Design Life-Cycle

assess.design.(don't)consume

Feier Shen

Des40A Section 2

Professor Cogdell

4 December 2019

Raw Materials: Life Cycle of Fossil Leather Bags

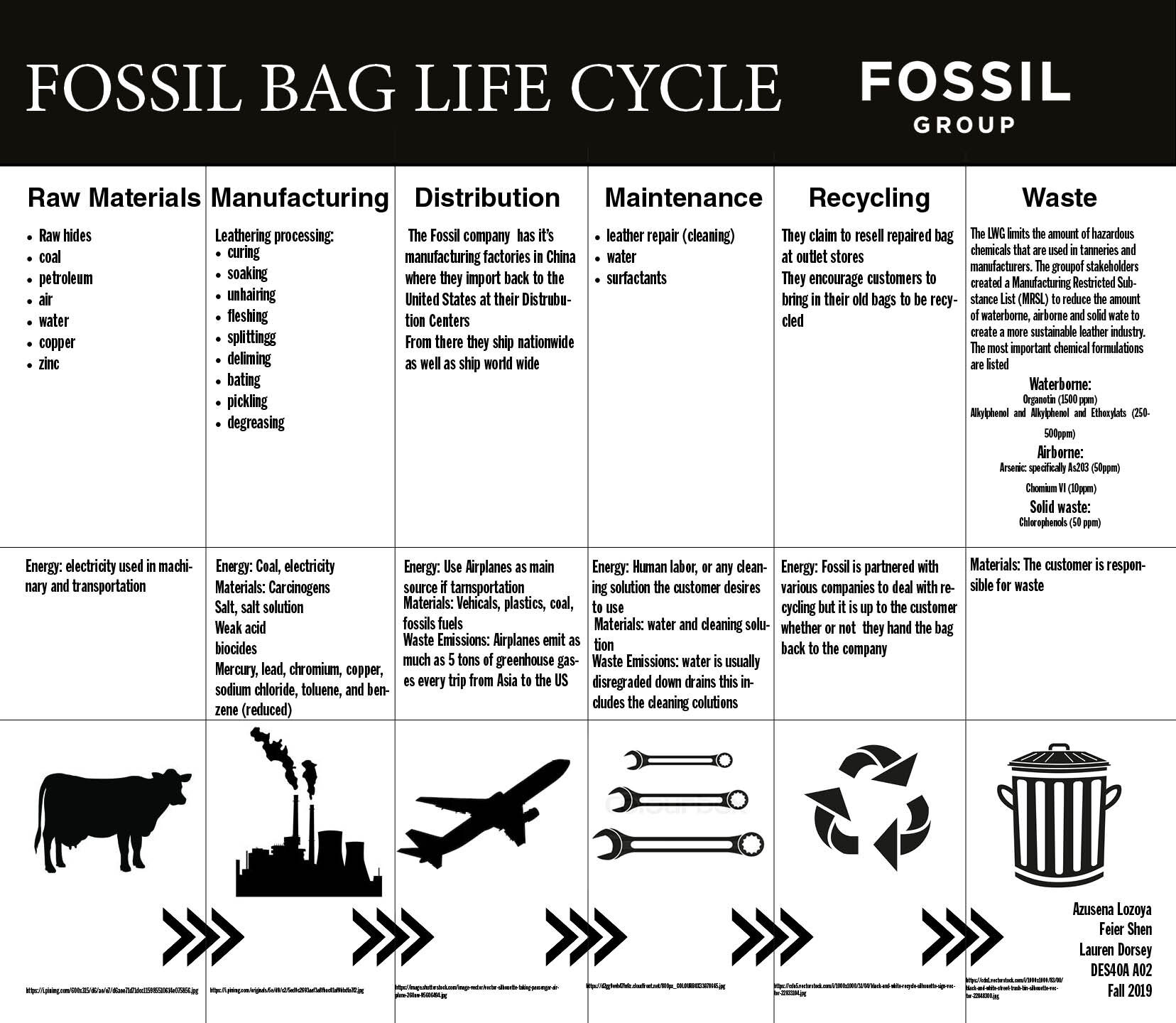

The Fossil brand is created under the Fossil Group, which was founded by American fashion designer and manufacturer, Tom Kartsotis, in 1984. Popularized for their leather products, Fossil states that they make their products with high-quality, real leather. This also includes their leather bags. Through the collaborations with Fossil Group and Leather Working Group, who advocate for ethical and sustainable production processes, the Fossil brand claims to be sustainable (“Going Global”). While they might claim to be sustainable and put forth the effort to collaborate with sustainable organizations, it is still questionable whether their practices are sustainable in actuality with the materials they use. In this life cycle study of Fossil leather bags, I will focus on the raw materials that go into their production. For a typical Fossil leather bag, leather, polyester, and brass are the three main components. Leather is used on the exterior of the bags, polyester for the interior, and brass for the hardware. I will go through the acquisition of raw materials, the manufacturing process, distribution, maintenance, recycle, and waste management.

While Fossil tried to make a statement about sustainable leather production practice, the method of acquisition for hides to make leather seems anything but sustainable. The making of leather starts with the acquisition of raw hides and skins. When removing the hide from the animal, the animal is usually alive because “as soon as an animal’s heart stops beating, its skin will begin to rot” (Brown, 213). It is quite brutal because the animal has to endure the pain of its skin being stripped off alive. This also implies that the animal is still barely alive (if shortly) after the skin is flayed from its body. It demonstrates that the environmental burden of leather production causes the suffering and deaths of countless animals each year. Although Fossil states that they are working with Fossil Group and Leather Working Group to make their leather production more sustainable and ethical, it doesn’t specifically show how they would approach the acquisition of animal hides for leather. Regardless of their claims, leather is still a product of animal cruelty and suffering.

There are multiple steps in the manufacturing of leather before it can be cut and made into bags. This process includes curing, soaking, liming, unhairing, fleshing, splitting, deliming, bating, pickling, degreasing (213). To prevent hides from deterioration, the hides have to be preserved before the leather making process. Some practices to preserve hides include salting, chilling, freezing, and the use of biocides (Anicca Solutions). The pelt then goes through the process of rehydrated (soaking). Afterward, the skinned is loosened up (liming) for the removal of unwanted hair, fat, and flesh (unhairing and fleshing) (Brown, 213). Then the pelt is split into the grain and the flesh layer (splitting) for deliming, which aims to neutralize “the alkali in the pelt, avoiding rapid changes in pH which could lead to distortion or disruption of the tissues” (Anicca Solutions). Next, the pelt is bated (the use of enzymes) to clean and soften the skin. During the pickling process, weak acid and salt solutions are used to adjust “pH for transportation, storage, or tannage” (Brown, 213). Before tanning, solvents or water-based systems are used to remove unwanted grease. Tanning is the process “which convert[s] the raw hides into leather, using vegetable, mineral, synthetic, or combination method” (213). According to the claim by the Leather Working Group, they would reduce the use of mercury, lead, chromium, copper, sodium chloride, toluene, benzene, and other toxic substances. However, they haven’t stated what they might use as substitutes. This practice might not be truly green but by regulating the use of these harmful substances, Fossil is taking steps to be more sustainable. The complex steps required to manufacture leather is a labor of time that might also damage the environment. The chemicals used during the process of converting rawhides to leather can pollute air and waters. As mentioned above, even though Fossil appears to advocate for sustainability, the reality of leather manufacture is hardly sustainable.

Besides the leather exterior, the polyester is used for the interior of the Fossil leather bags. Polyester is made through the chemical reaction using coal, petroleum, air, and water in a high-temperature vacuum. This reaction, called polymerization, forms a strong synthetic fiber as a result(Jr, Esteban Robles). As a complement to the leather exterior, the polyester interior is cut and sewn together with the leather that can provide high durability. However, the production process of polyester “uses harmful chemicals including carcinogens” (Francesca), which can cause severe environmental damage, polluting water and air if left untreated. Asides from the production of the polyester, the dyeing process of polyester can also be harmful because “polyester cannot be dyed using low impact and natural dyes”. This might mean resorting to synthetic dyes to yield better pigmentation. In a study called Biological Staining by F..J. Baker, he presents that “synthetic dyes are sometimes referred to as ‘coal tar dyes’, since they are manufactured from substances which, until recently, were only obtained from coal tar” (Baker). By doing this might raise environmental concerns for water supplies, especially for people who rely on those water sources to survive. Although Fossil is not explicit on how they dye their polyester fabric, there is a way of dyeing polyester green and naturally through the use of carbon dioxide as a dyeing medium (Pawar). A practice such as this would be aligned with Fossil’s claim to be sustainable and ethical. However, since it was not explicit, there is no guarantee that it was the case during their manufacturing process of polyester.

In addition to leather and polyester, brass zippers, buckles and other decorations are also a part that gave Fossil bags their iconic look. Brass is an alloy of copper and zinc (The Editors of Encyclopaedia Britannica). The hardness and softness of brass may vary depending on the ratio of copper and zinc. Other metals may also be used in the process such as aluminum, lead, and arsenic, to “improve machinability and corrosion resistance” (Bell). Due to its malleability, it can be forge, cast, and chased into desired shapes during manufacturing.

The manufacturing process takes place outside of the U.S. even though Fossil is based in Texas. In the description of bags on the Fossil website, it says that materials are imported. When tracing down the history of Fossil, the primary Fossil lines are in Switzerland and China (“Fossil Brand History”; Buchanan). For consumers in the U.S., this implies that the bags they buy will have to travel by air, which involves the use of oil and fuels for transportations.

From the online Fossil support, they say they would wrap the bags in plastic before shipping them for protection. Their intent to wrap their bags before shipping shows that they care for the bags to arrive at their customers' doorsteps undamaged. This layer of protection might prevent the leather from being scratched. The major materials that make plastic are oil and natural gas (“Life Cycle of a Plastic Product”). According to Yutaka Tokiwa (et al.), “most conventional plastics such as polyethylene, polypropylene, polystyrene, poly(vinyl chloride) and poly(ethylene terephthalate), are non-biodegradable, and their increasing accumulation in the environment has been a threat to the planet” (3723). This means that the choice of using plastic wrapper when distributing might have protected the bags, but it can also take a toll on the environment if not disposed of consciously. It seems what to do with the package depends on the consumers.

Regarding the maintenance of the leather bags, Fossil says on their website that there is a warranty for customers to ask the company for repairs. However, after the warranty, they do not accept returns and it depends on the consumer what to do with old/damaged bags. Even though Fossil produced these leather bags, it seems the consumers’ decision also determines a large part of their life cycle. Though they have clear repair and return policies, what they would do to take care of the leather, polyester fabric, and brass hardware is unknown. It also depends on the customer if they are going to send the bags to Fossil for maintenance, which might include washing and brushing with warm water.

Fossil claims that they would recycle and repair damaged bags and resell them at outlet stores, however, it’s unclear what they would do to the ones that are not able to be resold. If these materials end up in landfills, the polyester interior and the brass hardware is not biodegradable. This waste might accumulate and pollute the environment, which is the opposite of sustainable. While leather is biodegradable, the chemicals used to manufacture leather can harm the environment. Once again, it seems the responsibility to deal with old and/or damaged bags depends on the consumers. Fossil does not state information regarding the bag after it was bought by the consumer. It might be because that information such as this can sometimes be considered irrelevant by the supplier if the goal was for the consumer to buy their products. What might attract consumers is not the aftercare, but the new and the latest trending styles.

Going through the life cycle of Fossil leather bags, there seems to be less and less information regarding maintenance, recycle, and waste management. As consumers, people seem to pay more attention to the product they are getting instead of where it came from and going to end up. At the same time, companies such as Fossil doesn’t seem to be interested in including the narrative of their leather bags after they have produced and shipped them. It might be due to their lack of transparency on these subject matters or they simply didn’t think it was necessary. The Fossil company might claim to be sustainable and ethical, yet it might not be the case. Through the assessment of the raw materials used throughout the life cycle of Fossil leather bags, it seems their claim about sustainability is questionable. The animal cruelty and pollution involved in the life cycle of Fossil leather bags is not as ethical and sustainable as they claimed. However, Fossil at least gets the credit for collaborating with Fossil Group and Leather Work Group to start a conversation about sustainability and moving towards sustainable practices in the leather product manufacturing.

Bibliography

Anicca Solutions. “How Is Leather Made?” Advice on Leather Care, Leather Cleaning and More Brought to You by BLC, the Leather Experts, www.all-about-leather.co.uk/what-is-leather/how-is-leather-made.htm. http://www.all-about-leather.co.uk/what-is-leather/how-is-leather-made.htm

Bell, Terence. “Here's Why Alloys Can Change the Properties of Brass.” The Balance, The Balance, 2 Sept. 2019, www.thebalance.com/composition-of-common-brass-alloys-2340109.

Brown, Stephen G. "The making and coloration of leather." Journal of the Society of Dyers and Colourists 110.7 (1994): 213-214.

Buchanan, Norma. “Fossil Watches Made in Switzerland? Inside Fossil's Swiss Mission.” WatchTime, 3 Apr. 2019, www.watchtime.com/featured/fossil-watches-made-in-switzerland-inside-fossils-swiss-mission/.

“Crazing Technology for Polyester Fibers.” Duxford, United Kingdom: Woodhead Publishing, Duxford, United Kingdom, 2017.

“Fossil Brand History :: Fossil Watches Brand History.” Fashion Gear Latest Fashion Trends of Styles Fashion Models Fashion Designers, fashiongear.fibre2fashion.com/brand-story/fossil/timeline.asp.

“Fossil, Inc.” FundingUniverse, www.fundinguniverse.com/company-histories/fossil-inc-history/.

Francesca, et al. “The Environmental Impacts of Polyester.” Tortoise & Lady Grey, 30 Apr. 2019, www.tortoiseandladygrey.com/2016/08/29/environmental-impacts-polyester/.

“Going Global: Our Commitment To Sustainable Design.” Fossil Group, 11 July 2018, www.fossilgroup.com/going-global-commitment-sustainable-design/.

Jr, Esteban Robles, et al. “How Is Polyester Made? - How Is Polyester Made?” Craftech Industries, 14 Nov. 2019, www.craftechind.com/how-is-polyester-made/.

“Life Cycle of a Plastic Product.” Plastics Division : Life Cycle of a Plastic Product, web.archive.org/web/20100317004747/http://www.americanchemistry.com/s_plastics/doc.asp?CID=1571&DID=5972.

Marten, Ted. “How Are Handbags Made?” Our Everyday Life, 5 Feb. 2019, oureverydaylife.com/how-are-handbags-made-12171121.html. https://oureverydaylife.com/how-are-handbags-made-12171121.html

Pawar, Sushant S., et al. “A Novel Green Approach for Dyeing Polyester Using Glycerine Based Eutectic Solvent as a Dyeing Medium.” Heliyon, vol. 5, no. 5, 2019, doi:10.1016/j.heliyon.2019.e01606.

The Editors of Encyclopaedia Britannica. “Brass.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., 26 Apr. 2019, www.britannica.com/technology/brass-alloy. https://www.britannica.com/technology/brass-alloy

Tokiwa, Yutaka, et al. "Biodegradability of plastics." International journal of molecular sciences 10.9 (2009): 3722-3742.

“Where Are Fossil Watches Made?” Reference, IAC Publishing, www.reference.com/beauty-fashion/fossil-watches-made-4ff27f2f4d9dd0f6.

Baker, F. J. “Biological Staining.” Synthetic Dye - an Overview | ScienceDirect Topics, ScienceDirect, 1976, www.sciencedirect.com/topics/engineering/synthetic-dye.

Azusena Lozoya

Professor Cogdell

DES40A A02

Fall 2019

Energy

The American Brand ‘Fossil’ prides upon being a modern company that is sustainable. It’s a company which started in the ’90s that has used real leather for its bags. Fossil has its design base in Switzerland but manufacturers its products in China that implies the frequent use of Airplanes, trains and further modes of transport that each has their own large carbon footprint just to reach stores with its distribution stores being in Germany, Asia and Dallas. Being an American brand, there is so much outsourcing that requires enormous energy consumption which leads to pollution, waste and unnecessary energy consumption. As well as the huge industry it requires to upkeep the livestock and agriculture it takes to feed those animals.

The Fossil company relies on its global aviation to serve it’s customers like most companies, however, one flight from Asia to the US can produce as much as 5 metric tons of carbon equivalent emissions, which includes both carbon dioxide and other greenhouse gasses. One flight from the West to the East coast across the U.S. produces at a minimum 1 metric ton of carbon dioxide. In comparison, every human combined produces 5 metric tons of carbon dioxide produced every year on the planet. The carbon footprint produced by Airplanes alone is so immensely impacting our planet that it’s a leading cause of global warming.

Despite Fossil’s efforts to be sustainable what they fail to recognize their efforts are bandages on the broken bones of the foundation, they stand on. Some may claim that they need to cooperate with the capitalist’s way of doing things but in actuality what their goal first and foremost is to generate money. Rarely do companies stray away from the path made out by previous companies that claim it to be the most profitable. The Fossil company is an American based company in Richardson, Texas and they manufacture their bags in China, most likely to take advantage of the cheap labor force. This isn’t a mystery to anyone as many companies do this now to the point of it being “common business practice”. Not only is it a humanitarian issue, but it also affects everyone through the increase of carbon emissions through transportation from China to the distribution centers in the United States. The bigger problem is when looking at the political standpoint of shipping internationally, countries like China and the United States have customs or taxes for shipping worldwide and one way the United States bypasses this heavy cost is not shipping directly. For instance, Instead of one plane from China to the United States, it’s shipped from China to Taiwan and then to Australia and so on until it finally reaches the US. While companies save thousands of dollars from tariffs and fees there is no such much as a thought into the caron footprint each plane ride leaves behind.

Factories also negatively impact the environment through air pollutant emissions, toxic waste disposal, and water contamination. They're the major offenders when it comes to greenhouse gas contributions. Factories alone are responsible for nearly two-thirds of the emissions to blame for global climate change. This is due partly in fact to the American way of consumerism, Fashion companies like Fossil constantly design and manufacture new items for every season, every holiday, and new trend. In response to the fashion industry demand to be the newest thing, this leads to factories having to pump out new products one after another without care for the energy consumption required to keep up these places.

With having its emphasis on manufacturing in China, it further adds to China’s title of having the largest carbon footprint in the world since 2004. Despite being one of the richest and most populated countries in the world it hasn’t made a large stance on reducing carbon emissions with its reliance on coal power until recently. According to the NEA, in the first three quarters of 2017, coal consumption in China reached 2.81 billion metric tons, an increase of less than 1 percent from 2016. A similar estimation of 2.82 billion to 2.83 billion tons is corroborated by the Energy Research Institute of the NDRC. American companies like the Fossil Group are playing their hand in not only relying on other countries for cheaper labor but using their broken system to further capitalize on wealth.

Fossil promises it’s authenticity when it comes to its leather bags, however the upkeep it requires to raise and maintain livestock takes up so much energy, materials, etc. There is also the waste from livestock like cows we must consider. A cow on average releases between 70 and 120 kg of Methane per year. Methane is a greenhouse gas like carbon dioxide (CO2) and the negative effect on the climate of Methane is 23 times higher than the effect of CO2. The energy consumed in livestock operations is almost solely direct energy consumption and is relatively low compared with crop operations, both as a percentage of total operating expenditures and on a total energy basis. Livestock upkeep consumes direct energy for ventilation systems, refrigeration, lighting, heating, watering, motors, and waste handling, whereas crop operations use energy to plant, harvest, irrigate, and dry crops. A total of almost 30% of all agricultural farming is used just to feed our livestock. Fossil not only uses leather for its bags but watches, handbags, wallets, etc. which all require leather in some shape or form.

When the bags are finally manufactured and transported, it’s either sold in stores or online. The Fossil group from 2016 to 2018 alone operated 217 stores nationwide and 484 globally. Retail buildings consume $20 billion in energy each year. If retailers are able to harness the energy efficiencies available by leveraging existing technologies, this consumption could be reduced by $3 billion a year according to Schneider Electric. Even though statistics show that retail stores are opening fewer and fewer stores every year due to online shipping this doesn’t negate the energy costs of shipping. Approximately 96% of fuel from transportation is in the form of petroleum, 2.6% is natural gas, and less than 1% is biomass, electricity, or other fuels. Overall, transportation is responsible for approximately 70% of all U.S. petroleum consumption. Some might claim that shipping is putting fewer drivers on the road because the products are coming to them but according to Tanya Mohn from Forbs magazine, An average driver in the United States spends an additional 20 minutes behind the wheel each week compared to five years ago. That adds up to nearly an hour driving and traveling 31.5 miles a day - a five % increase. Collectively, over the course of a year, Americans are spending more time driving -- something like 70 billion hours, an 8% increase from 2014.

So Americas are driving more, buying items meant to be replaced as soon as the season changes and relying on a limited fuel source destroying our ozone layer. The Fossil Group has set out to stand out from the rest but it remains a prime example of American greed and exploitation of resources. They outsource from countries in China, as well as the huge transportation carbon footprint created just to sell move their products from one country to another. The constant emissions from, planes, trucks, cars, ships, etc all contribute a wider problem that no one is tackling which is the waste of energy and effect it has on our environment.

Bibliography

“Environmental Impact of Aviation.” Wikipedia, Wikimedia Foundation, 21 Oct. 2019, en.wikipedia.org/wiki/Environmental_impact_of_aviation.https://en.wikipedia.org/wiki/Environmental_impact_of_aviation

“Leather Industry.” Leather Industry - an Overview | ScienceDirect Topics, https://www.sciencedirect.com/topics/earth-and-planetary-sciences/leather-industry

Weise, Elizabeth. “Flying Is Bad for the Environment, Here Are Some Tips to Make It Less Carbon-Intensive.” USA Today, Gannett Satellite Information Network, 27 Dec. 2018, https://www.usatoday.com/story/news/2018/12/26/flying-bad-environment-heres-what-do/2350488002/

“Supply Chain.” Fossil Group, www.fossilgroup.com/compliance/supply-chain/.https://www.fossilgroup.com/compliance/supply-chain/

“Fossil Brand History ": Fossil Watches Brand History.” Fashion Gear Latest Fashion Trends of Styles Fashion Models Fashion Designers, fashiongear.fibre2fashion.com/brand-story/fossil/timeline.asp.http://fashiongear.fibre2fashion.com/brand-story/fossil/timeline.asp

Calculation of a Corporate Carbon Footprint (CCF) for a Leather Factory with Evaluation of Internal Energy Consumption in Comparison to the BEET Energy Benchmark (Best Energy Efficiency for Tanning). ECO2L, Jan. 2013, http://www.eco2l-leather.com/wp-content/uploads/2013/01/ECO2L-Leitfaden.Handbook-complete-1-2013_GB1.pdf

“U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.” Energy for Growing and Harvesting Crops Is a Large Component of Farm Operating Costs - Today in Energy - U.S. Energy Information Administration (EIA), https://www.eia.gov/todayinenergy/detail.php?id=18431

“Fossil Group: Number of Stores by Region Worldwide 2016-2018.” Statista, https://www.statista.com/statistics/912484/fossil-group-number-of-stores-by-region-worldwide/

Mohn, Tanya. “Americans Are Driving More, And That Means More Risk.” Forbes, Forbes Magazine, 28 Feb. 2019, https://www.forbes.com/sites/tanyamohn/2019/02/27/americans-are-driving-more-and-that-means-more-risk/

Jamieson, Meriah. A $3 Billion Opportunity: Energy Management in Retail Management. Schneider Electric, http://resourceadvisor.com/assets/a_3_billion_opportunity_energy_management_in_retail_operations.pdf

Lauren Dorsey DES 040A Christina Cogdell December 4th, 2019

FOSSIL Leather Handbags (Waste and Emissions)

Before I conducted any research on natural leather, I assumed that the overall process of leather, beginning with attaining hides from cows and sometimes pigs, sanitizing those hides, tannery and chemical processing, dying, and manufacturing would be a concise and much more sustainable process given that leather has been a common material in fashion apparel for many years. However, with the research I have now conducted, I find that many tanneries, factories and manufacturers have an incomprehensible amount of waste and emissions throughout the process. When specifying what kind of waste and emissions, I am dividing my research into three categories being waterborne, airborne and solid waste, to explain what we know is only a small portion of the leather industry. Many organizations have maintained this process to produce leather goods, a process that lacks energy efficiency and ignores large amounts of waste at every step, but there are some companies that are finding new ways to make the leather industry as sustainable as possible. The FOSSIL company attempts to consider the amount of waste and emissions that go into the creation of their leather bags, which is seen through their partnership with LWG (Leather Working Group) and in collaboration in the Sustainable Leather Sourcing Project. Their practices with leather are much more sustainable compared to the practices that are taken with common tanneries, and their production and manufacturing. The companies’ priority is to move forward in sustainability and to create an environmentally friendly manufacture of tanning but does not consider the recyclability of those leathers.

FOSSIL Inc., a popular American brand based in Richardson, Texas and founded in 80s, has moved in a positive direction towards a sustainable leather industry through their collaboration with the Leather Working Group (LWG), a group of stakeholders that “develop and maintain a protocol that assesses the environmental compliance and performance capabilities of leather manufacturers.” (Leather Working Group ‘About Us’) The LWG works in collaboration with 400 members including leather manufacturers and suppliers as well as brands. It is common now in the 21st century that many companies are doing the same, but what sets FOSSIL apart from other companies working with the LWG is their independent work on the Sustainable Leather Sourcing Project. The objective of the project is to source leathers from preferred suppliers. Whitney Josey, director the FOSSIL Group’s Sustainability and Supply Chain explains, that the group works to “source leather from LWG-audited members because it means [they’re] sourcing from tanneries who are following the appropriate environmental factors, such as where [the leather] is coming from, the amount of water and chemicals used, and how it’s disposed of.”(FOSSIL Group, “Going Global”) The FOSSIL group regulates their tannery facilities to maintain a sustainable leathering process by conducting a bi-annual audit, to make sure each facility has met the requirements for the year. According to the LWG, “a rating of gold, silver, bronze or audited (a leather manufacturer that has gone through the audit process, but has not achieved a high enough score to be medal- rated) is awarded to tanneries depending upon their score during the auditing process.” (FOSSIL Group, “Going Global”) The LWG’s audited tanneries represent around 16% of total leather volume globally.

The LWG considers many aspects of waste in leather processing, especially waterborne waste. The waterborne waste in leather processing is the easiest to trace going back to the raw materials. According to the EPA, “animals [specifically cows] on factory farms produce 130 times as much excrement as the entire human population, without the benefit of waste treatment plants.” (PETA) The EPA also acknowledged that livestock pollution including is the greatest threat to our waterways. This livestock pollution includes salt, lime sludges, sulfides and acids which prevent the hides skin from rotting. Although the LWG has not taken preventative action toward this type of waterborne waste, it is important to identify where we can first pinpoint waterborne waste in the overall process. Moving into tanneries, we see waterborne waste through chemicals such as mineral salts, formaldehyde, coal-tar derivatives, and various oils, dyes, and finishes. This large part of the leather process has been analyzed by the LWG already, and the group has already come to a solution to solve this problem.

In December of 2015, the Zero Discharge of Hazardous Chemicals (ZDHC) Leather Manufacturing Restricted Substances List (MRSL) was released to the leather industry and endorsed by the LWG (“A Guide to Understanding MRSL”). The MRSL is a specified list of hazardous and non-hazardous chemical formulations used in the leather industry. The purpose of such a detail-oriented oriented list is to regulate which chemicals need minimal use (hazardous chemicals) and which can be used more (non-hazardous chemicals). The LWG made a separate list, shown in Figure 1 of the Restricted Substance List (RSL), a list of chemicals that should not be used in any part of the leather process.

According to the MRSL, tanneries and manufacturers under the LWG reduce the use of waterborne waste like Carbon Black, a formulation that is prevalent in Polycyclic aromatic hydrocarbons (PAHs), “natural components of crude oil and are a common residue from oil refining” according to the MRSL (“MRSL 2015”). Another significant waterborne waste in organotin which, when associated with plastics/rubber, inks, paints, metallic glitter, polyurethane (MSRL limited to a sum of 1500 ppm per chemical supplier) products and heat transfer material, becomes a biocide. The MRSL notes this formulation should be used minimally because it is a biocide. However according ISC water solutions, a company that works to create clean, non- hazardous water in many different countries, biocides in water can be oxidized to “eliminate your nuisance microbes while protecting the environment.” (ISC) Again, the objective of the MRSL is to list the minimum use if hazardous formulations but to also show the benefits of non-hazardous chemical formulations. Alkylphenol (AP) and Alkylphenol Ethoxylates (APEOs) a family of organic compounds (limited 250 to 500 ppm per chemical supplier) that are high performance, cost-effective, compounds that have been safely used in a wide variety of products and applications for over fifty years,”(APES Research Council) are commonly found in leather processing “in a variety of formulations such as detergents, wetting agents, emulsifier dispersing agents, dedusting agents for dyes and prints, dyes and pigment preparations, degreasing and fur scouring agents, fat liquors and greases, waterborne dispersions and emulsions used in the beam house and finishing agents.” (“MRSL 2015”) We see in Figure 2 that the MRSL requires their manufacturers and tanneries to be aware of the chemical formulations to prevent a mass amount of waterborne waste.

The same is also seen in the airborne waste and emissions of the LWG manufacturers and tanneries. My research in airborne waste did not extend itself in comparison to waterborne waste in leather processing. What I was able to find was the amount if arsenic used to process leather can be used in preservatives, pesticides and defoliants for cotton according to the MSRL, as well as any trimmings (associated with solid waste), ink, paints and synthetic fibers. According to Green Facts on Health and the Environment “arsenic is emitted into the atmosphere by high-temperature processes such as coal-fired power generation plants, burning vegetation and volcanism. Natural low-temperature biomethylation and reduction to arsines also releases arsenic into the atmosphere. Arsenic is released into the atmosphere primarily as As2O3 and exists mainly adsorbed on particulate matter. These particles are dispersed by the wind and are returned to the earth by wet or dry deposition.” (Arsenic) The MRSL limit their manufacturers to about 50 ppm per chemical supplier, as we see in Figure 3, showing the MRSL on Arsenic and Chromium. According to the LWG restricted list Arsenic is one of the most hazardous chemical formulation on the list, also considering fire retardants in manufacturing and factories, causing cases of leukemia and lung cancer in people that come into contact with it often, especially those who work in factories, or live next to these factories.

The solid waste found in the leather processing could be traced similarly to waterborne waste. The solid waste identified in the MSRL include organotin compounds, chlorophenols are polychlorinated compounds and naphthalene. According to the list, organotin “a class of chemicals combining tin and organics such as butyl and phenyl groups. Organotin are predominantly found in the environment as antifoulants in marine paints, but they can also be used as biocides (e.g. antibacterial), catalysts in plastic and glue productions and heat stabilizers in plastics rubber.” (RSL 2015) Chlorophenols and polychlorinated compounds are used as preservatives or pesticides. Under the Resource Conservation and Recovery Act (RCRA) regulations, chemical products like pesticides are considered "solid wastes" at the point where the pesticide's holder decides to discontinue the use of them. This is exactly what the LWG did in 2015. Because the pesticides found in leather processing became hazardous, chlorophenol and polychlorinated compounds are now “regulated and no longer of use” to the group. My findings in solid waste relate to the research found on both waterborne and airborne wastes, being that the MSRL has created a concise regulation process for leather manufacturing and tanneries.

Leather process would be nothing without chrome tanning, which is more prominent than vegetable tanning in the leather industry. Chromium VI is shown on the MSRL (Figure 3) in regulation if only 10 ppm. The difference in chromium, a chemical formulation commonly found in processing leather through chromium (III) and chromium (VI) (increasing during the leather process), the chemical can enter water, air and solid waste as well. According to the MRSL, the “two-bath process for tanning using potassium dichromate (VI) is no longer used by the leather industry. Potassium dichromate (VI) and other chromium (VI) compounds are banned and chromium (VI) residues in chromium (III) tanning agents are restricted.” (“MRSL 2015”) The Manufacturer Restricted Substance List was extremely beneficial in identifying the hazardous chemicals in the processing leathers, whether waterborne, airborne or solid waste.

The research I gathered on the process of the leather industry indeed is very concise, however I did not fully understand the importance of the chemical formulations throughout the process and how much of an impact they have on our environment. With this said, the FOSSIL groups collaboration with the LWG has shown progressive change in the industry. If apparel brands like FOSSIL, begin to partner with more stakeholder groups like LWG, the leather industry will become more sustainable than it is already is. It is important to look at the bigger picture when it comes to amount if waste we develop, and it seems as though the LWG is already there.

Bibliography

“About Us.” Improving Environmental Stewardship, www.leatherworkinggroup.com/who-we- are/about-us.

“Alkylphenols & Ethoxylates Research Council.” Alkylphenols & Ethoxylates Research Council, alkylphenol.org/.

“Arsenic.” 2. Where Does Environmental Arsenic Come from?, www.greenfacts.org/en/arsenic/l- 3/arsenic-2.htm#2p0.

“Environmental Hazards of Leather.” PETA, 22 June 2010, www.peta.org/issues/animals-used- for-clothing/leather-industry/leather-environmental-hazards/.

“Going Global: Our Commitment To Sustainable Design.” Fossil Group, 11 July 2018, www.fossilgroup.com/going-global-commitment-sustainable-design/.

Leather Working Group. “Manufacturing Restricted Substance List.” MRSL 2015, 2015, www.leatherworkinggroup.com/contentfiles/LWG-18.pdf?v=1.

Leather Working Group. “The Guide to Understanding MRSL.” A Guide to Understanding MRSL, The Leather Working Group, 2017, www.roadmaptozero.com/programme/manufacturing-restricted-substances-list-mrsl- conformity-guidance.

User, Super. “What Is Carbon Black?” Environmental Aspects - What Is Carbon Black? - International Carbon Black Association - ICBA, carbon-black.org/index.php/what-is- carbon-black/environmental-aspects.

“Welcome to ISC – Your Complete Wastewater Treatment Solutions Provider and Chemicals Supplier.” Industrial Specialty Chemicals, Inc., www.iscwater.com/.

“Welcome!” PSEP, psep.cce.cornell.edu/.

Figure 1: The difference between RSL and MRSL is that the RSL (which was created by the LWG before 2015, the year the MRSL was published by the company) is list of chemicals in finished leather, rather than the tannery process and manufacturing, including the chemicals that are hazardous to the workers.

Figure 2: The chart above indicates what chemical formulations contribute to the waterborne waste, specifically Alkylphenol, a family of organic compounds that are commonly used in the dyes.

Figure 3: The table is also from the MRSL, however this table indicates the airborne waste (Arsenic (As)) and solid waste (Chromium (VI)), both of which are used with caution and restriction in chemical suppliers.