Design Life-Cycle

assess.design.(don't)consume

Samuel Lee

DES 40A

Professor Cogdell

12/6/18

Materials

Question: Why does a device as simple as a USB flash drive require the acquisition of such complicated materials in order to start the production process?

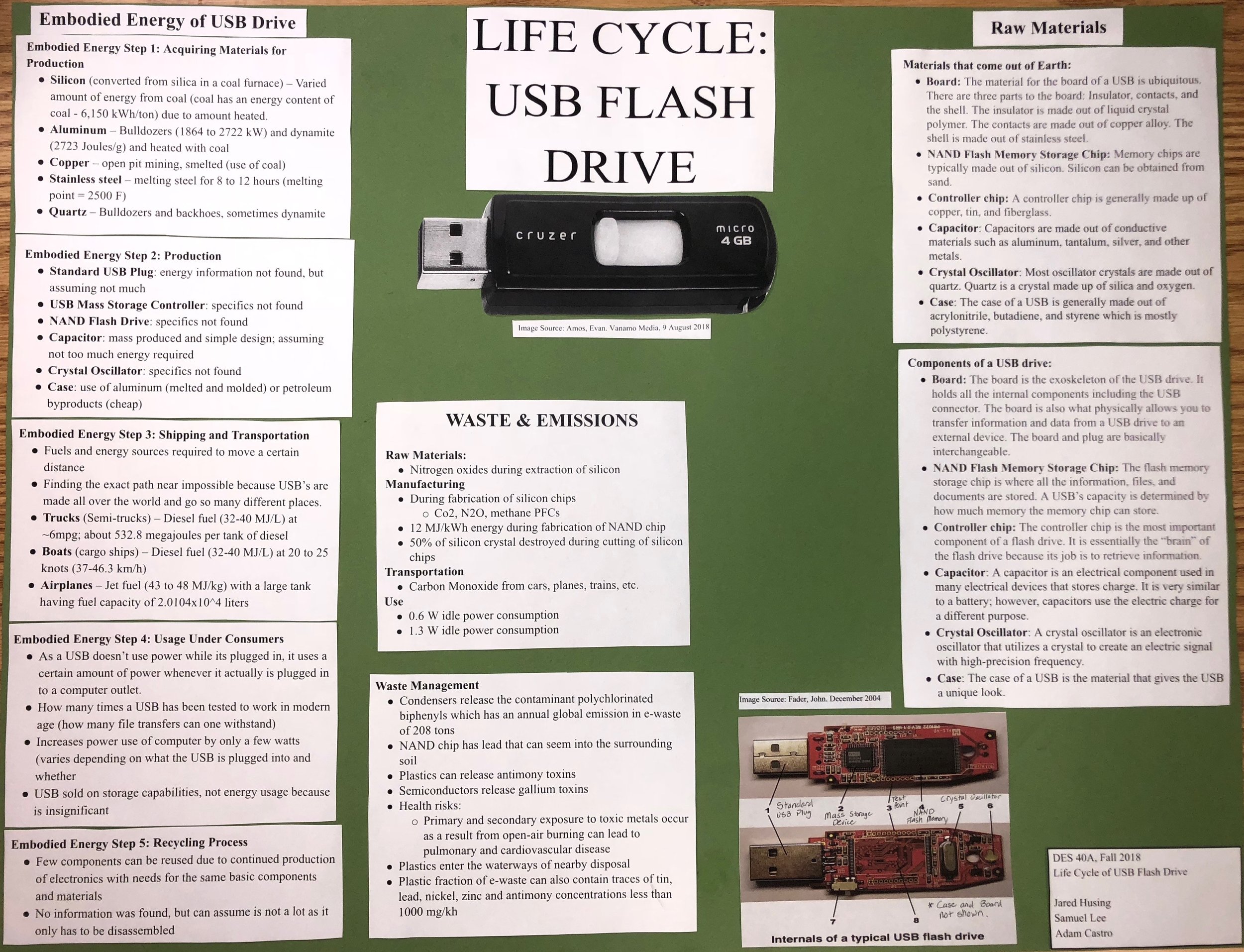

USB flash drives are ubiquitous in the technological sector. It is one of the simplest ways to transfer data from one electronic device to another. USB flash drives to the naked eye look every simple; however, this is just not the case. In order to a create a USB, one must acquire complicated materials to start and complete the production process. This essay will talk about the primary and secondary materials needed to complete the production process. Generally, there are six parts to a USB flash drive: Board, NAND flash memory storage chip, controller chip, capacitor, crystal oscillator, and the case.

The biggest part of a USB drive is the board. While it is one of the simplest parts of a USB, it requires the acquisition of hard to find materials. A board is made out of an insulator, contacts, and a shell. The first step in its cycle is to gain the materials which are liquid crystal polymer, copper alloy, and stainless steel. Liquid crystals can be found everywhere. The majority of them can be found in pegmatites which are veins formed from the liquids in the formation of granites. Copper alloys alone are not found under the Earth. One needs to first obtain copper then metal to create the alloy. Copper is found in distorted cubic crystal chunks. The ore has to first be mined then extracted to get the copper. Most common places to find Copper in the United States are the major mines in Arizona, Michigan, New Mexico, and Montana. Similar to copper alloys, stainless steel alone will not be found under Earth. Stainless steels are made out of iron ore, chromium, silicon, nickel, carbon, nitrogen, and manganese. Iron ores are found in the Earth’s crust. Chromium can be found in chromite ores which are produced in South Africa, India, Russia, and Turkey. Silicon is found in sand. Nickel can be found in the Earth’s crust. Carbon is abundant on Earth and can be found in water, rocks, magnesium, iron, and even our atmosphere. Nitrogen is found in all living organisms on Earth; however, it is also present in our soil, water, and air. Manganese is an abundant metal that can be found in the soil. Once the necessary materials have been obtained, manufacturers structure the exoskeleton of the USB.

While Silicon is the most common element on Earth after oxygen, the production process of a flash memory drive is complex. A flash memory storage chip is made out silicon. Silicon can be obtained from sand. The sand must be melted and polished to yield silicon. Once the silicon has been obtained, the silicon is made into single crystal cylinders that are six to eight inches. The cylinders are then integrated with various circuit parts with the aid of computers. Once the cylinders are integrated with the circuit parts, the circuits are layered with glass by exposing the silicon to temperatures of 900 degrees for an hour or longer. The finished memory storage chip is then integrated with the USB’s exoskeleton.

Controller chips are mostly made out of copper; however, the other materials required to finish the production process make it hard to make them. A controller chip is generally made up of copper, tin, and fiberglass. Copper is found in distorted cubic crystal chunks. The ore has to first be mined then extracted to get the copper. Most common places to find Copper in the United States are the major mines in Arizona, Michigan, New Mexico, and Montana. Tin can be found in cassiterite ores, which can be found in Bolivia, Malaysia, Indonesia, and Nigeria. Fiberglass can be obtained from glass which can be made from sand. Fiberglass is made out of glass that is made out of extremely thin strands. Most of the time Fiberglass can be bought from companies or even made with a fiberglass kit. Once the required materials have been obtained, the base is created with fiberglass sheets. The sheets are then stacked on one another with epoxy until they are thick enough to support the board. Then copper sheets are applied to both sides of the base. Once all the boards are applied with copper, the boards are once again coated with copper and tin. Lastly the controller chip is integrated with the circuits inside a USB.

Producing capacitors is an arduous task because the metals required to make it aren’t found alone in nature; instead, the metals have to be processed and combined to form new compounds. Capacitors are made out of conductive materials such as aluminum, tantalum, silver, and other metals. Aluminum is considered as the most abundant metal in the Earth’s crust; however, the metal cannot be found alone. Manufactured aluminum is the combination of other elements to form compounds. Aluminum is mostly made from the combination of potassium aluminum sulfate and aluminum oxide. Tantalum is found in the material columbite-tantalite. Tantalum can be extracted from mines in Australia, Canada, and Brazil. Silver is found all around the world. Silver can be found in mines that are located in the United States, Canada, Mexico, Peru, and China. Once the required materials have been obtained, two metal plates are placed parallel closely to each other. The plates are close, but they never touch. The plates are then connected to a terminal wire, which is what connects the capacitor to the rest of the circuit of a USB. The two metal plates are placed closely together with a dielectric.

Crystal oscillators are very complex machines; however, it is pretty easy to make one as the materials needed are quite abundant and easily obtainable. A crystal oscillator is an electronic oscillator that utilizes a crystal to create an electric signal with high-precision frequency. Quartz is made out of saturated solutions or when silicon bonds with oxygen from magma. Crystalline silica can be found in the earth’s crust. Sand, stone, and concrete are some of the materials that contain silica. Oxygen is abundant; you can basically find it everywhere. Once the required materials have been obtained, the crystal is used as a resonator to create a constant frequency.

The case is no doubt the simplest part of a USB; however, because USBs aren’t created equal, the materials needed vary greatly. The case of a usb is generally made out of acrylonitrile, butediene, and styrene which is mostly polystyrene. Acrylonitrile is an organic material that can be found in the earth’s atmosphere. It occasionally decomposes when reacting with oxygen and hydroxyl. Acrylonitrile is important to the manufacture of plastics that are useful. Butadiene is a chemical that is produced when processing petroleum. It is mainly used in the production of synthetic rubber. Styrene is another chemical that is used when producing plastics. Styrene is harmful to humans when exposed. Both Butadiene and Styrene are created as byproducts of other production processes. The chemicals are used in the creation of the unique shape that USB drives have.

The common trend when obtaining the materials needed to create a USB is that the primary and secondary materials aren’t simple. Some of these materials require multiple materials to create that particular material. For example, copper alloy alone cannot be obtained; it is the combination of copper and different metals. Regardless, the production process to create a USB flash drive is a complicated one.

Capacitors, learn.sparkfun.com/tutorials/capacitors/all.

Error, www.premiumusb.com/blog/hows-a-usb-flash-drive-mad.

“How Do Capacitors Work?” Explain That Stuff, 30 Mar. 2018, www.explainthatstuff.com/capacitors.html.

“INSIDE A FLASH DRIVE.” How USB Flash Drive Works?, 4 Nov. 2011, howflashdriveworks.wordpress.com/what-is-a-flash-drive/.

“Quartz Crystal Oscillator and Quartz Crystals.” Basic Electronics Tutorials, 21 Feb. 2018, www.electronics-tutorials.ws/oscillator/crystal.html.

“US6733329B2 - USB Flash Drive.” Google Patents, Google, patents.google.com/patent/US6733329B2/en.

“USD610156S1 - USB Flash Drive.” Google Patents, Google, patents.google.com/patent/USD610156S1/en.

“What Are the Different Types of USB Cables? | Samsung Support UK.” Samsung Uk, www.samsung.com/uk/support/mobile-devices/what-are-the-different-types-of-usb-ca

“What Is a Crystal Oscillator? - Definition from Techopedia.” Techopedia.com, www.techopedia.com/definition/2245/crystal-oscillator.

“What's Inside A USB Drive?” Premium USB, www.premiumusb.com/blog/whats-inside-a-usb-drive.

Jared Husing

DES 40A

Professor Cogdell

6 December 2018

Embodied Energy of a USB Flash Drive

A person has a research paper to type in collaboration with two other students. They currently use a collaborative feature on a word processing program that enables all members of the party to edit the same page at the same time. This is at least an example of the complex and technologically advanced civilization we are today. But what about 10 years ago? A time when computers were much larger than what we in 2018 utilize. During this time, in order for people to work with each other on the same document or file, they had to use a universal serial bus, or what is commonly known today as a USB flash drive. Fast forward to today, and people still largely use USB drives despite changes such as collaborative capabilities of word processors and cloud saving over the internet. USB drives, given their size and efficiency, still remain predominant. As this media of external storage is produced and is utilized daily by many people whether they need it for an managerial meeting with colleagues or they want to share game files with a friend, the drive has a particular amount of energy put into it and that it uses every time that it is plugged in. However, in today’s world with so many different ways to store, share and transfer files, what justifies the continued use of USB drives? Well, the general use of a standard USB flash drive justifies the device’s embodied energy through its life cycle because it is efficient in energy consumption, effective in storing information and files, and reliable for a person to utilize for many years before the device has reached the end of its life cycle.

The first step in manufacturing a USB flash drive is acquiring the necessary materials in order to begin the production process. The main component of all devices that use electricity or that is high-tech is silicon (Gray, Making Silicon from Sand). Industrial acquisition of silicon involves the gathering of silica rich sand, clay and dirt. These basic contents that one could literally find on the ground anywhere near them doesn’t require too much energy because they are rather easily obtainable. The sands and dirt are then mixed together for industrial conversion to silicon. “Industrially, silica is converted to pure silicon by heating it with coke (a form of coal, not the drink) in a furnace” (Gray). The furnace melting process takes a varied amount of energy depending on how much silica is being melted down. Usually, the industrial furnaces use coal to heat, which has a thermal energy content of 6,150 kWh/ton (or kilowatts an hour per ton) (How Stuff Works, How Much Coal is Required to Run a Light Bulb).

Aluminum, which is for the further conducting of electricity in the final product, needs to be mined from the Earth, something of which takes more energy than just melting down sand and dirt. Aluminum is found primarily in bauxite which is fairly common and found near Earth’s surface. Once bauxite or another aluminum-rich ore have been prospected, then bulldozers clear the land and dynamite is used to loosen the ground and bring the ore to the surface (Harris, How Aluminum Works). It’s difficult to find out how much energy is used by the bulldozers during the total length of the process, but a single bulldozer operating at 100% engine load uses about 1864 Kw (kilowatts) to 2722 kW at any given time depending on the engine size and what model the bulldozer is (Klanfar, Korman, Kujundzic, Fuel Consumption and Engine Load Factors of Equipment in Quarrying). Dynamite, on the other hand, is used for displacing the ground and has an energy content of 2,723 Joules per gram (Muller, Energy and Power). As dynamite is used more by the pounds (lb.) in industrial mining, a pound of dynamite has about 1,235,152 Joules. As the bauxite has been obtained, it’s then mixed with other compounds and heated under pressure in the Bayer Process to create alumina and further aluminum (Harris).

Copper is either mined from underground or from open pit mining (Calcutt, Copper: Mining and Extraction). The copper ores, of which are abundant in Earth’s surface, are mined and then pulverized to begin removing copper concentrates. The concentrates are then put into a smelter to remove impurities. Again, a smelter or industrial furnace use coal to heat the contents.

Stainless steel is also a key component of the USB drive. In order to obtain industrially, steel must be melted with chromium, silicon, nickel, carbon, nitrogen and manganese in an electric furnace for about 8 to 12 hours of intense heat (How Products are Made, Stainless Steel). As steel melts around 2500°F (1370°C) (Kross, What’s the Melting Point of Steel), there would need to be a very high and consistent electrical input. However, I was not able to find a particular measurement of the electrical requirement. Now melted, the steel alloy is now cast into a solid form and sold to the USB manufacturer.

Quartz is the last major raw material for building the components of a USB drive. Found commonly in a very large deposit in Arkansas and several other places around the globe, the mineral is mined in open pit mines. Primarily bulldozers and backhoes (a piece of mining equipment with a tractor and loading bucket) are used to remove dirt and clay to reveal a vein of quartz, but sometimes dynamite or TNT is used (McKenzie, How is Quartz Extracted?). This process is similar to the mining of that of aluminum meaning the energy used to extract quarts is very similar to that of the aluminum mining process. Once all the essential raw materials are acquired, the production process for a USB flash drive can begin.

Now that the necessary primary raw materials have been processed, now is time for them to be manufactured into basic components in order to build the final product of a USB drive. The silicon is essentially the primary component of most of all the pieces. The silicon is then cut into super thin layers known as wafers and are then polished through a process called photolithography, where a layer of photoresist is placed on the wafer and then exposed to a UV light mask shaped in the pattern of the microprocessor’s circuits (McKane, How a Computer Chip is Created). A process called ‘doping’ then takes place which is where the photoresist is washed off and the wafer is ‘hit’ with ions to alter the conductive properties of the wafer (McKane). The wafer is now fabricated with other metals such as aluminum and copper for energy conducting. The wafer is then cut into ‘dies’ which are then used in the flash drives components. An example of the parts that this makes up is the USB mass storage controller and the NAND flash drive (Boyd, Life-Cycle Assessment of NAND Flash Memory). Specifics on how much energy is required for this process was not found.

The standard USB plug is made of aluminum, as it’s the male part that plugs into computers and other devices. I couldn’t find exactly how this process is accomplished, so I’m having to assume the manufacturer melts down the aluminum and molds it into the standard USB plugs.

The capacitor is the electrical component of the USB flash drive. As the flash drive doesn’t have its own power source, it has power input to it from the computer or device itself. It works by taking in energy, storing it, and then sending it in a rapid discharge along the circuitry of the device. A capacitor is made of conductive materials such as aluminum and other metals (Jimbo, Capacitors). Through research, I couldn’t find information regarding how much energy is used in creating capacitors but only what it takes to build a capacitor. As the idea is fairly simple and cheap, my assumption is that capacitors are massed produced and don’t require too much energy to build.

Next is the crystal oscillator. This component is made simply out of a silica-quartz crystal. The quartz, once mined, is refined to where it is eventually small enough to be used in electronic devices and their components. The crystal oscillator is used to create a precise frequency for the USBs energy whenever it’s plugged in and allows the data transfer between the USB and the connected device (Quartz Crystal Oscillator). Unfortunately, information on the energy of this production process was not found, but I’m assuming that since the crystal oscillator is just a miniscule, silica-rich quartz crystal, then the energy used can’t be too much because the raw quartz just has to be refined and minimized from its true raw form.

Lastly in the production process is the outer casing for the interior components once they are all together. The cases are commonly plastic or metal. If it’s metal, it’s usually made out of aluminum. However, if it’s plastic then there are several materials that could be used. Common plastics used are acrylonitrile, butadiene and styrene. Acrylonitrile is an organic compound that can be taken from the atmosphere and made out of ammonia and propylene (Boustead, Acrylonitrile-Butadiene-Styrene). Butadiene and styrene are chemical byproducts from processing petroleum, meaning that the energy required for these processes isn’t much (Boustead). Together, these individual components made from the raw materials can now be pieced together, and the manufacturing company now has themselves a new shipment of USBs ready to be sent around the world for consumers to buy.

As so many different companies produce USB flash drives, it’s difficult to determine the exact path a USB may take, but nonetheless, the newly manufactured USB drives begin a multi-step shipping process that take it to the marketed destinations. For the instance of this research, I’m just going to find the average fuel efficiency of the most common transportation methods across the globe. Of these methods involves that of trucks, ships and boats, and airplanes (cargo). Heavy duty and medium duty trucks, of which include “tractor-trailers (semi-trucks), buses, package delivery vans and other large trucks, are among the least efficient and most heavily used vehicles on the road.” (Cuttino, New Fuel Efficiency Standard Set for ‘Big Rigs’ and More). These land-based transportation units travel an average of 120,000 miles annually and get about 6 miles per gallon (Cuttino). In the United States, ‘big rigs’ consume 37 billion gallons of fuel every year (Cuttino). Today, many semi-trucks use diesel engines such that of the Detroit Diesel DD15 14.8-liter incline six-cylinder engine (Berg, 10 Things You Never Knew About 18-Wheelers). The “energy density of diesel fuel ranges from 32 to 40 megajoules per liter (MJ/L) (Nektalova, Energy Density of Diesel Fuel). The estimated total energy output is roughly 532.8 megajoules per tank of diesel for a semi-truck.

Maritime shipping is the world’s largest and mostly used means of shipping overseas and other waterways. “To cope with speed requirements, the propulsion and engine technology has improved from sailing to steam, to diesel, and to gas turbines” (Rodrigue, The Geography of Transport Systems). The movement to these types of energy sources for propulsion was to improve the efficiency of power output and cut costs for the waterway shipping companies. A cargo ship while operating at normal levels operates from about 20-25 knots (1 knot = 1 marine mile) which equates to 37-46.3 kilometers per hour (km/h) (Rodrigue). As there are many different sizes of cargo ships, finding an average volume of diesel fuel wouldn’t be accurate but we know that diesel fuel has from 32 to 40 MJ/L.

Air transportation has been growing exponentially ever since the Wright Brothers’ maiden flight in 1903. Over the past 100 years, advances in aeronautics brought a massive increase of consumerism across the world and in more recent years, the USB flash drives. There are three types of airplanes that are used both for shipping and passenger use. Short-range aircrafts have small capacities and travel the implied short distances. Medium-range aircrafts, which are the most common, operate within a continent with a range of about 5,000 kilometers. Lastly, long-range aircrafts cross oceans and operate intercontinentally with a range of about 14,000 kilometers (Rodrigue). All the aircrafts use aviation fuel as their energy source which has a standardized energy density of 43 to 48 MJ/kg (megajoules per kilogram) (Gofman, Energy Density of Aviation Fuel). Using a long-range plane, a Boeing 737-300 for example, has a standard fuel capacity of 2.0104x10^4 liters (Eller, Energy and Power of Flying). The USB flash drives take a number of different combinations of these transportation systems. Once the device is present at retailers across the world, the flash drive is then displayed for sale and consumers can now purchase the product to suit their needs.

Now that the USB drive is in a consumer’s hands, they can enjoy the functionality of the flash drive until either the storage capacity reaches its limit, the device simply becomes too old and wears down, or it breaks. Every consumer of a USB flash drive has different living environments and also use the device in different amounts while in their possession. USB drives are estimated to last about 10,000 to 100,000 write or erase cycles depending on the memory technology used (Life Expectancy of a USB Flash Drive). It’s estimated that frequent use of a USB is about 10,000 times within 10 years. In fact, because USB flash drives are so new in terms of how long the technology has been around, most USB drives are still accessible as the memory chips (NAND flash drives) haven’t yet been rendered obsolete due to just time and oxidation of the material (Premium USB, How Long Can USB Drives Last?). Each time the USB is plugged into a computer or other device, the USB uses a certain amount of power, as the USB doesn’t have its own power source. Trials have shown that “power consumption increases when a flash drive is plugged into a laptop” by several watts (Magnes, Power Consumption of Flash Drives), but the change in energy usage by the laptop is insignificant compared to the usage of the flash drive and being able to move and save files for the lifetime of the USB device. In fact, USB marketers and companies market and sell the flash drive based on memory and conventional use instead of energy efficiency (Magnes). Once the USB flash drive has become unwanted, breaks, or becomes obsolete, the device has finally reached the end of its life, so now is time for the device to be recycled back into something else.

The USB flash drive can now be dissected into its original components in order to allow the cheaper production of new electrical devices or appliances. USBs could eventually make their way to an electronic recycling plant; however, little is out there on the specifics of recycling a USB drive. As I’ve stated before, flash drives are fairly new to the world of technology and most are still in use while not many have deteriorated to the point of recycling the individual parts. I’m having to assume that USBs can be disassembled and can send the standard USB plug, capacitor, and case (metal or plastic) to be used with other products such as in the production of other USB drives. Some companies, such as Recycle USB, take donated, unused or unwanted USBs and make them into learning tools for children 5-12 years of age (Recycle USB, Recycle Your Flash Drives for a Good Cause). In this instance, the USB is simply wiped of its containing files of which are then replaced with a standalone computer system for teaching (Recycle USB, Recycle Your Flash Drives for a Good Cause), not necessarily dissected to be recycled into something else. As such little is known, I cannot make an estimate of how much energy is relied on for this part of the life cycle process.

The general use of a standard USB drive justifies the device’s embodied energy through its life cycle because it is efficient in energy consumption, effective in storing information and files, and reliable for a person to utilize for many years before the device has reached the end of its life. Throughout its time as a functional piece of hardware, a USB flash drive offers an effective way of transferring and saving files from your computer without the need for internet in order to do so. The total energy put into the USB from the mining of the primary raw materials, to the production of the flash drive, to the shipping, usage and eventually the recycling of the device cannot fully be calculated due to insufficient information available to the public, but I’m assuming that the embodied energy of the device is enough to justify the continued use of USB flash drives despite today’s onset of cloud saving over the internet.

Word Count: 2808

Works Cited:

Berg, Phil. “10 Things You Never Knew About Semitrucks.” Popular Mechanics, Popular Mechanics, 28 Nov. 2018, www.popularmechanics.com/cars/trucks/g116/10-things-you-didnt-know-about-semi-trucks/.

Boustead, I. Acrylonitrile-Butadiene-Styrene Copolymer (ABS) . PlasticsEurope, 2005, pp. 1–14, Acrylonitrile-Butadiene-Styrene Copolymer (ABS) .

Boyd, Sarah, et al. “Life-Cycle Assessment of NAND Flash Memory.” IEEE Xplore Digital Library, 14 Oct. 2010.

Bynum, John. “Why USB Flash Drives Are Still Relevant.” MediaFast, 27 Jan. 2018, www.mediafast.com/why-usb-flash-drives-are-still-relevant/.

Calcutt, Vin. “Introduction to Copper: Mining & Extraction.” Standards & Properties: Metallurgy of Copper-Base Alloys, NACE International, Aug. 2001, www.copper.org/publications/newsletters/innovations/2001/08/intro_mae.html.

Cunningham, Andrew. “A Brief History of USB, What It Replaced, and What Has Failed to Replace It.” Ars Technica, Ars Technica, 17 Aug. 2014, arstechnica.com/gadgets/2014/08/a-brief-history-of-usb-what-it-replaced-and-what-has-failed-to-replace-it/.

Cuttino, Phyllis. “New Fuel Efficiency Standard Set for 'Big Rigs' and More.” The Pew Charitable Trusts, 16 Aug. 2016, www.pewtrusts.org/en/research-and-analysis/articles/2016/08/16/new-fuel-efficiency-standard-set-for-big-rigs-and-more.

Eller, Andrea. “Energy and Power of Flying.” Stanford Coursework, Stanford University, 14 Nov. 2013, large.stanford.edu/courses/2013/ph240/eller1/.

“Energy Use in Industry.” Factors Affecting Gasoline Prices - Energy Explained, Your Guide To Understanding Energy - Energy Information Administration, 23 July 2018, www.eia.gov/energyexplained/index.php?page=us_energy_industry.

Gofman, Evelyn. “Energy Density of Aviation Fuel.” E-World, 2003, hypertextbook.com/facts/2003/EvelynGofman.shtml.

Gray, Theodore. “Making Silicon from Sand.” Popular Science, 17 Oct. 2005, www.popsci.com/diy/article/2005-10/making-silicon-sand.

Harris, William. “How Aluminum Works.” HowStuffWorks Science, HowStuffWorks, 8 Mar. 2018, science.howstuffworks.com/aluminum2.htm.

“How Long Can USB Drives Last?” Premium USB, 4 May 2017, www.premiumusb.com/blog/how-long-can-usb-drives-last.

“How Much Coal Is Required to Run a 100-Watt Light Bulb 24 Hours a Day for a Year?” HowStuffWorks Science, HowStuffWorks, 3 Oct. 2000, science.howstuffworks.com/environmental/energy/question481.htm.

Jimbo. “Capacitors.” Capacitors, Sparkfun, learn.sparkfun.com/tutorials/capacitors/all.

Klanfar, Mario, et al. “Fuel Consumption and Engine Load Factors of Equipment in Quarrying of Crushed Stone.” pp. 163–169., doi:DOI: 10.17559/TV-20141027115647.

Kross, Brain. “What's the Melting Point of Steel?” It's Elemental - Isotopes of the Element Barium, education.jlab.org/qa/meltingpoint_01.html.

“Life Expectancy of a USB Flash Drive.” Flashbay, www.flashbay.com/blog/usb-life-expectancy.

Magnes. “Power Consumption of Flash Drives.” Real Archaeology, 27 Apr. 2011, pages.vassar.edu/ltt/?p=1029.

McKane, Jamie. “How a Computer Chip Is Created – From Sand to CPU.” MyBroadband, MyBroadband, 15 Apr. 2017, mybroadband.co.za/news/hardware/200748-how-a-computer-chip-is-created-from-sand-to-cpu.html.

McKenzie, Eleanor. “How Is Quartz Extracted?” Sciencing.com, Sciencing, 24 Apr. 2017, sciencing.com/quartz-extracted-8700692.html.

Muller. “Energy and Power and the Physics of Explosions.” The Physics of the World Trade Center Tragedy, muller.lbl.gov/teaching/Physics10/PffP_textbook_F08/PffP-01-energy-F08.htm.

Nektalova, Tatyana. “Energy Density of Diesel Fuel.” E-World, 2008, hypertextbook.com/facts/2006/TatyanaNektalova.shtml.

“Quartz Crystal Oscillator and Quartz Crystals.” Basic Electronics Tutorials, 21 Feb. 2018, www.electronics-tutorials.ws/oscillator/crystal.html.

“Recycle Your Flash Drives For A Good Cause.” RecycleUSB, www.recycleusb.com/.

Rodrigue, Jean-Paul, et al. The Geography of Transport Systems. Routledge, Taylor & Francis Group, 2017.

“US Chemical Profile: Acrylonitrile.” Trusted Market Intelligence for the Global Chemical, Energy and Fertilizer Industries, ICIS, 4 Sept. 2011, www.icis.com/explore/resources/news/2011/09/05/9489888/us-chemical-profile-acrylonitrile/.

“What's Inside A USB Drive?” Premium USB, www.premiumusb.com/blog/whats-inside-a-usb-drive.

Adam Castro

Professor Cogdell

DES040A

06 December 2018

Emissions and Waste of USB Flash Drives

Flash drives have become the most widely used, reliable form of external data storage. During the 1990s NAND flash memory prices dropped and USB had become a common standard for connecting devices to PCs. This gave way for the rise of a new data storage alternative, one that can be conveniently taken anywhere and transfer data between PCs. Then in late 2000, IBM became the first company to sell USB flash drives in the United States (Goldstein). The USB flash drive has not fundamentally changed in the past 18 years, and are still readily sold today. Even with modern data storage and transfer services (Airdrop, Dropbox, etc.) the USB flash drive is still commonly used. Although the waste created by flash drives contributes to an ever-growing amount of global e-waste, the production of flash drives leaves a small enough waste impact to justify its use and production.

A standard USB flash drive has five main components. The board holds all of the internal components of the drive and includes the USB connector. The flash drive uses the board as a means of transferring power and data to and from the USB (Long). The NAND flash memory storage chip saves and stores the user’s data. The NAND chip connects to the main circuit board, which contains an insulator, contacts, and a shell. A crystal oscillator controls data output through a phase-locked loop, regulating the data storage. The controller chip is the brain of the flash drive (Goldstein). It retrieves information from the drive and records information onto the NAND flash memory storage chip. And finally, standard USB drives come in either a plastic or metal case (Goldstein). Because plastic cases are far more common, that will be the standard used in this research. These raw materials are acquired in the first stage of the USB flash drive’s life cycle.

Acquisition and transportation of raw materials is the first stage in the flash drives life cycle. Unfortunately, there is little actual information about the specifics of a USB flash drives lifecycle. Also the company Sandisk details their corporate responsibility on their website, they give no real specifics on the lifecycle of their products. In fact, because USB flash drives are made by so many different companies, it is hard to pinpoint the exact process used to make every flash drive. Luckily, the main components of flash drives are shared through other computer accessories as well as computers themselves. The board is composed mainly of silicon. The production of sand into silicon takes about 10 gallons of water to produce and releases nitrogen oxides as a toxic byproduct (Henrik). The plastics used for an average USB flash drive case are made out of butadiene, acrylonitrile, and styrene. Styrene in particular can release harmful toxins during their extraction. And of course, CO2 emissions occur during the transportation of these raw materials to the manufacturing phase. After the transportation stage, the raw materials are then processed and manufactured to create a working flash drive

During the manufacturing phase, the raw materials are processed and compiled to create the product for sale and distribution. The components of a flash drive, including the NAND flash memory chip, boards, plastic casing, and semiconductors, are typically manufactured in China, Singapore, and Malaysia. However, there are also plants in Japan, Europe, Korea, Taiwan, and the U.S. (Boyd). These components are then shipped and assembled primarily in China, Europe, and the US. The production phase of the flash drive holds the largest share of smog emissions from nitrogen oxides (NOx) and carbon monoxide (CO). The emissions from the fabrication of the silicon used to create the boards and NAND chips can also include CO2, N2O, methane, and PFCs (Boyd). During the production of a NAND flash memory storage chip, 12MJ/kWh is consumed during the fabrication process, and water consumed during the process is 1.76 L/kWh (Boyd). The polysilicon crystal used to make the board of the drive is particularly inefficient, as nearly 50% of the crystal is destroyed in the cutting process. As for energy consumption during this phase, it takes 1.5 kW of electricity for every square centimeter of the silicon wafer (Decker). The production of the plastic casing can result in CO2 and N2O emissions into the atmosphere, as well as the introduction of microplastics in nearby water supplies of plastic production plants (Verma 705). Once these components are processed and compiled to create a working flash drive, they are then sent off to distribution.

Of course, the emissions created in the transportation and distribution phase are not insignificant. The competed flash drives are typically compiled in China, Singapore, and Malaysia, and are shipped to all corners of the world, primarily the U.S. and Europe. The transportation phase has the second largest smog emissions behind the production phase and generates seventeen to twenty-three percent of the nitrogen oxides and carbon monoxide emitted during the flash drives life cycle (Boyd). These toxic gases also include a fair amount of CO2 that is produced by the planes, boats, trains, and trucks used to ship and distribute the flash drives across the world and through the countries (Boyd). Once the drives are distributed, they are then sold and used by the consumers.

Given the practical use of flash drives, many of them have a long lifespan of use and create minimal waste and emission during their working lives. During their working lives, USB flash drives only create waste in the form of energy consumption when plugged into a device. A flash drive has an idle power is 0.6W and an active power of 1.3W. With thirty percent active, seventy percent idle operation over a four-year lifespan on 8000 hours, a standard drive would use 6.4kWh, which is drastically lower than most built-in storage devices found on PCs and laptop (Boyd). Furthermore, the average NAND flash chip within the drive can withstand 100000 to 1 million erase cycles, so the lifetime is most commonly limited by external damage done to the drive, rather than hardware failure or obsolescence (Boyd). After the flash drives have lived out its usefulness, it is finally thrown away and enters the final stage in its life cycle, waste management.

The waste created by a standard flash drive may be small individually but contributes to the world's ever-growing e-waste problem and plastic build up. Most electronic products that fall into the category of electronic waste, or e-waste, is disposed of improperly and end up in landfills, along with other household items. These landfilled electronics do not break down naturally and can pollute the surrounding land. In the case of flash drives, condensers release the contaminant polychlorinated biphenyls which has an annual global emission in e-waste of 208 tons (Robinson). Furthermore, the NAND chip has lead that can seem into the surrounding soil, plastics can release antimony toxins, and semiconductors release gallium toxins (Boyd). As for the electronics that are properly disposed of as e-waste, it is processed by the country that generated it or it is outsourced to developing countries. Out of the forty million metric tons of e-waste is produced globally a year, 13% of that weight is recycled by developing countries (McAllister). These developing countries hold informal recycling markets that process and disposed of the e-waste improperly. These countries include China, India, Pakistan, Vietnam, and the Philippines, and they handle 50-80% of this e-waste, often incinerating or dismantling the electronics (McAllister). This informal sector's recycling methods magnify health risks. Primary and secondary exposure to toxic metals occurs as a result of open-air burning to retrieve valuable components from electronics, such as gold traces (McAllister). Combustion from burning e-waste creates fine particulate matter, which is linked to pulmonary and cardiovascular disease (McAllister). Wind patterns in Southeast China disperse the toxic particles from open-air burning across the Pearl Delta Region, affecting a population of forty-five million people (McAllister). These particles can also enter the "Soil-crop-food pathway," one of the most significant ways toxins from heavy metals enter the human bloodstream (McAllister). The contaminants from e-waste can also enter aquatic systems from nearby dumpsites of processed and unprocessed e-waste. E-waste contaminants can also travel through the air through dust particles in wind or sandstorms (Robinson). The plastic casing of USB flash drives also adds to the massive amount of plastic waste generated by e-waste. Plastics incinerated in landfills are commonly incinerated, releasing toxic gases like dioxins, furans, mercury, and polychlorinated biphenyls into the atmosphere (Verma 701). The plastic fraction of e-waste can also contain traces of tin, lead, nickel, zinc and antimony concentrations less than 1000 mg/kh (Robinson). Not only do these gases contribute to climate change, but inhaling these contaminants increase the risk of heart disease, aggravate respiratory ailments, cause rashes, nausea, or headaches, and cause nervous system damage (Verma 701). The most effective way to eliminate these dangerous toxins is by complete incineration. With complete combustion, almost 90% of plastic material is reduced to carbonic acid, CO2, and water (Verma 705). Mismanaged plastic waste often finds its way to the ocean, where it can be consumed by fish or other wildlife, seriously reducing their life expectancies (Verma 705).

Despite the number of toxins a USB flash drive can emit after it lived out its usefulness, the USB flash drives lifespan is long and inconsequential enough to justify the waste and emissions it causes. Because of the sheer amount of times a flash drive can be reused by wiping its data and re-uploading new files, users are more likely to keep a flash drive until it dies and less likely to throw it out before it reaches the end of its usefulness. Furthermore, because USB flash drives hold important data, a user would be unlikely to throw out flash drives they don't even use in fear of losing irreplaceable files. Plus, although the global e-waste build-up has many devastating effects on the environment, USB flash drives take up a very small amount of the e-waste load. The waste created by a single flash drive is fairly insignificant in the tremendous e-waste crisis, and their usefulness combined with their long life makes the justifies the waste it produces throughout its life cycle.

Works Cited

Boyd, A. Horvath and D. Dornfeld, "Life-Cycle Assessment of NAND Flash Memory," in IEEE Transactions on Semiconductor Manufacturing, vol. 24, no. 1, pp. 117-124, Feb. 2011.

Decker, Kris De. “The Monster Footprint of Digital Technology.” LOW-TECH MAGAZINE, 2009, www.lowtechmagazine.com/2009/06/embodied-energy-of-digital-technology.html.

Goldstein, Phil. “What Is a Flash Drive: Your Answer for Simple File Transferring.” BizTech Magazine, 2 June 2017, biztechmagazine.com/article/2017/06/usb-flash-drive-made-file-transfers-simple-and-easy.

Henrik Myrhaug, Edin & Tveit, Halvard & Eivind Kamfjord, Nils & Andersen, Johan & Grøvlen, Åslaug. (2012). NOx Emissions from Silicon Production.

“INSIDE A FLASH DRIVE.” How USB Flash Drive Works?, 4 Nov. 2011, howflashdriveworks.wordpress.com/what-is-a-flash-drive/.

Long, E., Kokke, S., Lundie, D., Shaw, N., Ijomah, W., & Kao, C. (2016). Technical solutions to improve global sustainable management of waste electrical and electronic equipment (WEEE) in the EU and china. Journal of Remanufacturing, 6(1), 1-27. doi:http://dx.doi.org/10.1186/s13243-015-0023-6S.

McAllister, Lucy. “The Human and Environmental Effects of E-Waste.” Population Reference Bureau, 4 Apr. 2013, www.prb.org/e-waste/.

“Quartz Crystal Oscillator and Quartz Crystals.” Basic Electronics Tutorials, 21 Feb. 2018, www.electronics-tutorials.ws/oscillator/crystal.html.

Raynaud, Julie. Valuing Plastic : the Business Case for Measuring, Managing and Disclosing Plastic Use in the Consumer Goods Industry. Nairobi, Kenya : UNEP, 2014

Robinson, Brett. “E-waste: An assessment of global production and environmental impacts”, Science of The Total Environment, Volume 408, Issue 2, 2009, Pages 183-191, ISSN 0048-9697, https://doi.org/10.1016/j.scitotenv.2009.09.044.

SanDisk. “Reducing Our Environmental Impact.” SanDisk - Environmental Responsibility, Western Digital Technologies, Inc., 2018, www.sandisk.com/about/corp-responsibility/environmental-responsibility.

“What’s Inside A USB Drive?” Premium USB, US Digital Media, 12 Jan. 2017, www.premiumusb.com/blog/whats-inside-a-usb-drive.

Verma, Rinku. “Toxic Pollutants from Plastic Waste - A Review.” Microplastic Contamination in Aquatic Environments An Emerging Matter of Environmental Urgency, vol. 35, Elsevier, 2016, pp. 701–708.

Yussup, N., Ibrahim, M. M., Lombigit, L., Rahman, N. A. A., and Zin, M. R. M. Implementation of data acquisition interface using on-board field-programmable gate array (FPGA) universal serial bus (USB) link. United States: N. p., 2014. Web. doi:10.1063/1.4866106.