Design Life-Cycle

assess.design.(don't)consume

Noopur Dekate

Danae Navarrette, Ryan Gardon

DES 40A

Professor Cogdell

The Life Cycle of the Raw Materials in Biodegradable Golf Balls

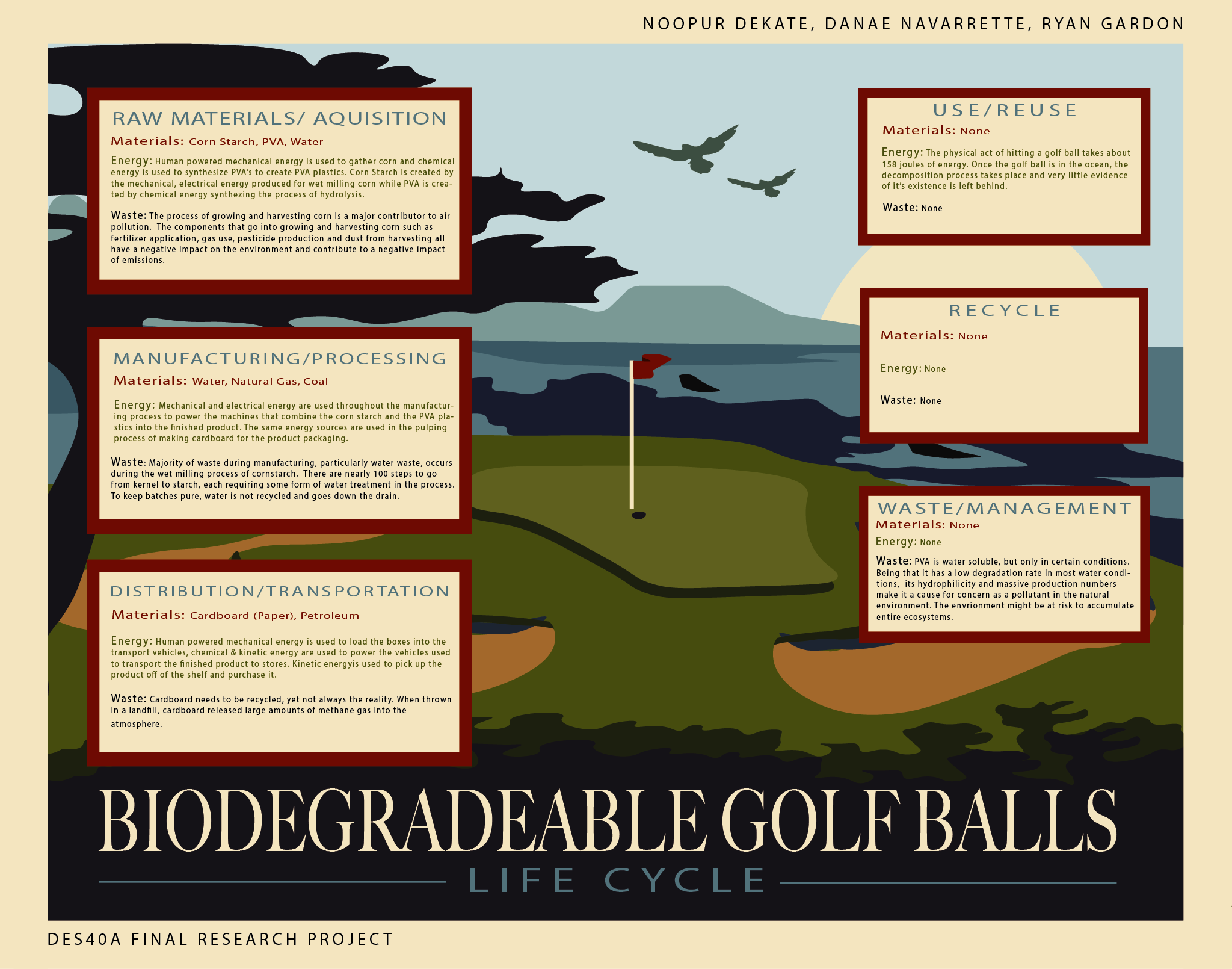

Each year, around 1.2 billion golf balls are produced for recreational and entertainment use (Cen.acs.org). As golf courses are often near water, a large percentage of golf balls inevitably end up in our oceans, lakes, and rivers: “It is estimated 300 million balls are lost or discarded each year in the United States alone.”(Lorie). Biodegradable golf balls were created to be a sustainable and dissolvable option for athletes and leisure players. The golf balls are created primarily by two raw materials: corn starch and Polyvinyl Alcohol, commonly referred to as PVA. These raw materials are involved in the creation of biodegradable golf balls during the acquisition, manufacturing, and processing stages. Adhesive tape and cardboard are used to transport the golf balls to customers across the nation. Despite the attempt to promote sustainability through the biodegradable design, the distribution, recycling, and waste management of this ball have not been as eco-friendly as the product claims to be. Throughout the lifecycle of the creation of the biodegradable golf ball, the intention to stay dissolvable has been in mind, but even this may not be sustainable. The biodegradable golf ball is a more eco-friendly alternative than its counterpart, but cannot be the final result if true sustainability is the ultimate goal.

Cornstarch is an important main ingredient that goes into the production and composition of the biodegradable golf ball. Although the effects of cornstarch itself on the environment are negligible, the effects of the processing of the cornstarch are anything but. The production of cornstarch is long and energy-intensive: “Cornstarch is produced from corn kernels in a refining process known as wet milling ... The softened kernel is then passed through mild attrition mills, in which corn is coarsely milled to free germ from the fiber, protein, and starch” (Luo). The process of wet milling requires the input of excessive electric energy into the system. This is what allows the kernel to be softened, milled, and ground into usable material. While it is important to ensure the cornstarch is germ-free so it can be used, the processes in which the mills get their energy source are from non-reusable and environmentally harmful resources. On top of this, the creation of the raw material leads to severely devastating outputs. The wet processing of corn leads to their waste products in the water: “With wet processing, it comes in the form of water pollution and waste byproducts – things that can ruin the local ecology, farmland, and in some places, even the drinking water” (Luo). Because wet processing is such a major role in the production of corn starch, we need to take a step back to see the total effects of cornstarch on the environment, not just the result. The negative impacts of corn starch production cause the pathway to create a biodegradable product to be less than sustainable, even if it claims to be.

The corn industry involved in creating corn starch has further negative effects on the environment than just extensive use of water and energy. Corn monoculture worldwide has had devastating effects on the biodiversity of native grasslands and plains. Farmers plant hundreds of acres of one species of corn and have to til, Paul Johnsgard, a professor at the University of Nebraska-Lincoln, warns the public and farmers alike of the disappearance of biodiversity due to the corn industry: “Plowing up such fragile lands to raise … corn for a few decades, often until the topsoil blows away and the land is abandoned, is like throwing away a treasure trove” (Price). The corn market is rapidly increasing from an already large sector. Due to an increase in demand for corn ethanol and now corn-based products, such as the cornstarch for biodegradable golf balls, it is predicted to only expand more. Unfortunately, with new products, such as this golf ball, corn distributors and farmers are only more willing to expand more, creating irreversible effects on the environment and the organisms who rely on it. Corn starch and the corn it comes from have an undeniable impact on the environment, and are only one of several raw materials involved in the creation of biodegradable golf balls that impacts the environment.

Polyvinyl Alcohol (PVA) is a raw material in several common, everyday items as well as biodegradable golf balls. Its versatile use can be seen from Tidepods to glue. PVA is a major material in the manufacturing of biodegradable golf balls, yet it has major effects on the environment. This is creating an unsustainable production process for the golf balls’ lifecycle. PVA is plastic and is derived from oil and petrochemicals (Eteeshop). It is arguably better than normal plastic because it dissolves but still is not good overall for the environment. Because the end of the life cycle of the biodegradable golf ball is dissolving into the ocean, the raw materials being released by this product need to be beneficial, or at least unaffecting, to the ecosystem, it is being released in. Although PVA contains minimal amounts of petrochemical, biodegradable golf balls are sold in packages of six, and balls are commonly used, lost, and repurchased. The more this supplier sells, the more the effects of PVA on the environment it causes. In addition, Polyvinyl Alcohol is only dissolvable and biodegradable under certain conditions. The golf balls are only able to biodegrade via microbes in certain environments. Due to the need for the environment to be so specific, no academics are exactly sure how the ecosystems will be affected (Rolsky et. al). Marketa Julinova, an author in Science Direct states that: “As a result, the commercially produced water-soluble polymers of PVA… are essentially non-biodegradable and possess the capacity to accumulate in virtually all environmental media” (Julinova). This product should not be encouraging users to hit the ball into the ocean since no one is sure about the full biodegradable capabilities of this golf ball. Being one of the most essential materials involved in the creation of the biodegradable golf ball, Polyvinyl Alcohol has to be good for our oceans and the soil for the golf balls to be considered sustainable or good for the environment. Although they might be advertised as this, these golf balls are spreading plastic, polymers, and microplastics in our ecosystems.

Microplastics, such as those released by PVA, that are in oceans’ ecosystems affect all parts of the food chain and the environment as a whole. Due to the microplastics’ size, bottom feeders and smaller animals in the ocean ingest the toxic material. The plastic infests the fish’s population, causing the toxins to go up the food chain and affect larger species and increased populations of animals (Zarfl et. al). The effects on these animals could be extensive depending on the amount ingested, the toxicity of the plastic, and the species. Side effects of ingesting microplastics can span from depleting energy sources to reduced fertility to altered behavior. Attempts for legislative change of microplastic classification to hazardous have occurred but have thus far been unsuccessful. Unfortunately, there is significantly less public knowledge of the effects of microplastics on the organisms and, in turn, of ecosystems than what is needed for accurate consumer knowledge (Galloway). The environmental impact of PVA and microplastics from biodegradable golf balls should not be as easy to ignore as it is.

Even after biodegradable golf balls are manufactured, there are still negative environmental consequences from their transportation. Cardboard is an essential material that goes into the cradle-to-grave life cycle of the biodegradable golf ball during the distribution stage. It is used for the company's packaging and shipping and is, therefore, a crucial part of the commercial process. Cardboard is made from paper, recovered fiber, and, at times, recycled materials creating a more sustainable alternative to plastic packaging (Stasiškienė). The environmental issues of the biodegradable golf balls’ cardboard packaging start when the customer decides to dispose of it: “Currently, about 70 percent of cardboard-boxes shipped commercially are recovered for recycling” (Waste Disposal & Recycling). These recycled boxes are used to create even more boxes for shipping, creating a cyclical life cycle for some of the boxes. The problem arises when users throw away the box in a landfill instead of a recycling plant. Cardboard is biodegradable, but the product releases methane into the atmosphere while it breaks down (Hwest). The act of cardboard decomposition in the environment instead of being recycled takes up unnecessary space in landfills and contributes heavily to global warming. Cardboard is created from wood pulp and cellulose fiber. Due to this composition, in order to create more cardboard, more trees need to be cut down. The increased use of cardboard has a direct positive relationship with the increase in deforestation. Although, most people do not see the overall effects of deforestation, the impacts are severe. This includes increases of CO2 an and increase of extinction due to lack of habitat. All of these actions lead to massive negative impacts on the habitat and environment, affecting wildlife, ecosystems, and the atmosphere. The distribution of a product is an essential part of its entire life cycle. The material that goes into transporting a package of these biodegradable golf balls has severely increased its effect on the environment and should be acknowledged when considering the overall environmental impact of the golf balls.

Biodegradable golf balls have served as an eco-friendly, guilt-free alternative to regular golf balls, which are so commonly used. Their life-cycle includes being created by PVA and cornstarch, being shipped, then used by being shot into the ocean. By using PVA and cornstarch instead of plastic the ball is eventually doomed to disintegrate, unlike the regular one. Unfortunately, these raw materials lead to devastating effects on the environment during the whole cradle to grave life cycle. The Biodegradable Golf Ball company advertises its product as “Environmentally Friendly Golf Balls” (Golf Balls That Dissolve In Water - Eco-Friendly). Claiming the product is environmentally friendly or eco-friendly is incorrect and misinforms customers. Although it is an alternative, it cannot be the last iteration of the golf ball. The negative effects on the environment are still present, and if total sustainability is the goal, more effort is required to reach it.

Bibliography

Cen.acs.org, cen.acs.org/articles/95/web/2017/06/s-inside-golf-balls-chemistry.html#:~:text=About 1.2 billion golf balls,varying construction materials and designs.

Galloway, Tamara S., et al. “Interactions of Microplastic Debris throughout the Marine Ecosystem.” Nature News, Nature Publishing Group, 20 Apr. 2017, www.nature.com/articles/s41559-017-0116.

“Golf Balls That Dissolve In Water - Eco-Friendly.” Biodegradable Golf Balls, 22 Jan. 2020, biodegradablegolfballs.com/.

Hwest, and Hwest. “4 Reasons Why It's So Bad to Not Recycle Cardboard.” H West Equipment, 15 Sept. 2018, hwestequipment.com/4-reasons-why-its-so-bad-to-not-recycle-cardboard/.

Lorie, Anouk. “Biodegradable Golf Ball Feeds Goldfish.” CNN, Cable News Network, 26 Jan. 2010, www.cnn.com/2010/SPORT/01/14/biodegradable.golf.ball/index.html.

Luo, Lan. “What Are the Chemicals in Cornstarch?” Sciencing, 30 Mar. 2020, sciencing.com/chemicals-cornstarch-15444.html.

Julinova, Marketa. “Water-soluble polymeric xenobiotics – Polyvinyl alcohol and polyvinylpyrrolidone – And potential solutions to environmental issues: A brief review.” Science Direct, 2018, https://www.sciencedirect.com/science/article/pii/S0301479718310016. Accessed 19 October 2021.

Stasiškienė, Žaneta, and Rasa Juškaitė. "Optimization of the cardboard manufacturing process in accordance with environmental and economic factors." Environmental Research, Engineering and Management 2.40 (2007): 70-79.

Price, Aaron E. "Corn monoculture: No friend of biodiversity." (2008).

Rolsky, Charles, and Varun Kelkar. “Degradation of Polyvinyl Alcohol in US Wastewater Treatment Plants and Subsequent Nationwide Emission Estimate.” International Journal of Environmental Research and Public Health, vol. 18, no. 11, 2021, p. 6027., doi:10.3390/ijerph18116027.

“POLYVINYL ALCOHOL (PVA, PVOH): How Easily Does It Biodegrade?” Eteeshop, www.shopetee.com/blogs/plastic-pollution/dissolvable-plastic-should-we-use-it-for-our-products

Waste Disposal & Recycling, www.wm.com/thinkgreen/recycle-products/paper-cardboard.jsp.

Zarfl, Christiane, et al. "Microplastics in oceans." Marine Pollution Bulletin 62 (2011): 1589-1591.

Danae Navarrette

Ryan Gardon & Noopur Dekate

DES 040A

Professor Cogdell

Energy Life Cycle Assessment: Biodegradable Golf Balls

Modern day golf balls have demonstrated a huge swing and a miss when it comes to protecting the environment. The aerodynamically dimpled spheres often land in rivers, lakes, or oceans where, according to a study done by the Danish Golf Union, they can take anywhere from 100 up to 1000 years to decompose. Why might this be a problem? I’m so glad you asked. Unfortunately, the average golf ball is not exactly planned out perfectly for a graceful decomposition and rejoining with nature. According to the above study “during decomposition, the golf balls . . . release a high quantity of heavy metal. Dangerous levels of zinc . . . the zinc attached itself to the ground sediment and poisoned the surrounding flora and fauna” (Macfarlane). It is not difficult to see why someone needed to come up with a solution to this issue. Enter: biodegradable golf balls. They are made from two ingredients, polyvinyl alcohol and cornstarch. These two ingredients will biodegrade when they interact with water and reduce the harmful impact upon the environment. These balls are a great earth conscious alternative to pick up when planning your next day at the links. Though an actual biodegradable product is an excellent step towards bettering our environment, there is still work to be done when stepping back to take a look at the process as a whole. Even if we specifically hone in on the energy aspect of biodegradable golf balls, there are still a million and one things to consider. What types of energy are used throughout this process? How can we be more mindful about the types of energy we use? What about the energy expected to be generated by the consumer after the purchase of the product? It is nearly impossible to account for every unit of energy used in the process of just about anything but, luckily, this paper only aims to explore how the process of energy use in the production of biodegradable golf balls fails and succeeds, as well as offer humble suggestions on how to improve it.

To start off, one needs to be familiarized with the many different types of energy. Energy can be broken down into six major categories; chemical, electrical, radiant, mechanical, thermal, and nuclear. The actions that respectively pair with the above categories are absorbing nutrients from food, charging your phone, an x-ray machine, riding a bike, baking a cake, and an atomic bomb.

Energy is essential to everyday life and it bodes one well to know how to maximize the energy sources around them. If that were not enough, there are also subcategories of energies like kinetic, which is a branch of mechanical energy and is usually associated with a physical act. Learning about the different types of energy can also allow for better understanding of what it really takes to uphold the quality of life that we in Western society hold so dear. Once there is a baseline understanding of that, one can really start to fill in the gaps about progress, or lack thereof, towards sustainability. Now, this begs the question, what types of energy are essential to the manufacturing and distribution of biodegradable golf balls? Well, it is funny you should ask, as we move on to our next point that aims to explore just that.

Now, when it comes to manufacturing products, several types of energy come to mind, mechanical, chemical, and electrical to name a few. Which types of energy are paramount to manufacturing biodegradable golf balls? The simple answer is, a lot of them. The more complex answer is; mechanical, chemical, electrical, thermal, and even more when you factor in every miniscule step of the process. However, we are not going to dive that deep. It could be easy to get lost in a neverending rabbit hole of “If I catalog the energy usage of the manufacturing plant should I catalog the energy usage of the humans running the plant? What types of energy do they run on?” and so on and so forth. However, the focus of this paper is golf balls and that is what we are sticking to. I have chosen a snapshot of the production cycle of the golf balls themselves. The following energy types encompass the life cycle of the ball: mechanical energy to physically pick and gather the raw materials, chemical energy to power the vehicles that transport the raw materials to the factory, kinetic energy from that chemical energy that actually moves the vehicle, electrical energy to power the machines in the factory, chemical energy using hydrolysis to create the PVA plastics, electrical energy to power the wet milling process for cornstarch, electrical energy to power the machines used for producing the golf balls themselves, mechanical or chemical energy for the pulping process of the cardboard boxes, mechanical energy to pack the boxes/load them into transport vehicles, chemical energy to power the vehicles that transport the finished product to stores, kinetic energy from that chemical energy that actually moves the vehicle, and finally, 158 joules of mechanical (kinetic) energy to actually hit the golf ball into the water. Phew! That whole process accounts for a ton of energy. It is easy to see how each subset can lead you to a million different circumstances. Luckily, our field of view is narrowed to pertinent info. Now that we have a more comprehensive understanding of the types of energy used to manufacture biodegradable golf balls, let us pivot our topic to the effectiveness of this process.

With any process, highs and lows are a given. In this paragraph I would like to explore some things that the manufacturer does well in their process as well as some areas that could use improvement. While nothing is perfect, there are several good uses of energy when creating this product. They use recycled cardboard for packaging when possible as well as electric vehicles for transport. There can also be compounded effects of renewable energy sources if customers use electric vehicles if possible.. The process of synthesizing PVA is also fairly low energy. On the flip side though, the process of manufacturing this product also utilizes fossil fuels at several stages which is less than ideal with the current state of our planet, adding more emissions to the atmosphere is not exactly something to be proud of. Coal powered factories and gasoline powered cars have begun to stick out like a sore thumb in our minds as wasteful and irresponsible. I suspect that this step of the process is the largest pitfall. The process of gathering corn starch is fairly wasteful of water in its long wet milling process. This is a particularly sore subject to people in the state of California as any native knows that we have been in a persistent drought. On the bright side, after dissolution, there is no energy usage in the life cycle of the product. By creating a product that disintegrates into its environment, it eliminates two major steps where energy could be wasted which would be the efforts to reuse/recycle that product. Most of the time, even if a product is recyclable, it still ends up in landfills due to human error/laziness. Biodegradable golf balls eliminate the need for any human action after your swing. The hardest part of the process is remembering to buy the biodegradable balls. This is a positive thing because the less action expected out of the consumer, the better chance of working towards a truly “eco friendly” product becoming the standard of life. The question now becomes, is the good that this product does enough to outweigh the negatives of its production? If not, how can the process be reimagined to become more mindful and efficient? That is something that will be covered in our next paragraph which poses as a sort of “suggestions” section.

Let it be known that this author makes no claims of being an energy expert or a qualified counselor on how to reduce one's carbon footprint. However, through research I believe there are several ways to implement new practices that could potentially lead to more conscientious capitalism in this instance. Several actionable items would be switching to electric transport vehicles, using recycled cardboard packaging, offering incentives for recycling product packaging and transitioning to solar power when possible during the manufacturing process. These small but mindful changes could produce big results in helping to embrace change in our normally wasteful society. Many companies are trending towards making environmental changes by taking steps to (at least) be carbon neutral or by donating money to give back to protecting the environment. This is a model I think would work well for the Biodegradable Golf Ball manufacturer. While this is not an exhaustive list of solutions, they may be helpful in moving us a step in the right direction. The direction of conscientious capitalism as well as conscientious consumerism.

While no man made product will ever have a “perfect” life cycle, there are certain ones that get close. The goal is not perfection, as perfection in our world is unattainable, however the goal is progress towards changing the accepted standard. The goal is working towards a society that shares a general care for the wellbeing of our planet and a fire in their hearts to take action.

Small changes can make a big difference when implemented on a global scale. If even ¼ of manufacturing plants switched to cleaner energy, that would help reduce pollution by thousands of tons. There are so many actionable changes that manufacturers and consumers alike can make in order to positively impact the environment around them. All it takes is consumers standing up for what is right and raising expectations to meet a higher quality standard.

Biodegradable golf balls saw an issue and made a small step towards correcting it. While the ball itself is not perfect, it is a marked improvement upon its predecessor. I believe it is important to acknowledge the progress being made in the right direction as well as think critically about their processes in order to ensure that there is accountability and responsibility being taken for the impacts it has on our daily life and even our future. It is these types of changes that will hopefully become the industry standard that will lead us towards a brighter and better future and allow us to lead the lives we all deserve.

Works Cited

Burton, Kris. “UMaine Researchers Use Lobster Shells to Create Biodegradable Golf Ball - Umaine News - University of Maine.” UMaine News, 17 Aug. 2015, https://umaine.edu/news/blog/2011/03/30/umaine-researchers-use-lobster-shells-to-create-biodegradable-golf-ball/.

Chawla, Dalmeet Singh. “How Golf Is Polluting Our Oceans.” Medium, OneZero, 29 Jan. 2019, https://onezero.medium.com/how-golf-is-polluting-our-oceans-eddb8b59ddc9.

“Comparing Sports Kinetic Energy.” Wearefanatics.com, 3 Jan. 2017, http://wearefanatics.com/comparing-sports-energy/.

Karine Jarzecki, Betty Zhao, Kate Nakamura, Ping Wu. “Max Golf Balls: Biodegradable and Sustainable ... - CSBE-SCGAB.” The Canadian Society for Bioengineering, The Canadian Society for Bioengineering, 22 July 2018, https://library.csbe-scgab.ca/docs/meetings/2018/CSBE18222.pdf.

Kart, Jeff. “Study Says up to 75% of Plastics from Detergent Pods Enter the Environment, Industry Says They Safely Biodegrade.” Forbes, Forbes Magazine, 10 Aug. 2021, https://www.forbes.com/sites/jeffkart/2021/08/08/study-says-up-to-75-of-plastics-from-detergent-pods-enter-the-environment-industry-says-they-safely-biodegrade/?sh=5ece781b796a.

Macfarlane, Christina. “Golf Balls: 'Humanity's Signature Litter'.” CNN, Cable News Network, 10 Nov. 2009, https://www.cnn.com/2009/SPORT/11/04/littering.golf.balls/.

Levins, Cory. “All Boxed up: An in-Depth Look at How the Corrugated Box Is Made.” Air Sea Containers, Inc., Air Sea Containers, Inc., 5 Nov. 2021, https://www.airseacontainers.com/blog/all-boxed-up-an-in-depth-look-at-how-the-corrugated-box-is-made.

Luo, Lan. “What Are the Chemicals in Cornstarch?” Sciencing, 30 Mar. 2020, https://sciencing.com/chemicals-cornstarch-15444.html.

Mascari, John. “What Is PVA and What Is Its Impact on the Environment?” Blueland, 11 July 2021, https://www.blueland.com/articles/what-is-pva-and-its-impact-on-the-environment.

Mukesh Doble, Anil Kumar. “Polyvinyl Alcohol.” Polyvinyl Alcohol - an Overview | ScienceDirect Topics, https://www.sciencedirect.com/topics/earth-and-planetary-sciences/polyvinyl-alcohol.

“Physics of Golf.” Real World Physics Problems, https://www.real-world-physics-problems.com/physics-of-golf.html.

Sam. “Best Biodegradable Golf Balls for a Greener Golf Practice.” Ecomasteryproject, 28 Sept. 2021, https://www.ecomasteryproject.com/best-biodegradable-golf-balls/.

Saxena, S.K. “Polyvinyl Alcohol (PVA).” FAO.org, https://www.fao.org/fileadmin/templates/agns/pdf/jecfa/cta/61/PVA.pdf.

Vercalsteren, An, et al. Life Cycle Assessment Study of Starch Products for the European Starch Industry Association . Vision On Technology, Aug. 2012, https://www.starch.eu/wp-content/uploads/2012/09/2012-08-Eco-profile-of-starch-products-summary-report.pdf.

Wave Tribe | Share The Stoke ®. “When Golf Balls in the Ocean Are Harming the Environment.” Wave Tribe | Share The Stoke ®, https://www.wavetribe.com/blogs/eco/when-golf-balls-in-the-ocean-are-harming-the-environment.

Ryan Gardon

Danae N, Noopur D

Des 40A

Professor Cogdell

Emissions and Waste of Biodegradable Golf Balls

Each year, millions of golf balls are hit out of play by golfers and up in our oceans. What seems like an innocent act of playing a sport is actually polluting a valuable resource that we depend on for food. The predominantly plastic golf balls contain zinc oxide and zinc acrylate which are both known to be toxic in aqueous environments. Not only are they toxic to aqueous environments, but they also shed microplastics across the ecosystem. These microplastics are absorbed into the surrounding sea life over time and later end up in the sea life we consume, ultimately finding their way back inside of us, causing potential health problems (Chawala). One proposed modern fix to this pollutant is to have golfers switch to a more eco-friendly, biodegradable golf ball. Today, these biodegradable golf balls are derived from only two ingredients, the first being Cornstarch, and the second being Polyvinyl Alcohol (PVA). Both cornstarch and PVA are supposedly biodegradable compounds. Although these golf balls are biodegradable, does that necessarily mean that they are good for the environment? In this paper I will further examine the production process of both cornstarch and PVA to determine the environmental impact these biodegradable golf balls have on our planet. Specifically I will focus on the growing, harvesting, and wet milling of cornstarch as well as the water and gas pollutants emitted during the production and decomposition of PVA.

The first ingredient in the golf balls, Cornstarch, is used as the main mold for the body of the ball. Being a carbon-neutral and edible substance, when introduced into water, the compound breaks down into water and carbon dioxide in less than 90 days (Cowley). These two chemical compounds are not detrimental to the environment, at least in the amounts that the golf balls contribute. The production of cornstarch, however, does not have such a positive or neutral effect on our environment. The cornstarch used for these golf balls is the same as any household cornstarch ingredient. The production process of this material first starts out as a plant, corn, grown on farms, later to be harvested for its kernel. In the corn growing and harvesting process, “the vast majority, 86 percent, of emissions, happen on farms, with the rest occurring elsewhere in the supply chain” (Lambert). The process of growing and harvesting corn is a major contributor to air pollution as well as a contributor to a great deal of water waste. Components that go into the growing and harvesting of corn such as fertilizer application, gas use, pesticide production, and dust from harvesting all have a negative impact on the environment because of the gas emissions they cause. The largest pollutant of these steps is the fertilizer application process. Here, Ammonia is released from the fertilizer into the atmosphere in a gas state where it combines with other synthetic air pollutants, particularly nitrogen and sulfuric oxide. These particles travel long distances through the atmosphere into the air we breathe. Not only do these particles affect the growing and harvesting regions, but they also span across the globe. Nitrogen accumulation in the atmosphere is absorbed back into our soil. This acidifies and affects soil causing toxic damage to plant leaves leaving them more susceptible to “frost, drought, and pathogens. At its most serious, certain sensitive and iconic habitats may be lost.” (Rand)

Next up, after the growing and harvesting of the corn, the product is then taken to a plant where the corn undergoes a wet milling process. In this process, the corn goes from its original state as a kernel and is then broken up into smaller components, one of them being cornstarch. There are nearly 100 smaller process points that need to happen before starch is fully produced from its original state as a kernel, with each step there are potential sources of air pollution contribution. The main source of waste that comes from this wet milling operation comes from particulate matter that is emitted into the air during the breaking down of the material. Inside the process, as the kernel is heated, cooled, and poured from one step to the next, particulate matter is tossed into the atmosphere in gas or micro solid form. These particles contribute to VOC emissions also known as, volatile organic compounds, which much like the nitrogen from the fertilizer, are released into our atmosphere affecting the air we breathe (corn wet milling). Volatile organic compounds are emitted gasses that come from certain solids or liquids including many chemicals and are known by the United States Environmental Protection Agency to cause short and long-term adverse health effects. “Concentrations of many VOCs are consistently higher indoors (up to ten times higher) than outdoors” (EPA). Potential conditions like this can be extremely harmful to wet milling workers on site. A few health conditions they have been known to cause include, eye, nose, and throat irritation, headaches, loss of coordination and nausea, damage to the liver, kidney, and central nervous system, and in some extreme cases, cancer to both humans and animals.

Now, onto the second ingredient that serves as the outer coating to these biodegradable golf balls, Polyvinyl Alcohol. Polyvinyl alcohol, also known as “PVA” is a water-soluble synthetic polymer. The keyword here is “water-soluble” meaning that it dissolves in water. This material is often found in paints, adhesives, textiles, and coatings. The plastic coating serves as an outer shell to the inner cornstarch mold, once the ball is hit into the water, it dissolves, exposing the inner body that eventually breaks apart and dissolves into the ocean water. Although Polyvinyl Alcohol is biodegradable, there are some components of its production process that have a negative impact on the environment. To learn about the amount of waste and emissions produced to make PVA we must examine its production process. PVA is created in labs and plants in a process called pyrolysis. The pyrolysis process is the thermal decomposition of materials at elevated temperatures in an inert atmosphere. In this heating process of biomass, emissions can escape into the air in a gas form. In a study of estimation of industrial emissions during pyrolysis, within the decomposition process, while creating PVA, the most abundant particles emitted “were methane, ethylene, and propylene for both pyrolysis and combustion runs” (Conesa). Both methane and ethylene are major pollutants to our atmosphere. Methane accounts for nearly 10% of all US greenhouse gas emissions from human activities (EPA) as for ethylene, “Studies show that breathing air containing elevated ethylene oxide levels over many years increases the risk of some types of cancers” (EPA). Invisible to the human eye, Allowing micro particles like these in our atmosphere can be detrimental to our long-term health without us even knowing.

Recent studies suggest that although PVA is for the most part biodegradable, it is not fully diluted into most waters because water conditions are not ideal. Full dilution of PVA is dependent on the amount of microbes in the water that PVA is inserted in. Microbes encourage the breaking down of the material. PVA solubility is also dependent on the number of other particles previously diluted in the water. If the water is already supersaturated, no other particles can be dissolved, in this case leaving PVA in the water environment, undissolved (Kart). This is a large problem, especially if companies advertise their PVA materials as fully biodegradable and good for the environment. Remnants of plastics in our water impact surrounding ecosystems and the bio life within them. Diving further into PVA’s waste effects on marine life, “Initial studies revealed that PVA can alter gas exchanges, such as carbon dioxide exchange, affecting aquatic ecosystems” (Rolsky). PVA’s low degradation rates due to its hydrophilicity and wide range of uses make it a cause for concern as a pollutant in our natural environment. At the moment, not much research has been documented toward the monitoring of PVA’s biodegradability. This forms an issue in determining how practical of a solution the material is when creating biodegradable solutions, not just for golf balls but for multiple other purposes it serves as a dissolvable coating. As something that may seem like a sustainable material could just be further contributing to the pollution of our planet.

While the biodegradable golf ball is a step in the right direction and is far better for the environment than a typical plastic golf ball, there are still improvements to be made toward its design to be fully sustainable. Although using biodegradable materials such as cornstarch and Polyvinyl Alcohol may seem like harmless solutions, as we have examined further in their production process, we have found that it is the process of creating these materials that are still harmful to the environment. We can not fault the biodegradable golf ball company for marketing their product as eco friendly, because it does help the cause of plastic waste in our oceans; Companies like this, and consumers alike should be aware of the entire process that goes into making these products knowing the entire process of creation may not be so eco friendly and sustainable after all.

Bibliography

Chawla, Dalmeet Singh. “How Golf Is Polluting Our Oceans.” Medium, OneZero, 29 Jan. 2019, https://onezero.medium.com/how-golf-is-polluting-our-oceans-eddb8b59ddc9#:~:text=Savoca%20is%20the%20third%20author,the%20balls'%20durability%20and%20flexibility.&text=Even%20so%2C%20golf%20balls%20are,into%20the%20oceans%20every%20year.

Conesa, Juan A., et al. “Estimation of Industrial Emissions during Pyrolysis and Combustion of Different Wastes Using Laboratory Data.” Scientific Reports, vol. 10, no. 1, 2020, https://doi.org/10.1038/s41598-020-63807-w.

Cowley, Liné. “What Is Corn Starch Plastic? Compostable Plastic Eco World.” Eco World, 7 July 2021, https://ecoworldonline.com/what-is-corn-starch-plastic/.

EPA, Environmental Protection Agency, https://www.epa.gov/hazardous-air-pollutants-ethylene-oxide/background-information-ethylene-oxide#why.

EPA, Environmental Protection Agency, https://www.epa.gov/indoor-air-quality-iaq/volatile-organic-compounds-impact-indoor-air-quality.

Guthrie, Susan. “Agricultural Ammonia Emissions Carry Steep Costs.” RAND Corporation, https://www.rand.org/randeurope/research/projects/impact-of-ammonia-emissions-on-biodiversity.html.

Kart, Jeff. “Study Says up to 75% of Plastics from Detergent Pods Enter the Environment, Industry Says They Safely Biodegrade.” Forbes, Forbes Magazine, 10 Aug. 2021, https://www.forbes.com/sites/jeffkart/2021/08/08/study-says-up-to-75-of-plastics-from-detergent-pods-enter-the-environment-industry-says-they-safely-biodegrade/.

Lambert, Jonathan. “Growing Corn Is a Major Contributor to Air Pollution, Study Finds.” NPR, NPR, 1 Apr. 2019, https://www.npr.org/sections/thesalt/2019/04/01/708818581/growing-corn-is-a-major-contributor-to-air-pollution-study-finds.

Leander, Sandra. “Are Laundry and Dish Pods Biodegradable? Not Exactly, ASU Study Shows.” ASU, 26 July 2021, https://csteps.asu.edu/are-laundry-and-dish-pods-biodegradable-not-exactly-asu-study-shows.

Rolsky, Charles, and Varun Kelkar. “Degradation of Polyvinyl Alcohol in US Wastewater Treatment Plants and Subsequent Nationwide Emission Estimate.” International Journal of Environmental Research and Public Health, vol. 18, no. 11, 2021, p. 6027., https://doi.org/10.3390/ijerph18116027.