Design Life-Cycle

assess.design.(don't)consume

Caroline Martignetti

Professor Cogdell

Design 040A

9 December 2014

Post-it Note Raw Materials

A Post-It note, a three by three inch sheet of paper that often holds important content that would be forgotten without its presence. Such a simple device for keeping track of ones schedules, to do lists, ideas or reminders. Like so many other products used today it is rare for one to think about how such a small thing can be comprised of such a multitude of materials. Each of those materials involves labor, energy usage and waste, making a product so much more than its final form. This paper will discuss the raw materials of a Post-It note, highlighting the main materials used in production and some used in product transportation and the ultimate waste of the full life cycle. Through the discussion of raw material usage, a Post-it note will thus be transformed from a simple piece of paper to an energy and resource rich product that holds no possibility for sustainability.

The first element of a Post-It Note is their notorious colored paper. When thinking about the raw materials of paper it is easy to assume its merely manufactured wood, but when one dives deeper into the process it is clear wood is just one of many materials used to make paper. Due to privacy concerns there is little to know research on 3M’s exact paper making formula but for the purpose of this paper we will assume they follow a standardized process.

This process begins with timber. Though many different types of wood can be used, and even scraps from saw mills, three preferred types of wood are Fir, Birch and Spruce tree timber[1]. Each of these three types of trees can be found scattered across the Northern Hemisphere [11,15,20]. Due to their presence in North America it is not a stretch to assume that 3M could be finding their timber supply locally. The next element of papermaking is debarking the tree. Using a mechanized process the bark is removed from the tree and the remaining timber is then sent into a chipping machine. Once the wood has been chipped the next process is called the pulping process[1].

The pulping process can either be mechanized or chemical[1].Due to Post-It Notes paper’s smooth and uniform appearance and for the purpose of this paper we will assume 3M uses a chemical pulping process[2]. The main raw material essential for paper making is the cellulose, which makes up about fifty percent of woods content, this pulping process allows for cellulose to be accessed[2].In order to access the cellulose content of wood, the chips are cooked with a chemical combination of caustic sodas, sodium sulfide and sodium hydroxide[16]. Sodium sulfide is colorless and can be created by carbothermic reduction of sodium sulfate. Sodium Sulfate can be traced back to a natural mineral called Mirabilite. Mirabilite can be found in various locations sharing the element saline water[19].Sodium Hydroxide is an in organic compound and can be manufactured various ways[18]. A concoction of both caustic sodas remove the binding material, called lignin, used to hold the cellulose fibers together. The end product after the chemical pulping process is then shipped to a paper mill where it enters a circular tank with water called the hyrdrapulper. This step breaks up the pulp further. The mixture then enters a container called the blend chest. In here the dyes are added[1]. A combination of chemicals can be used to create a specific color for the paper, for example the chemical tartrazine could be used in order to produce the yellow of the paper signature to Post-It Notes[21]. The dyed pulp then proceeds through a refining and cleaning process. Finally it reaches the papermaking machine. It can be assumed that in this stage of paper making a large amount of electricity is being used to keep these machines running which introduces a new raw material to the process, coal or other fossil fuels such as natural gas[1].

The most defining part of the Post-It Note is the glue. The ability to stick without permanence and theoretically be reused and placed in a new location is unlike any other product that had come out in the market before it. This special adhesive was actually a mistake made by the now famous scientist Dr Spencer Silver. He was originally attempting to create a super strong adhesive for building planes, but instead he created a semi permanent adhesive that was reactant to pressure called Acrylate Copolymer Microspheres. Although a now genius invention, this type of adhesive left Dr Silver and others dumbfounded when it came to its application. This continued until Art Fry entered the picture and collaborated with Dr Silver making the infamous Post-It Note[4].

Through our research we were able to locate a published patent on the method of making microsphere adhesives. Though a very complex process we were able to decipher and highlight the key materials. The first is Carbopol 907. This is chemical used as a thickener or in other words a suspending agent{5}. Carbopol 907 is a polyacrilic acid. Polyacrylic acids are the popular name for synthetic high molecular weight polymers of acrylic acid. Acrylic acid can be produced naturally by algae[17]. It is only produced in four places in the US, BASF Corporation in Freeport, Texas, Hoechst Celanese in Clear Lake Texas, Rohm and Hass in Deer Park Texas and Union Carbide in Taft Louisiana[13]. The next compounds used in making this type of adhesive are the Alcohols, mainly Rhodasurf ON-8705. Rhodasurf ON-870 is an ethoxylated fatty alcohol . It has a non-ionic property and is used as an emulsifier or wetting agent[12]. Rhodasurf is synthesized from an alcohol based starting reagent (methanol) and treating it with potassium hydroxide and ethyalne oxide. Next the solution is pressurized with nitrogen and heated[14]. A chemical company called Solvay distributes Rhodasurf ON-870. Solvay has a large presence throughout the world and in the United States [7]. The next part of the adhesive is water. Nearly seventy percent total of the adhesive is comprised of water. Water is used mainly as a mixing agent with many of the main chemicals listed in this paper. Along with the other elements a small amount of mercury is used[5]. Mercury is found in deposits all over the world and is mainly obtained in the mineral cinnabar which is most prominent in Spain and Italy but also in the United States in California[6]. The last of the main elements added to create this adhesive is cellulose or plant matter. Cellulose is approximately twenty nine percent of the glue[5]. Cellulose is most commonly extracted from wood pulp, such as in the process in the previous paragraph, or from other plants such as cotton[1]. All these materials are heated, mixed and transformed through other processes such as emulsion or polymerization to ultimately create the perfect semi-permanent adhesive[5].

3-M products, in particular Post-It Notes, have a global reach. In order to get 3M’s products from place to place it takes a great deal of transportation and energy. As a group we decided to focus on the transportation from the 3M headquarters in St. Paul, Minnesota to Davis. 3M uses big rig trucks to hall their products back and forth. These trucks run on diesel fuel and it takes approximately one hundred and ninety gallons of diesel to go from St. Paul MI to Davis CA[3]. Diesel is a petroleum-based byproduct of crude oil[8]. Crude oil is a fossil fuel, meaning it was made naturally by the decay of animals and plants. Crude oil is most prevalent in the Middle East in countries such as Saudi Arabia and Iran[9].

Despite the plethora of raw materials that goes into the process of making and transporting a Post-It Note, little to none are used in the recycling process. A Post-It Note is either burned or trashed once used, this is due to the inability to separate the glue from the paper.

When attempting to research this product there were a number of obstacles when it came to the transparency of 3M. We were able to find a patent similar to Dr. Silver’s original but there may be variation between the two. When we attempted to contact the company in the hopes of finding more research on their paper manufacturing we were sent a reply as followed:

“While we strongly support education and wish to provide students with as much information as possible, the volume and detailed nature of the hundreds of requests we receive each month makes it impossible to specifically answer every question. To protect 3M's competitive information, we cannot discuss detailed marketing, manufacturing, distribution, laboratory or other 3M business practices. A great deal of information about good business practices is available in textbooks and general or industry focused business publications.”[10]

For this reason much of our research when it came to the paper processing had to be generalized. We were unable to locate a specific place where they obtained their materials, processed them and packaged them. Though we understand the reason for privacy, their response brought up larger questions about the overall transparency of large companies such as 3M. One of them became who has the right to knowledge of where consumer products are coming from? As the consumer you would think with every purchase you are entitled to know the materials put into it, the place where it came from and how it was made, somewhat like a food label for material products, but clearly this is not the case. This leads to a second question of why this information is being with held. We assume it’s due to potential competition, or losing ownership over an idea. Through our own research effort in this project we also now consider how surprising it is to find out how much goes into one little, disposable, Post-It Note and after learning this could the product become less desirable?

Despite the research limitations, understanding how many resources and materials go into the making of something as simple as a Post-It Note provides food for thought. There is a growing disconnect between people and the products used by them. There is a need for transparency in manufacturer’s and large company’s products, for without easy access to necessary information the public will never truly understand how many materials and how much energy and waste actually make up a product. Looking back through our research it is easy to see that the amount of materials going into a Post-It Note far outweigh the materials that are able to be reused or taken from a Post-It Note. For that reason Post-It Notes prove how such a small piece of material can be made up of much more than meets the eye. Due to the inequality between reusable resources and the amount of resources going into a Post-It note one can easily see that this is not a sustainable product.

Bibliography

1. Abdel-Rahman, Ahmed. "The Full Paper Making Process." The Full Paper Making Process. Pulp.com, 2013. Web. 04 Dec. 2014.

2."Chemical Pulp Production." Chemical Pulp Production. Metso, 2014. Web. 04 Dec. 2014.

3."Corporate Headquarters." Locations. 3M, n.d. Web. 26 Oct. 2014.

4.Hiskey, Daven. "Post-It Notes Were Invented By Accident." Today I Found Out RSS. Vacca Foeda Media, 2012. Web. 04 Dec. 2014.

5.Kaye, Howard B., Brian M. Vogler, and David Holbrook, K. Method of Making Microsphere Adhesive. Howard B. Kaye, David K. Holbrook, Brian M. Vogler, assignee. Patent US6201042 B1. 13 Mar. 2001. Print.

6.Lashier, Jonathan. "Search." Where Is Mercury Found in the World? PhysLink.com, 2014. Web. 05 Dec. 2014.

7."Location Finder." Solvay: Asking More from Chemistry. Solvay, 2014. Web. 4 Dec. 2014.

8.Majewski, W. Addy, and Hannu Jääskeläinen. "What Is Diesel Fuel." What Is Diesel Fuel. Ecopoint Inc. Revision, 2013. Web. 05 Dec. 2014.

9."OPEC Share of World Crude Oil Reserves." OPEC :. Organization of the Petroleum Exporting Countries, 2014. Web. 04 Dec. 2014.

10. "RE:Life Cycle of a Post It #USLN-9QXAYF-962737034343." Message to the author. 16 Nov. 2014. E-mail.

11.Reynolds, Laura. "Native Birch Trees." Home Guides. Demand Media, n.d. Web. 04 Dec. 2014.

12. "RHODASURF 870." Rhodia Group: Product Detail. Solvay, 2014. Web. 05 Dec. 2014.

13. USEPA. "Chemical Summary for Acrylic Acid." EPA. Environmental Protection Agency, Sept. 1994. Web. 04 Dec. 2014.

14.Wikipedia contributors. "Ethoxylation." Wikipedia, The Free Encyclopedia. Wikipedia, The Free Encyclopedia, 22 Aug. 2014. Web. 5 Dec. 2014.

15.Wikipedia contributors. "Fir." Wikipedia, The Free Encyclopedia. Wikipedia, The Free Encyclopedia, 15 Oct. 2014. Web. 5 Dec. 2014.

16.Wikipedia contributors. "Kraft process." Wikipedia, The Free Encyclopedia. Wikipedia, The Free Encyclopedia, 3 Sep. 2014. Web. 5 Dec. 2014.

17.Wikipedia contributors. "Polyacrylic acid." Wikipedia, The Free Encyclopedia. Wikipedia, The Free Encyclopedia, 28 Nov. 2014. Web. 5 Dec. 2014.

18.Wikipedia contributors. "Sodium hydroxide." Wikipedia, The Free Encyclopedia. Wikipedia, The Free Encyclopedia, 1 Dec. 2014. Web. 5 Dec. 2014.

19.Wikipedia contributors. "Sodium sulfide." Wikipedia, The Free Encyclopedia. Wikipedia, The Free Encyclopedia, 19 Nov. 2014. Web. 5 Dec. 2014.

20.Wikipedia contributors. "Spruce." Wikipedia, The Free Encyclopedia. Wikipedia, The Free Encyclopedia, 5 Dec. 2014. Web. 5 Dec. 2014.

21.Wikipedia contributors. "Tartrazine." Wikipedia, The Free Encyclopedia. Wikipedia, The Free Encyclopedia, 19 Oct. 2014. Web. 5 Dec. 2014.

Alex Kong

Cogdell

DES 40 (Section 1)

12/09/14

The Energy Unseen

Some stick them on top of their dashboards to remind them of upcoming events. Others find them helpful to use as bookmarks to mark off where they were last reading or to make notes of major themes and characters. Still others find them great for making artwork. No matter what people use them for, however, most will agree that Post-it® Notes have become a necessity for everyone. From its accidental beginnings at 3M1, Post-it® Notes have now stamped their place in the product placement world. These “sticky but not so sticky” notes amazing have a deceptively simple design: an adhesive that seems to last for just the right amount of time, coupled with 100-200 square cuts of paper that come in all sorts of colors, branded with 3M and packaged in conventional boxes2. Embodied in each little bundle of Post-it® Notes, however, is a unique process that involved complicated chemical compounds, scientists working behind closed doors getting these compounds to mix in just the right amounts, and a confidential means of obtaining the materials needed to create the paper and the colors they bear. This process is almost completely off limits to the average human being: 3M will not disclose information relating to the making of these notes. However 3M tries to justify this confidentiality, 3M shows that they are guilty of hiding certain dark secrets that go into the making of their product (in this case Post-it® Notes), including the shear amount of energy that goes into the making of it, to achieve profit.

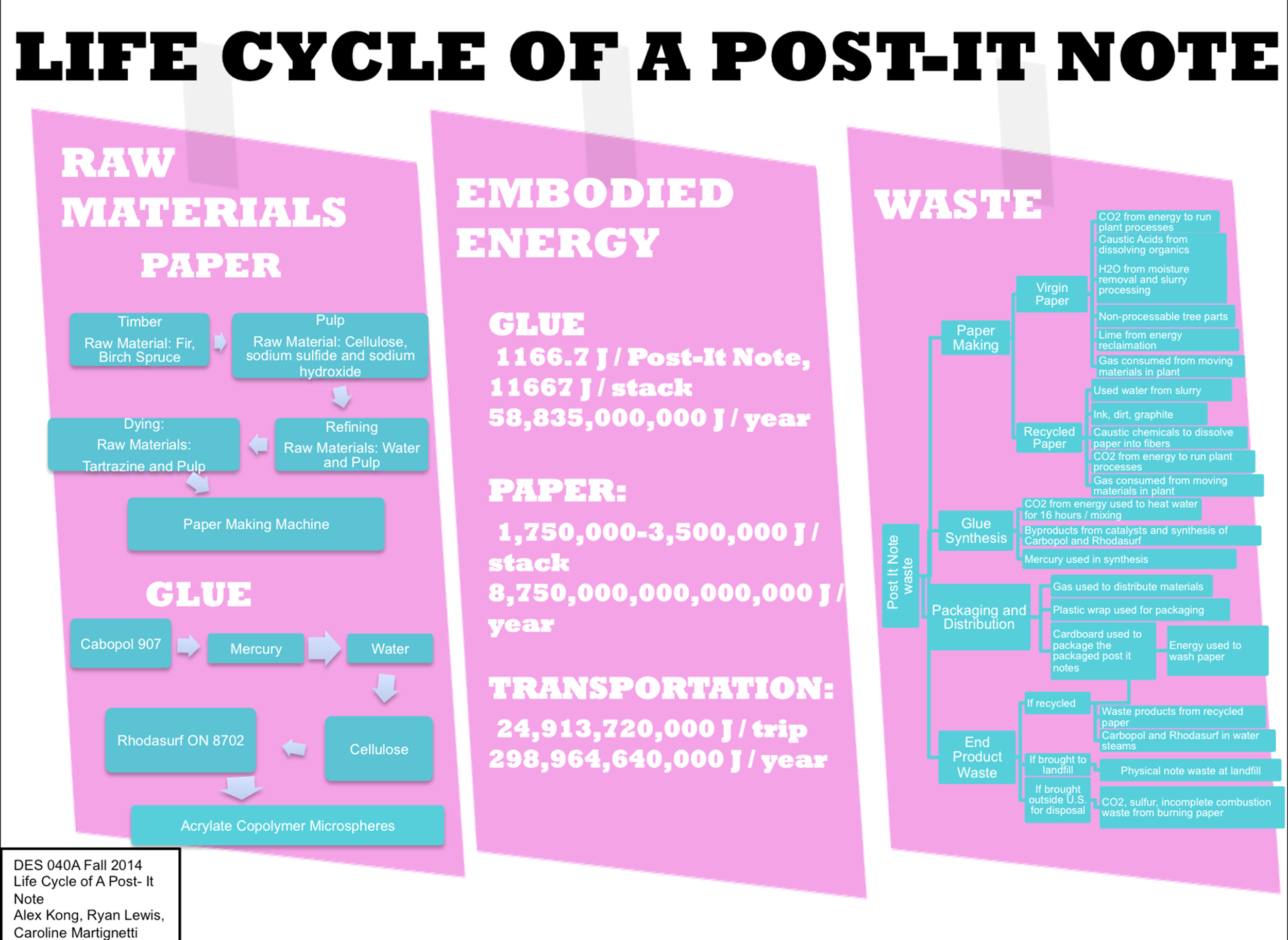

The confidential journey of a stack of Post-it® Notes begins at a factory in Cottage Grove, Minnesota3, not far from 3M’s actual headquarters. Scientists at 3M begin the process by obtaining the necessary ingredients to make the famous adhesive glue, also known as microspheres. Although 3M does not disclose any information regarding the adhesive glue, a patent that contains a common process used to make this adhesive glue can be found online, and because 3M is credited with inventing the microsphere, an assumption can be made that 3M’s process is exactly or almost exactly the same as outlined in the patent. In a nutshell, the making of the adhesive glue first involves the creation of sticky polymer spheres from Rhodasurf ON-870, ethylene oxide, benzoyl peroxide, and 2-ethyl hexyl acrylate using processes such as vacuums and heating for 16 hours. Then, by phase separation, the addition of more water, and the addition of a thickening agent (sodium carboxyl methyl cellulose slurry), the final adhesive is made4. Tedious calculations reveal the process to use up 1166.7 J per Post-it® Note. Assuming a normal pad of 100 Post-it® Notes, this amounts to 11667 J in total for one stack, which is equivalent to leaving a standard light bulb on for 583 seconds, or more than nine and a half minutes. And if we assume 50 billion Post-it® notes are produced each year5, this amounts to about 58,835,000,000,000 joules, or leaving 29,417,500,000,000 light bulbs on for a minute each. A coal-powered plant would need to be running for more than 32 days at maximum capacity to produce this amount of energy.6 This is not including the energy it takes to power the machines assisting in the process of making the adhesive glue. However, because 3M has disguised this process very well in a difficult-to-find and a difficult-to-read patent, the company does not have to worry about being accused of acting like a massive power plant every year. Firstly, the patent is almost impossible to find on the Internet. Secondly, the patent is extremely wordy, listing over 8 different variations and making it confusing to anyone reading it. Thirdly, the patent makes use of several chemistry terms and complicated compounds that the common reader will not understand, without going into any great detail over what the compounds are used in. And lastly, the patent is written very vaguely (ex. it does not say how much adhesive glue can be made out of this). Most people trying to find this exact process will not, and the ones that do will almost certainly not be able to decipher it. So despite the presence of a patent regarding the making of microspheres, 3M nevertheless still wins its first battle of hiding information from its users

After the adhesive glue is made, the glue then needs to be applied onto the paper. 3M does not document just exactly what goes into the paper it uses to make their Post-It® Notes, so we will assume part of this paper making process must result from the conversion of tree wood to a pulp, which then can be turned into paper via water extraction. The entire process takes on average 25-50 MJ (25,000,000-50,000,000 joules) per kilogram, including the energy of the machinery used to convert the pulp into usable paper7. A popular online shopping website lists the weight of a standard size of Post-it® Notes to be 2.4 ounces8, which if converted equals about 0.07 kilograms. Nevertheless, that is still 1,750,000-3,500,000 joules that goes into just the paper making of the Post-it® Notes. Assuming best case (lowest amount of joules used), that is equivalent to leaving 87,500 standard light bulbs on for a minute each. If we account for the 50 billion post-it notes 3M makes a year, then that brings total energy usage to 8,750,000,000,000,000 J. A coal-plant needs to run at full capacity for more than 4,861 days, or more than 13 years, to match this6. As with the adhesive glue, 3M also surreptitiously hides the shear amount of energy it takes to create its paper. Unlike with the microsphere patent, where 3M had to work to make it unreadable to the general public, here 3M simply releases an official statement saying it cannot specify what materials go into the making of its paper, nor can it tell us the machinery used and the energy it takes to power the process9. By releasing this statement, 3M is telling people that people are not entitled to know how much energy is put into not just their own paper making process, but any paper making process in general. Unfortunately, an official statement from a respected company is enough to get most people to give up in doing any further research on the matter. With that, 3M harnesses massive amounts of energy in its paper making process without the public knowing about it.

After the Post-it® Note stack has had the glue applied on it, it is now ready to be shipped to a local office supply store. From its factory in Cottage Grove, we will assume the final destination is the local Office Max Store in Davis on 2107 Cowell Blvd10. The calculated distance between the Cottage Grove factory and the Davis Office Max is 1916.44 miles11. Since much material is transported using big rig in the United States, we will assume transport is done by big rig, and over the route the distance was calculated with. The best MPG a big rig can achieve is 10 MPG12, meaning a big rig would need to use up about 191.644 gallons of diesel fuel. The energy content of a gallon of gasoline is about 130,000,000 J13, so burning 191.644 gallons of this will amount to 24,913,720,000 J of energy expanded for the whole journey. Assuming this journey is made once a month, this amounts to 298,964,640,000 J per year. This is a statistic 3M has a harder time of hiding, at least in terms of the size of the number. With its adhesive glue and paper making process, 3M could easily claim confidentiality. However, the public is well aware of the amount of energy that is used each year by motor vehicles. 3M cannot explicitly hide this from the public. However, they do not try and attempt to fix the problem of over-energy consumption on their big rigs. By utilizing big rigs for transporting the Post-it® Notes to its respective location, 3M can certainly be accused for its large energy usage in transport, but not for being the only one with this problem. Since 3M makes itself part of a larger problem, it is less likely to be specifically targeted for its energy consumption related to transportation. 3M also benefits from its relatively moderate size compared to other large corporations. Thus, the 298,964,640,000 J per year on transportation evaporates into the air as the public debates over how to control excessive transportation energy usage in general, but not specifically at 3M.

When all is said and done, 3M uses a total of 8,809,133,964,640,000 J in its adhesive note making process, paper making, and transportation of their beloved Post-it® Notes. Some may say that there is no real use in knowing the amount of energy 3M uses in its process in the first place. And, indeed, the number 8,809,133,964,640,000 J is quite daunting to both look at and pronounce. The issue here, however, is not so much the size or the quantity of the number. It is the fact that this number is unseen by the majority thanks to some clever business moves by 3M to hide the actual amount of energy that they use through the entire Post-it® Note making process. If 3M were only one company, the problem is more manageable. The main problem our society faces is several other companies like 3M, several much larger in size, also use strategic business moves to hide their enormously large energy consumption every year. By doing so, the public begins to focus more on the product and less on the energy that goes into it. While it can be argued that there is a greater awareness about the dangers relating to high-energy consumption, it can also be argued that this awareness is curbed by these company’s sly business strategies, such as claiming confidentiality, creating hard-to-read patents, or simply hiding under the problem rather than fixing it. And awareness does not necessarily translate into productive action, as evidenced by the fact that there are still large, energy-guzzling corporations running business as usual. If our society wants to change the problem relating to excessive energy consumption, the problem first needs to be addressed by people in the company willing to make changes in their production processes, or at least be willing to be more open and honest. Unfortunately, in a society where profit always comes first, the chances of this happening are not likely.

Endnotes

1. Under “Here’s How It All Began” in the article “History Timeline: Post-it® Notes”

2. Part of the “Self-Adhesive Note” article, created by Made How, see section “The Manufacturing Process”

3. 3M’s Cottage Grove Website homepage, “Welcome to 3M Cottage Grove, Minnesota”

4. A patent found under Google patents, “Method of making microsphere adhesive”, look specifically under “Description of Preferred Embodiment”

5. See second paragraph of “The ‘hallelujah moment’ behind the invention of the Post-it note”

6. Under Eastern Connecticut University’s section “Plant Efficiency”

7. Low-Tech Magazine’s “How much energy does it take (on average) to produce 1 kilogram of the following materials”, section for paper (from standing timber)

8. A listing on Amazon.com for Post-it® Notes, see “Product Information”

9. Email from the 3M factory, dated November 16, 2014

10. It is under Office Depot/Office Max “Find a Store”, zip code 95616, the first location

11. Distance Calculator, a service provided by GlobeFeed.com, provides driving distance between the two locations

12. Gizmodo.com, under article “Peterbilt’s New ‘Super Truck’ Gets 10 MPG”

13. Under section “Energy Content of All Fuels (in Joules), ocean.washington.edu

Bibliography

· 3M. Re: Life Cycle of A Post it #USLN-9QXAYF-962737034343. Message to

Caroline Martignetti. 16 Nov. 2014. E-mail.

· Batroot, Vickie. "Welcome to 3M Cottage Grove, Minnesota." 3M

Cottage Grove, Minnesota. 3M, n.d. Web. 06 Nov. 2014.

· Coal-Burning Electric Power Plant. N.p.: Eastern Connecticut State University, n.d.

PDF.

· "Distance between Cottage Grove, MN, United States and 2107 Cowell Boulevard,

Davis, CA, United States, (US)." Distance Calculator. GlobeFeed, n.d. Web. 08 Nov. 2014.

· Doyle, Daryl J. "Adhesives." Chemistry Encyclopedia. Chemistry Explained, n.d.

Web. 08 Dec. 2014.

· Energy in Natural Processes and Human Consumption - Some Numbers. N.p.:

University of Washington, n.d. PDF.

· Find a Store. Office Depot, n.d. Web. 23 Nov. 2014.

· Glass, Nick. "The 'hallelujah Moment' behind the Invention of the Post-it Note."

CNN. Cable News Network, 04 Apr. 2013. Web. 02 Dec. 2014.

· "History Timeline Post-it® Note Notes." Post-it® Brand. 3M, 04 Apr. 2013. Web.

06 Nov. 2014.

· Howard, Haye B. "Method of Making Microsphere Adhesive." Patents. Google, 13

Mar. 2001. Web. 06 Nov. 2014.

· "How Much Energy Does It Take (on Average) to Produce 1 Kilogram of the

following Materials?" Low-Tech Magazine, n.d. Web. 02 Dec. 2014.

· Post-It Notes. Amazon. N.p., n.d. Web. 03 Dec. 2014.

· Scott, Brenda, and Bronwyn Harris. "What Is a Polymer Adhesive?" WiseGeek.

Conjecture, 21 Nov. 2014. Web. 26 Nov. 2014.

· "Self-Adhesive Note." How Products Are Made: Volume 2. Made How, n.d. Web. 05

Nov. 2014.

· Tarantola, Andrew. "Peterbilt's New "Super Truck" Gets 10 MPG-Double the

National Big Rig Average." Gizmodo, 03 Mar. 2013. Web. 07 Nov. 2014.

Ryan Lewis

998108098

DES 40 12/8/2014

Post It Note Waste

Created on accident by Dr. Spence Silver while working to find a stronger adhesive while working for 3M, the Post It Note is a simple product composed of a small slip of paper with an adhesive strip. Despite its simplicity, the Post It Note has gained international attention making it one of the most popular office products today, netting 3M nearly one billion dollars annually [1]. The Post It Note, utilizing its utility, simplicity, and affordability has netted a permanent spot into offices and homes around the world. However, no product, not even one as simple as the Post It Note, exists in such a massive scale without having an equally large manufacturing and disposal industry behind it. The Post It Note as a product generates a significant amount of waste in both its manufacturing and end disposal as with any other product.

To correctly analyze the waste created by a Post It Note, one must first recognize the steps of its creation and manufacture. The Post It Note is simple; it only consists of a small paper square with a strip of adhesive across its top. This simplicity can be deceiving however, the processes behind creating both adhesives and paper are industries within their own rights. Paper for Post It Notes can be generated mainly in two ways, either from a freshly cut tree or from recycled paper. Freshly cut trees are first transported to a paper making facility using a helicopter and truck. After this, the wood is cut into small pieces with an industrial sized wood chipper and then moved into a pressure cooker. This process separates the paper into wood fibers and lignin. After an energy reclamation process, the wood fibers and lignin are washed and treated with bleach, then moved into a paper machine refiner, where the wood fibers and lignin are transformed into wood pulp. This wood pulp is then dried three times and pulled tight, forming the familiar paper we use today. During the third drying step, dyes and other chemicals would be added to give Post It Notes the color of the end users choice. The paper is then cut into pieces suitable for Post It Notes [2].

Another way for 3M to get the paper for a Post It Note is through utilizing recycled paper. With recycled paper, used paper is first placed into a pulper which blends the paper in a solution in order to separate out the paper fibers. Once the paper has been separated out, screens and other separation processes take out the ink, clay, dirt, and other unwanted material on the used paper. Once the used fiber has been cleaned, it is then dried and either used on its own or with virgin pulp to create a whole sheet of paper. It is important to note that this paper is downgraded; recycled paper becomes less useable after each recycling. Once the recycled paper is made, it is then too cut to size for a Post It Note [3].

The glue strip itself also has an interesting processing mechanic. Though the large scale manufacturing process of the glue is kept secret from the public by 3M [4], Sharp’s patent for the glue strip details a procedure for making the glue. The first step of the synthesis is to take water, then mix in Carbopol 907 (an alcohol derivative) and make the solution ph neutral. Rhodasurf ON-870 (another alcohol derivative) is then added along with an activator. The Carbopol and Rohdasurf make the solution sticky. After this, the solution is then polymerized and kept heated at 70 deg C for 16 hours. The heated solution is the added to a solution of microspheres; the spheres make the adhesive sticky but also removable. After adding cellulose (found in plants, trees, etc) as a thickening agent, the solution is ready to be placed on a stick note. Though at 3M this synthesis has been turned into a full blown manufacturing process, the waste stream of this process is derivative from that of the synthesis and can therefore be analyzed. The last step in making the Post It Note is the distribution and final steps of manufacturing, this likely takes place at a centralized 3M facility. Though 3M keeps their full process a secret, there is more than likely a facility that takes the small cut paper strips, applies the glue to the paper strip, and then packages the Post It Notes in plastic and distributes the Post It Notes worldwide.

A common misconception for many consumers is that the waste generated by a product is simply what goes into a landfill or what gets recycled at the end of the product’s life cycle. In reality, the majority of waste for many products is mainly generated from manufacturing; the end product is but a part of the whole. As detailed previously, the first step in making a Post It Note is the paper milling process. The virgin paper manufacturing process first creates waste in the form of carbon dioxide from powering a portion of the paper plant. The amount of carbon dioxide generation for just powering the mill is significant; in China one paper mill outputs 636,229 tons of CO2/year given the power source of the plant is coal [5]. In addition to the CO2, there are other waste products associated with energy generation based on power source. These other waste products very greatly from source to source, many mining operations for non-renewable energies create sulfides and other toxic wastes while renewable energy sources also must take into consideration wastes created in the manufacture of their infrastructure. In paper plants, the other portion of the plant that is not powered by an outside source is powered by the paper plant itself. Wood fibers and lignin after being separated out are placed into an evaporator, dried, treated with lime, burned and then added back into the product steam [2]. This creates a lot of waste, but also makes the most out of the wood delivered. The waste created from this process includes acids from the causticizer, particulates from the lime kiln (This can pose a threat to nearby steams and other water sources due to limestones effect on the pH of water), sulfides and other incomplete combustion materials from the wood chips. Other than powering the paper plant however, the most concerning waste that comes from a paper plant are chlorine compounds and dioxins from the bleaching process of the wood pulp [6]. However, chlorine compounds and dioxins are extremely dangerous waste products and were replaced in the 1990’s with totally or near totally free chlorine alternatives, though ~25% of the waste still contains chlorine compounds [7]. In addition, transporting the finished paper to a packaging facility and trees from the logging site to a paper processing plant would also create some waste in the form of carbon dioxide used.

The second option to obtain the paper for a Post It Notes is with recycled paper. Recycled paper is looked favorably upon because it prevents paper from going into a landfill and extends its shelf life. However, recycling the paper in itself also generates some waste. A significant amount of carbon dioxide and labor go into transferring waste to a recycling facility, powering the facility, and then taking the paper from the separation facility to a reclamation facility [8]. The comparative waste products for recycled paper versus virgin paper are however a much nicer prospect. With recycled paper the majority of the waste simply comes from the water used to re-slurry the wood fibers and the ink and other particulates that are on the paper are flushed out with the water. The paper in the recycling process does not need be re-chlorinated, accounting for most of the hazardous waste. The “inked” water is likely sent to a water reclamation facility where the particulate matter is easily removed.

Making the glue for the Post It Note also accounts for manufacturing waste. However, the full extent of this process is not officially documented for a large scale operation. Though lacking official documentation, the waste streams of the process can still be inferred. The process involves Rhodasurf and Carbopol, both of which are organic alcohol derivatives. This would involve all of the waste from dealing with these organic materials and then transporting them to the facility where the glue is made. The process also involves a step using mercury; unless a different process has been invented the mercury from the synthesis is most likely discarded as toxic waste. In the synthesis water also is heated to 70 deg C for 16 hours. Water has a high specific heat (it takes a lot of energy to heat up water as opposed to other materials) so the energy required to heat the water likely generates some CO2. Lastly, the process uses a lot more water than the resulting glue volume, so water is either recycled or discarded as waste in the glue facility.

Lastly, and likely the most familiar to the end user of the product is the physical waste produced at the end of the Post It Note life cycle. A portion of this waste is from the plastic wrapping the Post It Note comes in. This plastic is either recycled (for brevity, the waste stream of plastic recycling will be omitted) or thrown away in a landfill. Other than the plastic, larger packets of Post It Notes come in cardboard packages which more or less end up recycled or placed into a landfill akin to the plastic. All of the packaging is usually kept to a minimum, end users can even purchase an environmentally friendly Post It Note packaging from the 3M site to cut down on waste [9]. The Post It Note itself can end up in three places, either recycled into more paper, in a local landfill or shipped overseas to be dealt with there. The recycling of Post It Notes has dwindled however, as the demand for recycled paper lessens as electronic devices become increasingly popular. The Post It Note is usually on the chopping block for paper recycling facilities because though the glue is water soluble the Post It Note must be washed to be recycled. This combined with its small size and reports of issues from water treatment facilities about the difficulty of treating the glue from the Post It Note have resulted in few recycling plants accepting the Post It Note as worthwhile. Instead, the Post It Notes is usually thrown away in a landfill, where it takes up land. If the Post It Note does not end up in a landfill however, it can be shipped overseas to be, at best, recycled elsewhere or, at worst, combusted. Combustion of the Post It Note for energy would result in sulfur, CO2, and incomplete combustion waste products [10].

In conclusion, the Post It Notes is a relatively friendly waste wise product. Though there is a lot of CO2 involved in transportation and energy usage, the Post It Note is waste friendly in comparison to many products out there. Transportation costs and energy costs for facilities are requirements for just about any product. Probably the most concerning waste generated by the Post It Note is chlorine derivatives from the paper making process, however as mentioned these have been mitigated with non-chlorine waste products. Additionally concerning is the mercury that is potentially used in creating the adhesive, but a new process not involving mercury could have very well been invented and implemented by 3M. Recycled paper can be switched in for the virgin paper used to make the Post It Note, and the packaging for the product is kept at a minimum. Probably the greatest life cycle failure of the Post It Note is that it is no longer very actively recycled. Should the demand for recycled paper arise again however, the Post It Note is fully recyclable. All in all, the Post It Note has a deceivingly complex manufacturing process but minimizes waste output during and at the end of its life cycle.

Works Cited

[4] 3M, Debbie 3M Stationery and Office Supplies Division. "Subject: Re: Life Cycle of A Post It #USLN-9QXAYF-962737034343." 16 Nov. 2014. E-mail.

[7] Canada Environmental Protection Act. N.p., 17 Dec. 2007. Web. 06 Dec. 2014. <http://www.hc-sc.gc.ca/ewh-semt/pubs/contaminants/psl1-lsp1/pulp_mill_effluents_pate_blanchie/index-eng.php>.

[2]"International Comitte Paper Process PDF." (n.d.): n. pag. International Paper Process. International Paper. Web. 6 Dec. 2014. <https://www.internationalpaper.com/documents/EN/Sustainability/PaperProcess.pdf>.

[1] Inventive Genius. Alexandria, VA: Time-Life, 1991. 73. Print.

[5] Kong, Lingbo, Lynn Price, Ali Hasanbeigi, Huanbin Liu, and Jigeng Li. "Potential for Reducing Paper Mill Energy Use and Carbon Dioxide Emissions through Plant-wide Energy Audits: A Case Study in China." Applied Energy 102 (2013): 1334-342. Web. 6 Dec. 2014.

[10] "Life-Cycle Studies: Post-it Notes." Worldwatch Institute. N.p., n.d. Web. 06 Dec. 2014. <http://www.worldwatch.org/node/6387>.

[9] "Packaging." 3M US :. N.p., n.d. Web. 06 Dec. 2014. <http://solutions.3m.com/wps/portal/3M/en_US/3M-Sustainability/Global/ProductInnovation/Packaging/>.

[3] "Paper Making and Recycling." EPA. Environmental Protection Agency, n.d. Web. 07 Dec. 2014. <http://www.epa.gov/osw/conserve/materials/paper/basics/papermaking.htm>.

[8] "The Paper Recycling Process." The Paper Recycling Process. N.p., n.d. Web. 06 Dec. 2014. <http://www.paperonline.org/environment/paper-recycling/the-paper-recycling-process>.

[6] "Toward Sustainable Chemistry." Science 291.5501 (2001): 48-49. Web. 6 Dec. 2014.

Attached Email Transcript [4]

From: office@mmm.com

Date: November 16, 2014 at 11:38:18 PM PST

To: caroline.martignetti@gmail.com

Subject: Re: Life Cycle of A Post it #USLN-9QXAYF-962737034343

Dear Caroline,

Thank you for contacting 3M, the innovation company, Stationery and Office Supplies Division.

We appreciate your interest in information on our Post-It(R) Products. If you haven't already done so, the first place you should check is the 3M website at http://www.3m.com/about3M/index.jhtml. That area of the website will give you information about 3M's culture, products, technologies, innovation, marketing, community programs and history.

While we strongly support education and wish to provide students with as much information as possible, the volume and detailed nature of the hundreds of requests we receive each month makes it impossible to specifically answer every question. To protect 3M's competitive information, we can not discuss detailed marketing, manufacturing, distribution, laboratory or other 3M business practices. A great deal of information about good business practices is available in textbooks and general or industry focused business publications.

There also is a lot of information about 3M published through resources that are generally available in libraries and bookstores around the world.

We have attached the following information for you:

The Post-It® Notes Story

Inventor of Post-It® Notes

Post-It® Note Fun Facts

We wish we could have assisted you further with you request and hope that you find the information we were able to provided you helpful.

If you need any further assistance, please feel free to contact us directly at 1-800-395-1223. We are available Monday through Friday from 8:00 - 4:30 CT.

Regards,

Debbie

3M Stationery and Office Supplies Division

3M Center, Bldg. 225-3S-06