Design Life-Cycle

assess.design.(don't)consume

Image Sources:

https://www.polymershapes.com/product/abs/

https://www.amazon.com/TECKNET-Computer-Adjustable-6-Button-Ergonomic/dp/B08QZBY6Z2

Lizbeth B.O.

DES 40

Professor Cogdell

14 March 2023

Raw materials of a computer mouse life cycle paper

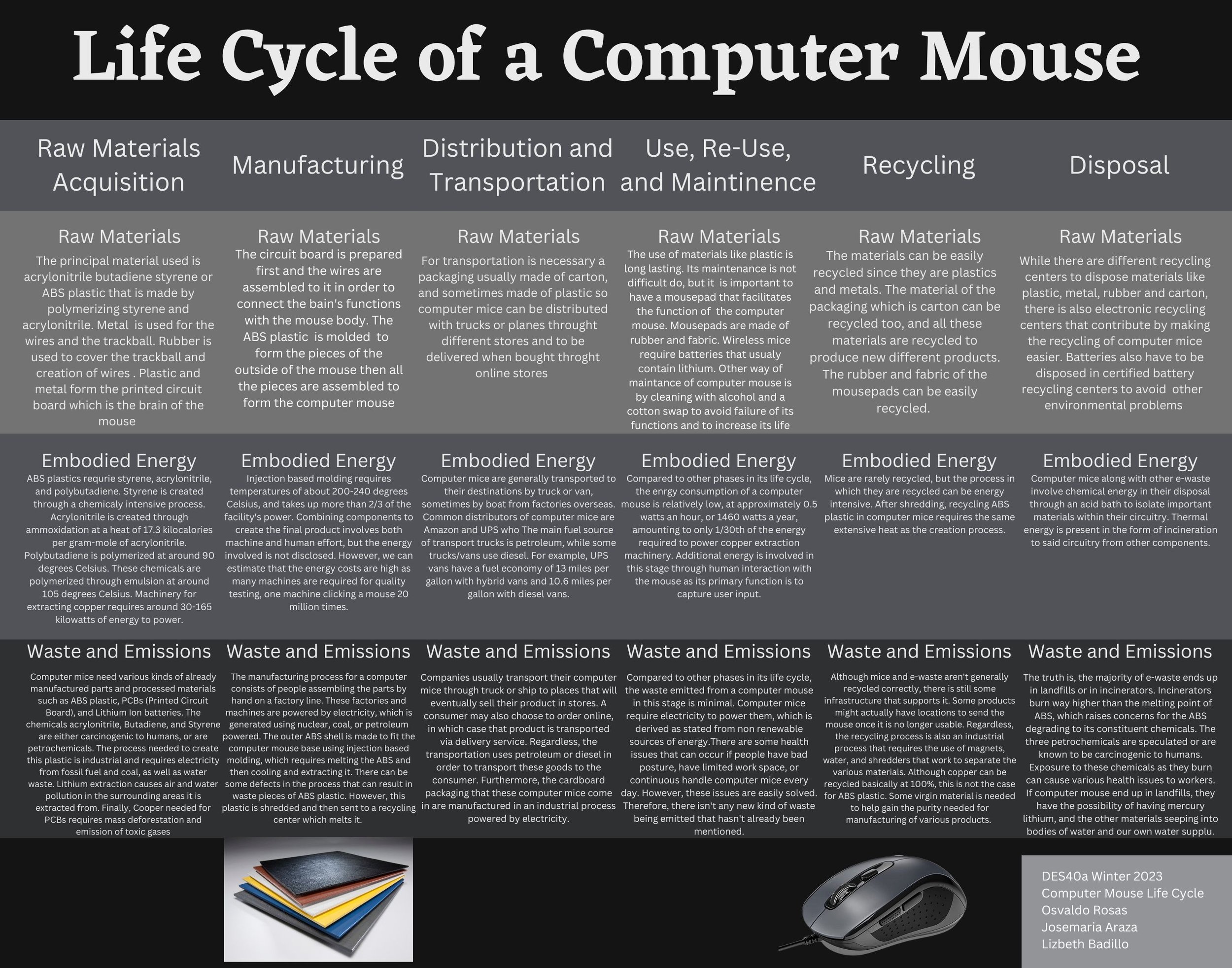

Nowadays a lot of people in order to perform different technological work utilize acomputer, but for this is important use of a computer mouse, since it helps to perform different tasks like selecting tools, copying and pasting words and texts, etcetera. Computer mice are part of different workspaces, they perform different functions, and they are helpful tools for technological work but the manufacturing of computer mice also affects the environment for which companies are trying to reduce their impact. The obtention of raw materials of a computer mouse is where it all starts for its process of manufacturing and it’s a fundamental step for the production of this technological tool. One object like this does not need a lot of materials to be manufactured but while almost all the materials that compound a computer mouse are easily recyclable most of its raw materials for its production do not come from recycled materials.

The computer mice are created by a specific process and they are compounded of materials such as plastic, metal, and rubber. These materials form a computer mouse but the material that most contributes to its production is plastic, more specifically acrylonitrile butadiene styrene or ABS plastic. The ABS plastic is created from three monomers which are acrylonitrile, butadiene, and styrene, and acrylonitrile provides chemical stability, and butadienecontributes strength, making this plastic a good material for a computer mouse in order to also be resistant (adreco plastics). The metal that the mouse has compounds the trackball which allows the computer mouse to move, and the trackball is usually covered with rubber, but also metal is used for the composition of the wires of a mouse (Olson), and a printed circuit board is also important in its composition since is the brain of a mouse, which is also created from plastic and metal, but these materials also contribute to an impact on the environment, especially ABS plastic which causes a huge smoke release when it is burned and which has a degradation span of 1000 years (Natarajan). The computer mouse needs the correct materials for its production but the finishing product could not be completed without its assembling, which leads to the manufacturing of a mouse.

The manufacturing of a computer mouse needs several steps, here is where all raw materials are assembled. The process begins with the circuit board that is prepared by a computer sequencer that puts the electrical components in order and the wires are attached to the circuit to connect its functions, leading to the assembly of the trackball, then the next step is the molding of plastic for the outside components of the mouse, and all these pieces are assembled together forming the computer mouse. After the assembly, quality control is made to corroborate that the mouse is doing its proper functions (How Products are Made article). The assembly in factories is usually made by machines, but a few mouses are assembled by people which reduces the use of machines and could help to decrease the carbon emissions of factories. There’s an alternative way for manufacturing of computer mice, which is biodegradable computer mice. This is expected by using PLA plastic instead of ABS plastic, for instance, PLA plastic is made by natural and sustainable sources such as cassava roots and corn starch (Ganeshan) which would reduce the carbon impact of computer mice in the environment. There are some companies thatuse alternative materials tomanufacture computer mice. This is an innovative idea to preserve the environment and one of those alternative ideas is recycled ocean plastic, which is the case of Microsoft which created a computer mouse for which 20% percent of its plastic is from recycled ocean plastic. Perhaps manufacturing is an important step of the process, it is important to transport and distribute the product.

The market provides the advantage of selling computer mice through direct stores and online stores, but before obtaining a computer mouse it has to be transported and distributed to the direct stores, and to homes if buying online. The computer mouse should not be transported by itself since it also includes the shield of packaging to preserve the quality and shape of the computer mouse. Usually, most computer mouses are packaged in a cardboard box or carton box that is made from paper and thin layers of plastic (Carton Council), and some computer mouses are packaged in plastic packages as well. Then they are transported and distributed in planes and trucks or even trains, which require fuel to be able to work. While the life cycle of computer mice needs a transportation phase to be distributed and utilized by people, they also need to be maintained to perform their work correctly and to have a long life.

The materials of computer mice might be long-lasting but it is necessary to provide them a good care to avoid premature failure during their life cycle since this would avoid extra waste of products when buying a new mouse. Commonly, computer mice are required to use mousepads which are usually made of rubber and fabric, in order to perform better usability since the mousepads allow for accurately measure the movement of the computer mouse and to avoid fractures when operating which helps to avoid deterioration of the computer mouse(Wikipedia). If a computer mouse is wireless it is necessary to use batteries so the mouse is able to perform its work, batteries which are made of steel, zinc, potassium, manganese,potassium, and graphite with a little bit of paper and plastic (Energizer), but also contain lithium. In other cases, a useful way to maintain a computer mouse is by cleaning it with alcohol and a cotton swap regularly to avoid technical problems (Mouse Maintenance article) and to preserve and increase its life. Besides maintenance and its corroboration to preserve the long-lasting life of a computer mouse, when the computer mouse stops functioning it should be disposed of correctly or it can be recycled to provide new products and help the environment.

Usually, the materials that compound a computer mouse are easily recycled. The plastic that compounds the mouse’s skin or even its packaging is completely recyclable, and plastic is utilized in several productions of products used by humans. Metal that forms the trackball and wires can be recycled in the proper recycling center. Rubber that covers the trackball and that forms the mousepad is easily recycled to make new rubber products and even transformed into fuel. The packaging compounded of the carton should be completely recycled without problem since carton is one of the materials usually most recycled. Batteries that wireless computer mice use can be recycled as well, although they contain lithium there are authorized disposal or recycling centers for batteries. Recycling centers for electronics are also accessible to people, these centers facilitate the disposal of computer mice, and more than 2400 recycling centers are accessible to the people in California ( California Recycling Industry). If a computer mouse is compounded of materials that can be recycled therefore its production should be made of recycled products, and humans need to cooperate to complete this work by recycling. Recycled plastic should be completely incorporated into the manufacturing of computer mice to reduce carbon impact. For example companies like Logitech have implemented the idea of using recycled plastic for the manufacturing of their computer mice. This idea is implemented by substituting ABS plastic with PCR which is recycled plastic to reduce its carbon impact. Logitech’s idea has been increasingly applied that 65% of their computer mice and keyboards include PCR plastic in their manufacturing or production (Sherman). Logitech has also created the initiative of including carbon labels in its packaging. Being the first company to create this implementation hopes that they won’t be the only company to collaborate with this idea and that other companies would also corroborate (Logitech) and this would help to create conscience in the carbon impact of products and to increase the recycling of electronic products like computer mice.

Production of computer mice creates significant numbers of carbon emissions in the environment starting with its raw materials that take a long time to degrade. Manufacturing is a process that requires machine work of factories that clearly have a carbon impact. Distributing and transportation also require materials and fuels that affect the environment. Maintenance needs materials that produce an impact on the environment as well and the production of computer mice will probably increase which would cause their carbon impact to increase too, perhaps we should consider using sustainable and alternative ways to be incorporated into their manufacturing, and one of those ways is using recycled plastic which would create a difference to the planet, and biodegradable computer mouse should be implemented in the manufacturing of companies too since plastic compounded of cassava roots and corn starch would reduce carbon impact. In general, if a computer mouse materials can be easily recycled through certified recycling centers therefore the materials used for its manufacturing should be recycled materials so the life cycle of a computer mouse would be more sustainable, and would create less carbon impact on the planet.

Bibliography

“ABS Plastic Properties: Great Advantages of Acrylonitrile Butadiene Styrene.” Adreco Plastics,2 Nov. 2022, https://adrecoplastics.co.uk/abs-plastic-properties/.

“About Cartons.” Carton Council, 16 Nov. 2022, https://www.recyclecartons.ca/cartons-101/. “California's Recycling Industry.” Californians Against Waste,https://www.cawrecycles.org/californias-recycling-industry.

“Carbon Labeling and Measuring Carbon Impact of Products.” Logitech,https://www.logitech.com/en-us/sustainability/carbon-labeling-measuring.html.

“Computer Mouse.” How Products Are Made,http://www.madehow.com/Volume-5/Computer-Mouse.html.

“Computer Mouse: Manufacturing.” Prezi.com,https://prezi.com/krwaibcga3ix/computer-mouse-manufacturing/.

“Design, Manufacture and Sustainable Analysis of Biodegradable Computer Mouse Using SolidWorks and 3D Printer.” Materials Today: Proceedings, Elsevier, 15 July 2019, https://www.sciencedirect.com/science/article/pii/S2214785319312180.

“How Are Computer Mouses Made? .” Keyboard Kings, 27 Mar. 2022,https://keyboardkings.com/how-are-computer-mouses-made/.

“Meet Our New Mouse Made from Recycled Ocean Plastic.” Microsoft Accessories,https://www.microsoft.com/en/accessories/sustainability/ocean-plastic-mouse.

“Mouse Maintenance.” Tutorial, 10 Apr. 2019,https://www.vskills.in/certification/tutorial/mouse-maintenance/.

“Mousepad.” Wikipedia, Wikimedia Foundation, 9 Feb. 2023,https://en.wikipedia.org/wiki/Mousepad.

Natarajan, Ganeshan Gujilva, et al. “Sustainability Analysis on Polymers Using Life CycleAssessment Tool (OPENLCA).” AIP Publishing, AIP Publishing LLC AIP Publishing, 7 Dec. 2020, https://aip.scitation.org/doi/10.1063/5.0034820.

“Rubber Recycling Archives.” RecyclingInside, https://recyclinginside.com/rubber-recycling/.

Sherman, Lilli Manolis. “Logitech Scales-up Use of Recycled Plastic in Electronic Products.”Plastics Technology, Plastics Technology, 23 Feb. 2022, https://www.ptonline.com/news/logitech-scales-up-use-of-recycled-plastic-in-electronic-pro ducts.

“What Is inside a Battery?” Energizer, https://www.energizer.com/about-batteries/what-is-in-a-battery.

Josemaria Araza

DES40a A03

16 March 2023

Embodied Energy of a Computer Mouse

Computing is involved in many activities today. From working on schoolwork, playing games, typing up documents, computers and laptops are essential to many aspects of everyday life. Computer mice are important as well, allowing users to do these tasks with accuracy. They can be used to click submit for an assignment, draw pictures, play games, and provide precision to user input. For a computer mouse to transmit user input to another device such as a laptop, it must first be connected to that device (usually through a USB). The mouse is able to send signals through this connection. A mouse requires electrical energy to run: capturing and transmitting user input and movement. It may seem that electrical energy is the main energy source in the lifetime of a computer mouse, as that is the aspect of a mouse which is seen everyday. Although computer mice mainly utilize electrical energy while in use, the majority of the energy utilized in a computer mouse’s lifetime is chemical, thermal, and mechanical, coming from the refinement of raw materials such as copper and styrene as well as in the manufacturing process, putting components like casing and circuitry together in the final product, being far greater than the electrical energy used while the mouse is being used..

Computer mice are composed of multiple components such as a circuit board, a plastic casing, various buttons out of said casing, sensors, and sliders at the bottom. These components are made of various materials, the most important component being the thermoplastic material Acrylonitrile Butadiene Styrene (ABS) plastic. ABS plastic as a thermoplastic can be molded into many things such as mouse casings and LEGOs. Three polymers are necessary for the creation of ABS plastic:styrene, acrylonitrile, and polybutadiene (Rogers). Each material also involves various chemicals in their creation. Styrene is created through a chemically intensive process, with chemicals such as benzene with ethylene, and ethylbenzene. With so many chemicals involved the process is intensive and requires much energy to happen (Chevron Phillips). Acrylonitrile is created through the combination of even more chemicals through ammoxidation at a high temperature, with the heat of polymerization at 17.3 kilocalories per gram-mole of acrylonitrile (Ineos). These high temperatures can be surprising as acrylonitrile is a component of a component of the mouse. Polybutadiene is a rubber formed from polymerization of more chemicals in another chemically intensive process involving many molecular chains at around 90 degrees Celsius (194 degrees Fahrenheit) (AZO Materials). Again, the high temperatures of this chemical are surprising. Styrene and acrylonitrile are polymerized (chemically combined) with polybutadiene through a process called emulsion (Rogers). The emulsion process to create ABS plastics again requires much effort and energy, requiring a temperature of around 105 degrees Celsius (221 degrees Fahrenheit) in which it can be molded again in the manufacturing process (Rogers). The high temperatures in which each component and the plastic itself are created are indicative of the effort and energy required to make a single mouse.

In addition to its plastic casing, the most important part of a computer mouse is its circuitry and electronic components, located on a circuit board, allowing it to perform its various functions: track user input, register various button clicks, and to transmit that information to the device it is connected to. The circuit board, sometimes known as a PCB or a printed circuit board, is where most of the components of a mouse are placed such as its sensors and its scroll wheel (PCBWay). A typical PCB has copper as its main material, allowing it to transmit signals and data. Copper, coming from copper oxide and copper sulfide ore is mined and later processed into copper sheets called cathodes (Superfund Research Center). The effort it takes to mine copper varies on the site, taking large machines to do so. These machines take a large amount of power to run, some requiring 30-50 kilowatts, while others such as a transport truck for bringing the mined copper to processing plants requires 165 kilowatts of energy (Sarah). This is a large amount of energy for such a small, yet vital component of the mouse. Some computer mice also contain lithium batteries, which require the extraction of lithium, which again require the same processes as copper to mine. Additional fuel costs result from the location of these mining facilities, for example lithium mining occurs in Australia, which must then be shipped to China to become lithium batteries.

After its components such as the circuitry and plastics are made, computer mice are created within a manufacturing plant. Usually this is done with machinery, but sometimes, human effort is involved. The initial step in creating a computer mouse is creating the casing from the ABS plastic. This is done through a mold, ensuring that all mice from a plant are of a uniform shape. This process is called injection based molding, in which the ABS plastic is heated to temperatures at around 200-240 degrees Celsius (400-460 degrees Fahrenheit)(Rogers), at around 0.20-0.35 kilowatt hours per kilogram. In the facilities that process the plastic, molding accounts for about 66% of the facility's total energy (RMG). The lithium batteries that some mice contain are also energy consuming, with 12.5kgCO2 per kilogram of lithium per battery. Placing wiring, sensors, buttons, and the circuit board within the newly made casing can involve machinery or human effort (BPS Customs). The voltage/power of human/machine effort is not disclosed, but additional machines are required for quality control to ensure mice can flow smoothly along surfaces and are durable for long-term use, one such machine in a Logitech factory clicking a mouse 20 million times (Savage).

Computer mice are generally transported to their destinations by truck or van, sometimes by boat from factories overseas. Common distributors of computer mice shipping are companies or services like Amazon and UPS. The main fuel source of transport trucks is petroleum, while some trucks/vans use diesel. For example, UPS vans have a fuel economy of 13 miles per gallon with hybrid vans and 10.6 miles per gallon with diesel vans (Lammert & Walkowicz). This is again, far more energy intensive than the actual use of the mouse itself.

Compared to other phases in its life cycle, the energy consumption during the use of a computer mouse is relatively low compared to other phases within its life cycle. A mouse must be plugged into a device such as a laptop to track user input. Compared to the device it is plugged into, the energy consumption of a computer mouse is very low (EnergySage). The average power consumption of a desktop mouse is approximately 0.5 watts an hour (12). This is due to the fact that a mouse’s sensors do not capture extensive information, only binary information such as if a button is pressed or not, as well as how fast the mouse is going. Even gaming mice, which may contain extra buttons or RGB lights are not as electrically consuming as one might expect. The average person uses their computer/laptop around 8 hours a day, with a wattage of 0.5 W an hour, this amounts to 4 watts a day, or if the mouse is being used 365 days a year, about 1460 watts a year. This amount of energy is about 1/30th the amount of energy a copper extracting machine needs (Sarah). This excludes all the other processes in the making of a computer mouse such as the creation of ABS plastic and even the machinery to put it together. This is concerning as the amount of energy required to make a mouse far outweighs the energy in its use, meaning that much energy is used to spend little.

Another aspect in the use of a computer mouse which involves energy is effort from the consumer themselves. Without user input, a computer mouse has no other purpose. The user must make an effort to move the mouse, track where it is on their desk and on the screen, as well as click buttons on the mouse (usually only the left and right mouse buttons). The energy involved here varies depending on the user, but is similarly minimal compared to the energy used in the production of the mouse itself.

Computer mice are not recycled very often, but when they are, the plastics are shredded and put through the same heat extensive process as in creation (ERI). Effort is also being made to make less single-use mice and more reusable, recyclable materials by companies such as Logitech, involving more effort and energy in switching to these new materials (Logitech). Computer mice are disposed of similarly to other electronic devices in what is known as “e-waste.” Disposing of electronics is an intensive and sometimes dangerous process (EPA). For example, incineration is sometimes involved to isolate important components such as circuitry, other methods include chemical energy in the form of an acid bath to isolate important metals within the circuitry itself (TechReset).

The majority of energy involved in a computer mouse’s lifetime is not electrical, but rather a mix of chemical, thermal, and mechanical. It does not result from its use, which is what the consumer generally sees, but from the creation of the mouse and its individual parts.The high cost of creating a mouse far outscales the energy cost of operating it, something that companies such as Logitech are beginning to acknowledge and work on, but is still something surprising and something consumers must take into consideration when buying/replacing their computer mice.

Bibliography

Arroyos, Vicente et al. “A Tale of Two Mice: Sustainable Electronics Design and Prototyping.”

CHI: Conference on Human Factors in Computing Systems, 28 April 2022, pp 1-10. dl.acm.org/doi/10.1145/3491101.3519823#sec-ref. Accessed 9 February 2023.

Arshad, Faiza et al. “Life Cycle Assessment of Lithium-ion Batteries: A Critical Review.”

Science Direct. 17 January 2022. sciencedirect.com/science/article/pii/S092134492200012X . Accessed 9 February 2023.

AZO Materials “Polybutadiene - Properties, Applications, Processing, and Types of

Polybutadiene (BR)” AZO Materials, 23 October 2002. azom.com/article.aspx?ArticleID=1719. Accessed 16 March 2023.

BPS Customs. “How Keyboarda & Mice are Made - China Factory Tour!” BPS Customs. 10

April, 2019. youtube.com/watch?v=GdwkFLLdgYI&t=444s. Accessed 16 March 2023.

“Carbon Clarity - Understanding Carbon Impact.” Logitech,

logitech.com/en-us/sustainability/carbon-impact-methodology.html. Accessed 9 February 2023.

Edge, Charles. “The History of Plastics in Computing.” History of Computing, 5 July 2021.

thehistoryofcomputing.net/the-history-of-plastics-in-computing. Accessed 9 February 2023.

EnergySage “How Many Watts Does a Computer Use?” EnergySage.

news.energysage.com/how-many-watts-does-a-computer-use/. Accessed 16 March 2023.

EPA, “Cleaning Up Electronic Waste (E-Waste).” United States Environmental Protection

Agency. 15 November 2022. epa.gov/international-cooperation/cleaning-electronic-waste-e-waste. Accessed 16 March 2023.

ERI. “Environmental” Electronic Recycling and IT Disposal Services.

eridirect.com/sustainability/environmental/. Accessed 16 March 2023.

Evanson, Nick. “Anatomy of a Mouse” Techspot, 12 January 2021.

techspot.com/article/2181-anatomy-mouse/. Accessed 9 February 2023.

Fenlon, Wes. “The Making of a Mouse.” PCGamer, 30 June 2016.

pcgamer.com/the-making-of-a-mouse/. Accessed 9 February 2023.

Humphries, Matthew. “Logitech Is Adding a Carbon Impact Rating to Its Products.” PCMAG,

PCMag, 17 June 2020, pcmag.com/news/logitech-is-adding-a-carbon-impact-rating-to-its-products. Accessed 9 February 2023.

Ineos “Acrylonitrile Safe Storage and Handling Guide” Ineos.

ineos.com/globalassets/ineos-group/businesses/ineos-nitriles/she/acrylonitrile_brochure.pdf Accessed 16 March 2023.

Kamalakannan, R et al. “Sustainability Analysis on Polymers Using Life Cycle Assessment Tool

(OPENLCA).” AIP Conference Proceedings, 7 December 2020. aip.scitation.org/doi/10.1063/5.0034820. Accessed 9 February 2023.

Keyboard Kings “How are Computer Mouses Made?” Keyboard Kings.

keyboardkings.com/how-are-computer-mouses-made/. Accessed 9 February 2023.

Lammert, M & Walkowicz, K. “Thirty-Six Month Evaluation of UPS Diesel Hybrid-Electric

Delivery Vans.” National Renewable Energy Laboratory. March 2012. nrel.gov/docs/fy12osti/53503.pdf. Accessed 16 March 2023.

Logitech “FY22 Impact Report” Logitech.

logitech.com/content/dam/logitech/en/sustainability/pdf/resources/fy22-impact-report-portrait.pdf. Accessed 16 March 2023.

“Logitech G502 Lightspeed Wireless Gaming Mouse.” Amazon.

amazon.com/Logitech-Lightspeed-PowerPlay-Compatible-Lightsync/dp/B07L4BM851?ref_=ast_sto_dp&th=1. Accessed 9 February 2023.

Mario. “How Much Power (Watts) Does a Mouse Use?” The Home Hacks DIY.

thehomehacksdiy.com/how-much-power-watts-does-a-mouse-use-full-review/. Accessed 16 March 2023.

PCBWay “Body and Raw Materials of Computer Mouse” PCBWay 18 December 2013.

pcbway.com/blog/Engineering_Technical/Body_and_Raw_Materials_Of_Computer_Mouse.html. Accessed 16 March 2023.

RMG “Injection Molding Facility Energy Consumption Summary” Rex Materials Group.

rexmaterials.com/activek_apps/rmg/assets/tcs/Facility%20Energy%20Use%20Summary%20-%20Overview.pdf. Accessed 16 March 2023.

Rogers, Tony, “Everything You Need to Know About ABS Plastic.” Creative Mechanisms, 13

July 2015. creativemechanisms.com/blog/everything-you-need-to-know-about-abs-plastic Accessed 16 March 2023.

Sarah. “Copper Mining Equipment” Jian Fucheng Hydraulic Equipment Co., LTD. 18 May 2022.

fuchenglhd.com/blog/copper-mining-equipment/. Accessed 16 March 2023.

Savage, Adam. “The Makings of a Gaming Mouse: Inside Logitech’s Labs. Adam Savage’s

Tested. 5 June 2013. youtube.com/watch?v=HwrkXSO4788.Accessed 16 March 2023.

Stachura, MP. “Eco-Design In Practice - Case Study With Computer Mouse.” International

Design Conference - Design 2006, 15 May 2006, designsociety.org/download-publication/19155/ECO-DESIGN+IN+PRACTICE+-+CASE+STUDY+WITH+COMPUTER+MOUSE. Accessed 9 February 2023.

“Styrene" Chevron Phillips Chemical.

cpchem.com/what-we-do/solutions/aromatics/products/styrene. Accessed 16 March 2023.

Superfund Research Center “Copper Mining and Processing: Processing Copper Ores,”

Superfund Research Center, University of Arizona. superfund.arizona.edu/resources/learning-modules-english/copper-mining-and-processing/processing-copper-ores. Accessed 16 March 2023.

TechReset. “E-Waste Disposal Techniques.” TechReset.

techreset.com/itad-guides/e-waste-disposal-techniques/. Accessed 16 March 2023.

Osvaldo Rosas

DES 40A

Professor Cogdell

16 March 2023

Waste of the Computer Mice

The modern computer mouse is an electronic device used to point and click at things on a computer screen. Without it, human communication with computers could not exist, and interacting with this technology would be impossible. Computer mice are referred to as e-waste which is an umbrella term for various types of computer and technology related waste. Statistics show that about 50 million metric tons of e-waste is generated globally each year (Global E-Waste - Statistics & Facts). Though computer mice at a glance seem to not result in vast amounts of waste, they are still part of a substantial pattern of waste creation and dispersion. Although computer mice are a heterogenous product, most of the waste produced by computer mice comes from the life cycle industrial processes of extracting, processing, recycling, and waste management of materials and components such as ABS plastic, PCBs, and lithium ion batteries.

Because of the various components needed for a computer mouse, the extraction of raw materials and components is actually the processing of raw materials into secondary materials, as well as having already manufactured parts ready in order to be put together. The first and most obvious part that needs to be made is the outer shell material. There are a variety of different materials that can be used. However, the most common material used across the market is ABS plastic. ABS plastic isn’t necessarily extracted from somewhere. Rather, ABS plastic is a result of a chemical process known as emulsion and continuous mass polymerization which results in ABS (What Is ABS Plastic and Is It Recyclable?). ABS plastic is machined into sheets which are then sent out to various companies in order to make their products. ABS plastic is very heat resistant, flexible, and durable, which is why it is used among many sectors of business. This is also the step in which waste is emitted from the manufacturing of ABS plastic resin. There are three main kinds of waste emitted: water, solid, and gas waste. Specifically, process wastewater is generated and emitted from various processes including dehydration of ABS grafting base materials, cooling water, washing waste water from the waste process gas scrubber used for drying abs, waste cooling water from ABS emulsion reaction tanks, etc (Huang). For process gasses, there were many various chemicals which resulted “from the burnings of direct combustion generators, regenerative incinerators and heat medium heater” (Huang). Finally, for solid wastes, they mainly derived from the sewage treatment and production which consisted of biochemical residue that was burned or disposed of (Huang).

The next component that needs to be made is the PCB (Printed Circuit Board). PCBs are what conduct electrical signals. In short, they tell them what to do and where to go, which is how you are able to use many electronic devices. They come in a variety of colors like green, blue, and beige. They are used throughout many electronic devices such as computers, laptops, calculators, and computer mice (PCB Manufacturing Process - a Step-by-Step Guide). PCBs are an integral part of any electronic device, which is why it should be discussed in greater detail. The raw materials that need to be extracted or processed in order to make these components are copper, various metals, and epoxy resin. Waste is most notably derived from copper mining which is extremely harmful to the environment in the form of deforestation, water pollution, and human health risks. Copper mining is pursued through an open-pit operation, meaning everything has to be cleared including forests and their ecologies (How Does Copper Mining Affect the Environment?). Water pollution results from the surrounding bodies of water being polluted by copper, turning the water a reddish color that affects wildlife, water reserves, and farmland (How Does Copper Mining Affect the Environment?). Finally, there are human health risks in the form of exposed rock that emits radioactive substances and damaging chemicals, as well as the release of toxic chemicals that pollute the air which can harm workers’ skin, eyes, and lungs (How Does Copper Mining Affect the Environment?). The other issue is the epoxy resin used to help protect the copper from oxidizing. Most resins used to help cover the boards are made from epoxy, a chemical derived from the industrial process of petroleum (Chemistry Basics). Even after all of these materials and sources of waste, there is one more important component needed: lithium batteries.

Lithium batteries are used in a variety of applications, most recently in the boom for electric vehicles. However, lithium batteries are also used within computer mice in order to recharge wireless types of computer mice. The main materials needed for lithium batteries are lithium and other minerals like graphite, cobalt, and manganese (Igogo). The main material that should be discussed is lithium because of its use in pushing renewable electric energy. Lithium extraction is also extremely harmful to the environment. Lithium is a non-renewable mineral that causes air contamination, as well as contamination of the soil as it is being exposed to the air (Campbell). There is also water waste being wasted, as shown in the two statistics stating that about 21 million liters are used per day, and about 2.2 million liters of water is needed to produce one ton of lithium (Campbell). Lithium batteries, as well as ABS plastic and PCBs, are just three of the main components that are needed to manufacture computer mice. However, these were some of the most impactful materials and components that emit the most visible waste.

The next step in the life cycle of a computer mouse is its manufacturing. The manufacturing process is more or less straightforward since it is mainly people assembling the computer mice by hand and passing various checkpoints that test out its functions, durability, and longevity. First, the factory making these mice has to approve a design for the outer ABS shell, the PCB, and other components. As such, they create a base which acts as an outline so that ABS can then be made into the shape of the intended design. This is done through the process called Injection molding. Injection molding is when molten plastics are injected into a mold cavity, cooled, and then ejected (Xometry). This process is what results in the outer shell of a computer mouse. The notable waste that is derived from this injection molding is not the physical residue, although that is part of it, but rather it is the melting that happens once this physical residue is sent to be recycled. Part of the recycling process is melting down the separated ABS plastic so that it can be made into pellets or sheets to be sent back into other factories in this recycling system. However, more of this process will be expanded on further in the waste management section. The thing to know is that when this plastic is melted, there are concerns with the plastic becoming toxic.

Once this, along with the other parts are outsourced and transported into the factories, then the assembling can occur. The factories themselves require people to assemble and check the functions of the mice. However, it starts with putting all the necessary components together such as the PCB, ion batteries, and other components like the sensors to be assembled and installed into the base and then sealed into the ABS shell. This process is done on an assembly line which is powered by electricity, further contributing to the waste which is provided by the nuclear power, natural gas, and coal (Electricity Production and Distribution). Once these computer mice are assembled and tested, they are ready to be sent out and shipped.

Transportation and Distribution is the next process for this product’s lifecycle. Most of these products are shipped using rigid or cardboard boxes that have foam, or some kind of impact absorbing material. These boxes are sometimes outsourced to companies that specialize in packaging. For example, these companies will cut, size, print, and ship the boxes for companies to use in their products (Mouse Packaging Boxes: Packaging for Computer Mouse). It's important to note that although cardboard boxes themselves are easily recyclable, the manufacturing process isn’t a green process. Packaging is a very industrial process that involves machines, forklifts, and gas powered electricity (Corrugated Cardboard). Once the computer mice are assembled and placed into their packaging boxes, they are ready to be sent to various places to sell. Some stores can include Best Buy, Walmart, Amazon, and many more.

Once a consumer purchases a computer mouse and begins using it, there isn’t much new waste being generated. It is obviously getting power from a power source which in turn is plugged in to an outlet which draws out the necessary electricity in order for the computer and computer mouse to function. Electricity as mentioned above comes from natural gas, coal, and nuclear power. However, something interesting is that there are some, although not major, health side effects that can occur from using computer mice. Poor posture, limited mobility, and precision needed to interact with a computer can sometimes lead to pains or aches in the neck, hand, wrist, forearm, and elbow (Office Ergonomics - Computer Mouse - Common Problems from Use). Most of these issues can be solved by using a better posture, purchasing more ergonomic computer mice, or consumers allocating more workspace for their hands to move. Thus, for the most part, using a computer mouse does not emit new kinds of waste and in enormous amounts. However, this is not the case for the last two processes: Recycling and Waste management.

Computer mice have an average lifespan of five to seven years for the average user, but this changes to two to three years if consumers use it every day for work or gaming (How Long Does a Computer Mouse Last?: Average Lifespan). Once the computer mouse is no longer functional, it is disposed of in one of two ways. The best way to dispose of computer mice is to take them to a specific recycler who handles e-waste. These recycling facilities sometimes are in a program that the manufacturer of the product recommends to go to in order to recycle. The recycling process consists of shredding the computer mice and sorting using two methods: magnetic and water separation. Magnets help separate ferrous metals like steel, while water currents help separate the remaining residue like glass and plastic (Kosak). The recycling process is also an industrial one that consists of belt lines transporting all of these materials to be separated. They are also electrically powered and depend on gas and coal. Once these processes are complete, the materials extracted like the copper, ABS plastic, and other materials can be further recycled or sold on site. Materials like copper can be easily recycled, which is good. However, this is not necessarily the case for ABS plastic. ABS plastic that is sorted needs to be melted down, and then virgin material needs to be introduced in order to get the intended purity (What Is ABS Plastic and Is It Recyclable?).

The other way that most people dispose of e-waste is they throw it away in the trash, which ends up in landfills or burned in incinerators. The burning of e-waste in general is very harmful to the environment, and this is especially true for computer mice when they are burned. This is because the melting of ABS plastic past its melting point (between 200 degrees and 392 degrees fahrenheit) can cause ABS to decompose into its constituents: butadiene, acrylonitrile, and styrene (Acrylonitrile Butadiene Styrene). Butadiene is carcinogenic to humans, acrylonitrile is possibly carcinogenic to humans, and styrene is a petrochemical that is reasonably anticipated to be a human carcinogen (Acrylonitrile Butadiene Styrene). The mouse itself also contains other materials not mentioned like mercury in its PCB and the lithium batteries (if it is wireless). If these materials are burned, then they can possibly contaminate the air and water surrounding the area, as well as harming humans should they come into contact.

Therefore, although computer hardware companies that make computer mice do use recyclable materials and say they emit low waste, that does not paint the whole picture. The bulk of the waste caused by products like these are not coming from assembling the mouse, but rather the extraction/mining of raw materials needed for components, processing into secondary materials like ABS plastics, and the overall recycling and waste management that comes from shredding and melting these materials repeatedly

Bibliography

“Acrylonitrile Butadiene Styrene.” Wikipedia, Wikimedia Foundation, 15 Mar. 2023, https://en.wikipedia.org/wiki/Acrylonitrile_butadiene_styrene#Hazard_for_humans

Campbell, Maeve. “South America's 'Lithium Fields' Reveal the Dark Side of Electric Cars.” Euronews.green, 21 Nov. 2022, https://www.euronews.com/green/2022/02/01/south-america-s-lithium-fields-reveal-the-dark-side-of-our-electric-future#:~:text=According%20to%20a%20report%20by,water%2C%E2%80%9D%20says%20the%20report.

“Chemistry Basics.” Epoxy Europe, 9 July 2019, https://epoxy-europe.eu/epoxies/chemistry-basics/#:~:text=The%20majority%20of%20epoxy%20resins,ethers%20with%20three%20ring%20atoms).

“Computer Mice Recycling & Disposal.” All Green Electronics Recycling, 24 Sept. 2021, https://allgreenrecycling.com/certified-computer-mice-recycling/.

“Corrugated Cardboard.” How Products Are Made, http://www.madehow.com/Volume-1/Corrugated-Cardboard.html#:~:text=From%20the%20paper%20mill%2C%20rolls,and%20glued%20to%20make%20boxes

“Electricity Production and Distribution.” Alternative Fuels Data Center: Electricity Production and Distribution, https://afdc.energy.gov/fuels/electricity_production.html#:~:text=According%20to%20the%20U.S.%20Energy,biomass%2C%20wind%2C%20and%20geothermal

“Electronic Waste Facts.” The World Counts, https://www.theworldcounts.com/stories/electronic-waste-facts

Essentra Components. “Your PCB Substrate: A Guide to Materials.” Essentra Components US, Essentra Components, 23 Aug. 2019, https://www.essentracomponents.com/en-us/news/solutions/pcb-electronics/your-pcb-substrate-a-guide-to-materials#:~:text=PCBs%20are%20generally%20made%20of,that%20offers%20so%20many%20choices

“Global E-Waste - Statistics & Facts.” Statista, Ian Tiseo, 8 Feb. 2023, https://www.statista.com/topics/3409/electronic-waste-worldwide/#:~:text=More%20than%2050%20million%20metric,of%20e%2Dwaste%20per%20capita

“How Does Copper Mining Affect the Environment?” Federal Metals Inc. |, 11 Aug. 2022, https://federalmetals.ca/how-does-copper-mining-affect-the-environment/#:~:text=Copper%20mining%20has%20a%20devastating,affects%20environmental%20and%20human%20health

“How Keyboards & Mice Are Made - China Factory Tour!” YouTube, YouTube, 10 Apr. 2019, https://www.youtube.com/watch?v=GdwkFLLdgYI&ab_channel=BPSCustoms. Accessed 15 Mar. 2023.

“How Long Does a Computer Mouse Last?: Average Lifespan.” Gadget Review, https://www.gadgetreview.com/how-long-does-computer-mouse-last#:~:text=it%20function%20better.-,How%20Long%20Should%20a%20Computer%20Mouse%20Last%3F,down%20to%202%2D3%20years

“How To Recycle Computer Mice - ERI.” YouTube, YouTube, 20 Mar. 2017, https://www.youtube.com/watch?v=Xo8n1Lyd-vA&ab_channel=ERI. Accessed 15 Mar. 2023.

Huang, Pingsha, et al. “A Case Study of Cleaner Production in Acrylonitrile Butadiene Styrene Resin Companies in China.” Science Alert, 30 Nov. 1899, https://scialert.net/fulltext/?doi=jest.2010.148.158#:~:text=The%20processes%20of%20ABS%20resin,during%20the%20last%20two%20decades

Igogo, Tsisilile, et al. Supply Chain of Raw Materials Used in the Manufacturing of Light-Duty Vehicle Lithium-Ion Batteries. Clean Energy Manufacturing Analysis Center, https://www.nrel.gov/docs/fy19osti/73374.pdf

Kosak, Martin. “How to Recycle e-Waste?” Sensoneo, 14 Mar. 2023, https://sensoneo.com/how-to-recycle-e-waste/

“Mouse Packaging Boxes: Packaging for Computer Mouse.” IBEX Packaging, 9 Sept. 2022, https://ibexpackaging.com/custom-mouse-packaging-boxes/

“Office Ergonomics - Computer Mouse - Common Problems from Use.” Canadian Centre for Occupational Health and Safety, Government of Canada, 2 Mar. 2023, https://www.ccohs.ca/oshanswers/ergonomics/office/mouse/mouse_problems.html

“PCB Manufacturing Process - a Step-by-Step Guide.” Pcbcart, https://www.pcbcart.com/article/content/PCB-manufacturing-process.html

“Plastics Recycling at Amtek Plastics.” Amtek Plastics UK, Website Vision, https://www.amtekplastics.co.uk/recycling#:~:text=The%20Plastic%20Injection%20Moulding%20process,after%20the%20process%20is%20finished

“Recycle Material - ABS.” Let's Recycle It , 4 June 2021, https://www.letsrecycleit.eu/abs-recycling/#:~:text=Once%20ABS%20has%20been%20sorted,a%20wide%20variety%20of%20industries

“Recycled Acrylonitrile Butadiene Styrene (R-ABS).” Cirplus, https://www.cirplus.com/materials/recycled-abs

“Styrene and How It's Made.” Michigan Foam Products LLC, 1 Apr. 2019, https://michiganfoam.com/styrene-and-how-its-made/#:~:text=Styrene%20is%20a%20clear%20organic,chemical%20materials%20to%20produce%20Styrene

“Styrene.” Wikipedia, Wikimedia Foundation, 7 Jan. 2023, https://en.wikipedia.org/wiki/Styrene#Hazards

“TENORM: Copper Mining and Production Wastes.” EPA, Environmental Protection Agency, 16 Feb. 2023, https://www.epa.gov/radiation/tenorm-copper-mining-and-production-wastes#:~:text=Copper%20mining%20waste%20storage%20piles,and%20waste%20rock%20and%20overburden

“What Is ABS Plastic and Is It Recyclable?” Plastic Collectors Save the World, 23 Apr. 2020, https://www.plasticcollectors.com/blog/what-is-abs-plastic/

Xometry, Team. “ABS Injection Molding: Definition, Applications, Process, and Techniques.” Xometrys RSS, Xometry, 24 Oct. 2022, https://www.xometry.com/resources/injection-molding/abs-injection-molding/#:~:text=Injection%20molding%20is%20a%20highly,parts%20with%20limited%20human%20interaction