottle shapes are made; the vessel also stops in Taiwan to collect the caps that are manufactured there. The labels are made in New Zealand and transported separately to Fiji (Wujec 4-6). The wastes created in this transportation process will be discussed later.

Gleick et al. report that “approximately one million tons of PET were produced to make the plastic bottles consumed in the United States in 2007 and three million tons were produced globally” (3). It is not possible to determine exactly how much FIJI Water has contributed to these figures, because it is a private company and has not released its annual sales.

Additionally to the petroleum used to make the PET, there is much water waste and greenhouse gas (GHG) emissions involved in its manufacturing. According to “Fiji Water, Energy, and You,” it takes 294.3 kg of water to make 1 kg of PET resin, and the manufacture of one ton of PET produces 3 tons of carbon dioxide; “Bottling water thus created more than 2.5 million tons of CO₂ in 2006.” Though not specific to the FIJI Water blanks, Amcor Plastics, who makes the product for FIJI Water, reports 10.9M tons of GHG emissions in its 2013 GRI Report, and a global water use of 9.08 gigalitres.

Aside from the environmental concerns, the most shocking of statistics in this industry are the health risks involved in PET manufacture. Tapped interviewed residents of a city near an oil refinery, some of whom have lost relatives to cancer caused by the benzene emissions, and others who have severe breathing problems for the same reason. Benzene is a part of crude oil, which is used in plastics manufacturing, and is found in higher concentrations near refineries. It evaporates quickly and sinks into low-lying areas, and can leak from storage tanks and contaminate well water. It is extremely toxic to humans, and can cause cancer, anemia, and damage the immune system (“Facts About Benzene”). These facts highlight the moral issues involved in water bottle manufacturing: it is not worth wasting such exorbitant amounts of water and GHGs, and costing people their lives because it’s more convenient to use a plastic bottle than to carry a reusable one.

Distribution and Transportation

As mentioned earlier, the components of FIJI Water’s bottles are manufactured in a variety of countries, which means that they have to travel thousands of kilometers before reaching the consumer. To transport the blanks, caps and labels, which are made in California, Taiwan and New Zealand, respectively, cargo vessels must travel a total of 18,815km (“Fiji Water, Energy, and You”). “A container vessel uses 9g of fuel per tkm [metric tons per kilometer], 80g of water per tkm, and releases 17g of GHGs per tkm” (Pablo). An empty one liter bottle weighs about 0.025kg, so to transport it 18,815km, one bottle uses 4.23g of fuel[1], 37.63g of water[2], and 8g GHGs[3]. Pablo calculates that to transport the full bottle to the US from Fiji, there is a waste of “81g of fossil fuels, 720g of water, and 153g GHGs per bottle.” It’s also important to note that FIJI Water does not only export to the US, but to countries all over the world, so there are also fossil fuels, water and GHG emissions that are wasted in transporting to other parts of the globe.

From the ports, the bottles are loaded onto trucks, which transport them to warehouses and retailers. Consumers will also transport their bottles after purchase. It would be almost impossible to find all truck routes and efficiencies of the trucks, so there is no specific figure for the waste that is created in this portion of the process.

Another transportation factor that is easy to overlook is that involved with recycling: once a consumer puts his bottle into a recycling bin, a truck must then transport it to a recycling center, and from there to a manufacturer like Amcor Plastics, where the recycled PET is used. Trucks must also collect the bottles that are thrown into the trash, and transport them to landfills.

It seems almost farcical that there is such a complicated transportation chain involved in getting water to a consumer. There is safe, usually relatively local, drinking water readily available almost everywhere in the United States, yet consumers choose to purchase water that means cargo vessels and trucks must travel tens of thousands of kilometers. Several articles mention that consumers prefer this, despite the waste, because the bottled water industry has convinced them that bottled water is safer than municipal water. But this is not the case.

Use, Re-use and Maintenance

Because PET bottles are designed for one-time use, only the “use” part of this section will be discussed.

The bottled water industry continuously claims that its water is much cleaner and safer than municipal tap water; the IBWA says, “Bottled water is a safe, healthy, and convenient packaged food product, which is comprehensively regulated at both the federal and state level.” On the contrary, it is not “comprehensively regulated,” as a 2009 Government Accountability Office report found that FDA (Federal Drug Administration) safety protections are much less stringent than EPA (Environmental Protection Agency) protections; the FDA regulates bottled water as a food, and the EPA regulates municipal tap water. The report reads: “While FDA’s standard of quality regulations for bottled water are generally consistent with EPA’s drinking water requirements, FDA’s regulation of bottled water has been limited” (6). Further, the EPA controls tap water constantly, while the FDA relies on reports provided by the companies themselves every 3-5 years.

In addition, the huge increase in bottled water consumption has led to a wealth of studies aimed at discovering how safe or not bottled water truly is. All studies done by independent researchers have overwhelmingly found contaminants in bottled water, though not always at dangerous levels. Seven bottled water brands, including FIJI Water, showed levels of vinyl chloride, butadiene, benzene, styrene, and toluene, all of which can lead to reproductive defects and other health problems (Tapped). Other studies showed estrogenic contamination (Wagner et al., Bach et al.); antimony when bottles were stored at temperatures above 65℃, which is common in the southwest US (Westerhoff et al., Bach et al.); and formaldehyde and acetaldehyde as a result of “migration from PET into water” (Mutsuga et al., Bach et al.). Mutsuga et al. also found heterotrophic bacteria in PET bottles; when the water was sterilized, formaldehyde and acetaldehyde “migrated into commercial water from the PET bottle material.” The study concluded that either the bacteria or the chemicals will always remain.

Most of the studies did not include the names of the bottled water brands that were studied, so it is difficult to know whether FIJI Water does indeed have these contaminants or not. However, it is very possible, because the studies focused on PET bottles, which FIJI Water uses, and though not all of the chemicals found in bottled water are at dangerous levels, they can be when exposed to high temperatures. For health reasons, it makes more sense to drink tap water, which is strictly regulated and much safer than most bottled waters. The EPA will also immediately publish findings if tap water is found to be unsafe to drink, whereas the bottled water industry is less reliable because it performs its own checks and the FDA does not hold it strictly accountable.

Recycling

PET is often a preferred packaging material because it is easily recyclable. It is difficult to discover exactly how much energy is expended to recycle the product, because most sources cite the energy saved by recycling, rather than the energy used. Quoted figures include energy savings of 70% (“Recycling Fast Facts”), of 3 to 5 times less than the energy generated by waste (“Recycling Facts”), and that recycled material could have produced 7 million extra large t-shirts (“Recycling Facts and Statistics”).

Recycled PET is often used for non-food items—though some bottled waters do contain a mixture of virgin and recycled PET, but these pose risks of estrogen exposure (Bach et al.)—and can be used to make items such as t-shirts, sweaters, socks, sleeping bag fillings, and “about 1,200 soda bottles could carpet the average living room” (“Recycling Fact Sheet”).

Waste Management

However, the reality of recycling is grim. Though all PET products can be recycled, only 28% of the 700 million pounds of PET used “to produce soft drink bottles” were recycled in 1992 (Richard et al. 196) and this number increased slightly to 30.8% in 2012, according to the EPA. The rest ends up in landfills and incinerators. The EPA also reports that 2.8M tons were recovered, the equivalent of taking 670,000 cars off the roads per year; this is fantastic, but this figure would be three times greater if all PET were recycled. Or, better, if PET were not used, there would be no need to recycle it at all.

The reason PET is not being recycled has nothing to do with a lack of technology. In fact, “the processing technologies today are good enough to manufacture a product essentially equal in quality to virgin” (Pearson 8). The problem lays in the manufacturing industry, and in the lack of municipal recycling provision. A surprising 50% of Americans don’t have access to curbside recycling, and only 6 states offer water bottle deposit legislation, in which a 5-10¢ deposit is returned when consumers bring bottles to recycling centers. States with this legislation enjoy a much higher recycling rate than states without it (Tapped). In addition, there needs to be a customer to buy the recycled product, so if it is more economically viable for companies such as Amcor Plastics to use virgin PET, they will not use recycled versions; but as oil prices increase, so should recycled PET use (Pearson).

The most ethically shocking aspect of plastic waste is the Eastern Garbage Patch, which is a “huge soup of plastic” about twice the size of Texas, and floats in the Pacific Ocean between San Francisco and Hawaii where currents converge. In 2008, plastic there outnumbered plankton 46 to 1. This is hundreds of kilometers away from any human dwelling! What’s worse is that once the plastic breaks down into smaller pieces, it begins to look like food to fish, and scientists have found up to 26 pieces of plastic in a single fish (Tapped).

Conclusion

The vastly problematic environmental and health impacts of producing, transporting, and consuming bottled water far outweigh its convenience, and consumers need to be aware of the quickly increasing issues surrounding the industry. The population should be educated about its water sources, how safe it truly is, and what happens when one tosses a PET bottle into a recycling bin. A much healthier, less expensive, and more environmentally responsible alternative would be to purchase aluminum bottles and refill them with tap water that has not travelled almost 19,000km.

Bibliography

Agency for Toxic Substances and Disease Registry. Antimony. N.p.: Agency for Toxic Substances and Disease Registry, 1995. Print.

Bach, Cristina, Xavier Dauchy, Marie-Christine Chagnon, and Serge Etienne. "Chemical Compounds and Toxicological Assessments of Drinking Water Stored in Polyethylene Terephthalate (PET) Bottles: A Source of Controversy Reviewed." Water Research 46.3 (2012): 571-83. Elsevier. Web. 01 Mar. 2014.

Bloxham, Andy. "Fiji Water Accused of Environmentally Misleading Claims." The Telegraph. Telegraph Media Group, 20 June 2011. Web. 28 Feb. 2014.

"Bottled Water." Bottled Water. International Bottled Water Association, n.d. Web. 28 Feb. 2014.

Bottled Water: FDA Safety and Consumer Protections Are Often Less Stringent Than Comparable EPA Protections For Tap Water. Rep. Washington, D.C.: United States Government Accountability Office, 2009. Print.

Brandau, Ottmar. Bottle Production and Preforms: A Design Guide for PET Packaging. Waltham, MA: William Andrew, 2012. Print.

Brooks, David W., and Geoff A. Giles. PET Packaging Technology. Sheffield: Sheffield Academic, 2002. Print.

Climate Change Summit 2008, Sydney, Australia. FIJI Water's Path to Sustainable Growth. Fijiwater.com. FIJI Water, 2008. Web. 28 Feb. 2014.

Davis, S. C., R. Boundy, and S. Diegel. 2012 Vehicle Technologies Market Report. Rep. Oak Ridge, TN: Oak Ridge National Laboratory, Center for Transportation Analysis, 2013. Print.

"Facts About Benzene." CDC.gov. Centers for Disease Control and Prevention, 13 Feb. 2013. Web. 27 Feb. 2014.

"Fiji Water, Energy, and You: Deconstructing a Global Supply Chain." Fiji Water, Energy, and You: Deconstructing a Global Supply Chain. North Is Up, 18 Nov. 2008. Web. 28 Feb. 2014.

"Gallery: IS IT GREEN?: FIJI Bottled Water." Inhabitat Sustainable Design Innovation Eco Architecture Green Building Fiji Water Bottled Water Fiji Bottled Water Plastic Water Bottles Greenwashing Barbara Chung Plastic Bottles Comments. Inhabitat.com, n.d. Web. 28 Feb. 2014.

Gleick, P. H., and H. S. Cooley. "Energy Implications of Bottled Water." Environmental Research Letters (2009): n. pag. IOP Science. Web. 28 Feb. 2014.

Innovating for a Sustainable Future, GRI Report 2013. Rep. N.p.: Amcor, 2013. Print.

Jeffries, Adrianne. "IS IT GREEN?: FIJI Bottled Water." Inhabitat Sustainable Design Innovation Eco Architecture Green Building IS IT GREEN FIJI Bottled Water Comments. Inhabitat, 25 Sept. 2008. Web. 28 Feb. 2014.

Lenzer, Anna. "Fiji Water: Spin the Bottle." Mother Jones. Mother Jones and the Foundation for National Progress, Sept.-Oct. 2009. Web. 28 Feb. 2014.

Lynch, Ian, Colin Francis, Stefan Lutter, and Brendan Buckless. Fiji Water: A Sustainability Report. Http://www.uvm.edu/~shali/Fiji.pdf. University of Vermont, n.d. Web. 28 Feb. 2014.

Municipal Solid Waste Generation, Recycling, and Disposal in the United States: Facts and Figures for 2012. Rep. N.p.: United States Environmental Protection Agency, 2012. Print.

Mutsuga, M., Y. Kawamura, Y. Sugita-Konishi, Y. Hara-Kudo, K. Takatori, and K. Tanamoto. "Migration of Formaldehyde and Acetaldehyde into Mineral Water in Polyethylene Terephthalate (PET) Bottles." Food Additives and Contaminants 23.2 (2006): 212-18. Print.

Pablo. "What’s the True Environmental Cost of Fiji Water?" Triple Pundit RSS. Triple Pundit, 05 Feb. 2007. Web. 02 Mar. 2014.

Pearson, Wayne. "Chapter 1: Recycling Plastics from Municipal Solid Waste." Emerging Technologies in Plastics Recycling: Developed from a Symposium Sponsored by the Division of Polymer Chemistry, Inc., of the American Chemical Society at the Polymer Technology Conference, Philadelphia, Pennsylvania, June 3-5, 1991. Comp. Gerald D. Andrews and Pallatheri M. Subramanian. Washington, DC: American Chemical Society, 1992. 1-14. Print.

"Recycling Fact Sheet." Northeast Michigan Council of Governments. NEMCOG, n.d. Web. 11 Mar. 2014.

"Recycling Facts & Statistics." Keep America Beautiful. Keep America Beautiful, Inc., 2013. Web. 11 Mar. 2014.

"RECYCLING FACTS." Interesting Plastic Recycling Facts. MRC Polymers, n.d. Web. 10 Mar. 2014.

"Recycling Fast Facts." Stark State College. Stark State College, 2014. Web. 11 Mar. 2014.

Richard, R. E., W. H. Boon, M. L. Martin-Shultz, and E. A. Sisson. "Chapter 15: Incorporating Postconsumer Recycled Poly(ethylene Terephthalate)." Emerging Technologies in Plastics Recycling: Developed from a Symposium Sponsored by the Division of Polymer Chemistry, Inc., of the American Chemical Society at the Polymer Technology Conference, Philadelphia, Pennsylvania, June 3-5, 1991. Comp. Gerald D. Andrews and Pallatheri M. Subramanian. Washington, DC: American Chemical Society, 1992. 196-98. Print.

Rodwan, John G., Jr. Bottled Water 2011: The Recovery Continues. US and International Developments and Statistics. Rep. Alexandria, VA: International Bottled Water Association, 2012. Print.

Tapped. Dir. Stephanie Soechtig. Prod. Stephanie Soechtig, Michael Walrath, Michelle Walrath, and Sarah Gibson. By Jason Lindsey. Atlas Films, 2009. Netflix.

Terry, Beth. Plastic-free: How I Kicked the Plastic Habit and You Can Too. New York: Skyhorse Pub., 2012. Print.

Wagner, Martin, and Jörg Oehlmann. "Endocrine Disruptors in Bottled Mineral Water: Total Estrogenic Burden and Migration from Plastic Bottles." Environmental Science and Pollution Research 16.3 (2009): 278-86. Springer Link. Web. 01 Mar. 2014.

"Waste & Recycling | FIJI Water." FIJI Water. FIJI Water, n.d. Web. 28 Feb. 2014.

Wegelin, M., S. Canonica, A. C. Alder, D. Marazuela, M. J-F Suter, Th D. Bucheli, O. P. Haefliger, R. Zenobi, K. G. McGuigan, M. T. Kelly, P. Ibrahim, and M. Larroque. "Does Sunlight Change the Material and Content of Polyethylene Terephthalate (PET) Bottles?" Journal of Water Supply: Research and Technology--AQUA 50.3 (2001): 125-33. IWA Publishing Online. Web. 28 Feb. 2014.

Westerhoff, Paul, Panjai Prapaipong, Everett Shock, and Alice Hillaireau. "Antimony Leaching from Polyethylene Terephthalate (PET) Plastic Used for Bottled Drinking Water." Water Research 42.3 (2008): 551-56. Science Direct. Elsevier B.V. Web. 28 Feb. 2014.

Wujec, Mikayla. "FIJI Water: Behing the Bottle: The Creation of a Commodity." Diss. Concordia University, n.d. Print.

[1] (0.025kg/1,000t) x 9g x 18,815km

[2] (0.025kg/1,000t) x 80g x 18,815km

[3] (0.025kg/1,000t) x 17g x 18,815km