Design Life-Cycle

assess.design.(don't)consume

Emma Hasco

DES 40A

Professor Cogdell

6 December 2018

Spray Paint Can Materials

Created in 1949 by Edward Seymour, spray paint, also known as aerosol paint, is used as an alternative to painting a surface with a brush and paint. This product contains paint inside a pressurized container. When the paint mixed with a propellant (pressurized gas or compressed air) is released, a mist like substance comes out. This substance is the paint, which is easily used for many different surfaces. The packaging is most commonly made from tin plated steel or aluminum. A valve is used to seal the can and control how the paint is dispensed. The cap on the top of the valve controls the shape of the spray. The body of the spray paint can is where the mix of liquid paint concentrate and the propellant are stored. The dip tube is at the bottom of the valve and carries the paint from the bottom of the can body, out through the cap.

The easy and clean look of spray paint makes it a common product in many households and workshops. Spray paint can be used for many things such as to provide a smoother finish, to paint tricky areas that might be hard to reach with a brush, to touch up on a car’s paint job, exterior and interior use, and many more. Some may use spray paint to make graffiti as a form of creative expression. The standard sizes include 4.5 oz., 6 oz., 12 oz. and 16 oz., and a 12 ounce can of spray paint can cover about 18 to 20 square feet. As we can see from the sizes, this product is lightweight, compact, and simple, making it easy to move around and bring along for a project.

Although this product is less time consuming compared to other methods, and allows for a professional looking paint job, some of the materials used in a spray paint can are harmful to the earth and humans. Are the materials used to make spray paint sustainable or unsustainable? Although the tinplate or aluminum material used for the can body is eco-friendly, the negative environmental impacts and toxic VOCs found in the paint itself result in the product being unsustainable.

Production of Lacquer Tinplate and Aluminum

The two most common materials used for the body of the spray paint can are either lacquered tinplate or aluminum, which both have eco-friendly life cycles. Lacquered tinplate is made from a slim sheet of tin-coated steel, and is most commonly used to make many different types of containers. Aluminum is the third most plentiful element in the earth's crust. The use of either of these materials in the production of a spray paint can is one positive in the life cycle of the spray paint can.

Tinplate is a common material for containers because of the low weight and high strength properties. Tinplate is a thin steel sheet that’s then coated with tin. Iron, the fourth most common element in Earth's crust, and carbon combine to make steel. The production of steel is made from both recycled and raw materials. One source states, “production and recycling are not separate stages in the life of steel it is important to notice that they are one and the same process. Any steel object has about 60% recycled content within it. Stainless steel therefore isn’t consumed but is rather sustained” (bsstainless.com). The assessment above is important to consider when thinking about the environmental effect of materials used to make aerosol cans. Aluminum is another material that is commonly used for the body of a spray paint can. Aluminum is one of the most environmentally friendly metals on the planet. An analysis of the recycling process states that for every minute, over 100,000 aluminum cans are recycled in the United States (wastecare.com). More cans being recycled leads to more available resources at a lower cost. If recycled properly, aluminum will last forever, never wearing out. Furthermore, research has shown that the cost to recycle a can is less than manufacturing a new can (wastecare.com).

When recycled properly, the life cycle of both of these materials is eco-friendly, and therefore sustainable. But although the use of tinplate and aluminum in spray paint cans is a positive for the environment, other materials that go into the spray paint have environmental impacts that consumers should be aware of.

Materials and the Environment

Spray paint may make a job faster and easier, but the environmental impacts that come from the materials used in spray paint are important to know when looking into the sustainability of the product. Spray paint is a widely used product among many different demographics, such as professional painters, graffiti artists, and every day people such as myself. The easy to use product makes it a common household and workplace item. Because of the popularity of this product a look into the life-cycle, specifically the environmental effects, of the materials in spray paint is important in order to know what people are putting into the air and surface of the earth.

There are hundreds of spray paint brands, with Krylon (a division of Sherwin-Williams), for example, being the largest supplier of spray paints in the world. I looked into the website of Krylon to find any information on the negative effects of spray paint. The site provides information about how to safely use their product, such as following the directions on the back of their cans, as well as safety tips on using the product indoors. One obvious tip shared by Krylon states “make sure to keep away from heat, sparks and open flame. Don’t smoke. Extinguish all flames, pilot lights and heaters. Turn off stoves, electric tools and appliances, and any other sources of ignition” (Krylon). To no surprise, the website fails to mention the environmental effects and issues regarding the use of spray paint. Through research, I was able to find ways in which the materials used in spray paint effect the environment. The Connecticut Department of Environment Protection looks into the environment dangers of spray painting and states:

Paint spraying has potential air and water quality impacts. Most paints contain volatile organic compounds (VOCs) which evaporate quickly and are ignitable. Many paints are also toxic. When released to the atmosphere, VOCs combine with combustion emissions of nitrogen oxides (NOx) to form ground level ozone; which damages the lungs and degrades many materials. Marine paint may be toxic to aquatic and marine life. (ct.gov)

An environmental effect of the sprayed paint is clear is this statement, and causes concern for not only humans, but marine life as well. I will go in depth on the presence of the volatile organic compounds later in this paper, nevertheless it is clear that the materials used in the paint are harmful and should be taken very seriously for anyone using the product.

All spray paint cans contain some plastic elements in the production. The dip tube is used to transport the paint from one end at the bottom of the can, to the other end attached to the valve. The plastic cap is pressed down in order for the paint to be sprayed, while the lid is used to cover the cap in order to prevent dripping and messes. The dip tube, cap, and lid are all made from HDPE (high density polyethylene). The “afterlife” of these plastic items in the spray paint life cycle is very important. The topic of recycling plastic is an ever-present discussion in today’s world. Although the plastic items on the spray paint can may be small, they have a large impact depending on how they are recycled. Because the cap is attached to the can, rather than separate like the lid or a cap of a plastic water bottle, the recycling of this item becomes complicated. In many instances during the disposal process of a can (assuming the lid was properly recycled), the cap will fall off, and may be found in landfills, on the ground, or in the ocean. Plastic lids and caps such as the ones on a spray paint can do not biodegrade and therefore take hundreds of years to decompose. Because of the small size, the cap can travel very far in the ocean, and endanger marine life.

Being aware of the negative environmental impacts caused by the materials used to make spray paint is important when finding solutions to make this earth more environmentally stable. Although the plastic materials used to create the spray paint can are small, these non-biodegradable materials nevertheless play a role in the waste and pollution issue facing our nation today. Taking a more in-depth look into the production will allow for a greater understanding of the materials used, such as the dense material used to make the can itself.

Production and Hazard of VOC’s

Most paint used in spray paint contains volatile organic compounds, or “VOC” for short, which are carbon-based compounds, emitted as gases, and have chemicals that could have both short and long-term effects on health. Anything with a fragrant smell has VOCs released into the air. Volatile organic compounds can come from both natural and synthetic sources, but through research, a common theme relating to this matter would be the danger of inhaling VOCs. In relation to spray paint, the VOCs found in the paint prove to be toxic. Therefore, the use of products containing volatile organic compounds, specifically indoors, can expose beings to very high pollutant levels, which can cause many health issues.

Many are familiar with the “new paint smell” that seems to linger after the job is done. This smell is due to the volatile organic compounds in the paint. The VOCs easily evaporate into the air, and can live in the air after use for an extended period of time. One may assume that after the paint job is done, the fumes will go away, and the air in the house will be safe to breathe in. This is not the case, as VOCs may continue to seep into the air for several years after painting. Because of this extended exposure, the health concerns are great.

When furthering this research and looking into the specific VOCs that go into spray paint, Acetone, Xylene, and Toluene are three of the most common and all have short-term side effects. These side effects include itchy, watery, or burning eyes, skin irritations or rashes, nose and throat irritation, nausea, headache, dizziness, and fatigue. Organs effected by the exposure of these VOCs include eyes, skin, respiratory systems, central nervous system, and gastrointestinal tract, blood, liver and kidneys.

Longer exposure or exposure to these VOCs by someone suffering with health issues could cause more extreme health issues. Some VOCs are suspected carcinogens, as recorded by the U.S. Environmental Protection Agency. One study, the first worldwide European Community Respiratory Health Survey, looked into the relationship between asthma and the emissions from newly painted indoor surfaces. The findings were alarming to those effected by asthma. The chemical emissions from indoor paint, or spray paint, is indeed connected to asthma and the survey concluded that the VOCs found in indoor paints do cause inflammatory reactions in the airways. More long-term effects of spray paint include, “occupational asthma, allergic contact dermatitis, lung cancer, ‘painter’s syndrome’ which is prolonged inhalation of paints and solvents resulting in brain damage, damage to the reproductive system and kidney or liver damage” (Comcare).

As one can see, the danger of the VOCs in spray paint raises the question of whether or not this product is sustainable. Knowing about the toxicity of the paint may lead many people to decide to use a “greener” alternative to painting. Although “organic” is used in the name, in the case of spray paint, these compounds are far from safe. The reason organic is used in the name is because they contain carbon, but many specific VOCs contain toxic elements that make the VOC harmful. The extended presence of VOCs even after a job is complete, as well as the short and long-term side effects lead spray paint to be unsustainable.

Conclusion

Quite often, a paint job is something many people are looking to complete. In many cases, people go to spray paint for this task. Although spray paint is a cheap, fast, and professional looking alternative to the more time consuming and expensive roll on or paintbrush painting, the question of whether or not this product is sustainable must be asked. One sustainable aspect of a spray paint can is the tinplate or aluminum used for the body. These materials are extremely eco-friendly due to their abundance and recycling process. In today’s world, the environment is encouraged to be on the forefront of everyone’s mind. In the recent years, creating a “greener” environment has been one of the most important missions of almost all nations. Both the use and afterlife of spray paint materials cause worry when it comes to the environment. An awareness of what you are breathing into your lungs may seem obvious, but it actuality it is uncommon for many spray paint users to be aware of what is in the material they are spraying. One may hear the term “VOCs” mention as a byproduct of the paint they are spraying, but without a further knowledge through research as to it what the term means, the dangerous effects of inhaling toxic VOCs is unknown. I have found that the toxic volatile organic compounds found in the paint lead to short and long-term health effects. The materials-focused research I have conducted on the life cycle of the spray paint product has allowed me to understand the a more in-depth analysis of the product. The tinplate and aluminum used in the body is sustainable, but because of the negative environmental impact, and danger of the toxic VOCs, the product of spray paint, as a whole, is not sustainable.

Bibliography

“ALUMINUM CANS RECYCLING Consideration of Balers / Recycling Equipment for Aluminum.” Cell Phone Recycling, www.wastecare.com/Articles/Aluminum_Cans_Recycling.htm.

Comcare. “Spray Painting.” Comcare, 2014, www.comcare.gov.au/Forms_and_Publications/publications/services/fact_sheets/fact_sheets/spray_painting/spray_painting2.

Connecticut Clean Marina Guidebook. Connecticut Dept. of Environmental Protection, Office of Long Island Sound Programs, 2007.

“Krylon® Spray Paint Facts.” Krylon®: Make It Yours®, www.krylon.com/how-to/safety/krylon-spray-paint-facts/.

“Manufacturing of Synthetic Aerosol Spray Paint Blue | Raw Materials | Ingredients | ARTICLES | SOLVER CHEM - Production Process Productions Manufacturing Process Manufacture Formulations Formulation Formula Formulas Reciple Raw Materials Ngredients.” SOLVER CHEM. Web. 29 Oct. 2018. <www.solverchem.com/articles/aerosol-spray-formulations-articles/manufacturing-of-synthetic-aerosol-spray-paint-blue-raw-materials-ingredients/details>.

Peretz, Daniel H. Aerosols: Chemistry, Environmental Impact and Health Effects. New York: Nova Science Publishers, 2009. Print.

Sentryair. “The Hazards of Spray Paint Fumes.” Sentry Air Systems, Inc., 20 Oct. 2015. Web. 29 Oct. 2018. <www.sentryair.com/blog/ductless-spray-booth/the-hazards-of-spray-paint-fumes/>.

“Spray Paint.” How Products Are Made. Advameg, Inc., Web. 29 Oct. 2018. <http://www.madehow.com/Volume-7/Spray-Paint.html>.

“US20040035871A1 - Aluminum Aerosol Can and Aluminum Bottle and Method of Manufacture.” Google Patents, Google. Web. 29 Oct. 2018. <patents.google.com/patent/US20040035871A1/en>.

“Volatile Organic Compounds' Impact on Indoor Air Quality.” EPA, Environmental Protection Agency, 6 Nov. 2017, www.epa.gov/indoor-air-quality-iaq/volatile-organic-compounds-impact-indoor-air-quality.

“What Are Non-VOC Paints, and Why Does It Matter? (Part 1).” Wellbuilt Company, 2017, www.wellbuiltco.com/blog/19122017.

“What Are VOCs in Paint, and Is More or Less of Them Better?” Product Reviews and Ratings - Consumer Reports, 2008, www.consumerreports.org/cro/news/2008/04/what-are-vocs-in-paint-and-is-more-or-less-of-them-better/index.htm.

Weide, Robert, et al. “Spray Paint: How an Object Became an Object and a Subculture.” Nye.edu. Web. 29 Oct. 2018. <www.nyu.edu/classes/bkg/objectsblog/archives/spray.pdf>.

Wieslander, G., et al. “Asthma and the Indoor Environment: the Significance of Emission of Formaldehyde and Volatile Organic Compounds from Newly Painted Indoor Surfaces.” International Archives of Occupational and Environmental Health, vol. 69, no. 2, 1996, pp. 115–124., doi:10.1007/s004200050125.

Chad Park

DES 040A

Professor Cogdell

30 November 2018

Aerosol Can - Embodied Energy

At one point or another, most of us have used an aerosol can. With a push of a button, we can easily apply paint, polish, and lubricant—and many household chemicals such as deodorants and detergents come in aerosol cans. However, despite their ubiquity, many of us are unaware of how they are made and how much energy is required to make them. Modern aerosol containers have four main parts—a shell, a valve, a dip tube that extends from the valve to the liquid product, and a liquefied-gas propellant (The Editors of Encyclopaedia Britannica). The shell is most commonly made of lacquered tinplate—steel or iron coated with tin. Aluminium is commonly used too, but it is generally reserved for more expensive products (“Variable spray nozzle for product sprayer”). Nearly all aerosol cans contain a flammable or poisonous solvent as the propellant, which makes them a hazardous waste (“Aerosol Cans”). The amount of energy expended in the process by which aerosol cans are made can be inferred by studies of the manufacture of the cans’ most common material components—namely, lacquered tinplate—and taking into account the fact that the aerosol can is a hazardous waste means that knowing how to properly dispose of them at the end of their life cycle is imperative to ensuring personal safety as well as public health.

In order to understand how energy plays into the life cycle of aerosol cans, or for that matter any product or material, one must be familiar with the manufacturing process. As previously mentioned, steel is the prevailing material used to make aerosol cans. The process by which steel aerosol cans are made has been delineated by the Metal Packaging Manufacturers Association, a leader in the UK metal packaging industry. To start, a steel strip arrives at the can manufacturing plant in large coils. The steel strip is then cut into large rectangular sheets, at which point lacquer is applied to the side of the sheets that will become the internal surfaces of the cans and print is applied to decorate the external surface. Lacquer is a liquid made of shellac dissolved in alcohol, or of synthetic substances, that dries to form a hard protective coating for wood, metal, etc. Simply put, lacquer is often taken as synonymous with varnish. After the sheets are lacquered and printed, they are dried in an oven. The sheets are subsequently cut into small sheets, one for each can body. Each small sheet is rolled into a cylinder, the edges of which are welded by squeezing them together while an electric current passes through. This heats up the metal enough for a secure joint to be made. Afterward, the inner surface of the weld is sprayed with lacquer and cured by blowing heated air onto the external surface of the cans. Thereafter each can passes through a necking-flanging machine, which reduces (“necks in”) the diameter of the can wall and flanges the top and bottom of the can wall outward to accept ends. A cone top is fitted to the top of the can to accept the valve, and a domed end is fitted to the bottom to withstand the internal pressure. At the final stage of manufacture, each can passes through a pressure tester, which automatically rejects any cans with pinholes or fractures. After that, the finished can bodies are transferred to a warehouse to be palletized and then sent off to a filling plant. (“How a steel Aerosol can is made”). Knowing how aerosol cans are made is useful, but we have to go back and familiarize ourselves with the raw materials acquisition phase in order to accurately quantify the embodied energy of aerosol cans.

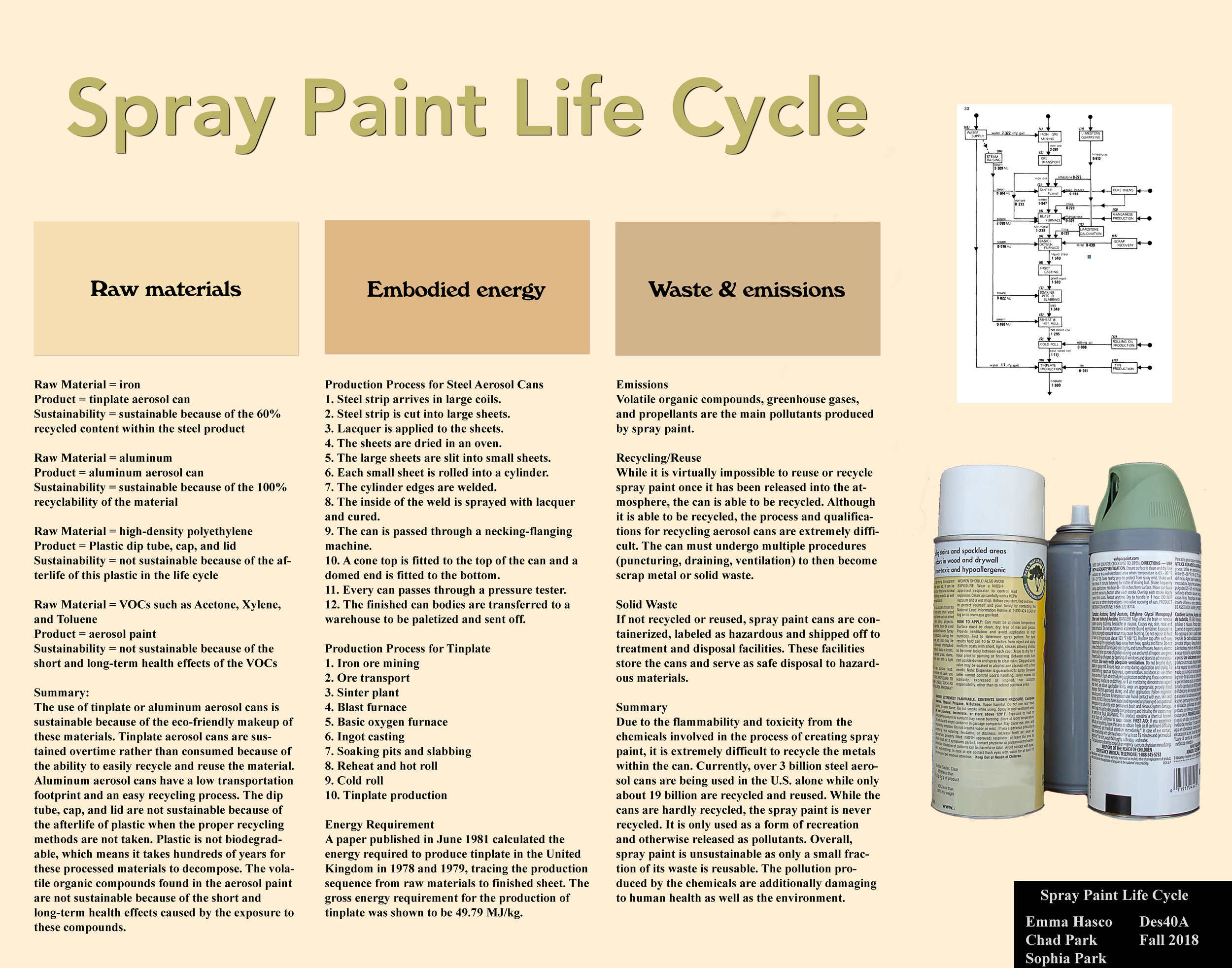

Energy inputs to the development of lacquered tinplate, a fillip to the manufacture of aerosol cans, have been measured by means of scientific studies. One study in particular, detailed in a paper published in June of 1981, calculates the energy required to produce tinplate in the United Kingdom in 1978 and 1979, providing a clear understanding of how energy plays into the life cycle of aerosol cans. The paper, written by Ian Boustead and G. F. Hancock, traces the production of tinplate from raw materials in the ground to finished sheet. Boustead and Hancock say tinplate is generally manufactured from hot rolled coil with hot rolled coil being produced from iron ore. They clarify, however, that all data from the study are representative of practices at three locations in the UK and several routes are possible for the conversion of iron ore into tinplate, but they concentrate on operations used by the UK industry. They present a flow diagram for the production of tinplate sheet from iron ore, which begins with iron ore mining and advances to iron ore transport. According to Boustead and Hancock, the principal sources of ore for the UK industry are Canada and Norway among six other countries. They assume an average sea transport distance of 2300 miles and take account of the transport energy. They add that a small amount of indigenous ore is available to the UK industry, but they ignore it in their calculations. The aforementioned flow diagram, which is included at the end of this paper, contains eighteen operations in total. Taking all the energy requirements for every operation into account, Boustead and Hancock conclude that the gross energy requirement for the production of one kilogram of tinplate is 49.79 megajoules. Of this, some 53% arises in the production of steel ingot from ore at iron works and 28% arises during the conversion of this ingot to tinplate sheet. The remaining energy is used in the provision of raw materials and services to steel works and rolling mills. Moreover, approximately 25% of the gross energy requirement also arises from the production and consumption of electricity. A further approximately 15% is due to the production and use of oil fuels while the remaining 60% arises from the provision of other fuels such as coal (Boustead, Ian, and G. F. Hancock). Now that we know how aerosol cans are made and how much energy is used by the processing of its principal raw material, we should delve into the later stages of the life cycle of aerosol cans which concern recycling and waste management in order to learn how to effectively assuage the environmental threat that aerosol cans may pose.

As previously mentioned, almost all aerosol cans contain a flammable or poisonous solvent as the propellant, making them a hazardous waste. Therefore, knowing how to properly dispose of them at the end of their life cycle is vital. Most aerosol cans are made of steel, which is easily recyclable. Aerosol cans that are completely empty may often be recycled at the curb; however, full or partially full cans cannot be placed at the curb because they are under pressure and may pose a threat to solid waste workers and others (“Aerosol and Paint Containers”). When packed under pressure, they can explode under certain conditions (Rethink Recycling). It is good to be in the habit of completely using up the contents of aerosol cans so that no propellant remains inside them when it comes time to dispose of them (“Aerosol and Paint Containers”). If an aerosol can contains any product, recycling programs will not accept it, even if it contains safe product such as whipped cream (“How to Recycle Aerosol Cans”). In fact, it is illegal in most states to dispose of a full or partially full can which is considered household hazardous waste by putting it in a landfill or incinerator (Bennett, Sophia). If one is unable to do this safely, he or she should dispose of the aerosol can at their local household hazardous waste (HHW) collection site or at a locally sponsored HHW event (“Aerosol and Paint Containers”). While aerosols do far less ecological damage than they did prior to the widespread ban on chlorofluorocarbons in the United States in 1978, the propellant inside many cans are flammable and still threaten the environment (“Can I Recycle Aerosol Cans?”). As innocuous as they may seem, aerosol cans could be dangerous if mishandled or improperly disposed of. With a good grasp of the life cycle of aerosol cans, one is able to gain a deeper awareness of the nature of industrial manufacture and how to mitigate its unintentionally negative consequences.

By being aware of how aerosol cans are made and the processes associated with their production, one is able to ascertain their embodied energy. Not only this, but by understanding each stage of their life cycle, one could reduce the harm that they may inflict on people and the planet.

Bibliography

“Aerosol and Paint Containers.” CalRecycle. California Department of Resources Recycling and Recovery, 23 Oct. 2018. Web. 4 Dec. 2018. <https://www.calrecycle.ca.gov/metals/paintcans>.

“Aerosol Cans.” Environmental Health & Safety. University of Florida, Web. 4 Dec. 2018. <http://www.ehs.ufl.edu/programs/chemrad_waste/maint_waste/aerosol-cans/>.

“Aerosol Cans.” Rethink Recycling. Rethink Recycling, Web. 4 Dec. 2018. <https://www.rethinkrecycling.com/residents/materials-name/aerosol-cans>.

Bennett, Sophia. “How to Recycle Aerosol Cans.” RecycleNation. ERI, Inc., 29 Apr. 2014. Web. 4 Dec. 2018. <https://recyclenation.com/2014/04/recycle-aerosol-cans/>.

Boustead, Ian, and G. F. Hancock. “Energy and Raw Materials Requirements for Tinplate Production in the U.K.” Resources and Conservation 06.01 (1981): 29-45. ScienceDirect. Web. 4 Dec. 2018. <https://www.sciencedirect.com/science/article/pii/0166309781900055?via%3Dihub>.

“Can I Recycle Aerosol Cans?” Recyclebank. Recycle Rewards, Inc., 21 June 2016. Web. 4 Dec. 2018. <https://livegreen.recyclebank.com/column/because-you-asked/can-i-recycle-aerosol-cans>.

The Editors of Encyclopaedia Britannica. “Aerosol container.” Encyclopædia Britannica. Encyclopædia Britannica, Inc., 18 June 2013. Web. 4 Dec. 2018. <https://www.britannica.com/technology/aerosol-container>.

“How a steel Aerosol can is made.” Metal Packaging Manufacturers Association. Web. 4 Dec. 2018. <http://www.mpma.org.uk/pages/data/aerosol.pdf>.

“How to Recycle Aerosol Cans.” Earth911. Earth911, Web. 4 Dec. 2018. <https://earth911.com/recycling-guide/how-to-recycle-aerosol-cans/>.

“Variable spray nozzle for product sprayer.” Google Patents. Google, Web. 4 Dec. 2018. <https://patents.google.com/patent/US5941462A/en>.

Sophia, Park

DES 40A

Professor Cogdell

14 November 2018

Spray Paint: Waste

Introduction

What is regarded as a fun pastime can oftentimes produce unintended ramifications,

such is the case with spray paint. Spray paint, most commonly associated with graffiti art, is made up of a variety of chemicals and metals. It contains multiple volatile organic compounds, which are liquids that are translated in the form of a gas (Sentryair). These gases produce vibrant colors. Many artists have chosen to use spray paint as a means to create large projects centered around voicing one’s opinions and bringing beauty through artwork. However despite the recreational and technological benefits, it is essential to recognize the damaging waste produced in spray paint as well as strides that have been and can be taken towards the re-use and reduction of waste. This paper will explore both the ways in which spray paint is recycled and the aftermath of its disposal.

Historically, the multi-functionality of the spray paint can has enabled it to be used as a form of expression, an industrial asset, and a defense against disease. The can itself was patented in 1927 by Erik Rotheim. It was originally used as a way to fight off malaria by spraying insecticides which then developed to a manufacturing industry asset and was lastly adopted by street artists (Ferguson). Although the can itself is in part made up of recycled steel and metals, the chemical contaminants of spray paint often render the metal useless. Spray paint, otherwise known as aerosols, emit chlorofluorocarbons (CFCs) and are highly flammable, making them extremely difficult to properly dispose of and recycle (Paul). Thus because of its hazardous properties, extremely damaging waste is added to the environment including, but not limited to, chlorofluorocarbons, nitrous oxide, acetone, xylene, toluene and hydrocarbons (Nelson). Spray paint and its cans are oftentimes viewed of as a form of innovation as the cans are created airtight with a on/off valve mechanism (“Facts on Aerosols...”). Additionally they represent creativity and expression that is seen in artwork today.

The sheer amount of chemicals and materials used in the production process of spray paint as well as its versatility makes it an important item to evaluate the waste processes of. Spray paint, including the can, is used for a variety of purposes. As mentioned above, historically it has been used for art, contamination, pesticides, and cleaning purposes. The on/off valve mechanism of spray paint, its tamper-proof technology, as well as its adaptability has enabled it to be used in a variety of occupations (“Facts on Aerosols”). Additionally, spray paint being comprised of both toxic and non-toxic substances renders it an important product to evaluate as the two materials uniquely influence the reusability of the other. While the metals in the can are non-toxic, the chemicals used to produce the paint are detrimental to the environment and deem the metal hazardous. This paper analyzes the two comprising parts of spray paint both separately as well as their impact on the other.

How it Works

The process that leads up the release of spray paint and the operations the materials undergo are significant indicators of the waste that is produced. The spray paint can contains a nozzle, paint basin, and air compressor. These three pieces are imperative to safely contain and release the toxins within the can. The high pressure from the tightly sealed can mixes the paint with the compressed air stream. The pressure from the air stream is estimated to range between 300 to 7,500 pounds per square inch (“Spray Painting”). In this process when spray paint is released through the nozzle atomization takes place: when liquid is broken up into particles to create a fine mist/gas. The mist is then released into the air and onto the canvas directly in front. The particles are widespread as they penetrate and pollute the air.

Spray Paint Components and Breakdowns

Starting with the inside, the spray paint itself is made up of toxic chemicals that make it difficult to safely release into the environment. Spray paints are primarily made up of five parts: solvent, binder, pigment, additives, and propellants (“Pollution Prevention”...). These five parts are responsible for maintaining the consistency, cohesiveness, and color. Within these five parts are extremely hazardous chemicals such as volatile organic compounds, known as VOCS, and greenhouse gases. These chemicals are not only damaging to human health, but also to the environment as a whole. Some of the main greenhouse gases, VOCs, and general chemicals used in the ingredients are: acetone, xylene, toluene, CO2, propane, butane liquified petroleum gas, methyl ethyl ketone, magnesium silicate, carbon black, and ethylbenzene. Unlike most other products, spray paint is unique because its waste comes in the form of both gas and liquid. When released into the air, spray paint takes on the form of a gas releasing the chemicals that are listed above, its makeup. If the chemicals released into the air come in close contact with humans it can result in symptoms such as irritation, nausea, pain, dermatitis, liver damage, and kidney damage. Thus it is harmful to human health and should be safely managed.

The tiny particles suspended in gas that make up aerosols, or spray paints, are also said to damage the ozone layer and alter rainfall. According to NASA, “Aerosols are thought to suppress precipitation because the particles decrease the size of water droplets in clouds” (Nelson). This poses a serious environmental problem as all life is dependent upon the consistent flow of water that comes from rain. The pollution released into the air from spray paint must be thus questioned as it interferes and inhibits the natural cycles that take place in nature.

Although the metallic can in itself is non toxic, the aerosols it contains has resulted in greater steps needed to recycle and dispose of the spray paint can. The primary materials put into the production of the can are steel, lacer tinplate and aluminum. All three metals under different circumstances would be considered recyclable materials, however due to the propellants created under pressure and the hazardous materials contained within the paint, the can is considered hazardous. While the can was considered pure metal before production, it now carries over some of the properties of the spray paint including, but not limited to, its toxicity and flammability. It is because of these traits that make it hard to dispose of the can unless it is empty or treated.

There are a few ways to treat and dispose of spray paint cans. A common practice is to containerize and label the spray paint cans as hazardous and send them to a treatment, storage, and disposal facility (“Aerosol Cans”). The cans sent to the storage facilities are not considered empty and may still contain hazardous waste. If this is the case, they must be punctured and drained with ventilation. If it is not disposed of through the storage facility, aerosol cans must follow the guidelines and regulations of the U.S. Environmental Protection Agency’s Resource Conservation and Recovery Act. This act specifies that an empty can is only considered empty if its mean residual remaining is less than 3%. The EPA’s Resource Conservation and Recovery Act also requires that cans be punctured and drained with ventilation. As seen above, it is possible to recycle aerosol cans however due to its toxicity it is extremely difficult and rare as only about 25% of the metals used in aerosol cans are recycled on average (“Facts on Aerosols”). Scrap metal from the can may be recycled if the spray paint inside is completely used up and if the can is properly punctured. Once the cans are sent off to be recycled they are separated magnetically and either crushed or baled for steel mills (“Facts on Aerosols”). During this process the combustible materials are used to generate electricity (“Facts on Aerosols”).

Conclusion

Spray paint, being a popular product, has oftentimes been overlooked in terms of its waste. While many view spray paint solely as a popular pastime, they do not recognize the chemicals released by each spray and the hazardous can that is left behind. Around three billion aerosol cans are produced and used within the United States on a yearly basis. However of the three billion only around nineteen billion are recycled and/or reused (“Did You Know?”). The practices involved in the creation of this product as well as the unsustainable materials that go into spray paint must be reformed. The enormous amount of energy and materials put into the production of spray paint is not justifiable by its results and instead has led to greater damage to the environment and life. There are few ways to recycle the can and the volatile organic compounds released are many. Additionally, the waste is difficult to take care of and manage. The U.S. government has to some extent recognized the toxicity produced from spray paint by enforcing regulations that deal with proper disposal as well as production however, there is yet much room for improvement. Recognition is the first step towards progress while reduction and reform is what is currently needed. If reform were to occur within the spray paint industry many harmful emissions and air pollutants would be eliminated, resulting in a happier and healthier environment.

Overall, upon assessing the entire waste processes of spray paint, including the can, one may conclude that it is an environmental hazard that should be reduced. This pastime has been overall detrimental to the environment as well as people’s health. The chemicals involved in the process has not only damaged the can permanently, but also will remain in the atmosphere for a while. Spray paint is an item whose negative effects are often unseen, but extremely prevalent.

Bibliography

“Aerosol and Paint Containers.” CalRecycle, 23 October 2018, www.calrecycle.ca.gov/

metals/paintcans. Accessed 29 October 2018

“Aerosol Cans: Guide to Handling and Disposal for Businesses.” Wisconsin Department of

Natural Resources, May 2016, dnr.wi.gov/files/pdf/pubs/wa/wa1784.pdf. Accessed 29

October 2018.

“Did You Know? Aerosol Cans Are Recyclable.” Penn Waste, 5 March 2013,

http://www.pennwaste.com/waste-management-resources/blog/test-14/. Accessed 6

December 2018.

Doka, Gabor (2003) Life Cycle Inventories of Waste Treatment Services. ecoinvent report No.

13. Swiss Centre for Life Cycle Inventories, Dübendorf, 2003

“Facts on Aerosols & The Environment.” Steel Recycling Institute, 31 March 2011.

www.steelsustainability.org/~/media/FIles/SRI/EarthDay/Aerosol%20Facts.ashx.

Accessed 29 October 2018.

Ferguson, James. “The Spray Paint Can is Invented, 1949.” Financial Times, 14 November

2008, www.ft.com/content/6fa3b94e-b05a-11dd-a795-0000779fd18c. Accessed 20

November 2018.

Nelson, Jennifer. “What You Need to Know About Aerosol Sprays.” MMN, 3 May 2016,

www.mnn.com/lifestyle/responsible-living/stories/what-you-need-know-about- aerosol-sprays. Accessed 29 October 2018.

Paul, Haley. “The Aerosol Can Debate Continues.” Earth911, 13 July 2009,

Earth911.com/living-well-being/health/the-aerosol-can-debate-continues/. Accessed 29 October 2018.

“Pollution Prevention and Compliance Assistance for the Healthcare Industry: Paints.”

Healthcare Environmental Resource Center. 2015, www.hercenter.org/

facilitiesandgrounds/paints.php. Accessed 20 November 2018.

“Recycling Aerosol Cans.” Krylon, www.krylon.com/community/recycling-aerosol-

cans/. Accessed 20 November 2018.

“Reduce Aerosol Can Use and Waste.” Partners in Pollution Prevention, April 2012,

engineering.unl.edu/downloads/research/P3/p2PPGuidelines

Aerosol%20Cans%20Guideline%20final.pdf. Accessed 29 October 2018.

Sentryair. “The Hazards of Spray Paint Fumes.” Sentry Air Systems, 24 April 2013.

www.sentryair.com/blog/ductless-spray-booth/the-hazards-of-spray-paint-fumes/. Accessed 29 October 2018.

“Spray Paint Fumes.” Sentry Air Systems, www.sentryair.com/spray-paint-fumes. Accessed 29

October 2018.

Weide, Robert. “Spray Paint: How an Object Became an Object and a Subculture.” New York

University, nyu.edu/classes/bkg/objectsblog/archives/spray.pdf. Accessed 29 October 2018.

�ҕ7�ݽ�Vd