Design Life-Cycle

assess.design.(don't)consume

Israel Rodriguez

12/5/18

DES 40A

Professor Cogdell

The Raw Materials for Vans Canvas Old Skool Shoes

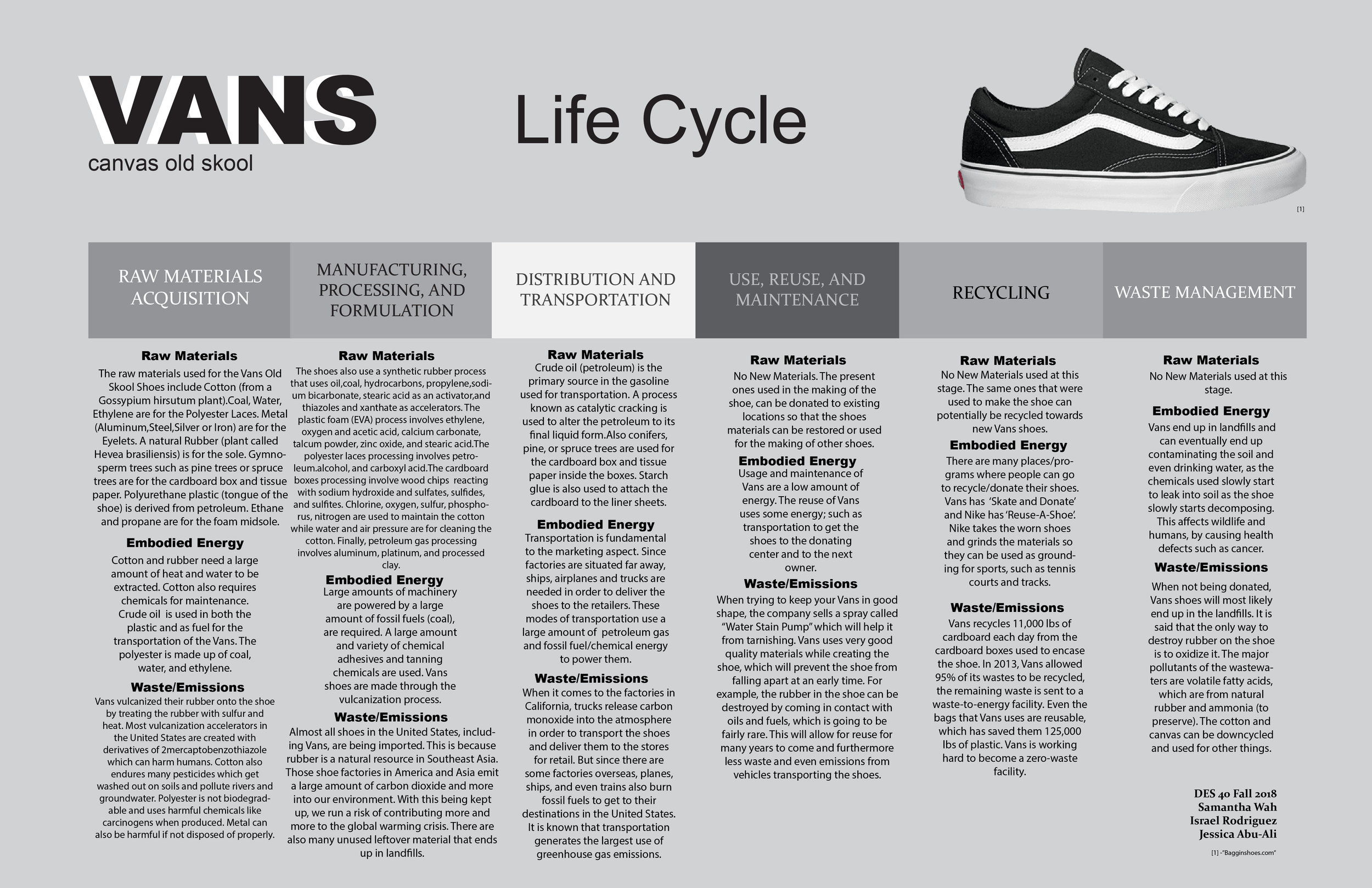

As we know shoes like any other product have to go through an extensive process to be converted from the raw materials that they are made of into the final product. In terms of consumer demand,the popularity of a shoe will determine how much of the Earth’s raw materials are used up in the shoe process. In particular, Vans Old Skool Canvas shoes have started to become more popular among college students, maybe because they are a simple and minimal shoe that can be combined with just about any outfit despite their potential to be of negative impact to our environment. There are many different materials that go into making these Vans Old Skool Shoes.Vans official website states these shoes are made of a “durable canvas upper, padded tongue and lining, metal eyelets and Vans original Waffle Outsole”(“Canvas Old Skool”), however where do we get these materials and the other’s not mentioned? Within this paper, we will look at the various raw materials that go into the extraction or creation,production,and transportation of the Vans Old Skool Canvas shoes and how these materials are altered along the way to reach the final product. By doing so we can hopefully get a better understanding of what our products are made of so that hopefully we can make smarter decisions as consumers to reduce the environmental damage that production causes.

One of the most important materials in making the Old Skool Vans is the rubber.Rubber is needed to make the gum sole and rubber foxing tape that goes around the main shoe. According to Neil Shoemaker, “lead designer of skate shoes for Vans” (NewComb 1), he says that the mixing “process starts by taking a certain percentage of raw gum rubber and raw synthetic gum rubber”(NewComb 1 ). Since Vans shoes were initially made to support the growing skateboarding culture of the 1970s, using two types of rubber would allow for better grip on the bottom of the shoe sole with the griptape of the skateboard. In addition, using a mixture of the two rubbers is cheaper and more efficient because natural rubber is more expensive and takes longer to harvest. (NewComb 1).Natural rubber comes from a plant called the Hevea brasiliensis also referred to as the rubber tree.This rubber tree is primarily found in the rainforest of Amazon region of South America which include locations such as “Brazil, Venezuela, Ecuador, Colombia, Peru, and Bolivia”(“Species Profile”). The tree produces a white liquid sap called latex, when part of the bark is detached. (“Species Profile”). However, when natural rubber (latex) is acquired you also have to go through process known as vulcanization. During this process the rubber undergoes heat and pressure to form it into usable material.On the other hand, synthetic rubber is initially mixed with oil,coal and other hydrocarbons. The resulting product called naphtha is then combined with a natural gas which I was not able to find.(“Production of Synthetic Rubber”)The naphtha is then polymerized with a monomer such as propylene then those two are polymerized with steam and a catalyst to form the solid rubber which in our case would be polyisoprene rubber (“Production of Synthetic Rubber). The synthetic rubber used is most likely polyisoprene because “Mineral-filled polyisoprene finds applications in footwear, sponges, and sporting goods”(“Polyisoprene”). Afterwards, the synthetic and natural rubber go through a compression molding process. In compression molding, “the rubber strips are compressed around a mold under pressure and vulcanized to form to the mold”(Freudenrich 1). Since rubber is considered to be weak in its natural form, sulfur is added along with applied heat to create a “crosslink between chains”(“How To Vulcanize”) and increase the resistance and strength of the rubber. Other substances used in the vulcanization process involve zinc oxide or stearic acid as activators, thiazoles and xanthate as accelerators (a salt)(“Materials Engineering”), as well as color pigments. However, I was not able to find what particular dye the Vans shoes used.Nonetheless, there are many materials that go into the top portion of these Vans shoes and we shall now see that the other major material called plastic provides the structure on which the top part lies.

The plastic used in these particular set of Vans shoes is important because the plastic material provides for the shape that the shoe will take on. In general plastic is “produced by the conversion of natural products or by the synthesis from primary chemicals generally coming from oil, natural gas, or coal”(“Plastics” ).Within my research however, I found out that open cell foam which is made out of Polyurethane plastic is used “in the tongues and collars of shoes” (“Foam For Shoes”) so I assume Vans uses this kind of foam plastic for their shoes. This particular foam is made out of polyurethane and originates from crude oil (fossil fuel) otherwise known as petroleum. The origin of crude oil are the leftover “remains of prehistoric algae and zooplankton whose remains settled on the bottom of an Ocean or Lake”(“Dept,Editorial”). Now we need to look at the foam inside the shoe that comprises the midsole of the shoe. It is safe to assume that since “Midsoles of shoes are all made from closed cell foam”(“Foam For Shoes”), Vans shoes also use this kind of foam. Although I could not find the particular closed cell foam that is used for the Vans Old Skool Shoes, I generalized that Vans uses a foam called ethylene vinyl acetate because “EVA foam materials are one of the most popular material as shoe insole”(“EVA Foam Material”).The reason for this is because this foam has “excellent cushioning & shock absorption”(“EVA Foam Material”). Continuing along, the ethylene vinyl acetate is commonly abbreviated as EVA. Ethylene is derived from the steam cracking of ethane and propane” (Lazonby).Vinyl acetate is “prepared from ethylene by reaction with oxygen and acetic acid over a palladium catalyst”(“Britannica”).Within the production of plastic, we also have materials such as calcium carbonate and talcum powder, zinc oxide, and stearic acid that are added along with heat and pressure to transform the EVA into the final plastic. Now that we have looked at the structures that make up the base of the shoe we move upwards to the outer appearance of the shoe that make the design of the shoe most known to people because of the famous Vans wave logo.

The top portion of the shoe consist of a raw material called canvas otherwise known as cotton cloth. The origins of cotton come from the seeds of a plant called Gossypium hirsutum. Cotton primarily grows in Mexico and Central America and “has been developed for extensive use in the United States, accounting for more than 95 percent of U.S. production”(“Cotton Incorporated”). Cotton is a natural raw element; however, it does require additional moisture, and heat to produce the final material. The process of transforming cotton uses a large amount of water such that “some experts contend that cotton is the largest user of water among all agricultural commodities” (“Cotton”).After extraction, cotton goes to the factory to undergo ginning where it “goes through dryers to reduce moisture content...and then through cleaning equipment to remove foreign matter”(“Truents”). Also we need to consider pesticides such as “aldicarb, phorate, methamidophos and endosulfan”(“Cotton & Pesticides”) that are used to maintain cotton.Although I could not find the exact raw materials used in the pesticides process, I found that the most common materials used to make pesticides include “Chlorine, oxygen, sulfur, phosphorus, nitrogen”(“Pesticide”). Since phorate is a liquid pesticide it is safe to assume that the cotton that Vans used contained kerosene or petroleum particles.(“Pesticide”).Along with cotton, the top portion of shoe also consist of laces made of polyester that are of equal importance to the upper part of the shoe.

Now we come to the polyester laces that are of important because they provide the user a way to adjust to their specific need of tightness. The laces that Vans uses are a synthetic made polyester fiber. The most common synthetic fiber is polyethylene terephthalate (PET). The process used to make synthetic polyester involves using”coal, petroleum, air and water”(“How Polyester is Made”). The primary raw material principle “used in the manufacture of polyester is ethylene which is derived from petroleum”(“Polyester”). Although I was not able to find what process Vans uses to make their laces, according to Craftech industries, a chemical reaction involving high temperatures "within a vacuum is the most common process in making polyester. (“How Polyester is Made” ). After this process a “petroleum byproduct, alcohol, and carboxylic acid are mixed to form a compound known as monomer or ester” (“How Polyester is Made”). After polymerization, the material is stretched using heat into long fibers to strengthen the durability between the polyester fibers. In addition to the laces themselves, we should also look at the material that holds the laces together, since they too require a whole new different material that is quite important for the structure of the shoe.

The metal eyelet although often neglected as a part of the shoe, allows for the user to adjust their shoe and make sure their shoes don't slip off their feet. The metal eyelets used in our particular shoes could be composed of a variety of materials because some metals that are often utilized to make eyelets consist of aluminum, iron,steel, silver, or copper. (“The Basic”) Although, metals aren’t found in the final form that is needed for production, they are found “buried in rock with deposits of other metals and they exist not as pure elements but oxides”(“The Science of Metals”). The metal ore is first extracted and then goes through refinement to separate the unwanted metal from the useful one. This is usually done by mechanical processing “using water to wash away unwanted materials, acid treatment, heating and electric processing”(“The Science of Metals”).Unfortunately I was not able to find the particular acid that is used for the process.Now that we have looked at the overall process of constructing the shoe, now these shoes are ready to go to the market; however, before the shoes are ready to be shipped some new raw materials have to gathered to construct the boxes for the shoe.

Within the packaging stage, we need to make sure the shoes are presentable and secure in their box before they are transported. It is likely that vans shoe boxes are built with corrugated cardboard because corrugated cardboard use more layers and are “durable, lightweight,and cost effective” (“Packages”), thus saving Vans Inc money and protecting their product’s better. I found that “pine trees provide the primary raw material used to make corrugated cardboard”(“Corrugated Cardboard ”).The process begins with placing tree bark chips in a “high-pressure tank called a batch digester” (“Corrugated Cardboard ”) where they are mixed with a solution containing sodium hydroxide, and other ionic compounds such as sulfates, sulfides, and sulfites(“Corrugated Cardboard ”).Afterwards, cornstarch glue is used to combine the cardboard to the liner sheets. In addition, we also need to look at the wrapping paper inside the box. I found that the paper typically used in shoe boxes is called a translucent wrapping/tissue paper. The tissue paper is typically “produced in special mills from wood pulp” (Wrapping Paper 1 ). The trees used to make the paper are categorized as softwood trees which come from gymnosperm trees,”usually evergreen conifers, like pine or spruce”(“Hardwood vs Softwood”). Now that the boxes have been formed, these Vans shoes are ready to be transported to the customers.

Now we come to final stage of the process which involves transporting the Vans shoes to its designated location. The vehicles utilized for transportation ,use gasoline which is derived from crude oil. Crude oil is “liquid obtained from the refinement of petroleum”(“Gasoline”). The crude oil is stored within “porous rock, or reservoir rock”(“Gasoline”). After the oil gets extracted, the oil undergoes a process known as catalytic cracking.Within this process a “catalyst, high temperature, and increased pressure”(“Gasoline” ) are used to alter the composition of the petroleum. The process uses “aluminum, platinum, and processed clay”(“Gasoline”) , as catalysts in order to convert the large molecules into smaller ones suitable for gasoline. I found that aluminum primarily comes from a ore(rock) called bauxite.Caustic soda (sodium hydroxide) is used to “dissolve the aluminum compounds found in the bauxite”(“Aluminum”). Other chemicals such as sodium, fluorine, and carbon are used in the metal smelting process. Finally, after all of these processes have been done, Vans Old Skool shoes are ready to be delivered to their desired location.

As we have noted there are many different materials that go into the making of these shoes;however, we need to consider the fact that many people do not know where they come from, thus it is important to be informed of what our products are made of. By getting informed of a product’s life cycle and materials, we can hopefully become more cautious of what we are buying because there are certain things like Vans shoes that for the most part are not recyclable.Although Vans has recently started to offer options for people to drop off their shoes to existing store locations so that the shoes materials can be restored or used for the making of other shoes.(“Vans Skate”)for the most part they are not recyclable.Vans shoes and shoes in general are often thrown out because shoes are not often popularized as a recyclable product. Hopefully by investigating the materials that go into our shoes we as consumers can slowly begin to make wiser decisions on our buying habits so we can help the Earth from getting depleted of all its natural resources for product’s like Vans shoes that have very little reusable qualities after its usage.

Bibliography

Albert, Zerkowitz. Canvas Shoes With Rubber Soles. US3029823A. United States Patent Office, Apr. 17, 1962. https://patents.google.com/patent/US3029823A/en?q=canvas&q=shoes&oq=canvas+shoes.

“Aluminum.” How Products Are Made, www.madehow.com/Volume-5/Aluminum.html.

Bagginshoes.com,bagginshoes.com/usd/vans-vans-old-skool-black-white-0d3hy28.html.

Britannica, The Editors of Encyclopaedia. “Polyvinyl Acetate.” Encyclopedia Britannica, Encyclopedia Britannica, Inc., 6 Apr. 2016, www.britannica.com/science/polyvinyl-acetate.

“Canvas Old Skool | Shop Shoes At Vans.” Vans USA - English, www.vans.com/shop/old-skool-canvas-black-true-white#hero=0.

Collector, Sole. The Science Behind Sneaker Rubber. Sole Collector. 11 May 2015. https://solecollector.com/news/2015/05/science-behind-sneaker-rubber.

“Corrugated Cardboard.” How Products Are Made, www.madehow.com/Volume-1/Corrugated-Cardboard.html.

“Cotton” How Products Are Made. 29 October 2018. http://www.madehow.com/Volume-6/Cotton.html

Cotton Incorporated. “The Classification of Cotton.” Razor Tie Artery Foundation Announce New Joint Venture Recordings | Razor & Tie, Rovi Corporation, web.archive.org/web/20070407185400/http://www.cottoninc.com/ClassificationofCotton/?Pg=2#Nature.

“Cotton.” WWF, World Wildlife Fund, www.worldwildlife.org/industries/cotton.

Truents.

“Cotton Fibers - the King of Fibers - Textile School.” Textile School, 28 Mar. 2018, www.textileschool.com/129/cotton-fibers-the-king-of-fibers/.

“Cotton & Pesticides.” Shop Ethical, www.ethical.org.au/3.4.2/get-informed/issues/cotton-pesticides/.

CROW. “Polymer Properties Database.” Polystyrene, polymerdatabase.com/polymer%20chemistry/Common%20Vulc%20Accel.html.

Dept, Editorial. “What Is Crude Oil? A Detailed Explanation on This Essential Fossil Fuel.” OilPrice.com, 8 June 2018, oilprice.com/Energy/Crude-Oil/What-Is-Crude-Oil-A-Detailed-Explanation-On-This-Essential-Fossil-Fuel.html.

“EVA Foam Material: The Best Definitive Guide.” FOAMTECH, 2 Aug. 2017, www.foamtechchina.com/eva-foam-material/.

“Foam For Shoes”. How Shoes are Made : The Sneaker Factory. 28 February 2018. https://sneakerfactory.net/sneakers/2018/02/foam-for-shoes/.

Freudenrich, Ph.D. Craig. “How Rubber Works.” HowStuffWorks Science, HowStuffWorks, 28 June 2018, science.howstuffworks.com/rubber4.html.

“Hardwood vs Softwood.” Mountain Bike vs Road Bike - Difference and Comparison | Diffen, www.diffen.com/difference/Hardwood_vs_Softwood.

“How Polyester is Made”. CraftTech Industries. 29 October 2018. http://www.craftechind.com/how-is-polyester-made/

“How Vans Shoes are Made: Vulcanized Construction”. How Shoes are Made : The Sneaker Factory. SneakerFactory.net. 2 October, 2018.https://sneakerfactory.net/sneakers/2018/10/how-vans-shoes-are-made/.

“How to Vulcanize Rubber Making Rubber Stronger Through Vulcanization.” The Properties and Uses of a Neoprene Rubber Sheet, www.rubbercal.com/industrial-rubber/how-to-vulcanize-rubber/.

Lazonby, John. “Ethene (Ethylene).” The Essential Chemical Industry Online, www.essentialchemicalindustry.org/chemicals/ethene.html.

“Materials Engineering.” Pitting Corrosion [SubsTech], 27 July 2013, www.substech.com/dokuwiki/doku.php?id=vulcanization_of_rubber.

Newcomb, Tim. “Watch How Vans Makes Its Secret Skate Shoe Rubber”. Popular Mechanics. Hernst Communication Inc. 8 Mar 2016. https://www.popularmechanics.com/adventure/sports/a19752/vans-skate-shoe-rubber/

Packages, Better. “Carton Sealing Solutions.” How Does Water-Activated Tape Work?, inbound.betterpackages.com/blog/whats-the-difference-cardboard-vs.-corrugated-cartons.

“Pesticide.” How Products Are Made, www.madehow.com/Volume-1/Pesticide.html.

“Plastics.” The Basics: Polymer Definition and Properties, plastics.americanchemistry.com/How-Plastics-Are-Made/.

“Polyisoprene Elastomers.” IHS Markit, May 2017, ihsmarkit.com/products/polyisoprenfe-elastomers-chemical-economics-handbook.html.

“Polyester”. How Products Are Made. 29 October 2018. Advameg,Inc.http://www.madehow.com/Volume-2/Polyester.html

“Porous EVA.” Porex, www.porex.com/technologies/materials/porous-plastics/ethyl-vinyl-acetate/.

“Production of Synthetic Rubber.” SIEMENS, Jan. 2013, w3.siemens.com/mcms/sensor-systems/CaseStudies/CS_Butyl_Rubber_2013-01_en_Web.pdf.

“Rubber”.Rubber and Other Latex Products. 29 October 2018. http://www.faculty.ucr.edu/~legneref/botany/rubber.html

“Species Profile: Rubber Tree.” Rainforest Alliance, Rainforest Alliance, www.rainforest-alliance.org/species/rubber-tree.

“The Basic Raw Materials Involved With Metal Fabrication.” ThomasNet® - Product Sourcing and Supplier Discovery Platform, www.thomasnet.com/articles/custom-manufacturing-fabricating/materials-metal-fabrication.

“The Science of Metals: a Simple Introduction.” Explain That Stuff, 6 Feb. 2018, www.explainthatstuff.com/introduction-to-metals.html.

“Gasoline.” How Products Are Made, www.madehow.com/Volume-2/Gasoline.html.

The Igbo, Sometimes (Especially Formerly) Referred to as Ibo, Are One of the Largest Single Ethnicities in Africa, www.faculty.ucr.edu/~legneref/botany/rubber.htm.

“VANS SKATE AND DONATE.” Vans - Ireland - English, www.vans.ie/skateanddonate.html.

W.L Smith. Rubber Shoe Sole. US2251468A. United States Patent Office, April 5, 1939. https://patentimages.storage.googleapis.com/c4/4e/bf/e7d279aa209c31/US2251468.pdf.

“Wrapping Paper.” How Products Are Made, www.madehow.com/Volume-6/Wrapping-Paper.html.

Samantha Wah

12/5/18

DES 40A

Professor Cogdell

Energy In The Vans Life Cycle

Vans footwear was successfully created to be comfortable, durable and stylish. Some of the most talented athletes are sponsored by Vans who help endorse and strengthen the authenticity of their brand and the trust with their customers. “Through event sponsorships and a chain of skateboarding parks, Vans has forged a unique niche in the booming youth sportswear market. The company's unflagging commitment to tracking the latest trends has put it in an excellent position to grab an even larger market share as it heads into the 21st century,” (Reference for Business). However, though Vans has revolutionized fashion/culture around footwear, they contribute a large amount to the greenhouse effect. Vans is a secondary industry that uses raw materials to make something new. The manufacturing and disposal stages of the Vans shoe life cycle causes the largest environmental impact, with all of the stages having negative effects. In the manufacturing stage, machinery and chemicals in large quantities are necessary for production. In the disposal stage, 38% of Vans shoes will end up in landfills and will contaminate the soil and drinking water over time. This harms the environment because humans and animals can consume the contaminated soil/water.

The life cycle of Vans begins with the acquisition of raw materials. These materials include cotton for the canvas, plastic for the foam, polyester for the laces, metal for the eyelets, and paper/cardboard for the packaging box. Cotton and rubber need an extensive amount of heat and water in their processes of extraction. Cotton also needs to use chemicals to maintain its properties. Crude oil (obtained from porous/reservoir rock families) is used in both the plastic and as fuel for transportation of the Vans. Other gasses used are ethane and propane. The synthetic polyester material is mainly made up of coal, water, and ethylene.

These materials are then used in the production stage. In this stage of manufacturing, large amounts of machinery and chemicals, powered by a large amount of fossil fuels, are required. These fossil fuels produce greenhouse gases when burned. Coal is usually the main source of energy used to power these factories because it is very cheap in comparison to oil or other energy sources. The burning of coal affects our atmosphere by producing carbon dioxide which contributes the greenhouse effect. The problem we are now facing is that the burning of fossil fuels: coal, oil and natural gas, done by humans is increasing the concentrations of greenhouse gases which enhances the greenhouse effect and contributes to the warming of the Earth. To further explain the greenhouse effect: “[first] Solar radiation reaches the Earth's atmosphere and heats the Earth, next heat radiates from Earth towards space, then some of this heat is trapped by greenhouse gases in the atmosphere; keeping the Earth warm enough to sustain life, then human activities such as burning fossil fuels, agriculture and land clearing are increasing the amount of greenhouse gases released into the atmosphere, and lastly, this is traps extra heat, causing the Earth's temperature to rise,” (Australian Government Department of the Environment and Energy). Companies like Vans add to this effect tremendously, “on average, the production of one shoe produces 30 pounds of carbon dioxide and there are more than 15 billion shoes produced each year,” (The Shoe Industry). Besides coal, chemicals used also add to the greenhouse effect during the manufacturing stage. A large amount and variety of chemical adhesives and tanning chemicals are used, such as chlorinated phenols, tribromphenol, chlorinated paraffins, dimethylfumarate, etc.. The downside is that it is easy for these chemicals to be leaked into the waterways and into the environment through the factory discharges. In turn, this can harm the wild life as well as the health of humans. Overall, the manufacturing production stage of Vans shoes threatens the environment with the amounts of carbon dioxide produced and the leakage of the chemicals that are used.

Vans shoes are made through the vulcanization process. Vulcanization is the process of heating raw rubber to cure it. This process creates cross links inside the rubber compound which bonds it together. Vulcanizing turns the once stretchable rubber to a tough and stretchable rubber that is ready to wear. In the vulcanizing oven the shoe is heated to around 110˚C where the nylon and polyester fabrics melts. “Uppers must be made of heat-resistant materials like suede, leather, and cotton canvas with metal hardware,” (How Shoes Are Made: The Sneaker Factory). This vulcanizing process must be made in a factory equipped with many specific machines. Besides the production of the Vans shoe, the energy that goes into the packaging stage of the cardboard box of Vans also creates a negative effect on the environment.

Transportation is another aspect that is usually ignored, also increases the amount of carbon dioxide emissions. Transportation is fundamental to the marketing aspect, so these emissions can’t always be removed. “Most footwear manufacturing companies choose to build factories in third world companies for cheap labour. Since these factories are situated far away, transportation such as ships, airplanes and trucks are needed in order to deliver the goods to the retailers,” (The Shoe Industry). This is detrimental to the environment because the transportation and exporting of the shoes is a essential part of the creation and success of Vans.

The last stage in the Vans shoe life cycle is the disposal stage. This is the stage with second largest environmental impact. “According to statistics, 38% of students in Fletcher’s Meadow secondary school throw out their old shoes and 42% donate them. For the 38% who throw out their shoes, these shoes end up in landfills and can eventually end up contaminating the soil and even drinking water, much like many other materials that are thrown out, as the chemicals used in the manufacturing slowly start to leak into soil as the shoe slowly starts decomposing,” (The Shoe Industry). This affects wildlife and humans because biomagnification and bioaccumulation can occur in the contaminated water or plants that they may have consumed, which can lead to health defects such as cancer. Considering the 42% who donate them, programs have been created to make donating shoes a more chosen option. To help prevent and lower these negative environmental impacts, people can recycle or donate their used Vans so that they do not end up in landfills. There are many places and programs where people can go to recycle or donate their shoes. For example, Vans has its own program called ‘Skate and Donate’. Their program advocates the reuse and recycling of shoes to ensure that Vans don’t end up in landfills. They explain the ease for customers to drop off their used shoes to a local store, no matter the condition the shoes are in. “All of the shoes you bring to one of our participating stores will either be reused or recycled in order to help preserve our environment,” (Vans). Their program makes a point in working together to help decrease the negative impacts on the environment, offering a 10% discount on your next purchase as an incentive. Another example is Nike’s ‘Reuse-A-Shoe’. The unique thing about this program is that Nike takes the worn shoes and grinds the materials so they can be used as grounding for sports, such as tennis courts and tracks. Both of the programs also include locations where you can go to drop off your shoes to make it as easy as possible. Besides donating, educating yourself and others about the negative impacts of the shoe industry on the environment is another helpful way to reduce the effects. Being vocal and raising awareness to these environmental impacts is simple, but it makes a significant difference.

With all of these negative effects to the environment and waste mentioned, Vans are beginning to shift by making sustainability changes in their company. “We operate offices, distribution centers and retail stores around the world. Our operations have an impact on the environment: they create waste, use water, and contribute to climate change by using energy from fossil fuels. Our commitment to youth means we must change,” (Vans Sustainability). This shows how they have became aware of the harm they are causing and that the Green Sole Operation is planning on improving the effects. “Vans also sponsored this Designmatters project, bringing together for the first time two upper-term courses, Design for Sustainability and Product Design 6: Innovation Studio. Students enrolled in both courses and worked on different aspects of the Vans challenge in each studio,” (Design Matters At At Center). Vans is shifting their offices to be LEED certified by incorporating renewable energy, water efficient technologies, and sustainable materials. In addition, their distribution centers were built using energy efficient lighting, their equipment was built using recycled/regional materials, and they have become a zero waste to landfill facility. They also have made sustainable changes in their retail stores, held events to raise awareness, and plan to take even more steps in improving their sustainability performance in the future.

The Vans life cycle from beginning to end requires a lot of energy to occur. The energy that goes into and out of the process creates very negative effects to the environment and tremendously adds to the greenhouse effect. Out of all of the stages in the Vans life cycle, the manufacturing and disposal stages cause the largest environmental impact. However, the Vans company is taking steps in the right direction to be more sustainable.

Bibliography

Chu, Jennifer. “Footwear's (Carbon) Footprint.” MIT News, 22 May 2013, news.mit.edu/2013/footwear-carbon-footprint-0522.

“Environmental Impact.” The Shoe Industry, Weebly, theshoeindustry.weebly.com/environmental-impact.html.

“Greenhouse Effect.” Other Degradable Polymers, Common Wealth of Australia, www.environment.gov.au/climate-change/climate-science-data/climate-science/greenhou se-effect.

“How Vans Shoes Are Made: Vulcanized Construction.” Page Redirection, 21 Oct. 2018, sneakerfactory.net/sneakers/2018/10/how-vans-shoes-are-made/.

Lazar, Lance. “Top 5 Most Common Materials Used to Make Shoes.” Kicks Guide, 17 Oct. 2017, www.kicksguide.com/top-5-materials-used-to-make-shoes/.

“Sustainable Ecosystem for the Future of Vans.” Designmatters, 8 June 2018, designmattersatartcenter.org/proj/vans/.

“Vans Old Skool Black/ White.” Baggins Blog, bagginsshoes.com/usd/vans-vans-old-skool-black-white-0d3hy28.html.

“Vans Sustainability | Eco Friendly Clothing, Charities & More.” Vans USA - English, www.vans.com/sustainability.html.

“Vans, Inc. - Company Profile, Information, Business Description, History, Background Information on Vans, Inc.” Reference for Business, www.referenceforbusiness.com/history2/77/Vans-Inc.html.

“Vans® | Official Site | Free Shipping & Returns.” Vans USA - English, www.vans.com/

Jessica Abu-Ali

12/5/18

Des 40A

Professor Cogdell

Vans Life Cycle: Waste and Emissions

Vans has many different shoes that have been dubbed “skater” shoes throughout the years and have included many designs that have become mainstream. Vans has recently created those same shoes in a more environmentally friendly product but for this essay I will be focusing on the different types of wastes that the company Vans produces through their processes for the “Canvas Old Skool” shoe and how it affects the environment. Though my responsibility in the group assignment is to record the wastes and emissions from this product, all of our three topics connect together. For example, we need to know the raw materials in order to find out their wastes, while energy is a big part in the process of creating waste and emissions. For this essay I will be dealing with Vans choices in material and how the wastes and emissions that come from the “Canvas Old Skool” has affected the environment negatively by contributing to global warming before they decided to achieve a green method of waste, all while giving attention to those negative affects through waterborne waste, airborne wastes, and solid wastes.

Acquiring the basic raw materials for the “Canvas Old Skool” gives off wastes and emissions from the chemicals being used once you find them and mold them into what you need through the manufacturing and processing. When separating the materials within the shoe you come out with rubber for the sole, canvas and cotton, polyester shoe laces, and metal eyelets. There are Vans factories in both California and overseas in Asia, specifically Vietnam and China. When we look at rubber, there was an open and closed anaerobic wastewater treatment system for a rubber-processing factory in Vietnam testing the greenhouse gas emissions. It showed recent results that “94.4% of the total chemical oxygen demand and 18.1% of ammonia nitrogen was removed.” (Environmental Technology, 2018) Originally, rubber is extracted from trees; the most well known tree would be the Hevea Brasiliensis that originates in South America. There is also synthetic rubber and Vans uses both types for their shoe. Synthetic rubber is “produced in a similar way to plastics, by a chemical process known as polymerization” (Recycling Rubber, 1) Vans vulcanizes this rubber onto the shoe, which by definition is treating the rubber with sulfur and heat which allows for greater strength, elasticity, and durability. Most vulcanization accelerators in the United States are created with derivatives of 2 mercaptobenzothizole. The major effect that can arise from exposure to 2 mercaptobenzothizole in humans is allergic contact derma-titis. “In a study of dermatitis among athletes, 43 young adults with eczematous skin lesions suggesting allergic contact dermatitis were patch-tested and 21% tested positive for 2-mercaptobenzothiazole.” (Monographs, 77) As you can see, vulcanization of rubber for Vans gives off negative emissions. When cotton is being grown, it endures many pesticides which get washed out on soils and pollute rivers and groundwater. “Cotton production (also) contributes to climate change because industrial fertilizers are produced using quantities of finite energy sources, releasing large amounts of carbon dioxide. Furthermore, the excessive application of nitrates to agricultural land leads to their being transformed into nitrous oxide, a greenhouse gas that is 300 times more destructive than CO2 in terms of global warming” (Organic Cotton, 2018) Cotton is known to be natural and sustainable, but when you realize how much is put into its acquisition and the chemicals they use it is not thought to have a positive impact on its emissions and wastes. Polyester is also a very dangerous fiber because firstly, it is not bio-degradable and its waste goes into the ecosystem and pollutes our ocean. Polyester production takes place in countries like China, which strategically is where one of Vans factories are. The “air and water pollution created by polyester production, is often discharged untreated. This results in significant water pollution. It harms communities in the close and far vicinities (due to downstream and downwind) of manufacturing plants.” (The House of Pillows) Thankfully, polyester is used only for the shoelaces of the “Canvas Old Skool”, but those shoelaces become waste that is not biodegradable, and that really affects our environment negatively. For the end of the shoelaces, they are metal eyelets. It was hard to find out what metal is was exactly, but most eyelets are composed of brass or stainless steel. “Steel and aluminum usually degrades when it is brought into contact with water. So to avoid this problem, one hundred percent stainless steel, Nickel or brass is recommended.” (Thomas Net) On a bright side, metals like stainless steel are 60% recyclable. “In 2007 27 million tons of stainless steel were produced, however as the use of stainless steel expands as stainless steel produced today will not necessarily be recycled for 20-30 years.” (British Stainless Steel Association) This is an old statistic, but we are continually using more of this metal and that is why the waste would take so long to be recycled. Vans only uses this for the eyelets, so it is not a huge amount of metal, therefore less waste contributing to the whole picture from other sources. Those shoe factories in both America and Asia emit a large amount of carbon dioxide and more into our environment. With this being kept up, we run a risk of contributing more and more to the global warming crisis. The process of acquiring raw material and the actual manufacturing of the shoe has negative impacts to our environment because of what I iterated above, but there are also negative wastes and emissions in transportation and positive maintenance results.

The Vans Company has a big importance in transportation for distribution from far overseas trips to close nearby drop offs, while also keeping a good record for its use and maintenance. Because there are factories overseas in Vietnam and China, a good amount of shoes are being imported. “Finished shoes are placed into an ocean freight container. “ (Sneaker Factory) These ship and even planes or trains are used and are burning fossil fuel emissions into the atmosphere to get to their destination in the United States. Factories in the United States use trucks that release carbon monoxide into the atmosphere as well. Even though they are quicker stops, there is still an emission. “The transportation sector generates the largest share of greenhouse gas emissions. Over 90% of the fuel used for transportation is petroleum based, which includes gasoline and diesel.” (EPA) You also have to factor in that emissions can rise and fall throughout time for transportation due to changes in the economy, the price of fuel, and other factors. An early estimate of the net worth of Vans is around $2 billion. For the usage and maintenance, Vans sells a spray called “Water Stain Pump” which helps the shoe from tarnishing. Vans uses very good quality material as stated above that will prevent the shoe from falling apart at an early time. For example, coming in contact with oils and fuels can destroy the rubber in the shoe, which is going to be a fairly rare occurrence. This could be a good and a bad thing because it can last long enough for you to not even have to recycle it because the shoe will allow for reuse for many years to come for less waste, but on the other hand if you do not want the shoe anymore, its waste will most likely end up in landfills if not donated. Discussing this reuse of the shoe is a great segway into the topic of recycling and the waste and management in the long run.

Vans has become a more eco-friendly company so their recycling practices have changed very effectively by trying to reduce and manage its wastes and carbon footprints that have affected the environment so negatively. Since 2013, Vans has become a zero waste facility. 95% of their waste is being recycled. Vans has a good process in recycling the cardboard boxes that the shoe comes in, they “recycle more than 11,000 lbs. of cardboard each day, saving enough energy to power the average American home for more than a year. (They) reuse as many inbound shipping boxes as possible for outbound shipping, saving more than 120,000 lbs. of cardboard a year.” (Vans Sustainability) They are currently searching for more and more ways to reduce waste. There is even their “SKATE-AND-DONATE” program that offers to collect and donate your used Vans shoes. This is to hopefully create an infinite loop of recycling. They do not want all the shoes to end up in landfills, which end up being the demise for these shoes. They say that our “shoes can still have a second chance, or their materials can be recovered.” (Vans “Off the Wall”) For rubber, they say that one of the ways to destroy rubber is to oxidize it, just like most materials. It exposes it to ozone that will later turn into dioxide when accepting the third atom. Natural rubber in fact is generally “quite resistant to oxidation. This is undoubtedly due to the natural antioxidants which are present in the non-rubber hydrocarbon constituents.” (Symposium on Aging of Rubbers, 5) Cotton and canvas can be down cycled and used for other things.

Making Vans has a high environmental cost because of the acquisition and manufacturing of the materials or wastes and a lot of emissions come from transporting and importing the shoes to the United States. It is a good thing that Vans has stepped its game up and decided to strive for a zero waste environment, which brings them up the scale on sustainability for shoes. Seeing the impact of what even a small part of the shoe does to the environment is eye opening and interesting and hopefully while time passes on we will address all of these issues head on until we progress.

Bibliography

“2-Mercaptobenzothiazole.” Monographs, 2004, monographs.iarc.fr/wp-content/uploads/2018/06/mono115-02.pdf.

Bhawan, Gandhi. “Recycling Rubber .” Practical Action, www.seas.columbia.edu/earth/RRC/documents/recycling_rubber.pdf.

“BRITISH STAINLESS STEEL ASSOCIATION.” What Is Stainless Steel?, www.bssa.org.uk/sectors.php?id=99.

“Characteristics of Greenhouse Gas Emissions from Ana.” Environmental Technology, 2018, www.tandfonline.com/doi/full/10.1080/09593330.2018.1459872.

gs graphic-studio. “The Risks of Cotton Farming.” Organic Cotton - Risk of Cotton Faming, 2018, organiccotton.org/oc/Cotton-general/Impact-of-cotton/Risk-of-cotton-farming.php.

“Importing Shoes : HTS Shoe Import Duty and Shoe Tariffs.” Sneaker Factory, 15 Mar. 2016, sneakerfactory.net/sneakers/2015/02/importing-shoes-hts-shoe-import-duty-shoe-tariffs/.

“More about Eyelets.” ThomasNet® - Product Sourcing and Supplier Discovery Platform, www.thomasnet.com/about/eyelets-26902403.html.

“Sources of Greenhouse Gas Emissions.” EPA, Environmental Protection Agency, 9 Oct. 2018, www.epa.gov/ghgemissions/sources-greenhouse-gas-emissions.

“Symposium on Aging of Rubbers.” Google Books, books.google.com/books?id=_Lc-d9WanVsC&pg=PA4&lpg=PA4&dq=the%2Bonly%2Bway%2Bto%2Bdestroy%2Brubber%2Bis%2Bto%2Boxidize%2Bit%2Batoms&source=bl&ots=Un1lKMlnke&sig=CzfSiwdC2pSk6Ie3q1zfJtog80w&hl=en&sa=X&ved=2ahUKEwia3PuP4YrfAhVLMqwKHb_3Ab0Q6AEwBnoECAgQAQ#v=onepage&q=the%20only%20way%20to%20destroy%20rubber%20is%20to%20oxidize%20it%20atoms&f=false.

“The Dangers of Polyester: It's Simply Not Worth It.” The House of Pillows, 17 Oct. 2018, www.thehouseofpillows.eu/polyester-production-blog/.

“Vans Sustainability | Eco Friendly Clothing, Charities & More.” Vans USA - English, www.vans.com/sustainability.html.