Design Life-Cycle

assess.design.(don't)consume

Irene Kim

Professor Cogdell

DES 40A

03/08/2023

Reed Diffuser Materials

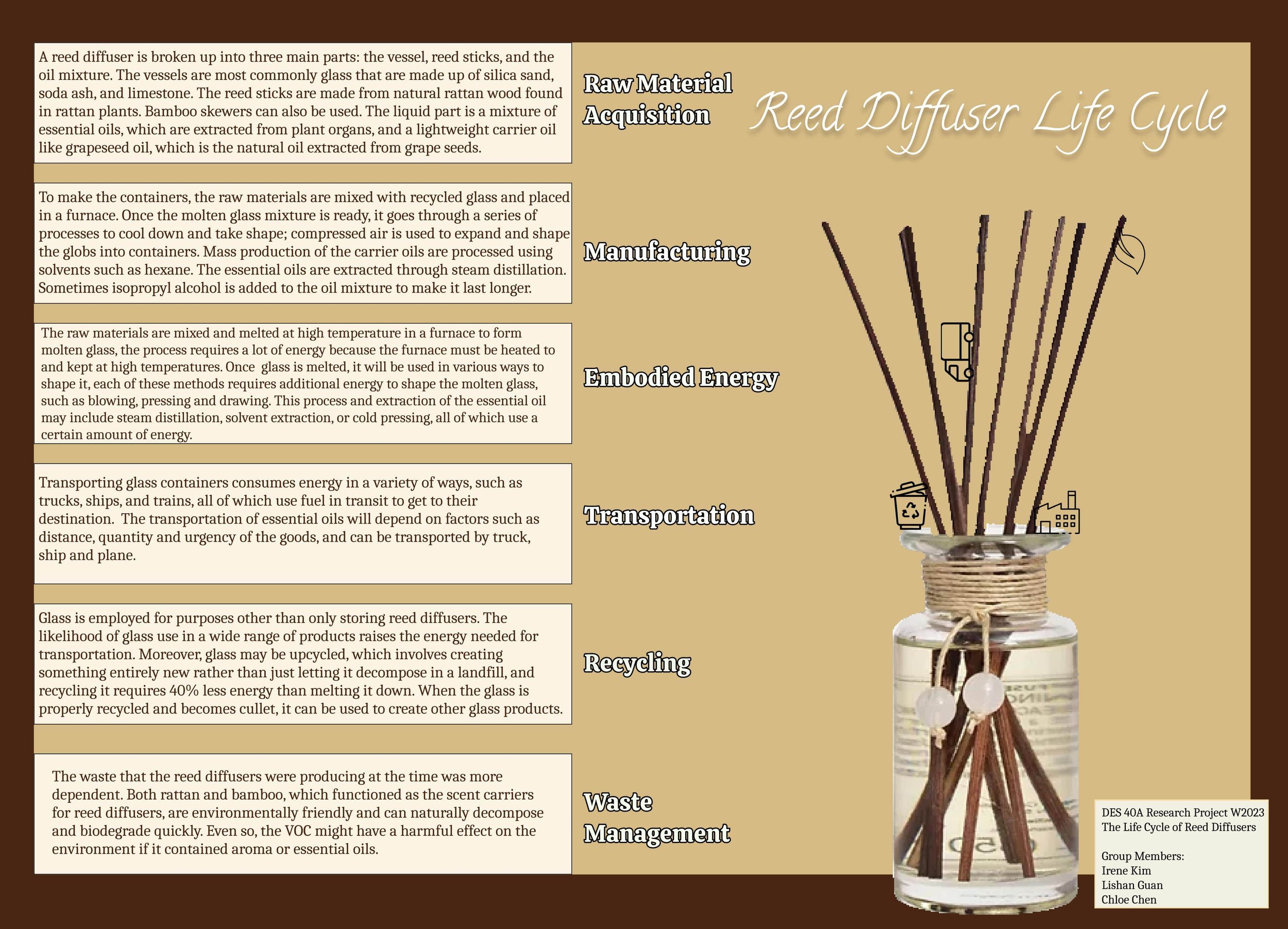

Home fragrance and aromatherapy date back to over 3500 years BC. During those times, aromatics were used in a variety of things, such as religious purposes, medicines, ritual and healing purposes, and more. Aromatherapy also takes different forms, a common one being reed diffusers. In ancient China, reed diffusers were used as a form of incense. In the Buddhist tradition, the reeds were lit to cultivate a peaceful and embracing environment for meditation and prayer. Since then, reed diffusers have evolved to be effortless to set up yet extremely effective, causing them to be more prevalent in home fragrance. Additionally, reed diffusers are a much safer option as they do not include an open flame. These diffusers are made with materials directly extracted or collected from the natural environment, and go through processes that increase sustainability.

The reed diffuser has an intriguing way of operating, and this process can only begin once the main pieces, which are composed of different raw materials, are assembled into place. Rather than being entirely made in factories, reed diffusers are often assembled at home. This is because the parts that make up a reed diffuser are common materials that people are likely to have already, and also because the diffusers are incredibly simple to set up. More specifically, reed diffusers work as an example of capillary action and are made from materials that can be sorted into three main parts: the vessel/container, reed sticks, and oils. Once the oils are poured into the vessel, the reed sticks are inserted inside the vessel. Each reed stick contains multiple cellular sections that run from top to bottom, which allows the oils to be absorbed from the bottom and carried to the top surface of the reed. The fragrance is then dispersed into the air. The vessels are usually in the form of glass containers or bottles that are made from natural and abundant materials, the major ones being limestone, silica sand, and soda ash. The traditional reed sticks are made of all-natural rattan wood. The liquid oil mixture inside the diffusers is a blend of any thin carrier oil and essential oils. More often than not, the raw materials that make the glass, reed sticks, and oil mixtures, are predominately created from abundant natural resources.

The glass used for the reed diffuser vessel is made of raw resources that are supplied by nature itself, which then go through an entire process to transform into the actual containers. As mentioned before, glass packaging is primarily made up of silica sand, soda ash, and limestone. Silica sand includes sand and gravels with high silicon dioxide content. The sand must have a high proportion of silica (a chemical compound composed of silicon and oxygen, mainly known as silicon dioxide) to be used in the manufacture of glass. Silicon dioxide is commonly recognized in the forms of quartz such as the mineral quartz, and sometimes in other rarer mineral forms known as tridymite (found in cavities in felsic volcanic rocks), but can also be found naturally in water, stone, and the earth. Quartz is found in large quantities as silica sands after millions of years of mountain-building cycles and erosion. It is most commonly extracted from the ground through open pit mining methods and is mainly located in places like the Alps, Brazil, or even Madagascar. High-grade silica sand is usually found as unconsolidated deposits below layers of soil and overburden. Silica sand itself is produced mainly in the United States, Italy, and France. Besides silica sand, soda ash is another essential component of glass. It occurs in many kinds of mineral waters, specifically in the mineral deposits of lake brines and certain springs. The richest source of soda ash is trona, a water-soluble mineral that Wyoming has the largest deposit of. Pure soda ash is produced by extracting naturally occurring trona ore and then processing it through filtering, concentration, crystallization, and drying. Soda ash can also be produced from sodium-carbonate-bearing brines or surface mineralization. In addition to silica sand and soda ash, limestone is needed to make glass. Limestone is a sedimentary rock that is commonly composed of shell fragments, coral, algal, and other organic debris; it principally consists of minerals like calcium carbonate (calcite). Modern limestones are commonly formed from marine sediment deposited on sea floors and are found in reefs, tidal flats, lagoons, and even windblown dunes. Limestones are continuing to form in environments such as the Caribbean Sea, Indian Ocean, Pacific Ocean islands, and more. Apart from these three natural components of glass, recycled glass, also known as cullet, is incorporated into the manufacture of the diffuser vessel. Internal cullet refers to waste glass produced from breakage or rejection by a quality control process during the manufacturing process, while external cullet is waste glass that has been collected or reprocessed for recycling. This broken or waste glass is used as a replacement for minerals, which helps to reduce reliance on other precious resources and save large quantities of energy and toxic emissions. Cullet is generally of the same composition as the mineral mixture but is collected to be crushed, sorted, cleaned of contamination, and melted with other raw materials to transform into new glass products. In the overall manufacturing and processing cycle, the main raw materials mixed with recycled glass are transported to batch preparation, then placed into the furnace to melt. Once the molten glass mixture is ready to be taken out of the furnace, it flows into a refiner to cool down and get rid of air bubbles. The molten glass then goes through the forehearth then the feeder, which makes globs that will shape into glass containers. The final product begins to take shape once the globs are dropped into molds in the forming machine. Compressed air is used to shape and expand the globs into containers. Each jar then goes through the annealing process that strengthens the glass to make it more durable. The finished glass product is then wrapped with bubble wrap (made out of polyethylene) and transported by trucks or trains. Towards the end of its life cycle, the glass containers are reused after glass reprocessing, at which they are cleaned, crushed, melted, and added to a cullet pile to be transported back to batch preparation, all to become a new glass product again. Recognizing this entire ongoing process helps get a better understanding of what materials go into glass containers, and how the raw materials offer environmental and economic benefits throughout their life cycles. Glass jars and containers are infinitely recyclable since glass itself is a sustainable, fully recyclable material. With the help of glass recycling, related air and water pollution are reduced, landfills have more room for other waste materials, and the preservation of natural resources advance. The chemical energy required to melt the raw materials has already been expended, which means that rather than manufacturing new glass from silica, soda ash, and limestone, the use of cullet can reduce energy consumption by a significant amount. This also reduces greenhouse gas emissions. The glass container itself is multipurpose and can be used over and over again. The natural materials used for the glass portion of the diffuser add to the overall sustainability of the product, and the earth’s ecosystems.

Compared to glass, the raw materials used to make reed sticks are a bit simpler. The most common type of reed stick used in reed diffusers is called rattan reed sticks, which are made out of rattan wood. This material is made from the rattan plant which is a type of climbing palm that mainly grows in the tropical regions of Southeast Asia and parts of Africa and Australia. The reed is the inner, wood-like portion of the rattan plant that is more porous and absorbent than the outside cane layer. Once the rattan has been harvested, the collecting process requires the rattan to be cut first, then the core rattan needs to be peeled out. In the case that natural rattan poles are discolored or infected by the time they reach processing units, prophylactic treatment is given after the extraction. After being cut directly from the vine, they undergo a drying process where they become durable and lightweight, hence why rattan is effectively used for reed diffusers. Because the rattan reeds are made in a straightforward manner, there is limited information on the actual processing of the product. Once the collected material is ready for consumer use, they are distributed and transported in bulk by truck or shipped overseas. Commercial reed diffusers typically use rattan reed sticks over bamboo skewers since they have clear channels and do not have nodes that interrupt the flow of the oils. All natural reed sticks do not require certain materials for the maintenance of the product, and high-quality rattan reeds can last up to six months. The reeds are biodegradable as they are made from all organic material. So once fully used, they can be easily discarded since they naturally decompose without inflicting any harm to the environment. The part of the reed that isn’t used in the manufacturing process can also be recycled into fertilizer for the fields or added into compost piles. All in all, rattan plants are most commonly used for the stick portion of a diffuser and are sustainably extracted from natural environments.

The final part of a reed diffuser is the liquid mixture, which consists of thin carrier oil and essential oils. Lightweight oils are used since heavy ones can clog the reed sticks and take longer to travel up the diffuser. A highly recommended base oil is grapeseed oil, but safflower and sweet almond oil are also commonly used. The lightweight base oil has the ideal absorption characteristics and is suitable for reed diffusers because of its neutral scent that blends well with most essential oils. Grapeseed oil is a natural oil that is extracted from the grape seeds leftover from winemaking, so when the grapes are pressed for their juices to be fermented into wine, the seeds that are left behind get pressed for the oil. Its production primarily occurs in wine-growing regions and is heavily around the Mediterranean Sea. Grapeseed oils can be pressed from grape varieties like chardonnay or riesling grapes. The wine grapes are usually picked by hand or machine at vineyard sites. Traditionally, grapevine producers hand harvest using knives or shears to cut bunches. Then the grapes are placed in collection baskets and transferred to the winery or special warehouses. Mechanical harvest of the grapes consists of machines traveling through vineyard rows to shake the vines that make the grapes fall to a conveyor belt. Once collected, foreign materials like spiderwebs are removed and the grapes are gathered into a special deposit to be transferred to the winery. The leftover seeds from this process are extracted using a cold-pressing extraction method to retain as many health-beneficial components as possible. Mass production of grapeseed oil is processed in factories using solvents such as hexane, which helps to extract oil from the seed. These solvents are removed from the grapeseed oil during the manufacturing process, but very small amounts may remain. The product is then bottled and sold, which is done mostly using trucks. Generally, organic grapeseed oil is manufactured without the use of raw materials derived from genetically modified materials and is biodegradable and relatively sustainable. It has a maximum shelf life of one year when stored properly. Besides carrier oil, essential oils are added to create the reed diffuser mixture. Economical essential oils with strong scents such as lavender, lemon, clove, and peppermint are most preferred for the diffusers, but it ultimately depends on personal preference. Essential oils are natural oils that are extracted from different parts of plants such as buds, flowers, leaves, seeds, and more. Using peppermint essential oil (my personal favorite) as an example, the oil is taken from the flowering parts and leaves of the peppermint plant. The plant is a natural cross between spearmint and watermint and is planted using rhizomes or stolons instead of seeds. It is also a perennial which means that the mint fields do not have to be replanted often. That being said, the first cut of harvested fresh leaves is normally intended for essential oil production. The peppermint plant is widely spread and cultivated throughout the world but is primarily grown throughout North America and Europe. The essential oils from the naturally grown mint leaves are extracted through distillation; larger companies use a process known as steam distillation to distill essential oils in bulk. They are distributed and transported only by ground transportation such as trucks and trains. Sometimes a fixative like an isopropyl alcohol is added to the carrier and essential oil mixture to make it last longer in the diffuser. Over time, essential oils start to oxidize which makes the aromatic quality gradually weaker. Although it is recommended to contact a local waste disposal site for instructions on how to dispose of this mixture properly, leftover diffuser oil can be used for other purposes such as body scrubs, which can be made by adding coffee grinds. All parts of the reed diffuser, even the oils, are made from natural resources that provide little to no harm to the environment.

After taking a thorough look into the raw materials that are used to make the vessel, reed sticks, and diffuser oil, as well as their life cycles, it is concluded that reed diffusers are environment friendly, sustainable, and safe overall. It is especially important for diffusers to not produce soot and other toxins, since they are to be fully inhaled and ingested. While researching and learning all about the natural and resource efficient materials of a reed diffuser, I began recommending reed diffusers to all my loved ones.

Bibliography

Courridge, Dalia. “How to Make Reed Diffusers: An Easy DIY Starter Guide.” Abbey Essentials, Abbey Essentials, 10 May 2022, https://abbeyessentials.co.uk/blogs/news/how-to-make-reed-diffusers-an-easy-diy-guide-and-your-questions-answered.

Garrity, Amanda. “You Can Make a Homemade Reed Diffuser in Just 5 Easy Steps.” Good Housekeeping, Good Housekeeping, 29 Nov. 2021, www.goodhousekeeping.com/home/a30730962/homemade-reed-diffuser/.

New York, LAFCO. “What Is a Reed Diffuser?” LAFCO New York, 27 Jan. 2022, blog.lafco.com/what-is-a-reed-diffuser/.

CandleScience. “How to Make Reed Diffusers.” CandleScience, www.candlescience.com/learning/how-to-make-reed-diffusers/. Accessed 6 Feb. 2023.

“Exporting Essential Oils for Food to Europe.” CBI, https://www.cbi.eu/market-information/natural-food-additives/essentials-oils-food. Accessed 6 Feb. 2023.

Fragrances, Iberchem. “What to Know before Using a Reed Diffuser - Iberchem.” What to Know before Using a Reed Diffuser, iberchem.com/reed_diffuser/. Accessed 6 Feb. 2023.

Georgia Melbourne Sep 18, Georgia, et al. “How Are Essential Oils Made?” Volant Europe, 2021, volantaroma.com/blogs/guides/how-are-essential-oils-made.

Admin. “Top 5 Popular Types of Rattan Materials Frequently Used to Manufacture Handicraft Products.” Simple Decor, 9 July 2022, www.simpledecor.vn/top-5-popular-types-of-rattan-materials-frequently-used-to-manufacture-handicraft-products/.

Ellis, Claire. “The Synthetics Series: An Explanation + Exploration of Synthetic Fragrances.” Malibu Apothecary, Malibu Apothecary, 27 Jan. 2021, malibuapothecary.com/blogs/clean-candles/history-origin-of-synthetic-fragrances.

Container Recycling Institute - CRI. www.container-recycling.org/assets/pdfs/glass/LCA-GPI2010.pdf.

Grant, Amy. “Can Vegetable Oil Be Composted - Learn about Composting Vegetable Oil.” Gardening Know How, 29 Aug. 2022, www.gardeningknowhow.com/composting/ingredients/vegetable-oil-in-compost.htm.

“Limestone.” Geology, geology.com/rocks/limestone.shtml.

DiffuserEssentials. “Disposing of Essential Oils.” Diffuser Essentials, Diffuser Essentials, 20 Apr. 2018, diffuseressentials.com/disposing-essential-oils/.

“Sustainability & the Environment.” Glass Sustainability & the Environment - Glass Alliance Europe, www.glassallianceeurope.eu/en/environment.

“Let's Make a Bottle: Understanding the Glass Bottle Formation Process.” Glass, Plastic, Metal Bottles and Caps Wholesale - O.Berk®, www.oberk.com/packaging-crash-course/glass-bottle-formation.

Correspondent, OKA. “The History of Rattan: Ideas.” OKA, OKA, 7 Sept. 2021, www.oka.com/uk/ideas/lifestyle/rattan-history.

Chloe Chen

Des 40A

Professor Cogdell

15 March 2023

The Embodied Energy of Reed Diffuser

Although it didn't get its name until the 20th century, aromatherapy has been around for thousands of years. Historically, it using to keep in good health at home, cultivate sentimentality, and make people feel good. Today, a reed diffuser is a popular home aromatherapy product that consists of a container containing scented oil and a set of porous reed sticks that absorb the oil and diffuse the scent into the air. Unlike candles, the reed diffuser is flameless and provides a continuous, subtle scent that can last for several weeks or even months. In addition to their aromatic properties, reed diffusers can also be used for decorative purposes as the container and reeds are styled to match any home decor. They are easy to use and require little maintenance, making them a convenient way to refresh your living space. Overall, A popular and convenient home fragrance choice, the Reed Diffuser provides a constant, subtle fragrance and decorative element to any room, making it a versatile addition to any home. The purpose of this research paper is to demonstrate the specific energy of the reed diffuser life cycle. The embodied energy of reed diffusers is a significant environmental concern due to the energy required to produce and transport the materials used. There is a need for increased awareness and consideration of embodied energy in the design and use of reed diffusers to reduce the impact on the environment. It is crucial to study its sustainability, as sustainability can determine the formulation and count the amount of each ingredient, throughout the life of the reed diffuser, the energy products being used contain essential oils (essential oils), reeds, and narrow-necked glass bottles. Among them, glass packaging, reeds, and other chemical aromatherapy materials are the most important parts of the product. Materials must go through multiple processes to develop products. These processes all involve matter and energy. This article will explain the energy used in the production, distribution, and use phases.

It's important to know how much processing the important raw material must undergo before a glass bottle can be produced. When checking the resources, the manufacturing process of the reed diffuser glass bottle has not been announced on the Internet, although traditional glassblowing and blow-molding glass methods are still used by some custom applications, most glass bottle manufacturing is an automated process. So, there will introduce the usual production methods. The website information of O-I company that specializes in container glass products, there shows specific materials for making glass, “Glass raw material is made from three natural ingredients: silica sand, soda ash, and limestone. These materials are mixed with recycled glass and are known as "cullet". Broken glass is the main ingredient in glass bottles and containers.” According to the information from O-I Company which also demonstrated how the main composed of the glass containers, “Globally, glass containers contain an average of 38% recycled glass, while glass bottles made in Europe contain up to 90% recycled glass, the data showed.” As the data provided by Thomas company which has served as North America’s number one industrial sourcing platform, “Typically, largely comprised of silica, with about 10% each of calcium oxide and lime. Small amounts of aluminum oxide, ferric oxide, barium oxide, sulfur trioxide, and magnesia also account for about 5% of soda-lime glass. Before melting, a cullet is added to the stock, accounting for anywhere between 15 and 60% of the final glass composition.” The batch mixture goes into the furnace. In the article “Are Electric Furnaces the Future of Glass Manufacturing?” by Krista Grayson, she mentioned that “the furnace is heated to about 1,300 to 1,550 degrees Celsius by gas and electricity to create the conditions to melt the glass.” From the information of “How Are Glass Bottles Made?” provided by Thomas, it was noticed that “When the molten glass mixture comes out of the furnace, it flows into the refiner, which is essentially a storage tank covered with a large crown to hold the heat. When molten glass reaches between 1050 and 1200 degrees Celsius, it is said to be in the plastic stage, and it is at this stage that pressure-blowing formation begins.” Gobs are glass cut and shaped into cylinders with shear blades. As Thomas mentioned in their guides, they involved, “The cut gob falls under the action of gravity and rolls through the appropriate channel to the die. A metal plunger presses the gob into a blank mold where it takes on the shape of the mold and is then called a parison. Next, the parison is moved into the final mold, where it is blown into the mold to assume its final dimensions. This method is usually used for wide-mouth glass containers but can also use to manufacture thin-necked bottles.” Compressed air is used to shape and expand the gob onto a glass container at this point in the manufacturing process, dropping to roughly 700 degrees Celsius. Bottles are often internally treated after molding, a process that makes the interior of the bottle more chemically resistant, which is an important reason if the bottle is intended to hold alcohol or other degrading substances. Internal treatments typically include treating the bottle with a gas mixture of fluorocarbons to strengthen the surface or reduce surface friction. Each glass bottle goes through an annealing step because some bottles may suffer from stress because of unequal cooling rates. The annealing process reheats the container and is then gradually cooled to release stress and make the bottle stronger. The information in the section “Cold End Processes” in the article “How Are Glass Bottles Made?” relates to how the end of the process of the glass bottle is, “At the stage when the bottles or glass containers are inspected and packaged in glass production, inspection is often done by a combination of automated and mechanical inspection, to ensure the integrity of the final product. Common faults include cracks in the glass, which is important to catch because they may compromise the component. Packaging methods will vary from factory to factory depending on the specific type of bottle and the size of the production run.” For reed diffuser packaging, the glass may be the best choice because glass is chemically inert and less permeable to water than plastic, making it better able to withstand processes such as pasteurization.

Unlike the process of making the glass bottle, the reed diffuser has other important parts of the material that are chosen for reed diffuser sticks. Reed diffuser sticks are typically made from natural materials such as rattan, bamboo, or other types of wood. These materials are chosen for their porous nature, which allows them to absorb and then bundled together to create a reed diffuser. Some manufacturers may also use synthetic materials for their diffuser sticks, but natural material is more commonly used. But some situations depend on the usage affection, bamboo rods are less effective than reeds, The channels in bamboo rods are interrupted by nodes which prevent the oil from traveling up the length of the bamboo and dissipating at the top. Natural rattan reeds have clear channels which allow for faster and more even scent distribution. The most common raw material is natural rattan. Rattan is a type of palm plant that grows in tropical regions and is known for its strength and flexibility. The vines are hollow in the middle, so cut the reeds from the vines and let them dry. This process makes them very strong and lightweight, which is why rattan is an excellent diffuser material. The rattan is harvested and then processed into thin, straight sticks that are suitable for use in diffusers. In general, reeds are considered to have relatively low energy compared to other materials. This is because they usually come from renewable resources and require minimal treatment before use. In addition, the lightweight of reeds reduces the energy required to transport them. Overall, the embodied energy of reeds used for diffusers is relatively low, making them a more environmentally friendly choice for producing diffusers than some other materials.

The most important part of the reed diffuser is the carrier contained in it, called the “essential oil.” Which is usually a blend of natural and synthetic ingredients. The embodied energy of essential oil used in a reed diffuser can vary based on several factors such as the type of essential oil, the method of extraction used, and how it is transported from production to distribution. The plant extraction process of reed diffusers has not been published on the Internet, so here are some extraction methods of other essential oil companies for reference. To get the most out of the plant material, many companies and factories steam distill the plants to extract the essential oils. Flowering plants are harvested with a hay cutter, which cuts and grinds the tops of the plants. The shredded material is blown into barrels on a truck that rides alongside the harvester. The bottom of this barrel is specially designed with perforated pipes for the introduction of steam, which constitutes the main body of the still, and the barrel is carried by car to the processing area to start a series of processes. Essential oils are typically extracted from plant materials using a variety of methods, Steam distillation is the most widely used method of extraction of plant essential oils. In the journal of Cleaner Production, volume 13, issue 8, page 833-839, “Cleaner production of essential oils by steam distillation” by Phineas Masango, he mentioned, “The proportion of essential oil extracted by steam distillation is 93%, and the remaining 7% can be further extracted by other methods.” This distillation process is placing a plant sample in boiling water or using steam to heat it. The heat applied during this process is the main reason for the rupture and breakdown of the cellular structure of the plant material so that the aromatic compounds or essential oils in the plant material are released. The evaporated compounds rise and enter a cooling chamber called a condenser unit. As the steam cools, they condense from the vapor into liquid form. After concentration, the essential oils and water from the water-soluble parts of the plant (called hydrosols or flower waters) are collected into a receiver with two separate outlets. Because oil and water don’t mix, essential oils will float on top of the water. So, the lower effluent will draw out the water, while the upper effluent will draw out the essential oils. Part of the reason steam distillation is such a popular essential oil extraction process is that volatile compounds can be distilled at temperatures below their boiling points. Therefore, the natural qualities of the plant material are less likely to be altered or diminished during processing. For this reason, the distillation of essential oils is often considered the only method of extraction that allows for purity.

Transportation is an important stage in product life. The embodied energy of a reed diffuser includes the energy used in the production of the container, oil, and reed, as well as the energy used in transporting these materials to the manufacturing location and then to the retail location or customer. The specific transport of a reed diffuser depends on various factors such as the distance traveled, the mode of transport used, and the efficiency of the transport method. For example, if a reed diffuser is manufactured locally and shipped by truck to a nearby retailer, its associated embodied energy may be relatively low, but if the material is transported over long distances or by less efficient modes of transport such as air freight, then the implied energy may be relatively low, and the energy content may be higher.

Embodied energy also includes the energy used to dispose of or recycle materials at the end of their useful life. As the product is thrown away, the reed diffuser container is usually collected and sorted for recycling, while any remaining oil is removed from the container. Utilize the processed material to break it down into its original form and use it to make new products. Containers and reeds can be shredded and melted down to create new plastic products, while essential oils can be extracted and reused in applications. By recycling the physical components of the reed diffuser, natural resources are conserved, and the energy and emissions required to manufacture new products are reduced.

While reed diffusers can provide a pleasant and long-lasting fragrance, the energy and environmental impact they embody should also be considered when making purchasing decisions. In the life cycle of the aromatherapy machine, not every stage adheres to the principle of environmental protection and energy saving. The process from raw materials to manufacturing to recycling. A more sustainable alternative is a reed diffuser, which often uses natural essential oils, which is a greener, healthier option. But it's worth noting that the production of the materials used for reed diffusers can have a huge impact on the environment. In addition, the production, packaging, and transportation of reed aromatherapy machines will generate greenhouse gas emissions. Overall, while reed diffusers can provide a more natural air freshener, it is important to consider whether there will be any long-term impact on the lifespan of the product.

Bibliography

Edward. “Let's Make a Bottle: Understanding the Glass Bottle Formation Process.” Glass, Plastic, Metal Bottles and Caps Wholesale - O.Berk®, https://www.oberk.com/packaging-crash-course/glass-bottle-formation.

How Glass Bottles and Jars Are Made | OI. https://www.o-i.com/our-story/how-glass-bottles-and-jars-are-made/. “How Glass Bottles Are Made.” How Glass Bottles Are Made, https://www.thomasnet.com/articles/materials-handling/glass-bottles-made/.

Layton, Andrew. “Are Electric Furnaces the Future of Glass Manufacturing?” Mo, 3 Feb. 2020, https://mo-sci.com/electric-furnaces-future-glass-manufacturing/.

LAFCO New York. “Diffuser Sticks: What They Are, How They Work, and Which to Choose.” LAFCO New York, 19 Jan. 2022, https://blog.lafco.com/diffuser-sticks/.

“How to Choose the Best Reed Diffuser Reed Sticks in Singapore?” Shiora Singapore, 14 Aug. 2022, https://shiora.com.sg/blogs/tips-for-you/how-to-choose-the-best-reed-diffuser-reed-sticks-in-singapore.

“How to Make Essential Oils.” Nourished Essentials, https://nourishedessentials.com/blogs/healthwellness/how-to-make-essential-oils.

Phillips, Harriet Flannery. “Guide to Making Essential Oils - Mother Earth Living.” Mother Earth Living - Healthy Life, Natural Beauty, https://www.motherearthliving.com/health-and-wellness/guide-to-making-essential-oils-zmaz91djzgoe/.

“Essential Oil Extraction Methods.” USA Lab, 4 Dec. 2020, https://www.usalab.com/blog/essential-oil-extraction-methods/#:~:text=Steam%20distillation%20is%20the%20most,the%20plant%20material's%20volatile%20compounds.

Phineas Masango, et al. “Cleaner Production of Essential Oils by Steam Distillation.” Journal of Cleaner Production, Elsevier, 17 June 2004, https://www.sciencedirect.com/science/article/abs/pii/S0959652604000654.

“Are Reed Diffusers Eco-Friendly?” Aery Living, Aery Living, 7 Dec. 2021, https://aeryliving.com/blogs/wellbeing-journal/are-reed-diffusers-eco-friendly.

Stanfield, Savanna. “Are Reed Diffusers Eco-Friendly? 13 Crucial Facts (You Should Know).” Citizen Sustainable, 18 Nov. 2022, https://citizensustainable.com/reed-diffusers/#:~:text=The%20reed%20diffusers%20themselves%20are,the%20compost%20and%20contaminate%20it.

“Reed Diffuser Articles and Reed Diffuser Information.” Reed Diffusers by The Diffusery, http://www.thediffusery.com/article_3/Reed-Diffusers-Explained-.htm.

Lishan Guan

Professor Cogdell

Des 40A

15 March 2023

Waste and Emission in a Reed Diffuser Life Cycle

At this point, the presence of reed diffusers cannot be separated from the overall effect of the interior environment. It was a very popular item on the market and it was a great value for the purchase. When it comes to releasing amazing aromas, reed diffusers are always a great product, whether it is used in a household setting or in a business setting. Yet producing the reed diffusers uses a lot of energy as well as generates a considerable amount of waste for the environment.

One of the primary ingredients in incense is essential oil. If you intend to extract plant essence or a single pound of essential oil, you might need an enormous amount of plant material. Several plants must be processed in order to get just a few droplets of oil. The majority of the plant is wasted since most of the plant's components are not used. Sometimes only a few drops of essential oil might be produced from a thousand distinct plants. For instance, three pounds of lavender blossoms are needed to distill about 15 ml of lavender essential oil, whereas roughly 242,000 rose petals are needed to generate about 5 mL of rose oil (Talvola).

By using certain plants and removal techniques, essential oils are extracted from the plant. These are the plants' liquid forms. The most common extraction technique among them is steam distillation, which can be used for natural compounds. With the addition of steam, a large stainless steel container that contains plant material is used in this technique. Hot water may flow out and cold water may enter the condensate bottle when the vaporized plant compounds are transferred there. The liquid that results from the steam cooling down is collected in the container below. Since the oil and water don't mix, the oil usually floats on top of the water (A Comprehensive Guide to Essential Oil Extraction Methods).

Essential oils are volatile organic compounds (VOCs), which build up in the body and lead to irritation when released by synthetic chemicals. The synthetic chemicals that have been stored in your body are broken down and removed by the VOCs in essential oils, which also reduce inflammation and infection. When used properly or in safe forms, essential oils are not poisonous. They are remarkably effective at eliminating fungus and mold. VOCs from breathed chemicals, however, can be harmful to your health. Essential oil air diffusers release a negligible amount of oil into the air. You cannot overdose on them, which might result in many negative side effects like those caused by harmful chemical-based synthetic air fresheners (Prana).

According to ACG Glass Europe's transport data, they ship or train their products, which results in fewer CO2, NOx, SOx, and dust emissions than trucking and lessens traffic congestion. Because the consumers for their factories are dispersed so widely across numerous nations, they continue to rely mostly on road transport for the transportation of the glass and their finished glass goods. Yet, numerous logistical innovations and attempts are always being made to broaden available options and lessen the environmental impact of our transportation. They are primarily focusing on the following options to lessen the environmental impact of our product logistics: committing to traveling shorter distances, using multimodal transportation to cut down on road travel, and developing innovative transport materials, as well as increasing the amount of glass transported each truck (Transport).

Reed diffuser was typically enclosed in a glass container. Glass manufacturing has a significant negative impact on the environment. Once a glass furnace has run nonstop for 24 hours and has a lifespan of at least 15 years, it cannot be halted or cooled. The environment is becoming severely polluted by current energy usage, carbon dioxide emissions, and nitrogen oxide emissions. Carbon dioxide was the only greenhouse gas emitted during the production of glass. It’s released during the burning of natural gas and the breakdown of raw materials during melting. Acidification may result from the sulfate in the batch materials decomposing, producing sulfur dioxide (SO2). Due to their high melting temperatures and, in some cases, because of the breakdown of nitrogen molecules in the batch materials, nitrogen oxides (NOx) also contribute to acidification and smog formation. Particles may enter the atmosphere as a result of molten glass and raw materials evaporating (Environmental Impact).

The production of glass has a significant negative influence on water pollution, and the raw materials used, like sand and minerals, are non-renewable resources. Glass cannot be broken down for at least 10,000 years. The ideal option is to reuse an item, because glass can be recycled endlessly, making it more sustainable than other materials. Furthermore, recycling glass conserves natural resources and uses up to 40% less energy because it melts at lower temperatures than virgin glass (Sarah).

To absorb the oil and distribute the aroma into the air, reed diffusers use bamboo or rattan skewers. Bamboo or rattan sticks are biodegradable, but if they contain fragrance oil—natural or synthetic—neither of them can be biodegradable since synthetic fragrance oil is made of harsh chemicals and natural fragrance oil contains volatile organic compounds. When the reed itself breaks down, the chemicals in synthetic oils and the VOCs included in both natural and synthetic perfumes can leak into the environment, poisoning the land and water.

Yet, there are frequent issues with sustainability. Bamboo and rattan are both very environmentally friendly materials for reed diffusers. Although both rattan and bamboo are renewable sources of energy, the growth and harvesting processes have some unanticipated environmental effects. In general, rattan takes around two years to mature and can be harvested. It is a plant that is good for the environment and helps to keep the landscape and many plants healthy (Interiors). Yet logging too much in order to accommodate demand could hasten the loss of natural vines. Bamboo has a significant impact on the environment because of how quickly it grows. Often, it generates 30% more oxygen than typical trees do (Lemmons). However, more area will need to be excavated in order to grow bamboo, leading to the loss of trees.

As they are made from renewable resources, natural fragrances are sustainable. As synthetic flavors are made from crude oil, they are not renewable. Make ensuring that it only uses organic essential oils is one approach for rendering reed diffusers more environmentally sustainable. These oils do, however, have some disadvantages. Their volatile organic compounds (VOC) can also be hazardous to the environment (Stanfield).

The pointless things could also be upcycled as another kind of recycling. Recycling is the process of transforming waste materials into useful materials. But, upcycling is a little unique. It's a technique for converting waste into higher-quality goods. Upcycling the stuff to make something fresh and actually contributing to it is preferable to sending it to be broken down and recycled. Comparable to recyclable garbage like paper, plastic, and other waste materials, going to the landfill usually requires energy. The amount of energy needed for recycling is greater than what is needed for upcycling. You can make adjustments to the empty container until your supply of reed diffusers runs out. Creating a piece of fashion trend items or an adornment for your home, for instance. This will create a unique living environment in the house. The same aroma should be used when refilling your empty container as opposed to a different one so that the new flavor doesn't contaminate the old. Reed diffusers can be used in any place as an aroma enhancer, including the car, the storage room, and the closets. And utilize the actual reed diffuser container to create some handiwork and artwork (Assi).

Therefore, even while reed diffusers can give the house a pleasant scent, there are significant environmental costs associated with the waste they generate and the measures they must take to reduce their impact. Many plants that are used to produce essential oils must be environmentally responsible and sustainable. Glass is not just used as a container for reed diffusers. Glass is most likely to be used in a wide variety of items, which increases the energy required for transportation. Yet, there is good news: glass can be recycled, which makes it more practical. But, there are times when you need to consider other recycling options for glass, such as upcycling turning it into something altogether new rather than just letting it decompose in a landfill. The main benefit of using rattan or bamboo as the medium for scent transmission in reed diffusers is that they are natural products, making them environmentally benign. But, if they are stained with essential oils, they probably won't biodegrade as effectively and will negatively impact the environment.

Bibliography

Assi, Sejal. “How to Upcycle Your Reed Diffuser.” Amaura Limited - Eco-Luxury Home Fragrances, Amaura Limited - Eco-Luxury Home Fragrances, 20 Sept. 2021, https://amauralondon.com/blogs/news/how-to-upcycle-your-reed-diffuser#:~:text=Put%20the%20diffuser%20reeds%20in,a%20star%20or%20a%20frame.

“A Comprehensive Guide to Essential Oil Extraction Methods.” New Directions Aromatics, https://www.newdirectionsaromatics.com/blog/articles/how-essential-oils-are-made.html.

“Environmental Impact.” AGC Glass Europe, https://www.agc-glass.eu/en/sustainability/environmental-achievements/environmental-impact.

Interiors, Dovetail. “What Makes Rattan Furniture Eco-Friendly? by Dovetail Interiors in Norwich.” Dovetail Furniture, Norwich | Upholstery, Carpets, Flooring, Cane Furniture & Much More., 30 Dec. 2020, https://dovetail-furniture.co.uk/what-makes-rattan-furniture-eco-friendly/#:~:text=Rattan%20can%20be%20fully%20grown,numerous%20other%20plants%20and%20landscapes.

Lemmons, Richard. “The Reality of Bamboo Products: Are They Sustainable? - Change Impacts.” Climate Policy Watcher, 15 Mar. 2023, https://www.climate-policy-watcher.org/change-impacts-2/the-reality-of-bamboo-products-are-they-sustainable.html.

Prana Therapy. “The Truth about VOC's and Essential Oils.” Prana Therapy, https://pranatherapy.nz/blogs/news/the-truth-about-vocs-and-essential-oils.

Sarah. “Is Glass Sustainable? Why Glass Is Bad for the Environment.” Sarah Bassett, 25 May 2020, https://sarahbassett.co/is-glass-sustainable/#:~:text=The%20biggest%20environmental%20impact%20from,such%20as%20 sand%20 and%20 minerals.

Stanfield, Savanna. “Are Reed Diffusers Eco-Friendly? 13 Crucial Facts (You Should Know).” Citizen Sustainable, 18 Nov. 2022, https://citizensustainable.com/reed-diffusers/#2_Are_Reed_Diffusers_Sustainable.

Talvola, Eliza. “Are Essential Oils Sustainable + ABCO's Zero Waste Solutions.” Appalachian Botanical Co., Appalachian Botanical Co., 26 Apr. 2021, https://appalachianbotanical.com/blogs/smart-shopper/sustainable-oils-zero-waste-solutions#:~:text=However%2C%20the%20magic%20of%20essential,the%20plant%20goes%20to%20waste .

“Transport.” AGC Glass Europe, https://www.agc-glass.eu/en/sustainability/environmental-achievements/transport.

Additional Bibliography for Poster Image:

“Sonoma Goods for Life® Mahogany & Cedar Reed Diffuser 11-Piece Set.” Kohl's, https://www.kohls.com/product/prd-5529586/sonoma-goods-for-life-mahogany-cedar-reed-diffuser-11-piece-set.jsp.