Design Life-Cycle

assess.design.(don't)consume

Ivy Liao

Christina Cogdell

Design 40A

December 9, 2014

CD and DVD Embodied Energy

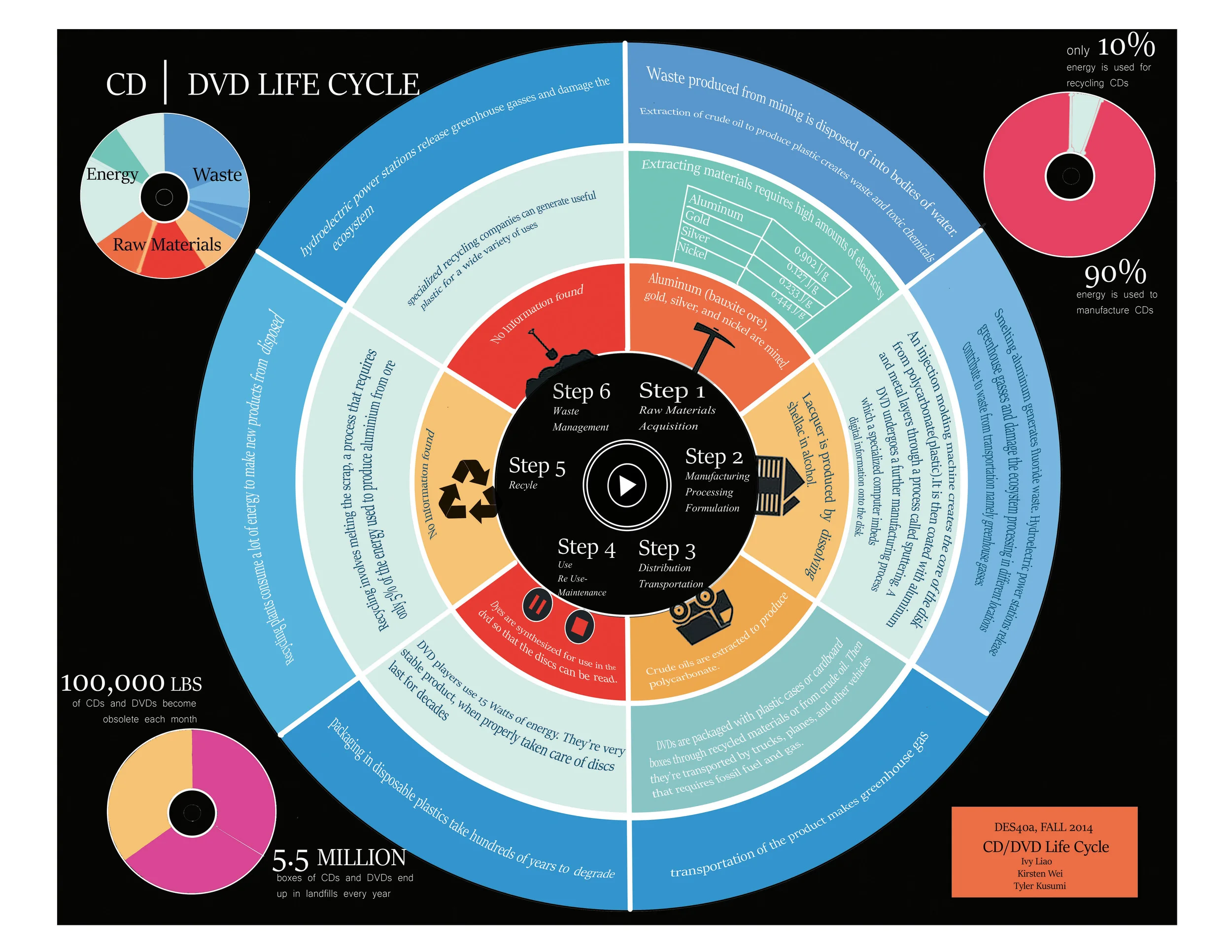

CDs and DVDs were pervasive for decades and have impacted a part of our lives at one point. From music to movies, these disks allow entertainment to be portable and tangible; however, with access to iTunes, Pandora, Netflix, and other services, CDs and DVDs are becoming obsolete. The general life cycle of a CD/DVD starts with the mining of raw materials (aluminum, gold, nickel, etc), the elements are then smelted and processed. This process is very energy intensive and produces large amounts of wastes. The final product is then packaged with jewel cases made from polycarbonates or recycled materials. Afterwards, they're transported and distributed. There're many ways to preserve a CD/DVDs life, one of which is to take note of its surrounding conditions. Lastly, recycling and waste management allow parts of the CDs/DVDs to be conserved and reused again. Nevertheless, extracting aluminum and the manufacturing process has harmed our ecosystem, environment and contributed to green house emissions. This report will go into detail about the embodied energy in the material acquisition, manufacture, distribution, maintenance, recycling, and waste management of CDs and DVDs.

The energy used to acquire raw materials include mining and extracting. Materials are extracted from the earth in the form of Bauxite ore, which has 15-20% Aluminum (0.902 J/g) ("Specific Heat"). The embodied energy for Aluminum is 211 GJ/ton and it includes all the energy required to make the material ("Bauxite Mining"). The process includes ore mining, ore crushing, and ore transportation. Mining and crushing entails machinery use, which requires mechanical and electrical energy. Bauxite occurs mainly in a belt around the equator in countries such as Africa, West Indies, South America, and Australia. Transporting the ore relies on excavators that can carry up to190 tons of ore. The bauxite is then carried to crushing or washing plants ("Bauxite Mining"). Aluminum is made by dissolving the oxide into molten salts, at around 960°C. A current is applied to help break down the oxide; the process typically loses around 50% of the incoming energy as low grade heat, which is due in part to the fact that the salts required to dissolve the oxide are so corrosive that there no practical way to keep the heat in ("The Trouble with Aluminum"). Extracting aluminum requires significant amounts of energy. After alumina is extracted from bauxite ore, further processing called "smelting" is necessary to convert it into aluminum. In this process, alumina is dissolved in a solution and a strong electric current is applied. The hydroelectric power stations require large reservoirs of water to generate its power. This process has generally remained unchanged since its invention in 1886 ("U.S. Energy Information Administration - EIA - Independent Statistics and Analysis"). Another important raw material, Gold(0.127 j/g) ("Specific Heat"), is also a highly energy intensive industry, extracting ore from deep mines and grinding the large quantity of ore requires 325 kW/h of electricity per gram ("Download PDFs"). Additional materials include Water(4.179 j/g) ("Specific heat"), Polycarbonate(1000-2000 j/kg) (Polycarbonate Material Properties), Lacquer, Dyes, Silver (0.233 J/g), Nickel (0.444 J/g), and Water (4.186 J/g)("Specific Heat").

Manufacturing and processing raw materials follow mining. First, An injection molding machine creates the core of the disk from Polycarbonate(plastic). It is then coated with aluminum and metal layers through a process called "sputtering". After both sides of the disk are completed, they’re combined with a hot melt(specific heat capacity at 1.3 J/g). The metal is shaped and rolled. A CD/DVD undergoes a further manufacturing process which a specialized computer embeds digital information onto the disk through tiny indents made by several tons of pressure. The exterior of the DVD is then coated with a layer of lacquer, a transparent material designed to repel dust and resist fingerprints and scratch marks. Lastly, the disk is decorated with additional layers by ink for labeling or artworks ("Understanding DVDs").

Distribution and transportation start with the CD/DVD packaging. The disks are packaged with plastic cases or cardboard boxes through recycled materials such as recycled bottles or crude oil (extracted from the earth and then combined with chemicals) ("Understanding DVDs"). After the packaging, the CDs/DVDs are sent to distribution stores such as Walmart, Gamestop, etc. They’re transported by trucks, planes, and other vehicles that obtain energy from fossil fuel and gas. In developing/underdeveloped countries, where most of the manufacturing plants are, transportation require a greater amount of fossil fuels due to the long distances.

Energy is embodied in maintaining, using and reusing CD/DVDs. DVD players use 15 Watts of energy and are considered a stable product ("DVD Player Power Consumption"). They can last for decades when treated with care and not exposing them to humidity, extreme temperatures, and light. Energy can be conserved by reusing and maintaining CDs/DVDs. For example, light scratches on the disk can be fixed with abrasive toothpaste. Unwanted CDs can be rewritten on the computer or donated to schools, organizations, etc to be reused. Instead of throwing them away, they can be sold to stores; not only does reusing CD/DVDs prevent waste and environmental impacts, they also promote a good cause.

Recycling involves melting the scrap, a process that requires 5% of the energy used to produce aluminum from ore, though a significant part (up to 15% of the input material) is lost as dross (ash-like oxide)("Recycling in Ohio"). This shows that recycling entails more manufacturing processes, increasing the greenhouse emissions in the CD life cycle. However, certain companies have adopted recycling the polycarbonate in the CDs/DVDs and implementing them to other uses such as car parts, equipments, etc. It takes about 1/10th as much energy to recycle plastics as it does to create plastic from raw materials. The EPA estimates that recycling one ton of aluminum saves the equivalent of almost 32 barrels of oil, significantly reducing the carbon footprint of the manufacturing process ("Energy to Recycle Glass Bottle vs. Aluminum Cans vs. Plastic").

While researching about the embodiment of energy in CDs and DVDs, I encountered quite a few failures and made assumptions. For example, the heating capacity of Lacquer, a transparent material designed to repel dust and resist fingerprints and scratch marks, is hard to find. Little was found as to how Lacquer is synthesized or produced. Furthermore, the energy required to transport the products isn't very quantifiable in this case. We aren't sure how far away a shop is from the manufacturing factory so I just assumed it required a lot of fossil fuels and energy. Another obstacle I faced was finding embodied energy in using CDs. CDs and DVDs are manufactured and produced very similarly; thus we grouped the two together. However, one of the minor differences is that there is no standard usage of electricity for a CD player. Unlike a DVD player, the devices that play CDs vary in electricity usage (some powered by batteries). Overall, the research for the embodied energy of CDs/DVDs was successful and there weren't major holes.

The energy used to produce CDs and DVDs is massive. Its role in the stages of the cycle is apparent and contribute to both the production and the function. The energy used to manufacture a CD/DVD starts with the mining of raw materials (Aluminum, Gold, Nickel, etc). The elements are then smelted and processed, using more energy. The final product is packaged, transported and distributed. Disks allow digital information such as entertainment to be easily accessible, even without the internet; however, with the introduction of new technologies such as the USB, iPod or iPad, it isn't surprising that CDs and DVDs are being used less and less. Why use a CD when you can listen to your iPod everywhere? Why use a DVD when you can now download movies to go? 5.5 million boxes of software go to landfills and millions more of music CDs are thrown away. Every month, 100,000 pounds of CDs are unwanted and disposed of ("The Recycling Center of America"). As designers, we should solve the sustainability problem revolving around CDs and DVDs. With the amount of energy used to create and dispose of them, their benefits are questionable.

Works Cited

"Bauxite Mining." - Norsk Hydro. N.p., n.d. Web. 07 Dec. 2014.

"Download PDFs." Using Life Cycle Assessment to Evaluate Some Environmental Impacts of Gold Production. N.p., n.d. Web. 09 Dec. 2014.

"DVD Player Power Consumption: 15W." , Application:Unversal. N.p., n.d. Web. 09 Dec. 2014.

"Energy to Recycle Glass Bottles vs. Aluminum Cans vs. Plastic." Home Guides. N.p., n.d. Web. 09 Dec. 2014.

"Polycarbonate (PC) Material Properties :: MakeItFrom.com." Polycarbonate (PC) Material Properties :: MakeItFrom.com. N.p., n.d. Web. 09 Dec. 2014.

"The Recycling Center of America." Facts/General Information. N.p., n.d. Web. 09 Dec. 2014.

"Recycling in Ohio." Recycling in Ohio. N.p., n.d. Web. 09 Dec. 2014.

"SharkPellets." Shark Solutions A/S -. N.p., n.d. Web. 09 Dec. 2014.

"Specific Heat." Specific Heat. N.p., n.d. Web. 07 Dec. 2014.

"The Trouble with Aluminium." The Conversation. N.p., n.d. Web. 08 Dec. 2014.

"Understanding DVD - Disc Construction & Manufacturing." Understanding DVD - Disc Construction & Manufacturing. N.p., n.d. Web. 09 Dec. 2014.

"U.S. Energy Information Administration - EIA - Independent Statistics and Analysis." Energy Needed to Produce Aluminum. N.p., n.d. Web. 09 Dec. 2014.

Kirsten Wei

Christina Cogdell

Design 40A

December 9, 2014

DVD Waste

DVDs have become vastly popular and commonplace since its collective invention by Philips, Sony, Toshiba, Pioneer, Time Warner, Mitsushita, Mitsubishi, Thomson, Hitachi, JVC, and Panasonic in 1993 (Tomo, “Who invented DVD?”). It’s abbreviated for both digital video discs and digital versatile discs. Affordable, long lasting, versatile, and with a high storage capacity, DVDs are a convenient medium for consumers around the globe. This paper will be focusing DVDs, but because both DVDs and CDs are made with the same materials there will be some overlapping sources. The primary difference in between them is that DVDs hold more data. As a relatively new product, precaution measures have not yet been made nor has public awareness been raised. Due to the fast pace of technology, discs are quickly becoming obsolete as electronic storage is constantly improving.The DVD’s wide availability and large scale production contributes to the immense amount of waste created during production that is devastating to our environment.

DVDs are mainly a composite of polycarbonate plastic, aluminum, and lacquer. The dimensions are: “4.72 inches (120 millimeters) in diameter and .047 inches (1.2 millimeters) thick. The positioning hole in the middle is .59 of an inch (15 millimeters) in diameter” (“How compact disc is made”). Variations include using gold, silver, or nickel in substitution of the aluminum. According to a study done by Department of Interior, “metal mines produced 989 million MT (metric tons) of waste” in just the U.S. alone. The machines used for mining consume massive amounts of energy and release carbon dioxide.

Despite being the most abundant metal in the earth’s crust, about 8.2%, aluminum has to be extracted from bauxite because it’s never found freely in nature due to its chemical properties (“The Element Aluminum”). A study conducted by EPA (US Environmental Protection Agency) found that “refinery processes generate about one ton of solid waste during the production of a ton of aluminum”. This being said, it’s not possible to pinpoint exactly how much of this waste is just from DVD production.

The extraction of aluminum from ore bauxite is done by smelting, an electrolytic process that requires vast amounts of electricity. Aluminum smelters are usually located near hydroelectric power stations near ports because many factories use imported alumina. Hydroelectric power stations cause detrimental damage to the environment by collecting decaying plant material which release large amounts of greenhouse gasses into the atmosphere. Many people are led to believe that hydroelectric power is “clean energy” because it harnesses the the renewable energy of water, but it produces a lot of pollution as well as displacing everything that was there previously. Smelting produces harmful fluoride wastes: perfluorocarbons, hydrogen fluoride gas, sodium and aluminum fluoride, and cryolite. Perfluorocarbons are a strong greenhouse gas, hydrogen fluoride gas is toxic to vegetation, and cryolite particulates, used in pesticides, harm organisms.

Plastics are derived from crude oil combined with natural gas and chemicals. In addition to the waste generated from the extraction of crude oil, burning of plastics also releases toxic fumes and chemical pollutants. It doesn’t help that once made, plastic take hundreds to thousands of years to degrade.

After each of the materials needed have been processed, they have to be transported to yet another location for production. These manufacturing plants have high energy consumptions and use certain chemical processes that all add to even more waste. Manufacturing plants are frequently found in less developed countries for cost reasons requires for longer transport distances.

Fossil fuels are the main sources of energy that drive our modern way of life today. It’s well known that the use of fossil fuels are causing global warming. There are also many negative effects that aren’t as widely known such as air pollution, water and land pollution, and thermal pollution. We have to take into consideration the fuel needed to transport each material to the processing plant and then the final product to places available for consumers.

The manufacturing process of a DVD is fairly complex. In the simplest terms, first a smooth glass master is made, then it’s coated with light sensitive material. Digital data is then transferred to the light sensitive material and chemically developed. The glass master is electroplated to produce a stamper. Molten polycarbonate is injected onto the stamper and sputtered with aluminum or another metal. Lastly, the disc is varnished with a lacquer for protection. Optionally, dye is added as artwork. The whole production is machine automated, so once again using energy generated from fossil fuels.

Packaging is another source of waste for the life cycle of a DVD. Whether it be cardboard or plastic cases, it also has to be manufactured somewhere and transported to a centralized location. Plastic cases and shrink wrap are both derived from crude oil. Cardboard and paper are made from cutting down trees that are very much needed for ecosystems around the world. Sometimes packaging is made from recycled materials, but transportation is always a factor in waste production.

DVDs are a very stable product and low maintenance, when properly taken care of, “CD/DVD experiential life expectancy is 2 to 5 years even though published life expectancies are often cited as 10 years, 25 years, or longer” ("Frequently Asked Questions (FAQs) about Optical Storage Media: Storing Temporary Records on CDs and DVDs."). The lifespan of DVDs are shortened by humidity, extreme temperatures, and light exposure. Light scratches on the surface can be inexpensively taken care of with mild abrasives such as toothpaste. One study “estimated single-disc footprint of 1.8 Kg of CO2 equivalent over its suggested useful lifetime of 10 years” (Biehn, 23).

Reuse is the best option for DVDs because it generates the least amount of waste. Unwanted DVDs can be resold, given away, or donated to schools, libraries and other organizations. A DVD’s reflective qualities can also inspire more creative ways of reuse such as being hung on fruit trees to prevent squirrels and birds from eating the fruit.

Recycling is the next best option, but the discs have to be processed again in order to separate the materials for alternate uses. Specialized recycling companies can generate quality plastic for a wide variety of uses such as, but not limited to, car parts, office equipment, and street lights. Especially because discs are relatively new, not much effort has yet been put into efficient recycling of the product. Not many companies would want to tackle the feat of disc recycling because it’s hard to separate the thin layers of different materials. The majority of discarded DVDs end up in landfills because most companies only accept large quantities of discs to be processed, leaving it difficult for individuals to get their unused discs to a company. Although recycling saves resources, the discs still need to be transported to the recycling company, processed, and redistributed. Unwanted discs that don’t make it to the recycling companies also need to be transported to landfills or incinerated. When incinerated, toxic fumes are released into the surrounding air.

It’s clear to see how detrimental the production of something we take for granted such as the DVD is to the environment. From acquiring the raw materials till its grave, the carbon footprint accumulates. Consumers should become more aware of the unseen costs of this simple luxury and spread that awareness to the other products around us as well. Technology has come along far enough that society should be able to find alternative, less damaging, solutions for data storage and not letting our valuable natural resources go to waste.

Works Cited

"Aluminum Production Wastes." Aluminum Production Wastes. Environmental Protection Agency, n.d. Web. 08 Dec. 2014. <http://www.epa.gov/radiation/tenorm/aluminum.html>.

"Frequently Asked Questions (FAQs) about Optical Storage Media: Storing Temporary Records on CDs and DVDs." National Archives and Records Administration. National Archives and Records Administration, n.d. Web. 09 Dec. 2014. <http://www.archives.gov/records-mgmt/initiatives/temp-opmedia-faq.html>.

Harris, William. "Aluminum Smelting." HowStuffWorks. HowStuffWorks.com, n.d. Web. 09 Dec. 2014. <http://science.howstuffworks.com/aluminum3.htm>.

"The Hidden Cost of Fossil Fuels." Union of Concerned Scientists. N.p., n.d. Web. 09 Dec. 2014. <http://www.ucsusa.org/clean_energy/our-energy-choices/coal-and-other-fossil-fuels/the-hidden-cost-of-fossil.html#.VIaQJTHF9GM>.

"How Products Are Made." How Compact Disc Is Made. N.p., n.d. Web. 09 Dec. 2014. <http://www.madehow.com/Volume-1/Compact-Disc.html>.

"Mining TENORM Wastes." EPA. Environmental Protection Agency, n.d. Web. 08 Dec. 2014. <http://www.epa.gov/radiation/tenorm/mining.html>.

Thomas Jefferson National Accelerator Facility - Office of Science Education. "The Element Aluminum." It's Elemental. N.p., n.d. Web. 08 Dec. 2014. <http://education.jlab.org/itselemental/ele013.html>.

Tomo. "Who Invented DVD?" Who Invented. N.p., 4 Nov. 2010. Web. 08 Dec. 2014. <http://whoinvented.org/who-invented-dvd/>.

"What Is the Difference between DVD-audio and CDs?" HowStuffWorks. N.p., n.d. Web. 08 Dec. 2014. <http://electronics.howstuffworks.com/question344.htm>.

"Wholesale CD Duplication, CD Replication, DVD Duplication, DVD Replication, USB Flash Drives by New Cyberian." How Compact Discs Are Made. N.p., n.d. Web. 09 Dec. 2014. <http://www.newcyberian.com/cd-manufacturing.html>.