Design Life-Cycle

assess.design.(don't)consume

Electric Scooter Life Cycle

Nicholas Kim

DES 40A

Professor Cogdell

Electric Scooter Raw Material

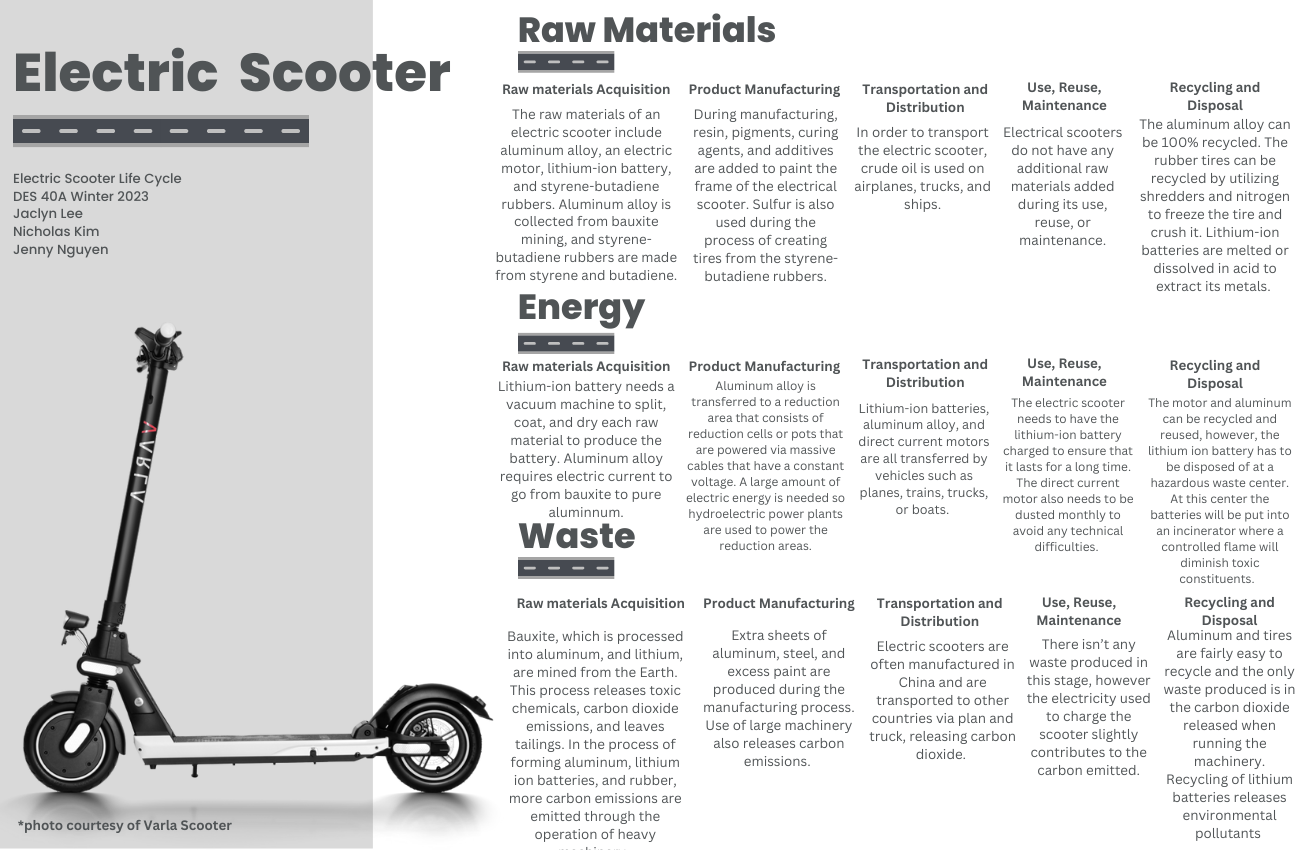

In recent years, electric scooters have been appearing within urban areas, and have increased in popularity with college students. They have been used as an alternate form of fast transportation, as they offer a speedy travel through their electrically powered motor. What allows the scooter to offer its travel in such a way is its motor, which is powered through batteries. The electric scooter is also made up of other resources such as rubber, aluminum alloy, and other materials. The raw materials of an electric scooter include materials such as styrene-butadiene rubbers, aluminum, and lithium-ion batteries, and as the life cycle progresses, new raw materials are introduced, and certain materials impact the environment during each stage, especially during the acquisition of raw materials and during the use of utilizing them.

The raw materials of an electric scooter mostly consist of aluminum alloy, lithium-ion batteries, and styrene-butadiene rubbers, and each are acquired during the first step of the acquisition of materials. Synthetic rubber is acquired in order to create the wheels of the tires. However, more specifically, tires are mostly made of styrene-butadiene rubbers. In order to produce such rubber, you need to obtain styrene and butadiene. Britannica, an online encyclopedia, describes styrene as, “liquid hydrocarbon that is importantly chiefly for its marked tendency to undergo polymerization. [...] a clear, colorless, flammable liquid” (“Styrene”). They also proceed to discuss how it is obtained as well: “Almost all styrene is now produced by dehydrogenation of ethylbenzene, a compound obtained by reacting ethylene and benzene-both of which in turn are derived from petroleum. More than 15 million metric tons of the liquid are made each year.” (“Styrene”). To clarify, styrene is made by removing hydrogen from ethylbenzene, a chemical produced from processing petroleum. In parallel to styrene, butadiene is also produced through the processing of petroleum. As stated in the article “Butadiene production process overview” by Claude White, “Over 95% of butadiene is produced as a by-product of ethylene production from steam crackers.” (White). After extracting these two resources, producing the rubber requires 75% butadiene and 25% styrene. It then needs to be copolymerized in an emulsion process, where it is done in a water solution (“Styrene-Butadiene Rubber”). In 2020, about 8.17 million metric tons of styrene-butadiene rubber was produced (“Production Capacity of Styrene-Butadiene-Rubber Worldwide in 2020 and 2025”). As a result of such a large production rate, it results in a large quantity of pollution as a consequence. Due to the primary raw material of styrene-butadiene rubber being petroleum, the process of extracting petroleum results in pollution such as oil spillage. For example, in the book “The Political Ecology of Oil and Gas Activities in the Nigerian Aquatic Ecosystem” by Prince Emeka Ndimele, he explains the number of crude oil spills in Nigeria from 2006 to 2015: “ Official records from the NOSDRA, the agency saddled with the responsibility of preparedness detection and response to all cases of oil spillage in Nigeria, indicates that there were over 5,000 spillage sites from over 9000 spills in Nigeria over the period from 2006 to 2015” (Ndimele). These high numbers indicate how frequent oil spills occur, and this only relates to one country's statistics. The fact that these oil spills occur so frequently heavily affects the environment around it, and the fact that electric scooters and other products require petroleum in its life cycle further encourages the acquisition of such harmful resources. In order to put the tires into use, the scooter needs a frame. According to the article “Life Cycle Assessment of Electric Scooters for Mobility Services: A Green Mobility Solutions”, Muhammad Ishaq explains how most electric scooters are 44.15 percent aluminum alloy. In order to obtain the large abundance of aluminum alloy, it requires three main steps. First, manufacturers must collect bauxite, a primary raw material containing mainly aluminum oxide which is mined typically from tropical and subtropical areas (“How Aluminum is Produced”). According to the article “How Aluminum is Produced”, it states the main sources of bauxite: “About 90% of global blauxite supplies are found in tropical and subtropical areas, with 73% found in just five countries: Guinea, Brazil, Jamaica, Australia and India. Guinea has the largest supply of bauxites, 5.3 billion tonnes (28.4% of the global supply)” (“How Aluminum is Produced”). Within these areas, open pit mines are used to collect a majority of bauxite, but some aluminum ores are found deeper underground. After collecting bauxites, they need to process the bauxite into alumina, or aluminum oxide, through the Bayer process. This process starts with dissolving crystalized aluminum hydrate, which comes from bauxite, in caustic soda at high temperature. As you lower the temperature back down, the aluminum hydrate crystallizes but the other elements in bauxite, called red mud, sit at the bottom, allowing it to be removed from the site. Aluminum hydrate can then be filtered out from the solution, and after being dehydrated, it results in alumina. Next, the alumina needs to go through an electrolytic reduction. The alumina is placed with molten cryolite, a conductive substance, causing the bond between aluminum and oxygen to break as an electric current passes through the alumina. The liquid aluminum then settles to the bottom, while carbon dioxide is produced from the oxygen. As a result of this process, about 1 tonne of aluminum can be made for every 4-5 tonnes of bauxite, but as a result about 4 tonnes of carbon dioxide is emitted into the atmosphere (“How Aluminum is Produced”). In order to make it ready for electric scooters, the aluminum needs to be turned into an aluminum alloy, a mixture of metals where aluminum is the predominant metal. After much research however, there was no specific aluminum alloy found, but often aluminum is used with carbon fiber. The last raw material of the electric scooter includes the lithium-ion battery. A lithium-ion battery is what allows the electric scooter to be powered and is made up of three main components. It is made up of electrodes, an anode and a cathode, and an electrolyte. The electrodes consist of an anode and a cathode, an anode being the electrode that releases electrons, and the cathode being the one that gains the electrons. Bringing the two together, the electrolyte provides the cell with a way for lithium ions to travel between the anode and cathode. In order to create these electrodes, metals need to be acquired. The anode is typically made up of graphite, while the cathode is typically an alloy of multiple metals (Gupta). Graphite is found naturally through mining, and the alloy can be made through melting multiple metals that are found through ores found in the ground. They then mix with a conductive binder and are then coated in aluminum if it is an anode and copper if it is a cathode. After the electrodes are fully prepared, they place the electrodes in a case, and finish the cell by injecting the electrolyte, typically a lithium salt, into the cell. This process repeats making approximately 290 GWh of lithium ion batteries, yearly, according to a 2018 statistic (Placek). Accompanying the large abundance of batteries, a large amount of lithium needs to be acquired as well. In Ian Shine’s article “The World Needs 2 Billion Electric Vehicles to Get to Net Zero. But is There Enough Lithium to Make All the Batteries?”, he discusses the statistics of lithium production in 2021: “Global lithium production totalled 100,000 tons” (Shine). The three main raw materials each come from smaller raw materials, and in the acquisition of these materials, it illustrates the environmental effect it has.

After assembling the main four components, these components are introduced to two new raw materials during the manufacturing process of an electrical scooter. Ingredients from powder coating and chemicals used to create tires. After the chassis is assembled through welding, bending, and cutting tubes or sheets of aluminum alloy, paint is applied to its surface through a dry powder coating process (“How It’s Made Electric Scooters”). The powder used during this process introduces the need for new raw materials to be used such as resin, pigments, curing agents, and additives. To be more specific, the type of resin used is typically an epoxy resin, which consists of mixing bisphenol A and epichlorohydrin, and pigments can be either organic or inorganic. As for curing agents and additives, they include dicyandiamide or hybrid for curing agents and benzoin or BYK 356 for additives (“What are the Ingredients of Powder Coating”). However all of these ingredients in powder coating depend on the type of scooter being used, as this report does not cover a specific type or brand of electric scooter. Utilizing the powder coat offers a way for there to be minimized waste as well.After being coated, styrene-butadiene rubber needs to be vulcanized to create tires for the frame. Vulcanization is the process of heating rubber with sulfur, an accelerator, and an activator at 140-160 degrees celsius in order to make the rubber stronger, harder, more elastic, and more weather resistant (Nair).Vulcanizing the material brings in more of these raw materials in order to further amplify the original primary materials found in the acquisition step of the life cycle, allowing it to be ready for the manufacturing stage. After creating these tires, the electrical components and tires are then added to the electric scooter, and the scooter is ready to be shipped.

Although there is no concrete detail found, it can be assumed that many modes of transportation are used to transport the electric scooter and the materials that were used to make it. Much the same, it can be assumed that electric scooters and its raw materials are mainly transported across the globe through ships, airplanes, and trucks. In each of these modes of transportation, a different type of fuel derived from crude oil is used. For example, trucks typically use diesel fuel, which is made through the refinement of crude oil (“Diesel Fuel Explained”). Similarly, airplanes and ships utilize fuels that come from crude oil as well. The use of this raw material during transportation causes there to be pollution in the air. For example, there are about 1 billion tons of carbon dioxide released worldwide every year due to airplanes, which is about 2.4% of carbon dioxide emissions on the planet. The carbon dioxide that gets released is a direct result of using the fuel that is in the plane (Kimbrough). Equally as detrimental, container ships emit about 140 million metric tons of carbon dioxide every year (Kilgore). Although it does not depict how much carbon dioxide is released when transporting specifically electric scooters and the materials it's made up of, it still highlights how it contributes as a small factor to the overall emissions.

Throughout the lifespan and use of an electric scooter, there are no new raw materials introduced. However, when their lifespan is over, new raw materials are introduced to dispose of the electric scooter when they can not be recycled. The frame of the electric scooter is largely made up of aluminum alloy, which is 100% recyclable. Aluminum alloy can be melted and recast without losing its properties and quality. For that reason, about 75% of scraps are recycled without using any chemicals (“Aluminum Recycling”). Meanwhile, for the tires of the scooter, liquid nitrogen is used to freeze the rubber after being cut up from a shredder. It can also then be made into smaller pieces, and is then given to other companies to be reused (“How are Automobile Tires Recycled?”). Examples of reusing tires include creating fuel from tires, creating rubber for shoes, or using rubber for playground turf (Rinkesh). If these tires are left for waste, they can be harmful to the environment as they take a large amount of space, can pollute water, and are flammable (“How are Automobile Tires Recycled?”). The hardest part to recycle within the scooter is the lithium-ion batteries. In order to recycle it, they are shredded and made into a powder. Afterwards, they are then liquified or dissolved in acid in order to recover the metal from the aluminum (“Are Lithium Ion Batteries Recyclable?”). Even though it is possible to recycle these batteries, it is still very difficult, and due to it, about 95% of lithium-ion batteries are still left to waste. These pose a risk to the environment, as these batteries are highly flammable, and can leak cobalt, manganese, and nickel (Gemes). Clearly, after seeing how these raw materials were originally obtained, to the end of their cycle, it highlights how these raw materials pose a threat to the environment.

Throughout the lifecycle of the electric scooter, many raw materials such as rubber, aluminum, and lithium-ion batteries are introduced throughout the process. However as each raw material is introduced, each has their own environmental factor within the life cycle. Due to such environmental factors, it questions how much electrical scooters improve the environmental process. Clearly, it removes the fossil fuels needed to operate other forms of transportation, but it still does not get rid of the negative effects that come from obtaining the raw materials required to build, use, and dispose of it.

Bibliography

Aluminum Recycling. https://alfed.org.uk/files/Fact%20sheets/5-aluminium-recycling.pdf.

Gemeš, Nikola. “The Truth About Lithium Ion Battery Recycling.” GreenCitizen, 12 Jan. 2023, https://greencitizen.com/blog/lithium-ion-battery-recycling/#:~:text=Yes%2C%20lithium%2Dion%20batteries%20are,like%20any%20other%20electronic%20waste.

Gupta, Nishtha. “Li-Ion Cell Manufacturing: A Look at Processes and Equipment.” Emerging Technology News, Emerging Technology News, 11 June 2021, https://etn.news/energy-storage/li-ion-cell-manufacturing.

“How Aluminium Is Produced.” Aluminum Leader, https://aluminiumleader.com/production/how_aluminium_is_produced/.

“How Are Automobile Tires Recycled?” Tire Reviews, Buying Guide & Interesting Facts - Utires.com, 20 Nov. 2021, https://www.utires.com/articles/how-are-automobile-tires-recycled/.

“How It's Made Electric Scooters.” YouTube, YouTube, 20 Apr. 2016, https://www.youtube.com/watch?v=zZfkbx2E5AE.

Ishaq, Muhammad. “Life Cycle Assessment of Electric Scooters for Mobility Services: A Green Mobility Solutions.” Wiley Online Library, 4 May 2022, https://onlinelibrary.wiley.com/doi/full/10.1002/er.8009.

Kilgore, Georgette. “Air Freight vs Sea Freight Carbon Footprint (the Real Numbers in 2023).” 8 Billion Trees: Carbon Offset Projects & Ecological Footprint Calculators, 20 Jan. 2023, https://8billiontrees.com/carbon-offsets-credits/carbon-ecological-footprint-calculators/air-freight-vs-sea-freight-carbon-footprint/#:~:text=A%20cargo%20ship%20produces%2016.14,metric%20tons%20of%20carbon%20dioxide.

Kimbrough, Liz. “How Much Does Air Travel Warm the Planet? New Study Gives a Figure.” Mongabay Environmental News, 1 Oct. 2022, https://news.mongabay.com/2022/04/how-much-does-air-travel-warm-the-planet-new-study-gives-a-figure/#:~:text=Airplanes%20emit%20around%20100%20times,of%20most%20countries%2C%20including%20Germany.

Nair, A.B., and R. Joseph. “Eco-Friendly Bio-Composites Using Natural Rubber (Nr) Matrices and Natural Fiber Reinforcements.” ScienceDirect, Woodhead Publishing, 25 Feb. 2014, https://www.sciencedirect.com/science/article/pii/B9780857096838500094.

Placek, Martin. “Production Capacity of Lithium-Ion Battery Factories Globally.” Statista, 6 Jan. 2023, https://www.statista.com/statistics/1247625/global-production-capacity-of-lithium-ion-battery-factories/.

“Production Capacity of Styrene-Butadiene-Rubber Worldwide in 2020 and 2025.” Statista, 25 Jan. 2023, https://www.statista.com/statistics/1063647/styrene-butadiene-rubber-production-capacity-globally/.

Shine, Ian. “The World Needs 2 Billion Electric Vehicles to Get to Net Zero. but Is There Enough Lithium to Make All the Batteries?” World Economic Forum, 20 July 2022, https://www.weforum.org/agenda/2022/07/electric-vehicles-world-enough-lithium-resources/.

“Styrene-Butadiene Rubber” Encyclopædia Britannica, Encyclopædia Britannica, Inc., https://www.britannica.com/science/styrene-butadiene-rubber.

“Styrene.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., https://www.britannica.com/science/styrene.

“What Are the Ingredients of Powder Coating? • Architectural & Industrial Metal Finishing.” Architectural & Industrial Metal Finishing, 10 Apr. 2021, https://aimetalfinishing.com/industry-news/what-are-the-ingredients-of-powder-coating/.

White, Claude. “Butadiene Production Process Overview.” Chemico-Biological Interactions, U.S. National Library of Medicine, https://pubmed.ncbi.nlm.nih.gov/17324391/#:~:text=Over%2095%25%20of%20butadiene%20is,other%20C4s%20by%20extractive%20distillation.

Jenny Nguyen

Professor Cogdell

DES 40

16 March 2023

Electric Scooter’s Energy Life Cycle

The electric scooter, derived from the Razor scooters in everyones’ childhood memory, greatly impacted modern society. Seen on the sidewalks of big cities, electric scooters have been a savior for tired tourists. Instead of walking, these electric scooters help tourists save their energy by allowing them to explore the city without the need to walk. Contrasting with all the energy saved by using the electric scooter, an immense amount of energy is used to produce the electric scooter. From production to recycling, energy ranges from heavy machinery to the manufacturing of the batteries used to power the scooters. Although electric scooters save time and benefit many, the energy used throughout the life cycle to produce these scooters is immense.

Starting from the beginning, there are many raw materials used to create electric scooters. One of the components is the lithium-ion battery. This raw material is known as the “fuel tank” of electric scooters. Lithium-ion batteries are popular materials used among many companies due to their advantages such as longevity. With such good quality material, the energy used to extract it must equal the same amount of work. First, to understand the energy used to produce lithium-ion batteries, the components must be noted. Lithium-ion batteries are composed of four main components, “two electrodes: one anode (holds the lithium ions when charged) and one cathode (holds the lithium ions when discharged), a separator that is placed between the electrodes to prevent contact and shorting, and an electrolyte medium that enables movement of lithium ions between the electrodes” (1). These four components go through three main stages to become lithium-ion batteries. The first step is electrode manufacturing. Within this step, the electrode has to be mixed with a conductive binder to form a solution which is then coated by a machine on both sides. Once coated, the electrodes are put into a drying oven to evaporate the solution. It is then put into a slitting machine to be cut into narrow strips and recoiled which is then transferred to a vacuum oven to remove any residual moisture. The second step is cell assembly. This is where the electrode is sent to a dry room where the separator is layered between the anode and cathode to form an internal structure of a cell. Then laser welding is used to connect the terminals of the cell. The final step is cell finishing where a process called degassing is used. This is where the gas bag is pierced into a vacuum chamber and the excess gasses are sucked off. The raw materials are able to be combined by using energy to create a lithium-ion battery. Another raw material used is aluminum alloy. There are three stages to creating an aluminum alloy. The first stage is when bauxite is extracted from the ground. A common way to mine for bauxites is by using open pit mines. Then, bauxite is reprocessed into alumina or aluminum oxide. Finally, pure aluminum is produced using electrolyte reduction. This is the process in which aluminum oxide is broken down into components using electric current. There is a piece of special equipment that is used to cut layers off the surface of the rock. An important raw material to take into consideration for the electric scooter is the direct current motor. This raw material is simple since it consists of mostly metals such as iron, copper, tin, and steel. Some other materials that are included are the armature or rotor and the coil or stator. The armature of a direct current motor is “a cylinder of magnetic laminations that are insulated from one another” (7). Two other materials that are consistent within the direct current motor are the commutator and brushes. The commutator supplies the electrical current to the armature winding. The commutator is able to supply this energy because the brushes “conduct electric current from the external circuit to the rotating commutator” (8). These raw materials are then shipped to factories to be implemented into creating the electric scooter.

Once raw materials are extracted and processed from primary materials to secondary materials, they can be manufactured and processed to become products that can build the electric scooter. Lithium-ion batteries have been explained in the previous paragraph. The process of making the primary materials into second materials totals up to a majority of the manufacturing process of creating the batteries. An important piece of information to highlight for lithium-ion batteries is that the vacuum is an extremely important machine for processing the batteries. For aluminum alloy, it is transferred to a reduction area that consists of reduction cells or pots that are powered via massive cables. These cables have a constant voltage at the electrodes and it varies from “4 and 6 volts, while the amperage can reach 300, 400 KA and more” (4). These reduction areas consistently require large amounts of electric power, so it’s necessary to use renewable energy sources. If renewable energy sources aren’t used then a greater amount of waste will be created so the renewable energy source will be more environmentally friendly but also save more energy. A solution to this is using a hydroelectric power plant to power the reduction areas. Direct current motors have a manufacturing process flow where the “first step is producing lamination for the pole piece and armature” (9). The end frame manufacturing of the motor involves a heat transfer device where there are slots for air to pass. Once all the manufacturing is done, these products need to be transported to be distributed to the different companies.

To add on, molten aluminum is transported in buckets to the cast house of the smelter. During this transportation phase, the aluminum still has to be processed. At these cast houses all admixtures are removed by remelting aluminum in a special furnace at 800 degrees Celsius. This allowed the resultant pure aluminum in the cast to solidify. For every material, such as lithium-ion batteries and direct current motors, the main sources of transportation are planes, trains, trucks, and boats. For lithium-ion batteries, transportation is extremely dangerous so it must be confirmed that all requirements are met before transportation. At the destination of these travels, it is time for the electric scooters to be put up to use.

After all the hard-work of extracting the raw materials, the manufacturing process, and then transportation, it is now up to the consumer to maintain the electric scooter. The energy used to maintain the electric scooter is simpler than the energy intake during the production process. For instance, the lithium-ion battery is known to last for more than a couple of years, however, it needs to be taken care of to last for a long time. The consumer must maintain some charge in the battery so that it doesn’t have to be replaced. The direct current motor also has an easy routine to maintain. The consumer just has to wipe off the dust, first, oil, etc. to ensure that the electric scooter lasts for a long period of time. No matter how much energy is put into caring for the electric scooter, there will come a time when it needs to be disposed of.

With every creation, there needs to be a way to dispose of it. A lot of materials used to manufacture electric scooters are hazardous to dispose of normally, therefore electric scooters need to be taken to recycling centers for hazardous waste. For instance, lithium-ion batteries and aluminum alloy are hazardous and that is a big component of the electric scooter. At these hazardous waste collection centers, incinerators are used to properly dispose of electric scooters. The machine uses controlled flame for thermal treatment. This treatment will “destroy toxic organic constituents in hazardous waste and reduce the volume of waste that needs to be disposed of” (2). In addition, many parts of the electric scooter can be recycled and reused. The disposal of the electric scooter is fairly simple compared to its creation. A simple stop at a recycling center will get the job done.

All in all, energy is weaved throughout the life cycle to produce, transport, and maintain the electrical scooter. The machines to create the different parts, the trucks, ships, and planes to transport the materials needed, and finally, the maintenance of the scooter when it is finally produced. For an eco-friendly alternative to transportation, the scooter has a complex energy life cycle.

Works Cited

Bonk, Lawrence. “Disposing Of Your Old Electric Scooter | Guide For Safely Disposing Of EWaste.” Gadget Review, 6 October 2022, https://www.gadgetreview.com/how-to-dispose-old-electric-scooter. Accessed 16 March 2023.

“DC Motor - Definition, Working, Types, and FAQs.” Byju's, https://byjus.com/physics/dc-motor/. Accessed 16 March 2023.

“Everything You Need To Know About DC Motors | RS.” RS Components, https://ie.rs-online.com/web/generalDisplay.html?id=ideas-and-advice/dc-motors-guide. Accessed 16 March 2023.

“Frequent Questions on Lithium-ion Batteries | US EPA.” EPA, 14 May 2022, https://www.epa.gov/recycle/frequent-questions-lithium-ion-batteries. Accessed 16 March 2023.

Gupta, Nishtha. “Li-ion cell manufacturing: A look at processes and equipment -.” ETN News, 10 June 2021, https://etn.news/energy-storage/li-ion-cell-manufacturing. Accessed 16 March 2023.

“How aluminum is produced.” About Aluminium, https://www.aluminiumleader.com/production/how_aluminium_is_produced/. Accessed 16 March 2023.

“How to Maintain an E-Scooter.” Bicycle Doctor House Calls, 16 December 2021, https://bicycledoctorflorida.com/2021/12/how-to-maintain-an-e-scooter/. Accessed 16 March 2023.

“The Importance of DC Motor Maintenance.” Hi-Speed Industrial Service, https://www.gohispeed.com/the-importance-of-dc-motor-maintenance/. Accessed 16 March 2023.

“Lithium Battery Manufacturing | Busch, United States.” Busch Vacuum Solutions, https://www.buschvacuum.com/us/en/applications/lithium-battery-manufacturing/#manufacturing-process. Accessed 16 March 2023.

“Mechanics and Manufacturing Methods -- Guide to Small Electric Motors.” Industrial Electronics, https://industrial-electronics.com/guide-small-electric-motors_3_1-5.html. Accessed 16 March 2023.

Jaclyn Lee

Jenny Nguyen, Nicholas Kim

DES 40A

Professor Cogdell

Electric Scooter: Waste

Electric scooter services such as Bird and Lime have quickly gained popularity in urban areas as they offer a convenient and eco-friendly mode of transportation. Although scooters don’t produce any harmful emissions while in use, emissions can be found in other stages of its life cycle. Waste is produced in almost all parts of its life cycle, but mainly in the product manufacturing, transportation and distribution, and recycling and disposal processes. In the manufacturing stage, waste in the form of aluminum alloys and paint is created. The transportation and distribution process also contributes to environmental waste, releasing carbon emissions. Even after a scooter has served its purpose, parts that are not recyclable contribute towards additional waste.

Most of the waste produced in an electric scooter’s life cycle is in the process of acquiring the raw materials needed to create one. Aluminum alloys, the most abundant material in an electric scooter, make up 44% of the total materials. Bauxite, the most commonly found aluminum ore, is first mined, then processed into alumina, or aluminum oxide (Muhammad). It’s mainly mined in Guinea, Australia, Brazil, Vietnam and Jamaica (“Aluminum”). The first step in creating aluminum is mining bauxite which is done by open-pit mining. This process leads to air pollution from the immense amount of dust created by blasting soil. These “resulting clouds transport about 2.0-2.5 million tons of dust” annually, which “settles on the surrounding vegetation [and leads to] stunted growth and even death of some trees,” (Coffey, Lad). The heavy equipment and machinery such as “front-end loaders, power shovels[, and] hydraulic excavators” also releases large amounts of emissions and exhaust that pollutes the air (Coffey). Not only does the mining produce airborne waste, but it produces waterborne waste as well. Mining of bauxite can easily lead to contamination of drinking water, filled with toxic chemicals such as aluminum, iron, arsenic, mercury, cadmium, lead, nickel and manganese (Murdoch). Next, the bauxite is crushed, ground, and washed to “remove some of the clay, reactive silica and sand waste,” (“Aluminum”). Then it is “put through a variety of water- and solvent-intensive purification processes,” (Coffey). These solvents, other chemicals, and metals that remain in the water are called tailings. Fine particles damage the environment by “releasing toxic metals, causing erosion and sinkholes, and contaminating soil and water supplies,” (Murdoch). Aluminum is then extracted from the bauxite through the Bayer refining process which consists of four stages: digestion, clarification, precipitation, and calcination. A “solution of sodium aluminate or green liquor and a precipitate of sodium aluminum silicate” is formed in the digestion phase when the bauxite is processed through a digester. In the clarification phase, “undissolved iron oxides and silica” makes up sand and red mud waste which is pumped into residue lakes (“Aluminum”). Around 360 to 800 kg of red mud is produced for each ton of aluminum oxide, and it is contaminated with alkali which chemically pollutes groundwater (Coffey). The production of lithium ion batteries consists of three steps: electrode manufacturing, cell assembly, and cell finishing. During the electrode manufacturing process, coated foil is put into a drying oven to evaporate the solvent. This creates a harmless vapor that is released directly into the surrounding environment. When assembling the cell battery, the cell must be filled with electrolytes then sealed, and must be “carried out in a dry room since moisture will cause the electrolyte to decompose with the emission of toxic gasses.” During the degassing process in the cell finishing stage, charging the battery the first time emits large quantities of toxic gas which is pushed out of the cell into a gas bag. The bag is punctured in a vacuum chamber and the gasses are sucked off, separated, and disposed of as hazardous waste (Gupta). To synthesize the basic materials for lithium-ion batteries, “heat between 800 to 1,000 degrees Celsius is needed,” which “can only cost-effectively be reached by burning fossil fuels,” adding more to the carbon dioxide output (Crawford). Almost 80% of lithium batteries are manufactured in China, “where coal is the primary energy source,” emitting even more greenhouse gasses (Crawford). The mining process of lithium, like all mining processes, is extremely damaging to the environment. It is most commonly performed in hard rock mines or underground brine reservoirs, where toxic chemicals such as hydrochloric acid can easily leak into local bodies of water. Similar to the process of mining aluminum, lithium miners must rely heavily on carbon dioxide producing machinery. Iris Crawford, a climate justice senior editor at the Environmental Solutions Initiative emphasizes that “for every tonne of mined lithium, 15 tonnes of CO2 are emitted into the air,” (Crawford). Sulfuric acid discharge, radioactive uranium, lime, and magnesium wastes are also common byproducts, affecting local communities that heavily depend on those water sources and land (Brooks). Rubber, specifically styrene-butadiene rubber used for tires, is also a main component of an electric scooter. Heavy machinery is again used such as a calendar, mixer, and screw-type extruder to produce the tires which releases carbon dioxide through the burning of fuel (Continental).

During the product manufacturing stage of an electric scooter, waste is produced in the form of paint, and extra aluminum and steel parts. Sheets of aluminum are cut into sprockets, which make up part of the back wheel of an electric scooter. The break disk is also cut from a sheet of stainless steel. Large machines required for these processes directly contribute to carbon emissions. In addition, scrap metal and extra fine particles formed during the cutting process are either auctioned off to scrap metal buyers, or sent to recycling facilities to be shredded and put into furnaces to be turned into new sheets of metal. During the shredding stage, hydraulic machinery which uses hydraulic oil is utilized which often leads to oil leaks. On a yearly basis, “370 [million liters of oil] is leaked from equipment,” contaminating “soil, groundwater, river water, and seawater,” (Continental, Parambath) . Such fluids have a fairly high chance of harming “humans, plant life, animals, and marine lif,” (Parambath). To paint parts of the electric scooter, powder coat dry paint particles are applied with an electrostatic charge. Electrostatic painting prevents a significant amount of waste, however the paints contain an extremely high concentration of volatile organic compounds, toxic fumes, and hazardous solid wastes. These substances can enter wastewater when coatings of the paint are cleaned from containers or equipment (Burns).

Transportation and distribution by plane and truck is the next step in the life cycle for scooters. A majority of electric scooters are assembled in China and weigh around 17.5 kg including packaging and accessories. To transport the scooters to Los Angeles, California, by plane results in 207 ton-km and to transport them from Los Angeles to Raleigh, North Carolina, by shipping and trucking, results in 70 ton-km per scooter (Hollingsworth). Both modes of transportation release large amounts of carbon dioxide from burning fuel. Planes additionally release water vapor, nitrous gasses, soot, and sulfate. Although water vapor may seem harmless, when put in extremely low temperatures in the atmosphere, it instantly freezes to create lingering contrails. These will trap infrared rays and “producing a warming effect up to three times the impact of CO2,” (Overton).

Although electric scooters themselves don’t release any emissions during the use and maintenance stage, the electricity needed to charge them produces slight carbon emissions. Electricity use “[contributes to] 4.7% of the total” carbon released (Hollingsworth).

The last stage of the life cycle is recycling and disposal of the scooter where a majority of the main components are able to be safely recycled. Aluminum is fairly easy to recycle and produces very little waste which makes it a great environmental friendly material. It can be sent to recycling centers to be “shredded, remelted and solidified,” and the machinery needed to power this process burns fuel, releasing carbon dioxide (Husband). Fuel is burned to heat furnaces to high temperatures and power machinery which will release carbon dioxide, but in comparison to the process of mining and creating new aluminum, it releases significantly less. Tires are also fairly easy to recycle due to the various ways they can be reused. Most tires are used to produce pyrolytic oil, but some can also be used to make ground rubber or be part of civil engineering projects. Letting tires naturally decompose takes around 150 years and releases “toxic organic compounds into the soil,” (Veléz-Arocho). But in the process of creating pyrolytic oil, pyrolysis doesn’t release any highly toxic substances and is cost effective. To recycle lithium ion batteries, the process is much more complex and energy demanding, but still possible. The first step is through the process of pyrometallurgy which “[recovers] nonferrous and precious metals” such as cobalt, copper, nickel, and iron by “conflagrating, incineration, and smelting in a plasma arc furnace, drossing, sintering, and melting at [a] high temperature,” (Murugappan). The next step is hydrometallurgy which is done to recover other metals by processing of the cathode material with strong solutions. However, these “processes generate environmental pollutants, such as furans, dioxins, and highly acidic wastewater,” (Murugappan).

Waste in different forms is produced in all parts of the life cycle of an electric scooter, with some parts more than others. Although electric scooters are thought of to be fairly eco-friendly as they do not release carbon emissions while in use, the collection of raw materials and production process heavily impacts the environment in other ways. There are many products that are often portrayed as environmentally friendly or green, but one should take into consideration how much waste is produced within the life cycle of a product in its entirety before making that judgment.

Bibliography

Aluminum. “Aluminium.” Aluminium | Geoscience Australia, Australian Government, https://www.ga.gov.au/education/classroom-resources/minerals-energy/australian-mineral-facts/aluminium#:~:text=Aluminium%20can%20be%20extracted%20(uneconomically,the%20alumina%20into%20aluminium%20metal.

Brooks, Emilie. “Lithium Extraction Environmental Impact · Eco Jungle.” Eco Jungle, 31 Dec. 2021, https://ecojungle.net/post/lithium-extraction-environmental-impact/#pollutes-water-sources.

Burns, Timothy. “Electrostatic Painting Advantages and Disadvantages.” EHow UK, 14 July 2020, https://www.ehow.co.uk/info_8382851_electrostatic-painting-advantages-disadvantages.html.

Coffey, Rebecca. “What Is Open-Pit Mining? Definition, Examples, Environmental Impact.” Treehugger, July 2022, https://www.treehugger.com/what-is-open-pit-mining-definition-and-environmental-impact-5219892.

Continental. “Tire Production.” How a Tire Is Made | Continental Tires, 2020, https://www.continental-tires.com/car/tire-knowledge/tire-basics/tire-production.

Crawford, Iris. “How Much CO2 Is Emitted by Manufacturing Batteries?” How Much CO2 Is Emitted by Manufacturing Batteries? | MIT Department of Mechanical Engineering, 1 Mar. 2022, https://meche.mit.edu/news-media/how-much-co2-emitted-manufacturing-batteries#:~:text=The%20Production%20Process&text=Currently%2C%20most%20lithium%20is%20extracted,are%20emitted%20into%20the%20air.

Gupta, Nishtha. “Li-Ion Cell Manufacturing: A Look at Processes and Equipment.” Emerging Technology News, Emerging Technology News, 11 June 2021, https://etn.news/energy-storage/li-ion-cell-manufacturing.

Hollingsworth1, Joseph, et al. “Are e-Scooters Polluters? The Environmental Impacts of Shared Dockless Electric Scooters.” Environmental Research Letters, IOP Publishing, 26 June 2019, https://iopscience.iop.org/article/10.1088/1748-9326/ab2da8#erlab2da8s2.

Husband, Tom. “Aluminum Recycling.” American Chemical Society, 2012, https://www.acs.org/education/resources/highschool/chemmatters/past-issues/archive-2011-2012/aluminum-recycling.html#:~:text=In%20the%20Western%20world%2C%20the,shredded%2C%20remelted%20and%20solidified%20again.

Ishaq, Muhammud. “Life Cycle Assessment of Electric Scooters for Mobility Services: A Green Mobility SolutionsM.” Life Cycle Assessment of Electric Scooters for Mobility Services: A Green Mobility Solutions, International Journal of Energy Research, 4 May 2022, https://onlinelibrary.wiley.com/doi/full/10.1002/er.8009.

Lad, Rohan. “Studies On The Impact Of Bauxite Mining Activities On Environment In Kolhapur District.” Proceeding of International Conference, 2012, https://www.unishivaji.ac.in/uploads/journal/Journal_42/42.pdf.

Overton, Jeff. “Issue Brief: The Growth in Greenhouse Gas Emissions from Commercial Aviation (2019, Revised 2022).” EESI, 2022, https://www.eesi.org/papers/view/fact-sheet-the-growth-in-greenhouse-gas-emissions-from-commercial-aviation.

Parambath, Joji. “Environmental Effects of Hydraulic Fluids.” Joji Books, 24 Sept. 2021, https://jojibooks.com/2021/09/24/environmental-effects-of-hydraulic-fluids/#:~:text=Many%20of%20these%20fluids%20and,%2C%20animals%2C%20and%20marine%20life.

R.M., Murugappan. “Pyrometallurgy.” Pyrometallurgy - an Overview | ScienceDirect Topics, 2021, https://www.sciencedirect.com/topics/earth-and-planetary-sciences/pyrometallurgy#:~:text=Though%20pyrometallurgical%20processes%20are%20said,are%20the%20major%20limitations%20associated.

U, Murdoch. “Dangers of Mine Waste Highlighted in U.N. Report.” Phys.org, Phys.org, 15 Nov. 2017, https://phys.org/news/2017-11-dangers-highlighted.html#:~:text=Mine%20tailings%20are%20the%20materials,contaminating%20soil%20and%20water%20supplies.

Veléz-Arocho, Javier. “How to Turn Tires into Alternative Fuel: Pyrolysis Process?” Diatom Environmental Services, LLC, 7 Oct. 2022, https://diatomenvironmental.com/how-to-turn-tires-into-alternative-fuel-pyrolysis-process/.