Design Life-Cycle

assess.design.(don't)consume

Tate Werlin

Raw Materials in Canvas Shopping Bags

There are two overarching categories into which all shopping bags fall: reusable and single-use [Muthu 1]. The production of single use shopping bags arguably places less strain on the environment than that of reusable shopping bags; the bulk of the environmental damage comes after the bags are repetitively disposed of. Reusable bags, on the other hand, have a larger upfront investment of energy and materials into their production. The idea behind this category is that the continuous reuse of the bag makes up for the lost energy and raw material consumption.

Merriam-Webster defines a shopping bag as, “A bag (as of strong paper) that has handles and is intended for carrying purchases” [Merriam-Webster]. Although this definition names paper as material out of which shopping bags may be constructed, they are also commonly made of plastic, canvas, woven plastics, and other textiles.

In this paper, we will look at the canvas shopping bag, which is a common alternative for single-use shopping bags. Unlike their plastic counterparts, canvas bags are made out of renewable materials and can be reused. The lifespan of an average reusable shopping bag is greater than that of 700 single use bags [reusethisbag.com].

Because canvas is made of cotton, a natural and biodegradable material, it is often regarded as a clean alternative to conventional single use shopping bags. An increasing number of retailers are pushing for the use of reusable shopping bags in an attempt to render a clean brand image amongst the growing consumer awareness of the plastic waste output derived from the use of plastic shopping bags [The Freedonia Group]. All of this begs the question: how much better are canvas bags really? By analyzing the raw materials intrinsic to all parts of a canvas bag’s life cycle, we can more effectively judge their efficacy as a replacement for single use grocery bags.

Canvas is a strong, unbleached fabric used in the production of tents, sails, heavy clothing, and bags [Cambridge Dictionary]. While retaining the flexible properties of other textiles, canvas is relatively stiff and sturdy in nature, giving it a unique set of applications. These properties make canvas ideal for shopping bags; it can hold a significant amount of weight without ripping. Furthermore, it retains the bag shape, allowing for goods to be loaded into and unloaded from the bag easily.

While canvas can be made from a number of natural fibers, we will examine canvas made from cotton as it is one of the most common sources [Wikipedia]. Cotton is a natural, cellulosic fibre which surrounds the seeds of the cotton plant. It is the most grown natural fibre in the world [Jans 2038]. The plant is natively found in subtropical regions, but is generally cultivated for agricultural use in temperate regions [Encyclopedia Britannica]. Beyond canvas, cotton can be used to make a wide variety of products such as clothing, baby products, and feminine products.

As with any agriculturally sourced product, water is a raw material which must be examined in the life cycle of canvas bags. This is especially true when it comes to cotton, which consumes a notoriously large volume of water. The production of 1 kilogram of pure, conventional cotton fibre consumes 22,000 kilograms of water [Muthu 24]. A kilogram of organic cotton consumes a slightly greater 24,000 kilograms of water [Muthu 24]. This is only true, however, where irrigation is used to water cotton crops whose water needs cannot be met by rainfall alone. According to Cotton Inc., only about 35% of the cultivated cotton in the United States is irrigated [Cotton Inc.]. This is significant as the United States produces over a third of the world's cotton and is the leading cotton exporter globally.

On top of the extensive use of water necessary in cotton cultivation, cotton crops are extremely prone to pests and infection [Chen 249]. This leads farmers to use pesticides to protect the plant, and lots of them. Despite using only 3% of farmland globally, cotton is responsible for 25% of the world’s pesticide usage [Chen 249]. Specifically, 16g of pesticides are used per kg of cotton fibre [Kalliala 18]. Pesticide use is concerning due to the negative effects it has on the soil and water quality, as well as the harm that it does to plants and other wildlife with which it comes into contact. Runoff from fields where pesticides are used can contaminate rivers and therefore drinking water. This is especially true in developing nations where there is a greater reliance and fewer regulations on untreated water [Chen 250]. Cotton pesticides are also a food contaminant in the U.S., due to the use of cottonseed oil in some processed foods [Chen 250].

Fertilizer is another material necessary for cotton cultivation. Cotton requires large quantities of it too. In fact, nearly half a kilogram of fertilizer is needed to produce a kilogram of cotton fibre [Kalliala 18]. It is worth noting that some cotton is grown without the use of fertilizers, but this is rare. In the U.S., only about 2% of cultivated cotton is organic, or grown without the use of fertilizers [Chen 250].

Once the cotton is fully grown, it is harvested using cotton spindle harvesters, which have large engines and run on fuel, thus adding fossil fuels to the list of raw materials we must consider in the life cycle analysis of canvas bags. Interestingly, some harvesters do more than just pick the cotton. They may also separate the fibres from the seed, remove any excess biological matter (such as leaves and stems), and bail the cotton fibre for the next processing steps. This three-in-one combination saves a significant amount of time and energy.

Various chemicals are also used in the manufacturing and processing of canvas. Formaldehyde, a carcinogenic chemical, is commonly used as a wrinkle-proofing agent for canvas [Chen 249]. While canvas is generally unbleached and undyed, bleach or dyes may be used to add color. Before dyeing, the canvas is treated with hydrogen peroxide and heated, either by being pulled through an oven or over a hot piece of copper [cotton.org].

Once the canvas has been produced and treated, it is assembled into the final product: the bag. This part of the lifecycle uses little new raw material. Pieces of the canvas are sewn together using thread into the bag shape, using only thread. In 100% cotton shopping bags the thread is, like the canvas, made from cotton. Although thread is most commonly derived from cotton, it can be made out of a great number of other fibers, both natural and synthetic [amefird.com]. After the bags are constructed, they are ready to be used.

The transportation and distribution of materials is key in virtually every step of the life-cycle of a canvas shopping bag. The harvested cotton must be transported to gins, the ginned cotton must be transported to mills and the woven textile must be transported to the factory where it will be sewn into the finished product. From here, the bags then must be distributed either to retailers or directly to customers. On top of all this, chemicals used to treat the cotton and the canvas as well as waste from the various steps in the processes must be transported to landfills or other waste disposal sites. Almost all of this transportation is based on one thing: gas. Because of the need for transportation at almost every step of the life-cycle of a canvas bag, fossil fuels are embedded within the product. They are necessary to turn materials into a product and put the product in the consumers hand.

Once the consumer has their bag, some upkeep is needed to prolong its lifespan. The most basic process within the maintenance of a canvas bag is washing, which consumes laundry detergent and water. If the bag tears or rips, the consumer can avoid disposing of the bag by sewing the hole closed or repairing torn stitches. As with bag construction, this would only consume thread, The maintenance and repair of reusable goods is important and extends well beyond canvas bags. It prevents the consumption of another product and therefore the consumption of all of the energy and raw materials embedded within it. Disposing of a reusable product everytime the product requires maintenance simply turns the reusable product into a disposable product but over a longer period of time.

At the end of the life-cycle of a canvas bag is recycling and waste management. While there are no new significant raw materials used in either of these steps, there are a few things that are important to note about them. A major advantage which canvas bags have over plastic bags is the fact that canvas bags are derived from biological matter, which means they biodegrade. After being used by a consumer, disposed canvas bags are broken down within landfills by microorganisms into harmless natural components. In contrast, Plastic bags can take up to 1000 years to break down, and even then the plastic never really goes away; it simply breaks apart into increasingly small pieces [totebagfactory.com]. Plastic bags are also light and easily carried by wind. This leads to plastic bags being blown into oceans and other environments where they were not originally disposed of, leading to extensive environmental damage. It is estimated that plastics comprise 80% of the waste within our oceans [totebagfactory.com].

Canvas bags impress and draw in many consumers. They are made out of plants after all, and are biodegradable. An examination of the raw materials intrinsic to the production of these bags, however, highlights serious concerns about the product. Cotton cultivation costumes huge amounts of water, fertilizer and pesticides.

As consumers, it is important to be aware of the fact that there are no perfect alternatives for harmful products. We should never assume that just because there is a push for a “greener” option that it is entirely harmless. If we can remain skeptical of green alternatives and be aware of greenwashing in marketing, then we can continue to make better choices for our planet and therefore for ourselves.

References:

Muthu, Subramanian Senthilkannan. Assessment of Environmental Impact by Grocery Shopping Bags. Springer Verlag, Singapor, 2016.

“Shopping bag.” Merriam-Webster.com Dictionary, Merriam-Webster, https://www.merriam-webster.com/dictionary/shopping%20bag. Accessed 1 Dec. 2021.

Lober, Douglas. “25+ Reasons to Use Reusable Grocery Bags (Updated).” Awesome Wholesale Reusable Grocery Bags & Bulk Shopping Totes, ReuseThisBag.com, 1 Nov. 2021, www.reusethisbag.com/articles/25-reasons-to-go-reusable.

Freedonia Group. “Retail Bag Industry Trends.” The Freedonia Group, MarketResearch.com Inc, www.freedoniagroup.com/Content/Retail-Bag-Industry-Trends.

“Canvas.” CANVAS | Definition in the Cambridge English Dictionary, dictionary.cambridge.org/us/dictionary/english/canvas. Accessed 1 Dec. 2021.

“Canvas.” Wikipedia, Wikimedia Foundation, 6 Nov. 2021, en.wikipedia.org/wiki/Canvas.

Jans, Yvonne. “Global Cotton Production Under Climate Change – Implications for Yield and Water Consumption.” Hydrology and Earth System Sciences., vol. 25, no. 4, European Geophysical Society, 2021, pp. 2027–44, doi:10.5194/hess-25-2027-2021.

Weigmann, Hans-Dietrich H. “Cotton.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., 4 Oct. 2021, www.britannica.com/topic/cotton-fibre-and-plant#ref68012.

“Irrigation Management - Why Irrigate Cotton?” Cotton Incorporated, 5 May 2020, www.cottoninc.com/cotton-production/ag-resources/irrigation-management/why-irrigate-cotton/.

Chen, Hsiou-Lien, and Leslie Davis Burns. “Environmental Analysis of Textile Products.” Clothing and Textiles Research Journal, vol. 24, no. 3, 1 July 2006.

Kalliala, Eija M., and Pertti Nousiainen. “Environmental Profile of Cotton and Polyester Cotton Fabrics.” Autex Research Journal, vol. 1, no. 1, 1999.

“From Field to Fabric- Cotton Fabrics.” Cotton, Cotton Counts, www.cotton.org/pubs/cottoncounts/fieldtofabric/fabrics.cfm.

“Thread Science- Choosing the Right Thread from Fiber to Finishing.” A&E, www.amefird.com/technical-tools/thread-education/thread-science/.

Written by Priscilla Greene — October 30. “Is Canvas Fabric Eco-Friendly?” Is Canvas Fabric Eco-Friendly?, Totebagfactory.com, 30 Oct. 2020, totebagfactory.com/blogs/news/is-canvas-fabric-eco-friendly.

-

Isai Hernandez

Waste in Canvas Shopping Bags

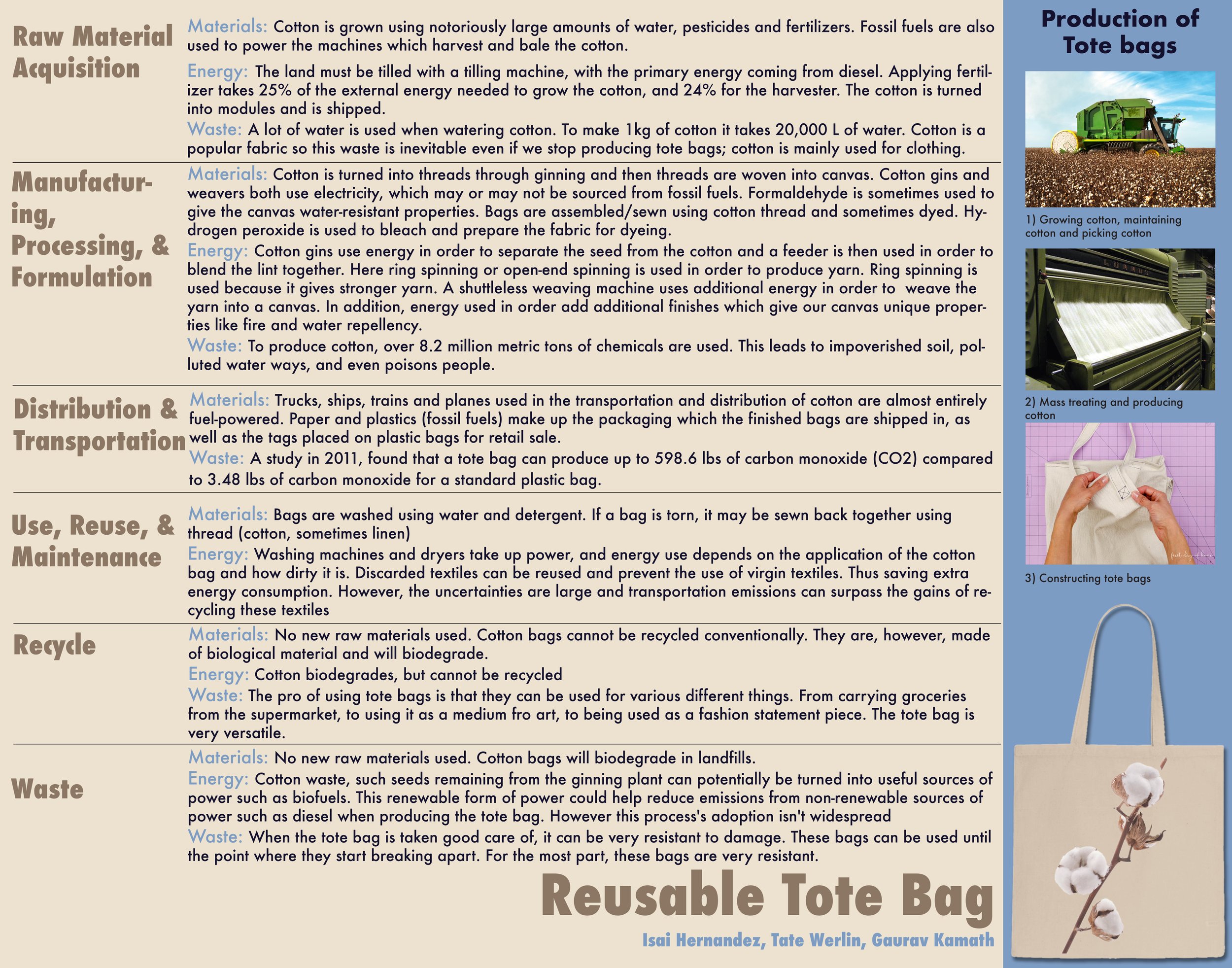

The canvas shopping bag has recently become a go-to bag. In California, they now charge you in the store in order to get single-use plastic bags. Recently, canvas shopping bags started gaining popularity. The canvas shopping bag is a canvas tote bag that is primarily made out of cotton. This bag is usually used when going to the supermarket and needs to carry stuff in a reliable sturdy bag. The canvas bag also works as a ‘sustainable’ alternative to the plastic bag. The popularity of canvas bags has risen in the fashion sense too. A lot of people like substituting their backpacks for tote bags.

In order to acquire the raw materials for the canvas shopping bag, there is a lot of waste. In order to grow cotton, you need to use pesticides and synthetic fertilizers. Over 8.2 million metric tons of chemicals were used to grow cotton (2016). This is not good for the environment because it leads to impoverished soil. Having impoverished soil means that the land is not going to be rich in nutrients, which makes it harder to grow anything on it. In order for it to be reset, it will take at least 100 years. Additionally, the high use of pesticides can pollute natural water sources. In some instances, rain can carry these pesticides and fertilizers into waterways and infect local residents that use the water sources.

When it comes to manufacturing, processing, and formulating cotton for the canvas shopping bag a lot of water and more toxic chemicals are used. Cotton needs to be scoured and bleached in order to make the fabric white and absorbent; which strengthens the tote bag. In order to make 1 kilogram of cotton, it takes about 20,000 liters of water. Cotton is a popular fabric so this waste will always be inevitable even if we were to stop producing tote bags, even though cotton is only used for clothing, there has to be a more efficient way to produce cotton without wasting that much water.

The distribution and transportation for canvas shopping bags are pretty high. A study in 2011 states that about 598.6 pounds of Carbon Dioxide (CO2) is produced from a tote bag. Compared to 3.48 pounds of Carbon Dioxide (CO2) produced from a standard plastic bag made from high-density polyethylene. This study however did not take into account ocean pollution.

The waste produced in the use, reuse, and maintenance of canvas tote bags can be very high. The thing about the tote bag is that in order to offset the use of the tote bag in comparison to the single-use plastic bag is that the tote bag has to be reused way more times than the single-use plastic bag. For conventional cotton, in order to have the same climate change as plastic bags, it has to be used 149 times. The necessary amount of reuse to have the same cumulative environmental impact as a classic plastic bag is 20,000 times. On the other hand, for organic cotton, the reuses necessary to have the same climate change as plastic bags is 52 times. The number of necessary reuses to have the same cumulative environmental impact as a plastic bag is 20,000 times (2018).

Lastly, the waste in recycling and waste management is basically the same. There are no official ways to try to recycle the canvas shopping bag but it will eventually biodegrade in the landfills.

References

Cook, Grace. “The Cotton Tote Crisis.” The New York Times, The New York Times, 24 Aug. 2021, https://www.nytimes.com/2021/08/24/style/cotton-totes-climate-crisis.html.

Ellis, Sam. “How Much Water Does It Take to Grow Cotton?” Farm & Animals, 28 Nov. 2020, https://farmandanimals.com/how-much-water-does-it-take-to-grow-cotton/.

“Integrated Crop Management: Water Management.” Advancing Cotton Educationwater Management, https://www.cotton.org/tech/ace/water-management.cfm.

“Life Cycle Assessment of Grocery Carrier Bags - MST.” Edited by Valentina Bisinella et al., Life Cycle Assessment of Grocery Carrier Bags, The Danish Environmental Protection Agency, Feb. 2018, https://www2.mst.dk/Udgiv/publications/2018/02/978-87-93614-73-4.pdf.

Thomas, Kristen. “Department of Commerce Energy and Environmental Quarterly.” The Impact of Textiles on the Environment, Department of Commerce Energy and Environmental Quarterly, Sept. 2016, https://www.osec.doc.gov/ofeq/documents/OSEEP/Docs%20&%20Newsltrs/Newsletters/FY2016/Newsletter-September%202016.pdf.

USDA. “USDA Coexistence Factsheets - Cotton.” USDA Coexistence Fact Sheets Cotton, United States Department of Agriculture, Feb. 2015, https://www.usda.gov/sites/default/files/documents/coexistence-cotton-factsheet.pdf.