Design Life-Cycle

assess.design.(don't)consume

Halen Hogerty

DES 40a

Professor Cogdell

15 November 2019

EOS Raw Materials Analysis

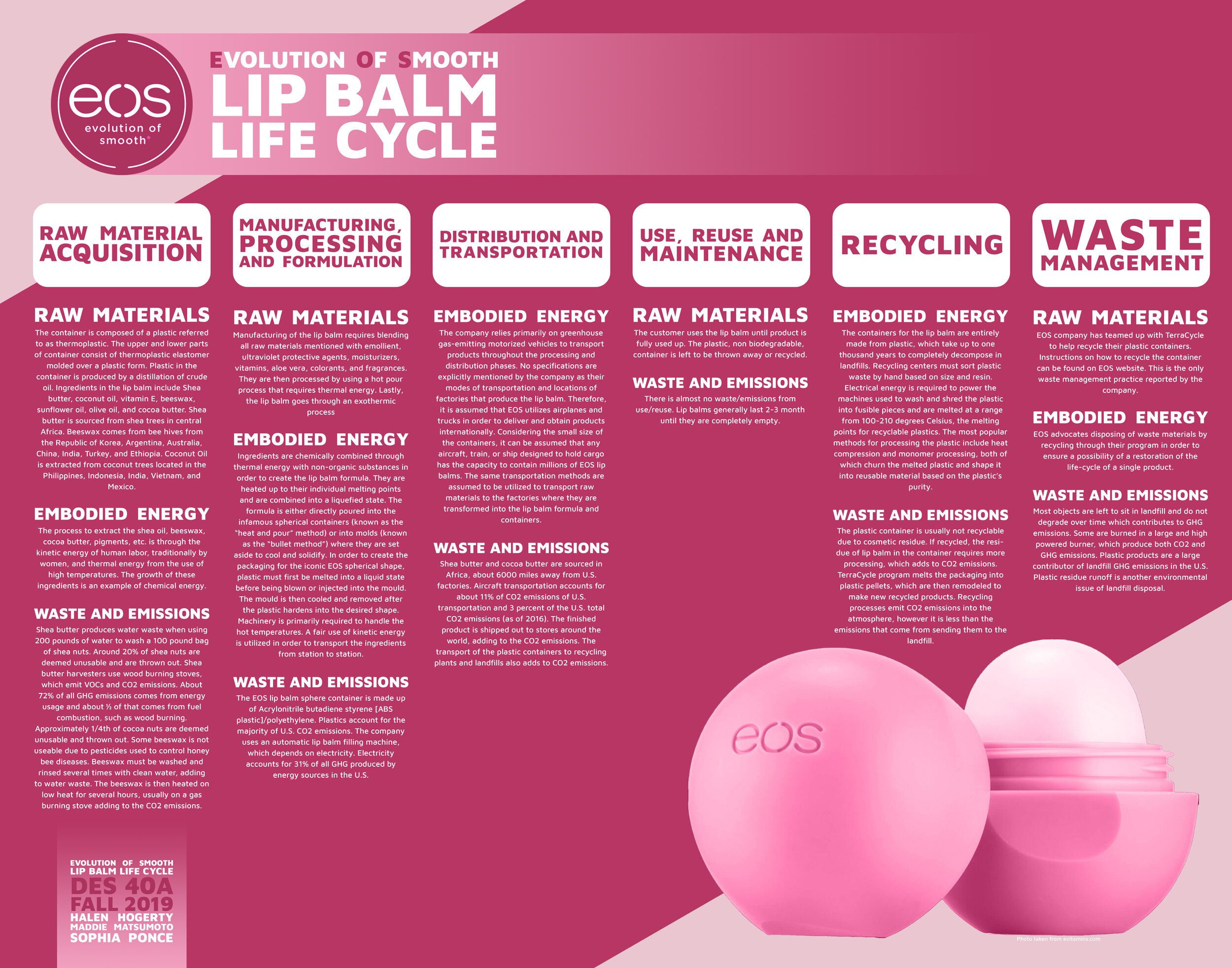

EOS is a lip balm that is known for using natural ingredients in order to have a moisturizing and soothing effect on the lips. EOS stands for “evolution of smooth,” and the company was founded back in 2007 by Jonathan Teller, Sanjiv Mehra, and Craig Dubitsky. Today, the company sells approximately 2 million units per week across the globe, and in 2015, they were the second-highest seller of lip balm in the United States (Belanger 2). EOS lip balms come in many different scents and flavors, such as strawberry, mint, vanilla, coconut, and many more (evolutionofsmooth 1). One factor that makes it easy to tell these lip balms apart from other well-known lip balm companies is that EOS products have an egg-shaped look to them. They also twist open revealing the lip balm shaped ball inside (United States Patent, 9).

The round egg-shaped container that encloses the lip balm is made up of a thermoplastic elastomer (TPE) injection that is molded over another plastic form. The lip balm itself mainly consists of a blend of natural waxes, oils, and fragrances (United States Patent 10). By considering these multiple raw materials that make up EOS lip balms, such as plastics, shea butter, vitamin E oil, and beeswax, it’s safe to conclude that the product is only partially recyclable and reusable.

Before introducing the major raw materials that are included in the production process of EOS lip balm, it is important to first mention regions around the world where these materials are are founded and grown.

There are seven different main ingredients that go into the process of making EOS lip balm, which include shea butter, cocoa butter, beeswax, olive oil, sunflower seed oil, coconut oil, and vitamin E. The company gets their shea butter from shea trees in central Africa, including Benin, Burkina Faso, Ghana, Ivory Coast, Mali, and Togo. Their shea butter is produced by first boiling and drying the fruit to extract the oil-rich kernels that are within. Then harvesters remove the kernels, ground, mill and knead them. Lastly, the oil is extracted and heated to produce shea butter (evolutionofsmooth 3). Cocoa butter is a rich natural fat that comes from cacao beans contained inside the pods of the Cacao Tree. Half the world’s commercial cocoa is produced in Central and South America, as well as in the Caribbean (New Directions Aromatics Inc, 2). Beeswax, the third ingredient of the lip balm, comes from bee hives from the Republic of Korea, Argentina, Australia, China, India, Turkey, and Ethiopia (Grand View Research 3). Vitamin E is an additional ingredient found in the lip balm, and is a fat-soluble vitamin that is an important antioxidant. Vitamin E can be found in many different foods, such as vegetable oils including palm oil, sunflower, corn, soybean, and olive oil. Other sources of vitamin E include nuts, whole grains, fish, and peanut butter (ScienceDaily 1). The top exporters of this product are China, Switzerland, Germany, The U.S., and Netherlands (Observatory of Economic Complexity 1). The next raw material, olive oil, comes from olive trees, where the olives are picked, and washed. Then the olives go through a pressing process, where stainless steel rollers rush the olives and pits in order to produce a paste (Alleman 2). The largest producer of olive oil is Spain, which makes 45% of the world’s olive oil. Italy and Greece are the next two largest producers (About Olive Oil 2). hThe top producer of sunflower seed oil is Russia, and 95% of their oil is sold in retail markets. Sunflower seeds are first processed by using an impactor or decorticator, which basically propels the seeds with a rotating blade in order to detach the hulls from the meats. The impacted seeds are then sent to a hulls separator where the extraction process is continued (Gonzalez-Perez 3). The last ingredient to be mentioned is coconut oil, which comes from coconut trees in the Philippines, Indonesia, India, Viet Nam, and Mexico (indexmundi 1).

After analyzing where these primary raw materials are produced, and how they’re extracted, it’s now important to see just how much of these ingredients go into the final lip balm product.

There are a number of different primary raw materials that make up the small round EOS lip balm, and these materials are found all throughout the world. It’s now important to observe how these materials are formed together to make the lip balm of EOS products. The first step in manufacturing the company’s lip balm is create a blend of beeswax, coconut oil, olive oil, and jojoba oil. The blend can also include other ingredients such as, but not limited to, emollients, ultraviolet protective agents, moisturizers, vitamins, aloe vera, colorants, and fragrances (United States Patent 12). The white coloring seen in almost all of EOS lip balms comes from the chromophore, Anthoxanthins. An anthoxanthin is a group of ivory, yellow, or orange crystalline pigments that are similar to anthocyanins in their solubility in plant cell sap, but are derived from flavone and flavonol (Merriam-Webster 1). Plant sources that are used to portray this white color can include cauliflower, mushrooms, parsnip, potato, ginger, onions, jicama, bananas, and garlic. The sweet scent and flavoring that is present in the brand’s Tropical Mango lip balm, for example, is accomplished with the help of a masking flavor, such as some kind of fruit (mango), berry, or vanilla (Kokil 4).

EOS lip balm is created by using a hot pour process. With this process, the ingredients are combined and heated in a liquified phase and are then poured into the final packaging of the product. Spokes inside of the packaging or container help keep the lip balm in place once it has cooled and solidified. Thermal energy is used during the hot pour process. The lip balm goes through an exothermic process as it solidified. The energy lost during the solidification process is referred to as the latent heat of fusion (United States Patent 13).

So far, only the production of lip balm has been mentioned. Like stated previously, half of the product is made up of natural primary raw materials. However, the second half consists of secondary raw materials that aren’t considered natural.

The second part of EOS lip balm is the round, egg-shaped container that surrounds the balm. This container is formed by using secondary raw materials. Secondary raw materials are formed when a material extracted from the earth is processed, in order to be converted into a new compound, substance, of form, which then serves as a “new raw material” in another production process. In this case, the plastic used in the production of the EOS container is a secondary raw material since it’s derived from natural, organic materials, such as cellulose, salt, crude oil, natural gas, and coal. The first step in the production of plastic requires the distillation of crude oil. The crude oil then separates into fractions that consist of hydrocarbon chains (carbon and hydrogen). There are two different groups of plastics, which are thermoplastics and thermosets. The plastic used in the making of the lip balm is a thermoplastic, and these plastics are known to soften when heating and then harden again on cooling (PlasticsEurope 1). Both the upper and lower portion of EOS lip balm is comprised of a thermoplastic elastomer injection molded over a plastic form, which includes acrylonitrile-butadiene-styrene (ABS) copolymer (United States Patent 12).

Now that it’s clear what kinds of raw materials are found in the composition of the EOS lip balm product, it’s time to distinguish which of these materials are reusable or wasteful.

As stated previously, almost half of the EOS lip balm product is comprised of primary raw materials, while the other half consists of secondary raw materials. The EOS company claims their lip balms are 100% natural, and they are in fact, telling the truth (evolutionofsmooth 1). However, 100% natural does not mean 100% organic. Therefore, the lip balm is only partially organic, sustainable, and reusable.

When something is considered “natural,” that means the product can still be minimally processed, and not contain hormones, antibiotics or artificial flavors. However, the United States’ FDA and USDA don’t require any rules or regulations relating to natural foods and products. Organic products, on the other hand, are more regulated, and guarantees no toxic synthetic pesticides, toxic synthetic herbicides, or chemical NPK fertilizers are used in production (OrganicIt’sWorthIt 1). With this being stated, the ingredients that go into making the actual lip balm may be natural sourced ingredients, but they are not organic. The lip balm itself is, however, degradable in a sense, since it is absorbed into the lips. Unfortunately, the plastic container is not organic due to major processing that’s involved in manufacturing. The container also is not biodegradable, since plastic is known to take up to approximately 450 years to decompose into the Earth (Leblanc 2).

EOS does do a successful job in using mostly organic raw materials in the production of their moisturizing, sweet scented lip balms, and the company is currently making an effort to help recycle the plastic container that is left over.

Overall, due to the multiple raw materials used to produce EOS lip balms, such as plastics, shea butter, vitamin E, and beeswax, it’s reasonable to conclude that the product is only partially recyclable and reusable. The ingredients that are found within the actual lip balm are natural primary raw materials that make the chapstick, as a whole, biodegradable. However, the plastics that are used to produce the lip balm container are inorganic secondary raw materials, and are not biodegradable. Like mentioned previously, EOS has recently teamed up with TerraCycle to help recycle their plastic sphere containers. By doing this, the company is hoping to reduce the amount of product waste (evolutionofsmooth 1). EOS is headed in the right path with this concept. However, it would be even more environmentally beneficial if the company where to use a more sustainable material when manufacturing their lip balm containers.

Bibliography

About Olive Oil. “Olive Oil Production by Country.” 21 April 2015,

https://www.aboutoliveoil.org/olive-oil-production-by-country. Accessed 25 October 2019.

Alleman, Gayle A. “How Olive Oil is Made.” 2019,

https://recipes.howstuffworks.com/how-olive-oil-works1.htm. Accessed 17 November 2019.

Belanger. “How a Beauty Startup Went From an Incubator to Selling in 18 Countries.” 14 March,

2017, https://www.entrepreneur.com/article/290557. Accessed 16 November 2019.

Evolution of Smooth. “EOS.” 2019, https://evolutionofsmooth.com/collections/natural-organic.

Accessed 16 November 2019.

Evolution of Smooth, “Our Future is Sustainable and Transparent” 2019,

https://evolutionofsmooth.com/pages/our-story, Accessed 16 November 2019.

Evolution of Smooth, “Shea Better ™ Sustainability Program.” 2019,

https://evolutionofsmooth.com/pages/shea-better, Accessed 25 October 2019.

Gonzalez-Perez, Sergio. “The Extraction of Vegetable Oils.” Sunflower Seed, 2015,

https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/

sunflower-seed, Accessed 16 November 2019.

Grand View Research. “Beeswax Market Analysis, Market Size, Application Analysis, Regional

Outlook, Competitive Strategies, And Segment Forecasts, 2015 To 2022.” 2019,

https://www.grandviewresearch.com/industry-analysis/beeswax-market, Accessed 26

October 2019.

Index Mundi. “Coconut Oil Production by Country in 1000 MT.” 2019,

https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/sun

flower-seed, Accessed 14 November 2019.

Kokil, Suruchi. “Review on Natural LIp Balm.” Research Gate. 16 April 2016,

https://www.researchgate.net/profile/Suruchi_Kokil2/publication/30120445

1_Review_on_Natural_Lip_Balm/links/570c7e5008ae8883a1ffeed2.pdf, Accessed 14

November 2016.

Leblanc, Rick, “The Decomposition of Waste in Landfills.” 22 October 2019,

https://www.thebalancesmb.com/how-long-does-it-take-garbage-to-decom

pose-2878033, Accessed 16 November 2019.

Merrian-Webster. “Anthoxanthin.” 2019,

https://www.merriam-webster.com/dictionary/anthoxanthin, Accessed 16 November 2019.

New Directions Aromatic Inc. “Cocoa Butter - An Intensive Natural Moisturizer from the

Chocolate Tree.” 6 December 2017,

https://www.newdirectionsaromatics.com/blog/products/all-about-c

ocoa-butters.html, Accessed 25 October 2019.

Observatory of Economic Complexity. “Vitamin E, derivatives, unmixed.”

https://oec.world/en/profile/hs92/293628/, Accessed 16 November 2019.

OrganicIt’sWorthIt, “Natural vs. Organic.” 2019,

http://www.organicitsworthit.org/natural/natural-vs-organic, Accessed 25 October 2019.

PlasticsEurope, “How Plastics Are Made.” 2019,

https://www.plasticseurope.org/en/about-plastics/what-are-plastics/how-plastic

s-are-made, Accessed 16 November 2019.

Science Daily. “Vitamin E.” 2019, https://www.sciencedaily.com/terms/tocopherol.htm, Accessed

16 November 2019.

United States Patent Teller et al. “Lip Balm with Spherical Surface and Method for Producing.”

United States Patent, patent np.: US 8,888,391 B2, 2014, pp. 9-11.

Maddie Matsumoto

Sophia Ponce and Halen Hogerty

DES 040A A05

Professor Cogdell

EOS Embodied Energy Evaluation

Introduction

Dating back to the ancient Egyptians, humans continuously develop new products and techniques to preserve the healthiness of skin. Only several companies dominate the current skincare and cosmetic industries. In order to compete with the flourishing market, companies must consider unique strategies to appeal to the modern audience. One of the largest and newest brands, Evolution of Smooth (EOS), is widely known for their spherical organic lip balms. The company’s colorful, pastel aesthetics and minimalist design allows their products to stand out amongst the rows of lip care products. EOS openly supports transparency and sustainability, often promoting their own recycling program to their consumers. Although the company utilizes human labor to harvest and extract the organic ingredients within the lip balm formula, EOS primarily requires mechanical movers to manufacture the lip balm and plastic containers. These machines, including the vehicles used to transport the ingredients and EOS products as well as the mechanics involved in the recycling process, emit considerable amounts of greenhouse gasses, despite the company’s advocacy for sustainability.

Extraction of Materials

To obtain their organic raw materials, EOS relies on the labor of farmers/harvesters to source their ingredients, as well as their individual methods of processing each ingredient. The company partners with numerous sustainability-forward organizations to ensure the source of their product’s ingredients originate from local businesses. One of the main ingredients of EOS products is shea butter imported from South Africa. Shea trees take roughly 20-30 years to grow before they are ready for harvest. Each tree produces tens of kilograms of fruits containing kernels that are comprised of the vegetable oil used to make shea butter. The seeds are extracted by hot water and dried by the sun. The kernels are removed from the seeds by crushing the outer layers. Then, they are ground into a paste and boiled to separate the oil from the rest of the organic material. The congealed fat is then pressed into moulds at 30 tonnes of force by a shea butter press released by the Ministry of Agriculture, which then hardens into its final form as shea butter. The entire process from growing the seeds to extract the oil is through the kinetic energy of human labor, traditionally by women, and thermal energy from the use of high temperatures. The growth of the shea tree is an example of chemical energy. EOS directly addresses the working and living conditions of the women involved in processing their shea butter supply. The Shea Better Sustainability program is a partnership between Global Shea Alliance, the United States Agency for International Development (USAID), and the EOS supply chain that provides industry sustainability and higher quality of standards in regards to the product. Other primary ingredients of the lip balm include beeswax, essential oils, stingless bee honey. and pigments, all of which follow standard extraction and export procedures throughout the cosmetic market. Most ingredients are harvested by manual labor and are transported to factories for production and processing.

Manufacturing the Product

In addition to the harvested ingredients, chemical compounds and plastic are implemented throughout the production of the final lip balm product. Ingredients are chemically combined through thermal energy with non-organic substances in order to create the lip balm formula. They are heated up to their individual melting points and are combined into a liquefied state. There are several methods EOS implements into their cosmetic processing of their formulas. However, the particular spherical EOS lip balm has a solid construction, and therefore this section will focus on the chemical processing of solid lip balms. The formula is either directly poured into the infamous spherical containers (known as the “heat and pour” method) or into molds (known as the “bullet method”) where they are set aside to cool and solidify. The bullet method requires the extra step of removing the formula from their molds and cutting them to fit inside the plastic containers. In order to create the packaging for the iconic EOS spherical shape, plastic must first be melted into a liquid state before being blown or injected into the mould. The mould is then cooled and removed after the plastic hardens into the desired shape. Thickness of the container is determined by the mould, which is more easily controlled by the blowing process. Although the production process from raw materials to the completed product chemically transformed by thermal energy, machinery is primarily required to handle the hot temperatures. A fair use of kinetic energy is utilized in order to transport the ingredients from station to station. Processing the product, as well as transporting to and from the factories require the use of ground and air transportation.

Processing and Distribution of the Product

The company relies primarily on greenhouse gas-emitting motorized vehicles to transport products throughout the processing and distribution phases. No specifications are explicitly mentioned by the company as their modes of transportation and locations of factories that produce the lip balm. Therefore, it is assumed that EOS utilizes airplanes and trucks in order to deliver and obtain products internationally, especially as one of their main ingredients is she butter exported from South Africa. Gasoline is chemically utilized by motorized machinery and released into the atmosphere. Much of this section’s information is based on speculation due to the popularity of EOS products and processing of international goods. Considering the small size of the containers, it can be assumed that any aircraft, train, or ship designed to hold cargo has the capacity to contain millions of EOS lip balms. The same transportation methods are assumed to be utilized to transport raw materials to the factories where they are transformed into the lip balm formula and containers. Although the environmental impacts of aviation and freight cannot entirely be in the responsibility of EOS, utilizing these transportation methods contradicts the company’s values of sustainability.

Recycling and Processing of Wastes

EOS products comprise of materials that are not decomposable, therefore waste enters the garbage collection system or the company’s own recycle service. Customers are provided the choice of either throwing their lip balms in the trash after use, or recycling it through the company’s partnership program with TerraCycle. The program guarantees free shipping, therefore requiring the use of motorized vehicles to deliver the waste to TerraCycle with only a chance of the product to be reusable. Additionally, the containers for the lip balm are entirely made from plastic, and are therefore considered a non-biodegradable waste product which takes up to one thousand years to completely decompose in landfills. Recycling centers must sort plastic waste by hand based on size and resin. Electrical energy is required to power the machines used to wash and shred the plastic into fusible pieces. These pieces are melted at a range from 100-210 degrees Celsius, which are the melting points for recyclable plastics. The most popular methods for processing the plastic include heat compression and monomer processing, both of which churn the melted plastic and shape it into reusable material based on the plastic’s purity. Although it is not explicitly stated whether or not previously used and empty lip balm containers are reused by the company, EOS advocates disposing of waste materials by recycling through their program in order to ensure a possibility of a restoration of the life-cycle of a single product.

Conclusion

EOS markets their products as organic and provide options to their customers to dispose of the lip balms through their recycle program. The company partakes in partnerships with sustainability organizations in order to ensure to their audience that their ingredients are sourced with high quality standards. However, beneath the outward display of environmental consciousness, the company engages in motorized transportation to ensure their ingredients and products are obtainable at the international level, contributing to a main source of greenhouse gas emissions. The lack of information available to the public in regards to EOS’s processing and transportation methods creates an obstacle to obtaining a complete evaluation of the company’s sustainability. Regardless, the required embodied energy to produce a single spherical lip balm comprises primarily of thermal and chemical energy, along with traces of kinetic energy (human involvement). Although the lip balm itself is made of organic materials, the body of the product goes through irreversible chemical reactions, which ultimately ensures a non-sustainable waste product.

Bibliography

Benson, Heather A.E., et al. “Packaging of Cosmetic and Personal Care Products.” Cosmetic Formulation: Principles and Practice. CRC Press, 5 Apr 2019, pp. 401-412. https://books.google.com/books?hl=en&lr=&id=Dp-RDwAAQBAJ&oi=fnd&pg=PA401&dq=lip+balm+packaging&ots=VJhTIB-2Ev&sig=vO8axMzNKmrbl4qe1JzqQa4IlLY#v=onepage&q=lip%20balm%20packaging&f=false

Coggshall, W. L., and R. A Morse. Beeswax: production, harvesting, processing and products. Wicwas Press, 1984. https://www.cabdirect.org/cabdirect/abstract/19850216912

Gaertn, C. F. “Vitellaria paradoxa - C.F.Gaertn.” Plants for a Future. https://pfaf.org/user/Plant.aspx?LatinName=Vitellaria+paradoxa

Kar, A, and H.C. Mital. “The study of shea butter. VI: The extraction of shea butter.” Plant Foods for Human Nutrition, vol 31, issue 1, Mar 1981, pp. 67-69. Kar, A, and H.C. Mital. “The study of shea butter. VI: The extraction of shea butter.” Plant Foods for Human Nutrition, vol 31, issue 1, Mar 1981, pp. 67-69. https://doi.org/10.1007/BF01093889.

Koffi, B., et al. “Present and future impact of aircraft, road traffic and shipping emissions on global tropospheric ozone.” Atmospheric Chemistry and Physics, 09 Dec 2010. https://doi.org/10.5194/acp-10-11681-2010.

Marchand, Denis. “Extracting Profits With A Shea Butter Press.” IDRC Reports, Oct 1988, pp. 14-15. https://idl-bnc-idrc.dspacedirect.org/bitstream/handle/10625/23154/112600.pdf?sequence=1

“Processes, Stages, and Benefits of Plastic Recycling.” Compactor Management Company. https://www.norcalcompactors.net/processes-stages-benefits-plastic-recycling/

“Shea Better Sustainability Program.” eos Shave Creams and Hand & Body Lotions, https://evolutionofsmooth.com/pages/shea-better.

Tandale, Anjali, et al. “Lip Balm Production from Pigment Producing Actinomycetes.” IAETSD Journal For Advanced Research In Applied Sciences, vol 5, issue 4, April 2018, pp. 555-562. http://www.j-asc.com/gallery/74-april-715.pdf

Teller, Jonathan. Lip balm with spherical surface and method for producing. US20130308993A1, United States Patent and Trademark Office, 18 Nov 2014. https://patents.google.com/patent/US20130308993A1/en.

Yusof, Atuyah Athirah Binti, et al. “Production of Lip Balm From Stingless Bee

Honey.” Maldives National Journal of Research, vol. 1, no. 1, June 2018, pp. 57-72. http://saruna.mnu.edu.mv/jspui/handle/123456789/4295

Sophia Ponce

Des 40A, Sec 05

Professor Cogdell

4 December 2019

EOS Lip Balm Sphere: Waste and Emissions

The EOS lip balm sphere is a product that is sold worldwide and its unique design has added to its ever increasing popularity. The distinctive spherical container has created high demand for this product. The Evolution of Smooth [EOS] company has branded itself as innovative and eco-friendly. The advertisement of their company as environmentally friendly and the unusual design of the EOS lip balm sphere made it immediately popular in the United States when it launched and it is now sold throughout the world[1]. Unfortunately, the EOS lip balm sphere, although small in size, has a large impact on the environment due to the amount of waste and emissions that comes from harvesting materials, manufacturing the balm and its sphere, and the problems related to its eventual disposal.

The EOS lip balm contains three main ingredients: shea butter, cocoa butter, and beeswax. Each of these ingredients requires separate steps to manufacture and process the final product. When shea nuts have been harvested, EOS uses water that is collected from a local water source and dumped into large tubs where the shea nuts are rinsed of impurities. The rinsing process requires approximately 200 pounds of water to wash a 100 pound bag of shea nuts. The nuts are rinsed two times with fresh water, and after each rinse the water is thrown out. After the shea nuts are washed, they dry out in the sun. During the drying process, approximately 20% of the shea nuts are deemed unusable and are thrown out[2]. After the drying process is complete, the shea nuts are crushed by hand and then they are roasted and cooled repeatedly until the nuts reach a paste-like consistency. EOS has chosen to use a wood burning oven for this process to maintain temperature and better quality control. However, wood burning ovens emit volatile organic compounds [VOCs]. VOCs are released from burning fuel such as gasoline, wood, coal, or natural gas. As of 2013, about 72% of all greenhouse gas emissions comes from energy usage and about half of that comes from fuel combustion such as wood burning[3]. The transportation of shea butter to the United States also adds to the overall VOC emissions related to the EOS lip balm sphere. The EOS company has a Shea Better Sustainability Program that allows them to source the shea butter from Burkina Faso, Africa, which is approximately 6000 miles away from the United States. According to the Center for Biological Diversity, aircraft transportation accounted for about 11% of CO2 emissions from U.S. transportation and 3 percent of the United States total CO2 emissions in 2016. Like shea butter, the second main ingredient of cocoa butter requires almost exactly the same processing, therefore it has the same issue of emitting large amounts of greenhouse gases [GHG][4]. The cocoa butter used by EOS is harvested and processed in West Africa, in Ghana and Nigeria. With cocoa nuts, the same quality control must be done, and approximately 1/4th of the cocoa nuts are deemed unusable. One of the last main ingredients of the EOS lip balm is beeswax. In the beekeeping process of making beeswax, many drugs and pesticides are used to control honey bee diseases and deter other predatory bugs[5]. One main pesticide used is called acaricide, which is used to control mite predators. As for the processing, it is not very different for shea or cocoa. The beeswax must be washed and rinsed several times, each time using clean water. The beeswax must be heated on low heat for several hours; this is usually done on a gas burning stove adding to the CO2 emissions. Unlike the other two ingredients, EOS does not cite their sources of beeswax therefore it is hard to determine the amount of GHG emitted in the transport of this ingredient. Based on a 2003 data survey; conducted by The Food and Agriculture Organization of the United Nations, most beeswax exports is from Africa and China. If the beeswax used by EOS is sourced from either Africa or China, this is another contributing factor that may add pollutants created by material transport. All of these processes needed to produce the main ingredients for EOS lip balm creates approximately 30% waste in production and about 30-40% of GHG emissions for transport overall. Unfortunately, the harvesting and processing of these raw materials is not the only producer of waste and emissions created by this lip balm.

The manufacturing of all of the secondary materials to make the EOS lip balm is also a major factor in the product’s waste and emissions production. The EOS lip balm spheres are made in the United States; after all of the ingredients are shipped to the U.S. factories, the EOS lip balm sphere can be assembled. The container of the lip balm is mainly composed of acrylonitrile butadiene styrene [ABS plastic], a common thermoplastic polymer[6]. ABS plastic is thermally sound, allowing it to withstand high temperatures. The exterior of the lip balm is coated in polyethylene. According to the Center for Climate and Energy Solutions, plastics account for the majority of U.S. CO2 emissions into the atmosphere. The process for manufacturing the container and final product are machine based. First, all of the ingredients are placed in a large basin which is connected to an Automatic Lip Balm Filling Machine with Chilling Tunnel[7]. The ingredients are then heated until well combined. The liquid solution is then fed through a tube that places the correct amount of liquid into the lip balm container. The lip balm goes through multiple heating and cooling processing to produce the correct consistency. The machine then caps the lip balm and it is ready to ship. The manufacturing process is dependent on electricity, which accounts for 31% of all GHG produced by energy sources. According to a survey in 2013 by the Center for Climate and Energy Solutions, electricity and heat were the primary sources of greenhouse gas emissions. After everything is processed, the lip balms are shipped out to stores around the world, adding to the CO2 emissions that comes from the transportation of this product. The manufacturing of the EOS lip balm sphere accounts for about 20% of the waste and emissions that is produced. However, this is not where the waste and emissions created by this product ends.

After the EOS lip balm is produced, it is then sold and used by the consumer. The last thing that people think of in terms of the life cycle of a product is where it goes after it is used. However the disposal of cosmetic items plays a large part in the environmental impact of the product. As of August 2019, EOS lip balms sold approximately 9.2 million units across the United States[8]. Used EOS lip balm spheres will either go to the landfill or are recycled; both of these options will produce large amounts of waste and/or emissions through processing. Whether the spheres are recycled or taken to a landfill, transportation is involved, adding to the CO2 emissions of fossil fuels emitted in the life cycle of this product, but there are many more issues related to the waste disposal of cosmetic products. Many of the issues with cosmetics waste is that most containers contain residue of the product. The leftover residue requires extra processing and cleaning to approve it for the recycling process. Due to the current economic and political climate, many recycling plants are restricting more and more products from being recycled. Therefore many cosmetic containers are being deemed unfit to be recycled, resulting in many cosmetic products ending up in the landfill[9]. At the landfill, most objects are left to sit; otherwise they are burned in a large and high powered burner. Plastic products that are burned or left to sit in the landfill emit large amounts of GHGs and this will add to the impact on the environment that these products are creating in the United States[10]. To combat this issue, in September 2018, EOS has partnered with the company TerraCycle, a company that specializes in recycling hard-to-recycle materials. In order to participate in Terracycle recycling, the EOS lip balm customer will ship their empty EOS containers in the mail. Once collected, Terracycle cleans and melts the packaging into plastic pellets that can then be remolded to make new recycled products[11]. The recycling process still emits CO2 emissions into the atmosphere, however it is less than the emissions that come from sending them to the landfill[10]. One problem with this program is that it requires active participation by the consumer without any immediate incentive. Other companies, like LUSH, reward their customers with incentives to recycle by offering rewards or free products for participating. The LUSH recycle program has had positive results due to the incentive it gives its customers. Since EOS does not offer an equally enticing reward for using the Terracycle program, the collaboration of these two companies has not yet been shown to reduce waste.

The EOS company makes many claims about striving for sustainability and reducing the amount of waste that they produce, but they still have not resolved the many issues on the environment that their product creates as a result of its manufacturing and processing. Not only is the processing and harvesting of the materials used to make the lip balm environmentally detrimental to the planet but the waste and recycling processes amount to a shocking 50% of the waste and emissions produced from this product. The impact of EOS’s innovative lip balm sphere was immediate in the popular market. For EOS to be truly eco-friendly, the company must look at its effects on the environment from cradle to grave, from production and manufacturing to waste removal and responsible recycling.

Footnotes

1 Segran, Elizabeth. “The Untold Story Of How Lip Balm Upstart EOS Outdid Chapstick.” Fast Company, Fast Company, 20 Oct. 2016, https://www.fastcompany.com/3063333/the-untold-story-of-how-lip-balm-upstart-eos-outdid-chapstick.

2 “Shea Butter- Women’s Gold.” SEMAFO foundation. 2017. https://fondationsemafo.org/wp-content/uploads/2017/01/KariteDepliant2016-Ang-WEB.pdf

3 “Global Emissions.” Center for Climate and Energy Solutions, 4 Jan. 2018, https://www.c2es.org/content/international-emissions/.

4 Beckett, et al. “Beckett's Industrial Chocolate Manufacture and Use /. Fifth ed”. Ch 3. Chichester, West Sussex, UK :: John Wiley & Sons, 2017. Web.

5 “PRODUCTION AND TRADE OF BEESWAX.” Food and Agriculture Organization of the United Nations(FAO) ,http://www.fao.org/3/i0842e/i0842e12.pdf.

6 “US8888391B2 - Lip Balm with Spherical Surface and Method for Producing.” Google Patents, Google, https://patents.google.com/patent/US8888391B2/en

7 L, Jinyi. “Full Automatic Lip Balm Filling Machine With Chilling Tunnel.” Full Automatic Lip Balm Filling Machine With Chilling Tunnel, http://www.cosmetic-fillingmachine.com/sale-10613167-full-automatic-lip-balm-filling-machine-with-chilling-tunnel.html

8 Shahbandeh, M. “Lip Balm/Treatment Brand Unit Sales U.S. 2019.” Statista, 13 Sept. 2019, https://www.statista.com/statistics/463381/us-unit-sales-of-leading-lip-balm-treatment-brands/.

9 Cinelli, et al. “Cosmetic Packaging to Save the Environment: Future Perspectives.” MDPI, Multidisciplinary Digital Publishing Institute, 15 Apr. 2019, https://www.mdpi.com/2079-9284/6/2/26.

10 “Global Emissions.” Center for Climate and Energy Solutions, 4 Jan. 2018, https://www.c2es.org/content/international-emissions/.

11 Li, Yi. "Business model innovation of social entrepreneurship firm: A case study of TerraCycle." 2014 International Conference on Management Science & Engineering 21th Annual Conference Proceedings. IEEE, 2014.

Bibliography

Beckett, et al. “Beckett's Industrial Chocolate Manufacture and Use /. Fifth ed”. Ch 3.

Chichester, West Sussex, UK :: John Wiley & Sons, 2017. Web.

Cinelli, et al. “Cosmetic Packaging to Save the Environment: Future Perspectives.” MDPI,

Multidisciplinary Digital Publishing Institute, 15 Apr. 2019, https://www.mdpi.com/2079-9284/6/2/26.

“Eos Shave Creams and Hand & Body Lotions.” Shea Better Sustainability Program. Eos,

https://evolutionofsmooth.com/pages/shea-better.

“Eos Recycling Program.” TerraCycle, https://www.terracycle.com/en-US/brigades/eos.

“Global Emissions.” Center for Climate and Energy Solutions, 4 Jan. 2018,

https://www.c2es.org/content/international-emissions/.

L, Jinyi. “Full Automatic Lip Balm Filling Machine With Chilling Tunnel.” Full Automatic Lip

Balm Filling Machine With Chilling Tunnel,http://www.cosmetic-fillingmachine.com/sale-10613167-full-automatic-lip-balm-filling-machine-with-chilling-tunnel.html.

Li, Yi. "Business model innovation of social entrepreneurship firm: A case study of TerraCycle."

2014 International Conference on Management Science & Engineering 21th Annual Conference Proceedings. IEEE, 2014.

Pardee, Vera. “AIRPLANE EMISSIONS.” Center for Biological Diversity,

“PRODUCTION AND TRADE OF BEESWAX.” Food and Agriculture Organization of the

United Nations(FAO) , http://www.fao.org/3/i0842e/i0842e12.pdf.

“Reduce, Reuse, Recycle.” LUSH

https://www.lushusa.com/stories/article_reduce-reuse-recycle.html.

Shahbandeh, M. “Lip Balm/Treatment Brand Unit Sales U.S. 2019.” Statista, 13 Sept. 2019,

https://www.statista.com/statistics/463381/us-unit-sales-of-leading-lip-balm-treatment-brands/.

“Shea Butter- Women’s Gold.” SEMAFO foundation. 2017.

https://fondationsemafo.org/wp-content/uploads/2017/01/KariteDepliant2016-Ang-WEB.pdf

“US8888391B2 - Lip Balm with Spherical Surface and Method for Producing.” Google Patents,