Design Life-Cycle

assess.design.(don't)consume

Olivia, Herrick

Ana-Sofia and Tiffany

DES 40A

Professor Cogdell

Life Cycle of Vegan Leather Dr. Martens Chelsea Boots

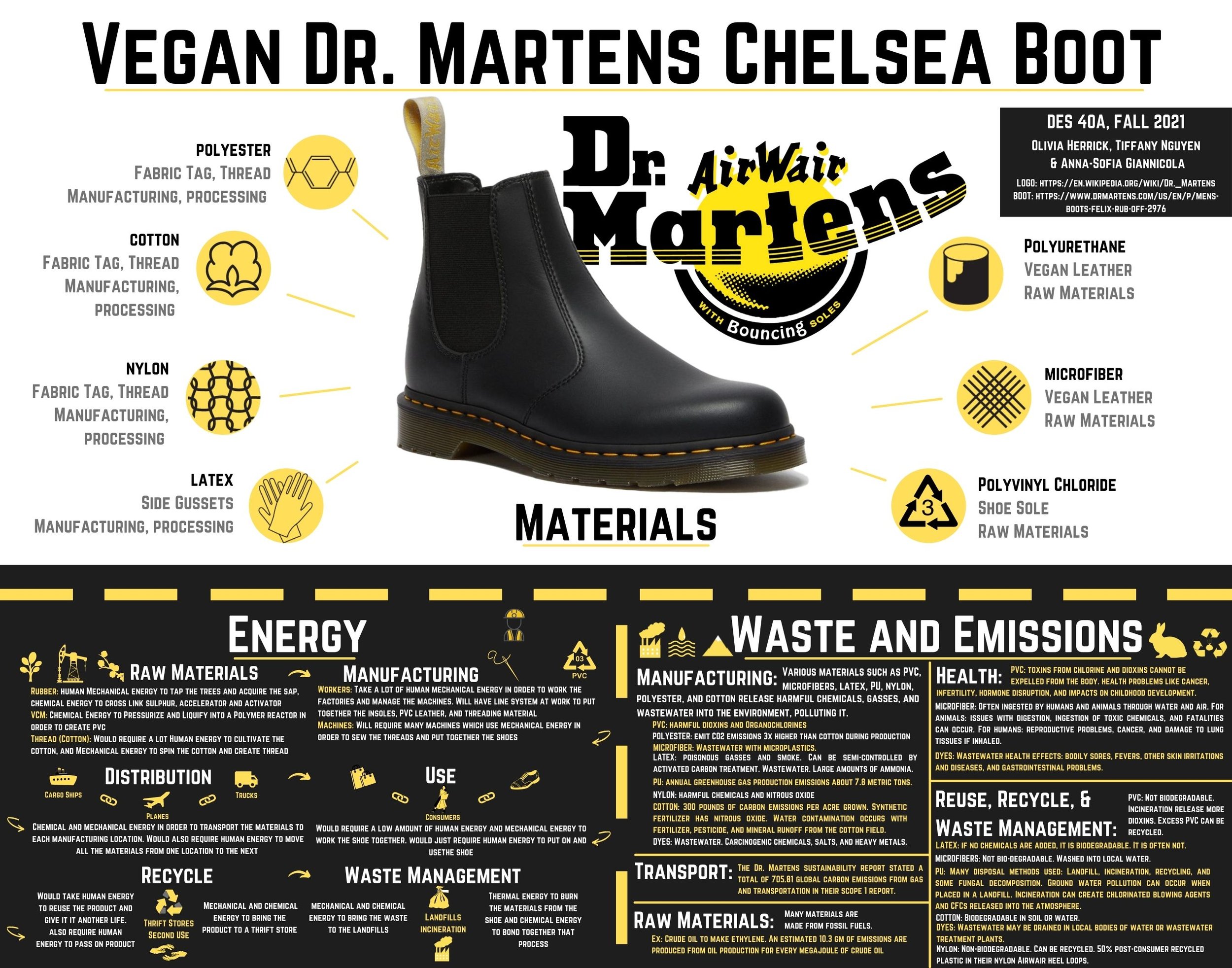

Since being founded in 1947 Dr. Martens as a British footwear have risen to fame distributing their classic shoes all over the world. Originally created in Germany during World War II these shoes have continued to be used as a working boot and more recently a fashion statement. Dr. Martens provides customers with a wide range of boots varying in color, style, and material. The main material used for production has been leather but in recent years Dr. Martens has also introduced the option of vegan leather. This provided an opportunity to cut back on the use of animal products that they have been relying on, since cattle are one of many contributors of greenhouse gases. Despite the reduction of animal products in manufacturing, vegan leather is not a sustainable solution either. Vegan/synthetic leather is manufactured from multiple plastic and fossil fuel derived materials that are not sustainable or easily broken down. This substitute does decline the effects of animal derived products on the environment but the manufacturing of vegan leather is not the solution. Although the Vegan Leather Dr. Martens ChelsEa boots do not contain animal materials in the production process, it uses a combination of synthetic and chemical materials that can be harmful to the environment.

The phases of “Raw Materials Acquisition” and “Manufacturing, Processing and Formulation”, are two phases of the Dr. Martens life cycle that uses a majority of materials introduced. The main materials that vegan leather is composed of are the secondary raw materials polyvinyl chloride (PVC), polyurethane (PU) and microfibers. PVC is a thermoplastic material derived from salt (sodium chloride) and oil. Chlorine (produced by the electrolysis of salt water) is combined with ethylene (obtained from oil) resulting in ethylene dichloride which is then converted at high temperatures to vinyl chloride monomer that is polymerized forming polyvinyl chloride resin; by adding plasticizers, such as phthalates, it creates a flexible PVC (“Polyvinyl Chloride (PVC)”). PVC is the main material molded and used for the sole and the welt on the shoe. Despite being well known for sterilizing water and producing its by-product of sodium hydroxide, the largest use of chlorine is in the manufacturing of PVC (Chlorine). Chlorine is also used in the production of PU. The reactive materials required to produce PUs are isocyanates, polyols, and additives (to protect vulnerable PU materials from heat, light, atmospheric contaminants, and chlorine) (“Polyurethane”). PUs are produced through exothermic reactions between alcohols (with two or more reactive hydroxyl groups per molecule (diols, triols, polyols)) and isocyanates (that have more than one reactive isocyanate group per molecule (diisocyanates, polyisocyanates)) (Polyurethanes). Microfiber is another synthetic material used in the production of Dr. Martens, this fiber is made using various polyesters and polyamides, commonly known as nylon, which are both also synthetic fibers (“Microfibers”). PU and microfiber are the two main materials that are used in the production of the vegan/synthetic leather for the boot. Being another synthetic fiber, polyester is a kind of plastic mainly derived from petroleum, which is a non-renewable resource (“Polyester”). Similar to polyester, nylon is also a synthetic fiber and a kind of plastic. Nylon is created from reacting carbon-based chemicals, found in coal and petroleum, in a high-pressure/heated environment through the chemical reaction known as condensation polymerization (“Material Guide: How Sustainable Is Nylon?”). The manufacturing process begins with stitching the vegan leather pieces together for the main body of the shoe. The materials used in the thread were not stated within the Dr. Martens website but most likely it could be a type of polyester, nylon or cotton thread according to the previous Dr. Martens 1460 boot life cycle. The iconic yellow thread, which is possibly a wax polyester or nylon thread, of Dr. Martens is used to stitch the PVC welt to the bottom of the shoe. The Dr. Martens Chelsea boot also includes elastic side gussets that allow the top of the boot to stretch when putting the shoe on since it does not have a zipper. Most likely the gussets are made from latex-based rubber and polyester fibers, since most common elastics are made with these materials (“Elastic (Notion)”). During the process, manufacturers also attach a fabric tag to the back of the shoe, which according to the previous Dr. Martens life cycle was stated to possibly be made of a polyester, nylon, cotton blend. Lastly the PVC sole is attached to the shoe with PVC welt at the bottom. There is no glue necessary to attach the pieces since the sole is melted onto the welt using hot blades and rollers (How Dr. Martens’ Are Made). Dr. Martens stated in their Sustainability Report that they plan on removing fossil-based chemicals by 2030 and having all of their footwear to be made from sustainable materials 2040. Unfortunately this seems to be a futile attempt due to the fact that their Vegan Leather Martens are almost entirely produced using synthetic materials derived from plastics and fossil fuels that have a devastating effect on the environment. Once Dr. Martens are manufactured, the next step in the process is to distribute and transport the product nationally, during their life cycle this product also requires maintenance during use.

The next phases of the life cycle, “Distribution and Transportation” and “Use/re-use/maintenance”, introduce fewer materials in the process but still have an environmental effect. In order to transport their products globally Dr. Martens, like many other companies, use fossil fuel derived gas/fuel for trucks, planes, or boats to ship products. For product packaging, Dr. Martens standard shoebox is fully recyclable, made from 95% recycled paper and printed with soy paper (Dr. Martens Plc Sustainability Report). For use, vegan/synthetic leather shoes typically have a shorter lifespan, compared to natural leather, and are not a reliable everyday shoe if the consumer wants the shoe to last. Vegan Leather Dr. Martens require little maintenance, within their ‘Shoecare and Product Advice’ they state, “to maintain vegan leather, don't let your boots sit wet/drying in direct sunlight for too long. To help keep them clean, use light soapy water or a standard wet wipe” (How Do I Look after My Vegan Docs). Vegan leather doesn’t use new materials within their maintenance, unlike natural leather which requires polish and other products to maintain the leather. Most of the polishes Dr. Martens sells for natural leather are waxed based with other natural oils that help to protect and keep the leather soft. Depending on the condition of Dr. Martens shoes, users can either resell/donate their shoes or if the shoes reach the end of their lifecycle they will be thrown away. As Dr. Martens continue towards the end of their life cycle, they require management in possible recycling and disposal.

Lastly, the phases of “Recycle” and “Waste management” uses some new materials, but the company still has difficulty with properly disposing of their products. Compared to natural leather products, which can last around 10-20 years with basic care and maintenance, an everyday-use synthetic leather product could only last 2-3 years before it begins to look cracked, worn or become unusable (“Synthetic Leather - What Can Make It a Great Choice for You”). For a material that requires a large amount of fossil fuel derived synthetic materials, vegan/synthetic leather has a shockingly short lifespan. Since Dr. Martens does not have a system, at the moment, to responsibly dispose of or reuse/refurbish worn boots, these boots will end up sitting in landfills. Despite being able to recycle PVC in various ways, due to cost and amount of labor needed to process this material there is only a small percentage of PVC waste that is actually recycled. As a thermoplastic PVC can be melted down and remolded multiple times but eventually the quality decreases. There are multiple ways of recycling PVC including energy-recovery techniques, mechanical recycling, and chemical (Sadat-Shojai). Despite these options being available they do have setbacks due to the fact that it can result in potential hazards, toxic by-products or there are preferred/specific requirements of the condition the PVC has to be in in order to be recycled. Even though PU is considered more sustainable than PVC, according to the American Chemical Society, “Conventional PU can’t be recycled simply by heating because it consists of polymer networks held together by strong chemical bonds that don’t flow when heated. Instead, PU can only be downcycled into less useful materials” (“New Recycling Method Could Make Polyurethane”). Similar to PVC, PU is another synthetic material that is difficult to recycle in a sustainable and useful way. Microfiber materials are not biodegradable and cause a large amount of pollution through the fashion and textile industry that commonly pollute our water. These synthetic fibers, such as polyester, nylon, polyamide and others can be regenerated and recycled into yarns that are channeled back into the manufacturing process to make more garments (Liu). Despite the effort to repurpose and recycle the materials used in the production of Vegan Leather Dr. Martens, many of these efforts are unsuccessful due to the amount of synthetic materials, risks of toxic by-products, and the inability to responsibly dispose or break down of materials. As continuous waste of the product continues to be disposed of Dr. Martens needs to work on solutions that reduce the production of harmful materials and waste.

Dr. Martens are making an effort stating their future plans for sustainability and the steps they will take to achieve these goals. Also the effort to cut back on the use of animal products is seen through their ‘vegan’ product line but the substitutes are still not efficient solutions. Consumers may think of ‘vegan’ as a product that will not cause harm to the environment when in reality they are using more harmful synthetic and chemical materials in the process. Companies seem to be falling back on the typical cycle of using synthetic materials as a cheaper alternative to replace natural materials. The production and tanning of leather is still not a completely sustainable option but it is a better alternative for the time it takes to decompose compared to synthetic leather. Overall Dr. Martens is addressing the issue of sustainability but they are branching off the issue, trying to find temporary replacements for profit, rather than addressing the problem straight on.

Bibliography

Chlorine, https://www.essentialchemicalindustry.org/chemicals/chlorine.html.

“Dr. Martens 1460 Boot - Design Life.” Cycle, http://www.designlife-cycle.com/dr-martens-1460-boot.

Dr. Martens Plc Sustainability Report. https://www.drmartensplc.com/application/files/9216/ 2506/1932/Dr._Martens_plc_Sustainability_Report.pdf.

“Dr. Martens.” Wikipedia, Wikimedia Foundation, 2 Oct. 2021,https://en.wikipedia.org/wiki/Dr._Martens.

“Elastic (Notion).” Wikipedia, Wikimedia Foundation, 15 July 2021,https://en.wikipedia.org/wiki/Elastic_(notion).

How Do I Look after My Vegan Docs? – Dr Martens - Customer… https://help.drmartens.com.au/hc/en-us/articles/360045251773-How-do-I-lookafter-my-Vegan-Docs-.

How Dr. Martens' Are Made - Youtube. https://www.youtube.com/watch?v=rO1YAx4QW1I.

Liu, Jianli, et al. “Microfiber Pollution: An Ongoing Major Environmental Issue Related to the Sustainable Development of Textile and Clothing Industry.” Environment, Development and Sustainability, Springer Netherlands, 3 Jan. 2021,https://link.springer.com/article/10.1007/s10668-020-01173-3.

“Material Guide: How Sustainable Is Nylon?” Good On You, 16 June 2021,https://goodonyou.eco/material-guide-nylon/.

“Microfiber.” Wikipedia, Wikimedia Foundation, 27 Nov. 2021,https://en.wikipedia.org/wiki/Microfiber.

“New Recycling Method Could Make Polyurethane Sustainable.” American Chemical Society, https://www.acs.org/content/acs/en/pressroom/newsreleases/2020/april/new-recycling-method-could-make-polyurethane-sustainable.html.

“Polyester.” CFDA, https://cfda.com/resources/materials/detail/polyester.

“Polyurethane.” How Products Are Made, http://www.madehow.com/Volume-6/Polyurethane.html.

Polyurethanes, https://www.essentialchemicalindustry.org/polymers/polyurethane.html.

“Polyvinyl Chloride (PVC).” Lenntech Water Treatment & Purification, https://www.lenntech.com/polyvinyl-chloride-pvc.htm.

Sadat-Shojai, Mehdi, and Gholam-Reza Bakhshandeh. “Recycling of PVC Wastes.” Polymer Degradation and Stability, Elsevier, 13 Dec. 2010, https://reader.elsevier.com/reader/sd/pii/S0141391010004556?token=3CE922BBCE08E031A91857538EE39E05BFD F74BC70A6364CC08D8E3EDE94F9B03DD7A5C049E69DCF6081BE0E1B927AC3&originRegion=us-east-1&originCreation=20211024173938.

“Synthetic Leather - What Can Make It a Great Choice for You.” Liberty Leather Goods,https://www.libertyleathergoods.com/synthetic-leather/.

Nguyen, Tiffany

Olivia and Anna-Sofia

DES 40 A01

Professor Cogdell

2 December 2021

Embodied Energy Vegan Dr. Martens Chelsea Boot

The original Dr. Martens have been a fashion staple since its beginning invention back in 1901. These shoes are not only sleek and classic, but they also carry history following the punk rock and alternative movement back in the 60s. Now they’re considered rebellious wears of self reflection definitely with their newer creations like the Vegan Dr. Martens Chelsea Boot. With their long line of history, comes a long story of embodied energy that has been used in order to keep these shoes a classic staple. The energy journey of extracting the raw materials, manufacturing the shoes, distributing them to available locations, the actual use of the shoe, its recycling process, and waste management are all extensive processes that require a lot of energy from a multitude of different sources. Through the entire lifespan of the Vegan Chelsea Dr. Martens, there is a large consumption of energy used in order to create the product, use the product, and also dispose of the product once its life cycle is completed.

In the beginning process of making the Vegan Chelsea Boot, it requires an extensive amount of energy in order to extract the raw materials to even begin the basis of its creation. The raw materials that are needed in order to create the boots are rubber for the sole and elastic of the gusset, PVC for the base of the shoe, and cotton for the thread of the boots. In researching which type of rubber that the Dr. Martens use: either synthetic or natural, the only information that was found was on a UK blog called Shoediary. They stated that, “The famous soles are made from an organic rubber”. It can be analyzed that natural rubber is used for their soles which would require a vast amount of human energy in order to cultivate all the ingredients together. It is stated that it would approximately take 12 hours in order to complete the cycling of tapping the trees in order to create the rubber (Coruba). The process would also require extensive chemical energy with ammonia and acid being added in order to stop the coagulation process (Coruba). In moving on to the base of the Chelsea boots, the making of PVC would be vast. In a report by Guichon Valves, they debriefed the PVC process with, “ First, the raw material VCM is pressurized and liquefied, and then fed into the polymerization reactor, which contains water and suspending agents in advance. Next, the initiator is fed into the reactor, and PVC is produced under a few bars at 40 – 60°C.” (Valves).Thus showing the vast process in order to just create the resin of the actual shoe. In the final piece of the raw materials, the collecting of the cotton in order to create the iconic Dr. Martens yellow thread would require a substantial amount of human, mechanical, and natural resources in order to create this portion. In a study done at Duke by Bill Schlesinger, he discovered that it took around 22,000 L of water top grown cotton (Shlesinger) and that it took around 60 MJ to produce cotton (Shelsinger). Not only does collecting the cotton and producing it take quite a lot of energy, turning the cotton into thread is another congested process. In an article by Our Pastimes, they state that it takes, “ 2,500 revolutions per second to take the cotton to the thread stage.” (Martin). This comes at a large helping hand from the machines that use mechanical energy in order to spin these wheels. Dying the cotton would be fairly easy since it would just require a chemical process in order for the thread to pick up the color.

While there is a lot of work going into the process of acquiring and making these raw materials, the manufacturing process in making vegan Dr. Martens also takes up a large amount of energy. Many of the Dr. Martens now seen are also majorly made in Asia with, “Vietnam producing the highest portion (39%), and England making the lowest portion (1%)” (Bryen). Since there was little information of the specific manufacturers producing the Vegan Dr. Martens, analysis of Chinese manufacturers that make other similar shoe brands stated that it took, “between 40 and 100-plus workers.”(Pak). This was the amount of human energy that it took in order to only make one pair of shoes. This gives insight to how much human energy would be needed in order to produce the shoes at the rates needed to meet consumers needs. This also preludes to the mechanical energy needed to manufacture these infrastructures and in a study by MIT it was shown that each shoe production omitted, “30 pounds of carbon dioxide emissions, equivalent to keeping a 100-watt light bulb on for one week,” (Chu). The manufacturing process shows the copious amounts of energy that goes into putting the shoes together, but even this process continues to scratch the surface of the amount of energy used in the whole process's lifespan.

In the next part of the Vegan Chelsea Boot Life Cycle, the distribution portion also is one of the biggest energy consumers in the shoe's lifespan. Since the boots are majorly made in Asia, if it were to be transported to the U.S. it must be shipped to a U.S. distributor which would take thousands of fossil fuels and many different energy types to bring over. In an analysis of how much energy an international flight would take, How Stuff Works shows that, “Over the course of a 10-hour flight, it might burn 36,000 gallons (150,000 liters)” This would require a large amount of mechanical energy that would then be converted into kinetic energy. The mechanical energy would also shift into gravitational energy as the planes fly higher. In looking into if a cargo ship were to bring over the materials, the amount of energy it takes to transport that is about a hundreds times more than a regular flight. In an article by Freight Waves, they state that, “ Ships in that size range can carry between 2.5 million and 3.5 million gallons of fuel.” (FreightWaves). This would then double the amount of human energy it takes to operate the management of these ships, and even more outsourced energy to maintain the functionality of these ships. Some smaller sources of distribution energy can be seen in more local settings with truck shipments where the shoes would actually be delivered to either the stores or the consumer's home. This effort would take human, mechanical, and kinetic energy in order to all function together to deliver the shoes to the right location.

After the process of distribution and the shoes get delivered to the right location, comes the use of the actual Vegan Chelsea Boot. This is the least energy consumed process with the consumers mostly just using mechanical energy in order to put the shoes in motion. The Chelsea Boot are usually used more as a fashion statement so these boots could be used for leisure activities and daily uses. This energy is pretty low and is energy efficient since it mostly takes energy out of other people wearing it out than any outside resources. In the next category of the system, recycling also takes a lower amount of energy depending on the recycling method that is being picked to move forwards. For most recycling methods of the boot, they would either be given to thrift stores or be passed down for second use. With bringing them to thrift stores it would take a low amount of mechanical and kinetic energy to most likely take a car and drop them off at a thrift store. Same goes for passing the shoes as a second hand option since it would most likely be connected within a person's inner circle so it would just take some human energy to pass it along. Unfortunately with the Chelsea Boot being vegan, their longevity wouldn’t last as long as real leather which would result in the quicker disposal of the classics.

In the final process of the Vegan Chelsea Boot lifespan, comes the total waste management of the shoes. This final process of the shoes lifespan also is a strenuous process because of the multiple possibilities of its final life. In the journey of heading to a landfill, it would take mechanical and human energy in order to pick up the trash and take it to the drop off site. Here, the Dr. Martens can sit and wait to degrade which can take a long process. Considering vegan leather is made out of plastics, “this takes years to degrade and releases toxic chemicals into the environment, which is unsustainable.” (Davis). Since this process could take up to 20-500 years to decompose another process that would be used to speed up the process is the use of incinerators that would thus end up burning the material. The incineration process would use mostly thermal energy since it takes a large amount of heat in order to burn the material. With this method there can also be seen to have some benefits. “So much heat energy is produced in the incineration process that it can actually be used to generate electrical power.” (Wpadmin). Regardless of this being a benefit, the disposal of the Vegan Dr. Martens are harmful to the environment and take a long amount of energy to completely get rid of the product. The landfill process is long and requires big machinery in order to dig the holes, and human energy in order to operate the machines.

Overall, the lifespan process of Vegan Dr. Martens Chelsea Boots are a long and energy consuming process that is quite unimaginable to understand considering the amount of energy to produce these boots are for only this shoe. The main analysis of this research showed the continuous use of human energy being involved in almost every aspect of the lifecycle system. While humans are still important in the process, it can be clearly shown that mechanical energy is taking over the use of human involvement. Within every system, mechanical energy is the most important element. With mass production being mostly only possible with the use of mechanical energy. Some other continuous energies seen throughout the process were chemical, kinetic, and thermal. In every step of the gathering of raw materials, to the manufacturing process, distribution, use, recycling, and waste management the large consumption of energy in order to create the Vegan Dr. Martens Chelsea Boot was clearly shown to be extensive.

Bibliography

Bryen, Rafayel. “Where Are Doc Martens Made?(England, Vietnam, or China?).” Work Wear Adviser, 3 Nov. 2021, https://workwearadviser.com/where-are-doc-martens made/#:~:text=Doc%20Martens%0are%20not%20only%20made%20in%20England,Martine%20and%20it%20will%20b%20fantastic%20%28if%20genuine%29.

Chu, Jennifer. “Footwear's (Carbon) Footprint.” MIT News | Massachusetts Institute of

Technology, https://news.mit.edu/2013/footwear-carbon-footprint-0522.

Contributors, HowStuffWorks.com. “How Much Fuel Does an International Plane Use for a Trip?” HowStuffWorks Science, HowStuffWorks, 21 May 2021, https://science.howstuffworks.com/transport/flight/modern/question192.htm.

Davis, Jessica. “Is Vegan Leather Worse for the Environment than Real Leather?” Harper's BAZAAR, 13 Mar. 2021, https://www.harpersbazaar.com/uk/fashion/fashion-news/a30640996/vegan-leather-sustainability/.

“How Is Rubber Made?” Blogs, 16 Oct. 2020, https://www.coruba.co.uk/blog/how-is-rubber-made/.

“How to Break in, Size & Lace Dr. Martens: The Shoe Diary.” Shoe Diary, 14 May 2021, https://www.office.co.uk/blog/brands/complete-dr-martens-care-style-guide/.

Martin, Pamela. “How Is Cotton Made into Thread?” Our Pastimes, 15 Feb. 2019, https://ourpastimes.com/how-is-cotton-made-into-thread-12309034.html.

Pak, Jennifer. “The Chinese Manufacturers behind U.S. Shoe Brands.” Marketplace, 4 Oct. 2019, https://www.marketplace.org/2019/10/03/the-chinese-manufacturers-behind-u-s-shoe-brnds/.

“PVC – Polyvinyl Chloride – Manufacturing Process of Polyvinyl Chloride (PVC) :” Guichon Valves RSS, https://guichon-valves.com/faqs/pvc-polyvinyl-chloride-manufacturing-process-of-polyvnyl-chloride-pvc/.

Schlesinger, Bill. “The Fabric for Our Lives.” Translational Ecology, 26 Nov. 2018, https://blogs.nicholas.duke.edu/citizenscientist/the-fabric-for-our-lives/.

Staff, FreightWaves, et al. “How Many Gallons of Fuel Does a Container Ship Carry?” FreightWaves, 16 Jan. 2020, https://www.freightwaves.com/news/how-many-gallons-of-fuel-does-a-container-ship-cary.

wikiHow. “How to Harvest Rubber.” WikiHow, WikiHow, 6 Sept. 2019, https://www.wikihow.com/Harvest-Rubber.

The World Counts, https://www.theworldcounts.com/challenges/consumption/clothing/cotton-farming-waterconsumption/story.

Wpadmin. “What Is Incineration Disposal?” Incineration Recycling, 14 June 2016, Mhttp://incinerationrecycling.com/incineration-disposal/#:~:text=Incineration%20disposa%20is%20considered%20a%20%E2%80%9Cthermal%20treatment%E2%80%9D%20ofcan%20actually%20be%20used%20to%20generate%20electrical%20power.

Anna-Sofia, Giannicola

Olivia Herrick & Tiffany Nguyen

DES 40A

Professor Cogdell

Life Cycle of Dr. Martens Chelsea Boot: Waste and Emissions

Dr. Martens is a popular British shoe brand that originally focused on creating comfortable leather work boots. The classic air-cushioned sole was made in post-war Munich in 1945 by Dr. Klaus Maertens to aid the recovery of a broken foot. The boot began to be worn by factory workers and mail carriers for workwear purposes. By the 1970s, Dr. Martens was adapted by the British anti-establishment youth culture. The brand has since been worn worldwide and has put forth many other shoes such as sandals, the Chelsea boot, and a “vegan” line of shoes. (“The History of Dr. Martens.”). While titled “vegan leather,” the manufacturers cater more towards animal cruelty-free conditions; the plastic-based materials involved in creating vegan leather may make vegan Dr. Martens Chelsea boots harmful to the environment and local organisms when considering waste and emissions.

While Dr. Martens say they are making efforts to create footwear from more sustainable materials in the future, the current process appears far behind their target. A sustainability report by the Environmental Profit & Loss declared that the environmental impact of vegan-leather production is about one-third lower than the leather production process (Davis). However, in the long run, garments made to be faux leather often use substances such as Polyurethane (PU) and PVC, which have a short lifetime and are not biodegradable (Petter.). Due to environmental concerns, Dr. Martens released a sustainability report addressing their goals to reduce their carbon footprint and become more sustainable in their production process by 2030 and 2040. For the most part, Dr. Martens appears to be upfront about many wastes and emission facts, such as their Streamlined Energy and Carbon Reporting Statement. The statement reports emissions of the 2021 fiscal year with a total of 705.81 global carbon emissions from gas and transportation in their scope one report (“Dr. Martens Plc Sustainability Report.” 61). The decisions and goals are admirable; however, in the grand scheme, Dr. Martens’ actions are not enough when considering their choice of environmentally damaging plastics.

One of the main materials in Dr. Martens' shoes are their PVC (polyvinyl chloride) soles (“Produce Responsibly.”). PVC is created from fossil fuels such as crude oil to make ethylene. An estimated 10.3 gm of emissions are created from oil production for every megajoule of crude oil (GARTHWAITE). Dioxins are produced in PVC's manufacturing process, harming the environment and human health (Comaniţă, Elena-Diana, et al.). PVC production in the United States accounts for around 40% of chlorine used within the country. When chlorine is involved in the manufacturing process, toxins such as organochlorines can be released into our air and water. When incorporated into human or animal bodies, these toxins cannot be expelled, and serious health problems occur, such as cancer, infertility, hormone disruption, and impacts on childhood development. In addition, PVC is also combined with phthalates, fungicides, and stabilizers with harmful metals (such as lead), in its production. When the substance is washed, these materials are released from the PVC (“PVC: The Poison Plastic.”). The softer PVC material created for Dr. Martens is extremely durable, as well as oil and fat resistant, giving the overall boot a longer life; but the material is not biodegradable. Much of the process necessary to decompose PVC requires incineration, releasing more dioxins into the environment (Buekens, Alfons, and Kefa Cen. 190). In Asia, Dr. Martens manufacturers regrind PVC waste and bring them back into the production of the outsoles. The company’s UK MIE facilities do not have the required regrinding facilities, so they partner with other manufacturers to reduce waste (wellies and jelly sandals) and recycle excess PVC into shoes. While PVC is utilized, Dr. Martens will continue to create many negative impacts on the environment (“Dr. Martens Plc Sustainability Report.” 59).

To create the “Felix Rub” vegan leather for the Chelsea boot, Dr. Martens uses a “microfiber poly-synthetics material.” In production, the creation of polyester materials emits a CO2 emission three times higher than cotton production. (Brodde, Kirsten.) When manufactured and washed, synthetic materials release microfibers, which are small pieces of plastic that can be released into our oceans, land, and air. As these microfibers are not biodegradable, they can continue to fragment into smaller pieces as they move through the water. While contaminated water from factories and production is meant to filter into wastewater treatment plants, microfibers still pass through the plants and go back to the environment (Shemitz, Leigh, and Paul Anastas.). Dr. Martens Chelsea boots do not necessarily contribute to the household waste of microplastics through washings (putting the boots through the washing machine is not recommended); the initial manufacturing and waste at the end of the boot’s life will release microfibers. Mark Browne, an Ecology researcher from The University of New South Wales, analyzed sediment samples over six continents and discovered that microplastics increasingly contaminated the water in denser populations. Another microplastics study by Mary Kosuth, Sherri A. Mason, and Elizabeth V. Wattenberg concluded that 81% of their simple tap water held microplastics, with 98% being microfibers (Dervishi, Kevin.). As they travel up the food chain, these microplastics are ingested by humans and animals, such as fish and birds. When consumed by animals, issues with digestion, ingestion of toxic chemicals, and fatalities can occur (Shemitz, Leigh, and Paul Anastas.). Health effects for humans when ingesting microfibers can occur, such as reproductive problems, cancer, and damage to lung tissues if inhaled (“What Is Microfibers Pollution and Why Is It Bad?”). The major health (towards humans and animals) and environmental problems with microplastics and microfibers make the idea of vegan leather less likely to be true, as animal life is harmed throughout the lifecycle of the Dr. Martens vegan Chelsea boot.

The materials for the gussets on the sides of the Dr. Martens Chelsea boots are not directly addressed by Dr. Martens; however, when searching to purchase the fabric individually, the main material appears to be made of latex elastic and polyester elastic (“Gusset Elastic: Avetco Leather Hides and Eva Foam.”). The waste and environmental impact of polyester and microfibers was already mentioned in the previous paragraph. Latex, made of natural materials such as the white liquid emulsion from the cells of plants like the Hevea brasiliensis (rubber tree), can be biodegradable. Yet, a lot of latex is treated with ammonia, tetramethyl thiuram disulfide, and zinc oxide to prevent bacterial decomposition (“Balloons' Effect on the Environment.”). A large mixture of poisonous gasses and smoke is created in latex production. Such gases can be controlled by activated carbon treatment; however, smoke particles can pass through and pollute the local atmosphere. Latex uses a lot of energy, water (for trees and washing), and chemicals in the process of its production. At the same time, wastewater with hazardous chemicals and thermal emissions creates a large impact on the environment. Wastewater from latex contains coagulation serum, skim latex coagulation, and field latex coagulation, which make a high oxygen consumption when moving into larger bodies of water. The large amounts of ammonia in latex can kill the organisms living in the water when wastewater is dumped. If the wastewater and gas from latex production are not treated well enough, much more pollution to our environment will occur (VISHNU .V, et al.).

The insoles for Dr. Martens's boots are made of polyurethane (PU) foam with tiny air bubbles, a material made from fossil fuels. (Liang, Chao, et al.). Polyurethane’s annual greenhouse gas emissions are about 7.8 metric tons in production. There are many ways polyurethane foam is disposed of at the end of its life, such as landfill, incineration, recycling, and fungal decomposition (Liang, Chao, et al.). PU foam waste consists of industrial scraps in production and waste at the end of its life use. When PU is placed in a landfill, soil and groundwater pollution can occur and, after some time, limited natural biodegradability. Some Fungi and esterase enzymes, as well as Bacillus and Pseudomonas can break down ester bonds of the chain leading to some microbial degradation of PU. If PU is incinerated, there are concerns about the presence of chlorinated blowing agents and CFCs (a greenhouse gas) being released into the atmosphere. PU foam in landfills accounts for 20-220 mg/m3 of CFC-11 in landfill gas. PU recycling includes physical, chemical, and thermo-chemical recycling processes through recycling plants such as the Orion Chemicals Orgaform in Semoy, France. Physical recycling involves regrinding, adhesive pressing, compression molding, injection molding, and particle bonding PU foams to be reused in other new PU foams (Deng, Yimin, et al.). While the production process of Polyurethane foam is not entirely environmentally friendly, there is evidence that the material can be recycled and slightly biodegrade over time.

The heel loops on Dr. Martens are made of nylon, while Puritan stitch machines are used to insert the classic bright yellow cotton stitching. Nylon is created from petroleum-based sources and is not biodegradable. The production of nylon releases harmful chemicals and nitrous oxide into the environment (Chen 251). An academic article studying the environmental impact and sustainability of textiles stated that one type of nylon, “Nylon 6”, produced 5.5kg CO2 emissions per kg of fiber, while “Nylon 66” produced 6.5kg CO2 emissions per kg of fiber (Muthu, et al.). The fabric, however, can be easily recycled, and Dr. Martens has begun to use “50% post-consumer recycled plastic” into their nylon Airwair heel loops (“Dr. Martens Plc Sustainability Report.” 43). Within the United States, cotton’s greenhouse gas footprint creates about 300 pounds of carbon emissions per acre grown. The nitrogen used in the synthetic fertilizer for cotton crops emits large amounts of greenhouse gasses that are pollutants to the environment, such as nitrous oxide (“Carbon Footprint and Air Quality – United States.”). During cotton production, water contamination occurs with the fertilizer, pesticide, and mineral runoff from the cotton field and into larger bodies of water. Such water pollution can affect biodiversity. (“Cotton.”). The waxed cotton thread used for the classic yellow stitching is a durable waterproof material, giving the material a long life while also having the ability to biodegrade. As the cotton fabric is created from a plant, it can biodegrade in soil or water (“Biodegradability of Cotton: CottonWorks™.”). The use of waxed cotton thread for the trademark yellow stitching around the Dr. Martens shoes is not as harmful to the environment as materials such as polyester; however, their yellow dye may be.

Many color dyes are used when creating the Dr. Martens Chelsea boot, and such dyes are drained to local rivers and impact the surrounding environments of the factories. According to Dr. Martens’ Sustainability report, their shoes are largely manufactured in Vietnam, China, Laos, Thailand, Bangladesh, and a small percentage in the UK (“Dr. Martens Plc Sustainability Report.”53). Their reports have no specific mentions of their production methods when using dyes. During manufacturing, fabrics are applied with chemicals and massive amounts of water in their dyeing process. Due to weaker regulations on industrial water pollutants in countries such as Bangladesh, dyed wastewater is often dumped into local rivers. These bodies of water have changed color to dark blacks, becoming thick and tar-like. Such dye mixtures consist of carcinogenic chemicals, salts, and heavy metals polluting the environment and drinking water sources. This wastewater dumping creates many health effects to the surrounding communities, such as bodily sores, fevers, other skin irritations and diseases, and gastrointestinal problems. The pollution has become so thick that light cannot penetrate the surface of such rivers, preventing aquatic plants’ ability to photosynthesize and impacting the ecosystem of surrounding organisms. Such wastewater is difficult to remove after being dumped into bodies of water and is not biodegradable. Actions have been taken to reduce the waste and improve water quality in some countries, such as environmental protection taxes, moving dye houses to industrial zones, and creating wastewater treatment plants (Regan, Helen.). Dr. Martens monitor their suppliers' use of water and production of wastewater through CSR audits, concluding that “the water use in our footwear suppliers is mostly for domestic purposes, like handwashing.” (“Dr. Martens Plc Sustainability Report.”54). While Dr. Martens states that they are doing their best to meet their sustainable 2040 goal, the lack of direct information addressing how their factories dye their vegan leather fabrics is suspicious and does not help their argument.

The non-degradable and harmful plastics used in the vegan Dr. Martens Chelsea boots make it less believable that these shoes truly follow the idea behind veganism. The term “veganism,” when not involving food, refers to a person who “abstains from using animal products (such as leather)” (“Vegan Definition & Meaning.”). The environmental and sustainability concerns behind the materials used in vegan leather negate the philosophy of not harming animals in veganism. The extensive environmental impact behind the aforementioned materials and chemicals used to create vegan Dr. Martens Chelsea boots affect and harm animal life. Hopefully, Dr. Martens will stick to their 2030 and 2040 goals of reducing waste and switching to more biodegradable materials.

Bibliography

“Balloons' Effect on the Environment.” The New York Times, The New York Times, 1 Apr. 1990, https://www.nytimes.com/1990/04/01/nyregion/l-balloons-effect-on-the-environment-8678 90.html.

“Biodegradability of Cotton: CottonWorks™.” CottonWorks, 8 Nov. 2021, https://www.cottonworks.com/en/topics/sustainability/cotton-sustainability/biodegradabilit y-of-cotton/.

Brent, Michael. “Differences between Polyethylene and Polyurethane.” Sciencing, 2 Mar. 2019, https://sciencing.com/differences-between-polyethylene-polyurethane-8514564.html.

Brodde, Kirsten. “What Are Microfibers and Why Are Our Clothes Polluting the Oceans?” Greenpeace International, 7 Apr. 2018, https://www.greenpeace.org/international/story/6956/what-are-microfibers-and-why-are-ou r-clothes-polluting-the-oceans/.

Buekens, Alfons, and Kefa Cen. “Waste Incineration, PVC, and Dioxins.” ProQuest, Oct. 2011, https://www.proquest.com/docview/897348186/fulltextPDF/20C4BFD2C4074486PQ/1?ac countid=14505.

“Carbon Footprint and Air Quality – United States.” Cotton LEADS - Sustainable Cotton Production, 26 Apr. 2019, https://cottonleads.org/sustainable-production/carbon-footprint-united-states/.

Chen, Hsiou-Lien, and Leslie Davis Burns. “Environmental Analysis of Textile Products.” Clothing and Textiles Research Journal, vol. 24, no. 3, 2006, pp. 248–261., https://doi.org/10.1177/0887302x06293065.

Christian, Scott, et al. “Vegan Leather Isn't as Ethical as You Think.” Vocativ, Vocativ, 11 Feb. 2016, https://www.vocativ.com/281599/vegan-leather-isnt-as-ethical-as-you-think/.

Comaniţă, Elena-Diana, et al. “Environmental Impacts of Polyvinyl Chloride (PVC) Production Process.” IEEE Xplore, 28 Jan. 2016, https://ieeexplore.ieee.org/abstract/document/7391486.

“Cotton.” WWF, World Wildlife Fund, https://www.worldwildlife.org/industries/cotton.

Davis, Jessica. “Is Vegan Leather Worse for the Environment than Real Leather?” Harper's BAZAAR, 13 Mar. 2021 https://www.harpersbazaar.com/uk/fashion/fashion-news/a30640996/vegan-leather-sustaina bility/.

Deng, Yimin, et al. “Reviewing the Thermo-Chemical Recycling of Waste Polyurethane Foam.” Journal of Environmental Management, Academic Press, 27 Oct. 2020, https://www.sciencedirect.com/science/article/pii/S0301479720314523.

“Design Responsibly.” Dr. Martens Plc (LSE: DOCS), © 2021 Dr. Martens Plc, https://www.drmartensplc.com/sustainability/design-responsibly/.

Dervishi, Kevin, et al. “The Microplastics Crisis–You Are the First Responder.” Science in the News, 27 Sept. 2019, https://sitn.hms.harvard.edu/flash/2019/microplastics-crisis/.

“Docs Shoe Care.” Docs Shoe Care | Official Dr. Martens Store AU, Dr. Martens AUS/NZ, 14 June 2018, https://www.drmartens.com.au/post/shoecare-for-your-docs.html/#:~:text=CAMBRIDGE% 20BRUSH,material%20with%20a%20glossy%20finish.

“Dr. Martens Plc Sustainability Report.” Dr. Martens, © 2021 Dr. Martens Plc, https://www.drmartensplc.com/application/files/9216/2506/1932/Dr._Martens_plc_Sustain ability_Report.pdf.

GARTHWAITE, JOSIE. “Measuring Crude Oil's Carbon Footprint.” Stanford News, 31 Aug. 2018, https://news.stanford.edu/2018/08/30/measuringcrude-oils-carbon-footprint/.

“Gusset Elastic: Avetco Leather Hides and Eva Foam.” Avetco Leather Hides and Eva Foam | Avetco Leather Is a Premier Leather Hide Supplier since 1997 and Has Been Providing Quality Leathers and EVA Sheets, Fabric, Accessories to USA Manufacturers and Consumers. Check Our Diversified Leather Inventory Shop Online with Confidence or Visit Our Showroom., 16 Apr. 2021, https://www.avetcoinc.com/product/knit-elastic-100mm/.

Howard, Gary T. “Biodegradation of Polyurethane: A Review.” International Biodeterioration & Biodegradation, Elsevier, 12 Feb. 2002, https://www.sciencedirect.com/science/article/pii/S0964830502000513.

Liang , Chao, et al. “Material Flows of Polyurethane in the United States.” ACS Publications, 7 Oct. 2021, https://pubs.acs.org/doi/full/10.1021/acs.est.1c03654.

Luximon, Ameersing, and Lanyin Jiang. “The Role of Footwear Fitting and Comfort in the Environmental Impact of Footwear.” Springer Link, 12 July 2016, https://link.springer.com/chapter/10.1007/978-3-319-41694-6_19.

“Microfiber Pollution: Our Clothes Pollute the Oceans.” Ocean Clean Wash, 5 July 2021, https://www.oceancleanwash.org/.

Muthu, Subramanian Senthilkannan, and Yi Li. “The Environmental Impact of Footwear and Footwear Materials.” Handbook of Footwear Design and Manufacture (Second Edition), Woodhead Publishing, 19 Feb. 2021,

https://www.sciencedirect.com/science/article/pii/B9780128216064000156.

Muthu, Subramanian Senthilkannan, et al. “Quantification of Environmental Impact and Ecological Sustainability for Textile Fibres.” Ecological Indicators, Elsevier, 3 June 2011, https://www.sciencedirect.com/science/article/pii/S1470160X11001385.

“New Recycling Method Could Make Polyurethane Sustainable.” American Chemical Society, 29 Apr. 2020, https://www.acs.org/content/acs/en/pressroom/newsreleases/2020/april/new-recycling-meth od-could-make-polyurethane-sustainable.html.

Petter, Olivia. “IS 'VEGAN LEATHER' REALLY MORE SUSTAINABLE THAN THE REAL THING?” The Independent, Independent Digital News and Media, 1 Nov. 2019, https://www.independent.co.uk/life-style/fashion/vegan-leather-real-fake-pvc-sustainable-s ustainability-fashion-ethics-a9060911.html.

“Polyvinyl Chloride (PVC).” Encyclopædia Britannica, Encyclopædia Britannica, Inc., https://www.britannica.com/topic/industrial-polymers-468698/Polyvinyl-chloride-PVC.

“Produce Responsibly.” Dr. Martens Plc (LSE: DOCS), © 2021 Dr. Martens Plc, https://www.drmartensplc.com/sustainability/produce-responsibly/.

“PVC: The Poison Plastic.” Greenpeace, 18 Aug. 2003, https://www.greenpeace.org/usa/wp-content/uploads/legacy/Global/usa/report/2009/4/pvc-t he-poison-plastic.html.

Regan, Helen. “Asian Rivers Are Turning Black. and Our Colorful Closets Are to Blame.” CNN, Cable News Network, 29 Sept. 2020, https://www.cnn.com/style/article/dyeing-pollution-fashion-intl-hnk-dst-sept/index.html.

Shemitz, Leigh, and Paul Anastas. “Yale Experts Explain Microplastics.” Yale Sustainability, 1 Dec. 2020, https://sustainability.yale.edu/explainers/yale-experts-explain-microplastics.

“The History of Dr. Martens.” The History of Dr. Martens | Dr. Martens, https://www.drmartens.com/us/en/history.

“Vegan Definition & Meaning.” Merriam-Webster, Merriam-Webster, https://www.merriam-webster.com/dictionary/vegan.

“Vegan Leather: What It Is and Why It Belongs in Your Closet.” PETA, 1 July 2021, https://www.peta.org/living/personal-care-fashion/what-is-veganleather/.

VISHNU .V, et al. “Environmental Issues Caused by Rubber Industry.” The Environmental Impact by Nearby Businesses, 8 Jan. 2012, https://businessimpactenvironment.wordpress.com/2011/10/03/environmental-issues-cause d-by-rubber-industry/.

“What Is Microfibers Pollution and Why Is It Bad?” Ocean Clean Wash, 5 July 2021, https://www.oceancleanwash.org/the-issue/.