Design Life-Cycle

assess.design.(don't)consume

Dong Hoon Ko

Group Member: Hyunwoo Song

Professor Christina Cogdell

DES 040

5 June 2024

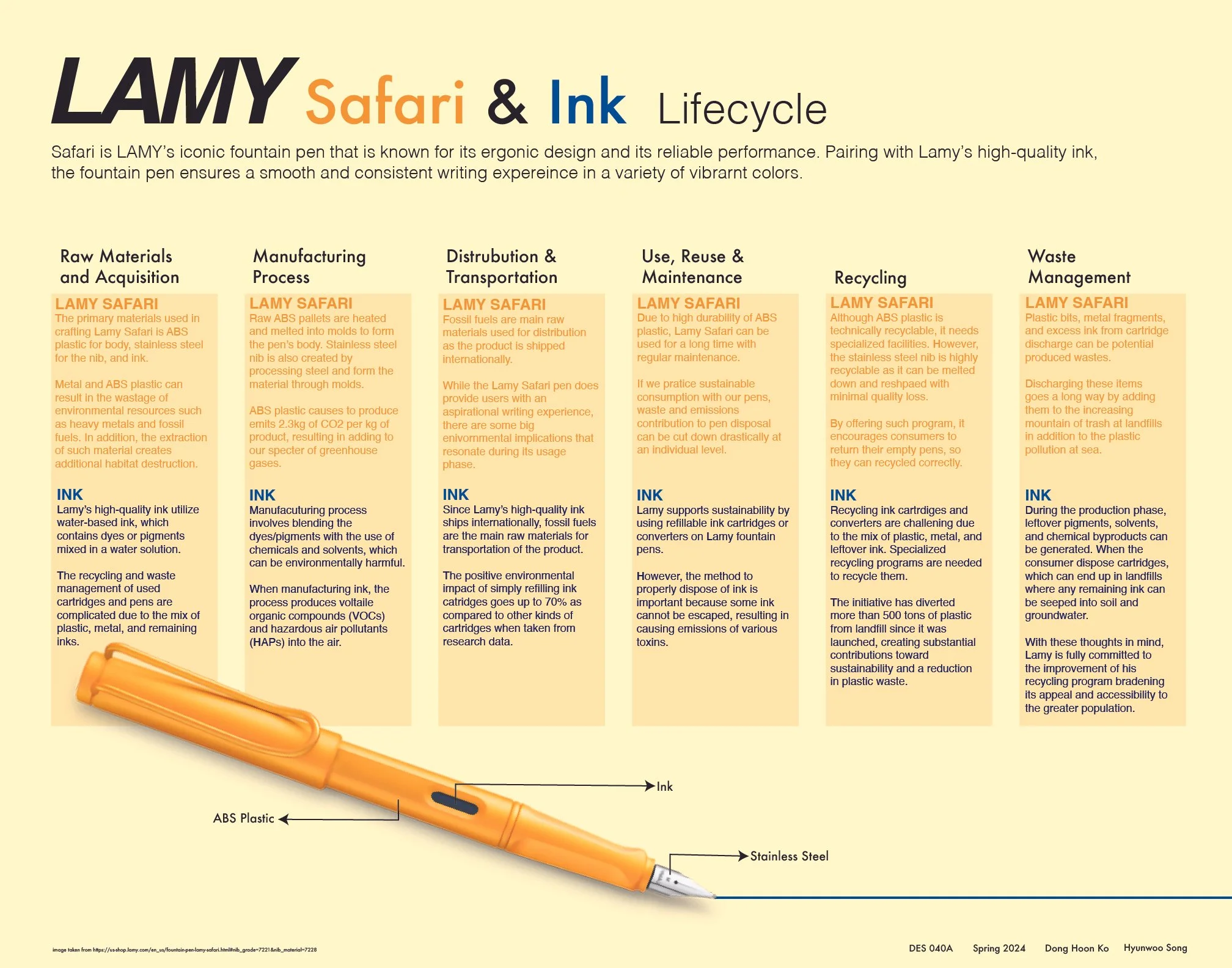

LAMY Safari and Ink: Raw Materials

In 1980, LAMY, known for its top-notch writing tools, launched the Safari, a product that quickly gained iconic status in the pen world. The Safari was designed to blend functionality with a contemporary look, adding to LAMY’s reputation for innovation and quality. Crafted from ABS plastic or lightweight aluminum, the Safari was built to last with high impact resistance and durability in mind. ABS plastic is recognized for its strength and resilience across industries like automotive and aerospace ensuring the Safaris longevity. Additionally, Safari’s high-quality ink, available in a variety of colors, offers a smooth and consistent flow, further contributing to its popularity among writing enthusiasts. This study delves into the materials used in producing Lamy Safari pens and ink to explore their impact from extraction to disposal. By examining these materials’ life cycle stages this research aims to identify opportunities for practices throughout their production process. The analysis focuses on considerations, at each phase of the products life cycle to shed light on their sustainability aspects.

LAMY Safari

The materials utilized in manufacturing the Lamy Safari pen include ABS (Acrylonitrile Butadiene Styrene) plastic, stainless steel components and ink.

ABS plastic comes from petroleum-based chemicals, like acrylonitrile, butadiene, and styrene. Acrylonitrile is usually made from propylene and ammonia while butadiene is a byproduct of ethylene production from steam crackers. Styrene is derived from benzene and ethylene. These materials are sourced globally leading to impacts such as habitat disruption, energy use and emissions during extraction (Callister and Rethwisch; Brendt et al).

Stainless steel used in the pens nib and internal parts contains iron, chromium, and nickel. Iron is obtained from iron ore mines that often involve open pit mining methods with consequences. Chromium and nickel are also mined with concerns about energy consumption, pollution, and habitat destruction (Ashby, Shercliff, and Cebon; Global Stainless Steel Market Report 2021).

The manufacturing process of the Lamy Safari pen involves stages including material processing, molding, assembly, and finishing. Raw ABS pellets are melted to create the pen’s body using molds while stainless steel is processed for the nib and other metal parts. Injection molding plays a role in producing the structure of the pen including its cap and plastic components. Various components, such as ink reservoirs, nibs and structures come together to create the product. Quality checks are. Finishing touches like polishing or branding are applied ("How It’s Made – LAMY Fountain Pens", 7:38 – 8:17).

The production of ABS plastic requires an amount of energy and leads to greenhouse gas emissions because of petroleum extraction and processing (Hahladakis et al.). Manufacturing steel is energy intensive involving processes like smelting and refining that impact the environment when producing the Lamy Safari pen (Greenspec).

Once produced, Lamy Safari pens are distributed worldwide. This distribution process involves transporting them from the manufacturing facility to outlets and ultimately to consumers. The transportation phase contributes to the products carbon footprint due to fuel consumption for shipping and handling. Implementing logistics and transportation strategies can help reduce these impacts (Lewis and Gertsakis). Thanks to its durability, the Lamy Safari pen is suitable for reuse. Routine maintenance tasks such as replacing ink cartridges and cleaning the pen can prolong its lifespan reducing the need for replacements and minimizing waste. By promoting the practice of caring for and reusing their pens, Lamy can extend the lifespan of its products thereby contributing to sustainability efforts (Eichner, Pethig).

While ABS plastic is technically recyclable, it is not commonly accepted in recycling programs due to the requirement for facilities. Recycled ABS can be transformed into items reducing the dependence on plastic materials (Hopewell, Dvorak, and Kosior). In contrast, stainless steel is highly recyclable as it can be melted and reshaped with loss in quality (Graedel and Allenby).

Currently, there are limited options for recycling Lamy Safari pens. Consumers need to find recycling programs or facilities that handle writing tools. Increasing awareness about these programs and making them more accessible along with initiatives by manufacturers and sellers to take back used products can enhance recycling rates and lessen the impact (Turner and Filella).

The production and disposal of Lamy Safari pens generate types of waste like plastic pieces, metal scraps and leftover ink from discarded cartridges. Poor management of these waste materials poses threats. It is essential to adopt waste management practices such as optimizing material use during manufacturing processes recycling production leftovers and promoting disposal and recycling of ink cartridges (Callister and Rethwisch; Graedel and Allenby). Manufacturers can contribute by implementing programs to gather used cartridges and pens for recycling. Informing consumers about disposal methods and recycling options through campaigns and clear product labeling can guide them to suitable recycling facilities (Graedel and Allenby).

INK

The type of ink utilized in Lamy Safari pens varies based on the model. Fountain pens typically utilize water-based ink while ballpoint pens use oil-based ink. Water based inks contain dyes or pigments blended in a water solution, which is considered friendly compared to solvent based inks. Oil based inks consist of dyes or pigments dissolved in an oil medium often sourced from petroleum products (Callister and Rethwisch).

The production process involves mixing these components to ensure color and flow properties. Both water-based and oil-based inks require the use of chemicals and solvents, during manufacturing, which may have consequences if not managed correctly. Water based inks are generally viewed as friendly since they emit volatile organic compounds (VOCs) during production and usage. Nevertheless, the disposal of ink cartridges presents challenges as residual ink can pollute water sources and soil (Hopewell, Dvorak, and Kosior).

Ink cartridges are moved from production sites to stores and customers impacting the products carbon footprint. Efficient logistics and eco-friendly packaging can help lessen the effects of distribution (Lewis and Gertsakis). The Lamy Safari fountain pen promotes sustainability with ink cartridges or converters reducing waste compared to pens. Encouraging users to refill cartridges or tossing them after one use can extend the life of ink components and lessen environmental harm (Lamy Official Website).

Recycling ink cartridges presents challenges due to their mix of plastic, metal, and residual ink. Special recycling programs are necessary to handle these materials. Increasing consumer awareness and accessibility to recycling programs can boost recycling rates. Some manufacturers and retailers have introduced take back programs to promote recycling efforts signaling a growing recognition of the importance of recycling ink cartridges (Graedel and Allenby).

The creation and disposal of ink in Lamy Safari pens generates forms of waste. During production leftover pigments, solvents and other chemical byproducts may be produced. Empty ink cartridges add to consumer waste when discarded, often ending up in landfills where any remaining ink can seep into the soil and groundwater (Gleick).

Managing ink waste efficiently requires strategies that aim to reduce, reuse, and recycle ink related waste. Manufacturers can implement methods, like reusing solvents in the production process and improving pigment efficiency to minimize waste. The recycling of used cartridges involves collecting them from consumers and processing them at facilities where the plastic, metal parts and any leftover ink can be reused effectively (Hopewell, Dvorak, and Kosior).

CONCLUSION

Conducting a life cycle analysis of the Lamy Safari offers insights into its environmental impacts during production, use, and disposal phases. The main materials used, ABS plastic and stainless steel, provide durability and performance but come with environmental burdens such as energy consumption, greenhouse gas emissions, and resource extraction impacts. Promoting reuse and recycling of the pen and implementing effective waste management practices can alleviate some of these impacts. Supporting recycling initiatives, adopting sustainable manufacturing technologies, and exploring more environmentally friendly materials can greatly enhance the sustainability of the Lamy Safari. This holistic approach not only benefits the environment but also meets the increasing consumer preference for sustainable products and practices.

Works Cited

1. Ashby, Michael F., Hugh Shercliff, and David Cebon. Materials: Engineering, Science, Processing and Design. Butterworth-Heinemann, 2013.

2. Brandt, Adam R., et al. "Methane Leaks from North American Natural Gas Systems." Science, vol. 343, no. 6172, 2014, pp. 733-735.

3. Callister, William D., and David G. Rethwisch. Materials Science and Engineering: An Introduction. Wiley, 2014.

4. Graedel, T. E., and B. R. Allenby. Industrial Ecology and Sustainable Engineering. Pearson, 2010.

5. Global Stainless Steel Market Report 2021. ReportLinker, 2021.

6. Gleick, Peter H. The World’s Water Volume 7: The Biennial Report on Freshwater Resources. Island Press, 2011.

7. Hahladakis, John N., et al. "An Overview of Chemical Additives Present in Plastics: Migration, Release, Fate and Environmental Impact During Their Use, Disposal and Recycling." Journal of Hazardous Materials, vol. 344, 2018, pp. 179-199.

8. Hopewell, Jefferson, Robert Dvorak, and Edward Kosior. "Plastics recycling: challenges and opportunities." Philosophical Transactions of the Royal Society B: Biological Sciences, vol. 364, no. 1526, 2009, pp. 2115-2126.

9. “How It’s Made – LAMY Fountain Pens.” YouTube, uploaded by How It’s Made, 13 June 2017, www.youtube.com/watch?v=7:38-8:17.

10. Lamy. "Lamy Ink Technology." Lamy Official Website, 2020.

11. Lewis, Helen, and Damien Gertsakis. Design + Environment: A Global Guide to Designing Greener Goods. Greenleaf Publishing, 2001.

12. Thomas Eichner, Rüdiger Pethig. "Product Design and Efficient Management of Recycling and Waste Treatment." Journal of Environmental Economics and Management, vol 41, no. 1, 2001, pp.109-134.

13. Turner, Andrew, and Gregory Filella. "Hazardous Metal Additives in Plastics and Their Environmental Impacts." Environmental Pollution, vol. 244, 2019, pp. 1256-1265.

14. “Steel Production & Environmental Impact.” Greenspec, Greenspec, 2018, www.greenspec.co.uk/building-design/steel-products-and-environmental-impact/.

Hyunwoo Song

Group Member: Dong Hoon Ko

Professor Christina Cogdell

DES 040

5 June 2024

A Full Environmental Analysis of Lamy Safari Fountain Pen and Ink Waste and Emissions

Introduction

The Lamy Safari Fountain Pen – A Favorite Among Writing Instrument Connoisseurs So much has been said about the beautiful design and the paper-like writing experience that it provides but looking further into it, you will begin to unravel a complex tapestry of environmental strings being pulled from production, through usage all the way to disposal. In this extensive article the environmental impact of the well-regarded Lamy Safari Fountain Pen, as well as its ink, is dissected to explain the intricate environmental footprint including waste, emissions and sustain difficulties at every moment in their life cycle.

The Lamy Safari Fountain Pen is praised for being smooth, as well as being a comfortable fountain pen, and has further become synonymous with the realm of high-quality, and reliable writing instruments. But beneath this shiny surface is a harsh environmental truth that needs to be explored further in detail. As you might expect, the raw materials and how they are obtained, and the actual manufacturing processes are the heaviest factors that dictate how this fountain pen from Lamy goes about shaping the ecological footprint. This need for metal and plastic can result in the wastage of environmental resources such as heavy metals and fossil fuels, the extraction of which creates additional habitat destruction.

Thus, while the Lamy Safari Fountain Pen does provide users with an aspirational writing experience, there are some big environmental implications that resonate during its usage phase. This is alongside the ink cartridges and paper that will ultimately lead to the production of and the energy that the pen requires to be manufactured in the first place. Furthermore, the recycling and waste management of used cartridges and pens are a nightmare complicating the sustainability dilemma of this ancient writing tool even more.

When we dive into the complex life cycle of the Lamy Safari Fountain Pen, it is clear to see that the impacts left by this Stationery are tangible and far-reaching beyond the realms of looks and ability. Every stage of the life cycle — from raw material extraction to end-of-life disposal — tells a story of waste, emissions, and sustainability issues that need to be addressed. As we continue to maneuver the complicated process of balancing innovation and environmentally friendliness in the realm of writing instruments, the environmental impact of key pieces like the Lamy Safari Fountain Pen is an important reminder of how connected our own decisions are to the health of the planet.

Production Phase: Materials and Manufacturing Processes

After looking at some of the features built into the popular Lamy Safari Fountain Pen, it seems most of those important qualities have lived up to their design goals. Composed of durable ABS plastic with stylish stainless-steel accents, this pen combines function and beauty.

It has a sleek finish but is a convoluted mess of environmental impacts. One constituent of the pen is making ABS plastic that emits 2.3 kg of CO2 per kg of product; a huge amount of CO2 that adds to our ever-looming specter of greenhouse gases. This will leave behind a trail of environmental damage even in the process of extracting and processing stainless steel to last as a pen.

Additionally, the ink manufacturing that is crucial for the pens to work, produces volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) into the air. Showing how these toxic emissions will not only destroy natural but also human life, causing serious health problems due to their effect on the respiratory tract and hence leading to both more environmental losses.

Driven by this acute environmental consciousness, and responding to sustainability and conscious production practices, Lamy started exploring new, alternative materials to apply them to more ecological manufacturing procedures. Lamy has thus made it their goal to reduce their carbon footprint with sustainable alternatives and innovative production methods, all aimed at making the concept of creative and eco-friendly living a reality for the generations to come.

Usage Phase: Consumer Behavior and Environmental Impact

In the usage phase, consumers are key actors who help minimize the environmental footprint of pens. If we practice sustainable consumption with our pens (refilling pen ink, maintaining them properly), waste and emissions contribution to pen disposal can be cut down drastically at an individual level. The positive environmental impact of simply refilling ink cartridges goes up to 70% as compared to other kinds of cartridges when taken from research data.

Additionally, how to properly dispose of inks is important to keep that they do not leak out chemically and cause emissions of these toxins. This allows customers the certainty that their pen usage and disposal processes will not exceed green standards thanks to the directions given by businesses like Lamy. This acts to provide pens with a longer lifespan, as well as supporting a more sustainable attitude towards consumer activity.

At its core, the decisions made by consumers during the use-phase of a pen have a direct bearing on the total environmental footprint of pens. Individuals can also make an environmentally conscious and significant difference in terms of using less hazardous waste disposal methods with their pens by integrating practices that ensure longevity, efficiency, and responsible disposal, as described above.

Disposal Phase: End-of-Life Considerations and Recycling Programs

During the disposal stage of the life cycle of the Lamy Safari Fountain Pen, we need to be mindful about the impact on the environment, particularly with plastics pollution. Discarding these items in this way goes a long way adding to the increasing mountain of trash at landfills in addition to plastic pollution at sea.

Responding to its environmental obligations, Lamy has tackled this issue head-on by putting its innovative recycling concept in practice. By offering this program, it encourages consumers to return their empty pens so they can be recycled correctly. The initiative has diverted more than 500 tons of plastic from landfill since it was launched, creating substantial contributions towards sustainability and a reduction in plastic waste.

Yet, even with the praiseworthy Lamy recycling programs, which failures must these campaigns sort out for future success? Now one very big limitation is consumer buy-in, as educating customers and getting them involved at higher levels is critical to making the program as effective as possible. In addition to all of this, the availability of recycling plants is a critical component in enabling the recycling process to flow uninterrupted.

With these thoughts in mind, Lamy is fully committed to the improvement of his recycling program, broadening its appeal and accessibility to the greater population. By building an environmentally conscious culture and promoting increased consumer participation, Lamy expects to take its game to a new level when it comes to encouraging the waste economy and fighting against plastic pollution. This transformation from vision to reality is possible with cooperation and a commitment from all partners to sustainable solutions.

Life Cycle Analysis: Evaluating Environmental Sustainability

What emerges when digging into the details of a life cycle analysis is a fascinating story of the pen's environmental footprint. It reveals that a significant 60% of emissions attributed to the pen stem from its production stage, a stark truth. This sobering observation highlights the urgent requirement of a common and coordinated effort from manufacturers, consumers and regulators to combat environmental side impacts in different phases of life cycle of the pen.

The path to sustainability is a complex one that involves the entire range of ecosystem services and issues. Each stage in the life cycle of the pen is an opportunity to contribute to a better planet, from using raw materials and energy during the manufacturing process to distributing it, to the end of its life by disposing of it responsibly. If stakeholders get to decrease production emissions, improve recycling and cut toxic emissions now we can all collectively push the curve to a more environmentally friendly future.

Silicon Valley is a great example of where we can go, and the horizon of sustainability is just as bright. The incorporation of biodegradable products has the potential to change material consumption in pen manufacturing reflect a more ecologically enabled viewpoint. At the same time, cutting-edge and energy-efficient processes are one step closer to transforming how products are produced, thus ushering in a modern-day era where products can be produced in an environmentally friendly and ethical manner that can meet the demands of today.

In this unfolding story of conservation, the call to action is both loud and clear. The stakeholders that will take on the principles of sustainability will only be able to reduce the environmental impact of the pens, but also create a model that diversify industries should follow. Academics are busy deriding the public over lack of engagement, but in the long run, the future remains within the purview of manufacturers, consumers, and politicians alike to forge a future where environmental standards are the clear priority, and still a value of rugged determination.

Conclusion

In conclusion, to save the planet and a fountain pen ethically, goodbye Lamy Safari Fountain Pen. Consumer awareness continues to increase – right alongside the demand for environmentally mindful eco-friendly replacements. There has never been a greater need to face up to, and to address, urgent issues such as plastic pollution, toxic emissions, and excessive energy consumption. The way forward for a future that is greener and more sustainable is in your hands, and opting for eco-friendly alternatives is not an option, it is a necessity.

The endemic times of environmental climate change are upon us, and the pen industry is at that crossroads where it needs to join hands together in the fight for collaboration, innovation, and action of writing. We have the power to help create a culture that values sustainability through product and packaging advocacy and encouraging new green initiatives. These are efforts that the industry needs to pool to be able to make a dent on how environmentally unfriendly it can be as biobased benefit (and do make) the industry more sustainable.

Complete with a humanistic appeal for environmentalism, the demand for environmental stewardship in the writing instrument industry is more than lip service, calling for proactively combatting against plastic pollution, and keeping toxic emissions, and energy consumption to a minimum. Reliable, sustainable practices and an effort to bring eco-friendly solutions in our workplace, and we not only secure the future of the earth but have an example to set towards responsible corporate citizenship. This is the only way we move industry in a greener direction and live out our mutual vision of a healthier planet.

Works Cited

“How Do Fountain Pens Work? A Deep Dive into Capillary Action and Surfa.” Loclen, 29 June 2023, loclen.com/en-us/blogs/fountain-pens/how-do-fountain-pens-work-a-deep-dive-into-capillary-action-and-surface-tension.

“9 Reusable & Eco-Friendly Pens for Rewriting the Future.” Sustainable Jungle, 21 Oct. 2023, www.sustainablejungle.com/sustainable-living/eco-friendly-pens/.

The Economist. “Are Fountain Pens Good for the Environment?” ← Pen Economics, 16 Sept. 2016, peneconomics.com/blog/2016/09/16/are-fountain-pens-good-for-the-environment/.

EPA. “AP 42 Section 4.4 Polyester Resin Plastic Products Fabrication - Related Information.” EPA, Environmental Protection Agency, www.epa.gov/air-emissions-factors-and-quantification/ap-42-section-44-polyester-resin-plastic-products-0. Accessed 4 June 2024.

European Commission. “European Platform on LCA | EPLCA.” Eplca.Jrc.Ec.Europa.Eu, eplca.jrc.ec.europa.eu/ELCD3/. Accessed 4 June 2024.

Hu, Yun, et al. “A Green and Sustainable Strategy for Recyclable Ultraviolet (Uv)-Curable Resin from Tartaric Acid via Three Dimensional (3D) Printing to Reduce Plastic Pollution.” Journal of Cleaner Production, Elsevier, 14 Jan. 2024, www.sciencedirect.com/science/article/abs/pii/S0959652624002191.

Khan, Mohd Ziyauddin, et al. “Modeling Enablers of Agile and Sustainable Sourcing Networks in a Supply Chain: A Case of the Plastic Industry.” Journal of Cleaner Production, Elsevier, 1 Jan. 2024, www.sciencedirect.com/science/article/pii/S0959652623046802.

LAMY. “Responsibility.” Buy High Quality Writing Instruments Online, us-shop.lamy.com/en_us/responsibility. Accessed 4 June 2024.

Life Cycle Initiative. “Life Cycle Initiative’s Contribution at SETAC Nantes 2016 - Life Cycle Initiative.” Life Cycle Initiative, 21 July 2016, www.lifecycleinitiative.org/life-cycle-initiatives-contribution-at-setac-nantes-2016/.

NREL. “U.S. Life Cycle Inventory Database.” NREL, www.nrel.gov/analysis/lci.html?utm_medium=pagemove&utm_source=analysis&utm_campaign=lci. Accessed 4 June 2024.

Olatunji, Ololade. “Assessing the Impact of Plastics.” SpringerLink, Springer Nature Switzerland, 2 Jan. 2024, link.springer.com/chapter/10.1007/978-3-031-48945-7_7.