Design Life-Cycle

assess.design.(don't)consume

Nazareth Fonseca Rodriguez

Taylor Patterson, Gabrielle Elyse Padre

Des 40A

Professor Cogdell

16 March 2023

The Life Cycle of a Bloch Ballet Pointe Shoe - Raw Materials

Ballet is an art form that dates back to the 19th century, a great piece of dance with emotions, rigorous form, and countless hours of perfection. What's the biggest ballet shoe company that maintains some of its most traditional formation and fabrication, where almost any dancer has owned a pair? Bloch. Bloch pointe ballet shoes are standard in most places, allowing it to be one of the most known brands with a great reputation. These are made with few materials, allowing for simple yet sophisticated enough construction by human hands. No two pairs of shoes are completely the same, which allows for uniqueness in every pair for every dancer when receiving a pair. Unfortunately, each pair may only last from one to maybe a handful of performances/practices before needing new ones, as they wear down quickly, which isn't good for the dancer's stability and consistency of their moves. Replacement of ballet shoes at such a fast pace gives us an idea of how many pairs of shoes each dancer can go through within a year- which is quite many. Unfortunately, these shoes are deemed unsustainable, as they aren't being recycled, and are almost impossible to do without expending more time and energy than what can be salvaged from it. These materials consist of natural leathers, cotton fibers, polyester + rayon (making the satin), trees which take the form of cardboard/paper, A paste (mysterious glue), and elastics. Bloch ballet pointe shoes are created with versatility in mind, suitable for many forms of dance, meaning they are kept rather minimalistic in their raw material formation and design, helping maintain the simplistic production and manufacturing of hundreds of these pairs, all made by human hands.

These shoes use a small quantity of materials to be made by these artisans who can make countless pairs of shoes a day. On Bloch’s website, they write it out clearly for us to understand the simple design behind these shoes- with details so accurate that even small mistakes can ruin a shoe. They state, “Pointe shoes are made up of several materials. The outside of a pointe shoe is made from satin. The pointe shoe toe block at the tip of the shoe is a firm box that is made up of layers of fabric, cardboard, and paper. These are packed together densely and hardened by pointe shoe pastes. The shank is made from layers of cardboard, while the sole of a pointe shoe is typically made from a thin piece of leather. A Paste is the standard paste that BLOCH uses. It is a firm, hard paste and was initially formulated to stand up to climate conditions of heat and humidity” (Bloch). Most of these materials do not need much processing, but the leather needs to go through the process of tanning, “In tanning the collagen of the hides is transformed into leather. Herewith the collagen of the hide is protected to microorganisms” (Twize). Now when we put this all together, we create a shoe/slipper for the dancer, which is only one essential piece of their attire. When we go into the distribution aspect of the raw materials being used to ship these shoes and how their customers receive them, we see that we use cardboard, adhesives for the tape to maintain such a package closed, and plastic bags for the shoe encasement. All these steps are produced in a factory based in many different locations across the world, with different machines and humans to make this process run smoothly. Without these artisans, the shoes and knowledge cannot be made and passed down to future generations of crafters. They’ve even mentioned in the “How It's Made” video that, if they were to place a maker from 70 years ago in a present-day shop, they wouldn't even have to learn anything new and could start as soon as they walked through the door.

From the show series “How it's made”, they future an episode where they show us the creation of ballet shoes, how they make each pair, and the process of how it's done. They also show us the machines they use to create stencils for the fabric, how they cut certain pieces, the folds needed for certain edges, the seams, precise measurements, the shoe molding, the materials needed to cast the shoe, the time it takes for each shoe to be completed, and how each step and material is applied. There are a lot of steps that go into this, as well as the crafter. It goes from having the main base on the outside to adding the seams, to being able to fold pleads to mold the shoe, adding the paste to form the box, making sure that the shoe is perpendicular for a stable hold while dancing, to adding the leather and insole for the shoe. In many places, we see that these crafters take years to develop their own techniques and styles. They also let the dancers come to them so they can decide who will be their (most likely) artisan for the rest of their dancing career. In the National Geographic documentary, we saw that there are people that have worked in this industry for over twenty years, and even then, it’s not a competition but a team effort into creating art. Once they've made enough pairs for certain dancers because they are frequent customers, creating that shoe to specific measurements becomes of ease, like muscle memory. This creates a bond between the customer and the crafter, which is something that machinery and mass manufacturing could never replicate nor adjust ever so slightly to one's liking and needs, since it would consist of one specific mold like standard sizing’s.

Although these shoes are great in fabrication and great upholders of their owners, they do not tend to last long, as many pairs are needed frequently when moving up over the years in professionality and difficulty of the dance. In this article, they went ahead and explained that “A professional ballerina can dance through 100-120 pairs of pointe shoes in one season. At a cost of about $80 each, PBT spends close to $100,000 on pointe shoes per year” (Pittsburg), while Gonzales mentioned that “....wearable pointe shoes may only last 20 to 45 minutes during an intense dance performance or only one performance before they tear apart” (Gonzales). So, we can assume that depending on the rigor of the dance and the weight of each dancer (this is because of the pressure applied to the shoe’s shank), each of them will go through different pairs at different rates. This article from Gonzales also spoke on how they tested different materials, their lifespan, tearing, and strength that they had, which could be a step in the right direction for better or longer-lasting shoes so they wouldn't have to replace them as much (Gonzales). The only issue that they had encountered within testing all these different materials was that some materials would cause the shoe to weigh more or weren't as flexible to allow for better freedom of movement for the dancer which could potentially be more harmful to their legs and feet since one’s individuals strength to withstand certain positions and movements vary. This shows us how not only are these shoes not vegan, (which is important to an extent for society and its animals), but all these shoes are duds and we have no actual waste management to do anything about this. Shoes are contaminated with bodily fluids, which also makes it harder to disinfect and reuse/recycle. Speaking of recycling, in a YouTube video created by Natalie Orr, a creator that focuses a lot on dance, we see her unboxing a few pairs of Bloch ballet shoes - one including the pointe shoe specifically. We get to see the packaging in which it comes in, which includes cardboard for the shipping, the adhesive tape which is needed to seal the box and the plastic bags that the shoe comes in. PET- or plastic pellets, are unsustainable and non-recyclable to an extent because plastic takes so long to decompose and is harmful to the environment due to the toxins it releases. Cardboard, thankfully, can be recycled and repurposed for the future, with an easier decomposition process that is less harmful to the environment and the people living all around it. The adhesive is typically made from water-activated paper tape, which is both good and bad because it does not contain as many plastic backings as regular scotch tapes used in most packaging processes.

To conclude, not only are all these raw materials considered simple and easy to access, and easy to create, but they're also great individual pieces of art in themselves. Unfortunately, they are not as eco-friendly (no way to discard them) as we wished they were. The raw material composition of the Bloch ballet pointe shoes is not sustainable, making manufacturing and distribution, not eco-friendly, which causes fatal waste management and no repurposing of the product. Their unique designs and availability to be customized to each individual is an artform in itself, and the time expenditure and craftsmanship on each pair reflect its value, as to why these shoes are not cheap and great for the versatility of the dance form. The hard work and dedication from human energy put into these shoes create a life within a shoe, before it is put to use and it creates a second life in its dance. The raw materials that go into this shoe are not a tough acquisition, but a tough challenge to be able to recycle, upcycle and dissect to return some materials back to their start. Not only are consumers aware of the harm that these shoes do to our environment when they have been used and need to be thrown out, but the manufacturers do not care much about trying to find an alternative solution to create a more biodegradable and just-as-strong shoe, but soon these materials will not be renewable and they will have to find new replacements to continue fabricating such textiles for the pointe. As the demand for this craft continues to stay at a steady rate, the artisans start to grow old and not many new people will join the craft, soon, these shoes will also go up in price, due to inflation yet demand for production.

Bibliography

“Ballet Pointe Shoe Pastes.” BLOCH US, 3 Mar. 2021, us.blochworld.com/blogs/advice-and-education/pointe-shoe-pastes.

Bedinghaus, Treva. “Dance All Night Long by Selecting the Best Pointe Shoes.” LiveAbout, 10 May 2019, www.liveabout.com/how-long-do-pointe-shoes-last-1006799.

Center, Smithsonian Lemelson. “A Better Pointe Shoe Is Sorely Needed.” Lemelson Center for the Study of Invention and Innovation, 28 May 2020, invention.si.edu/better-pointe-shoe-sorely-needed#:~:text=The%20inner%20sole%2C%20or%20shank.

Geographic, National. “Ballet Shoes: The Craft before the Dance | Short Film Showcase.” Www.youtube.com, 15 Dec. 2015, www.youtube.com/watch?v=hKeGX72V6VQ&ab_channel=NationalGeographic.

Gonzalez, Esthella, et al. “Comparative Analysis of Mechanical Properties for Pointe Shoe Fabrications.” AATCC Journal of Research, vol. 2, no. 6, Nov. 2015, pp. 7–13, doi:https://doi.org/10.14504/ajr.2.6.2.

How It's Made. “How It’s Made: BALLET SLIPPERS.” Www.youtube.com, 24 Feb. 2007, www.youtube.com/watch?v=ZP9gshA4YR4&ab_channel=swanodette89.

“How to Make Pointe Shoes.” The Pointe Shop, 23 Apr. 2015, thepointeshop.com/blogs/get-to-the-pointe/18099464-how-to-make-pointe-shoes.

Orr, Natalie. “BLOCH UNBOXING! BALLET SHOES, DEMI-POINTES, POINTE SHOES | Natalie Danza.” Www.youtube.com, 14 Nov. 2017, www.youtube.com/watch?v=rlKJtLoGEik.

“The Point of Pointe Shoes - Pittsburgh Ballet Theatre.” Pittsburgh Ballet Theatre, 2018, www.pbt.org/learn-and-engage/resources-audience-members/ballet-101/pointe-pointe-shoes/.

Thomason, Abigail. “Www.ChemistryIsLife.com - the Chemistry of Pointe Shoes (Ballet).” Www.chemistryislife.com, www.chemistryislife.com/the-chemistry-of-pointe-shoes-ballet.

Twize. “The Leather Making Process: Step by Step.” Nera Tanning, www.neratanning.com/knowledge/the-leather-making-process-step-by-step

Gabrielle Elyse Padre

Taylor Patterson, Nazareth Fonseca Rodriguez

Des 40A

Professor Cogdell

16 March 2023

Life Cycle of Bloch Pointe Shoes: Embodied Energy

The tradition of hand-making Bloch pointe shoes has been a cherished practice in the dance industry for decades. However, the increased use of synthetic materials and the amount of energy required to produce them, coupled with the environmental impact of acquiring raw materials, has led to significant ecological consequences. To make matters worse, professional dancers tend to discard these shoes at a rapid pace, which only adds to the environmental burden. With the technology available today, it is essential for companies to adopt a more circular business model that emphasizes environmental sustainability. This would involve designing a new style of pointe shoes that not only uses fewer resources but also gives back to the environment. By doing so, we can help to reduce the negative impact of the dance industry and promote a more sustainable future for generations to come.

The acquisition of materials for the box, shank, ribbon, and paste also requires the most significant amount of energy out of all raw products. Pointe shoes have a leather inner and outer sole which draws a connection to the meat industry, commonly known for its significant energy usage throughout the life cycle of cattle. Beef cattle are raised for only an average of 18 months, when their lifespan is usually 15-20 years (Grandermarnier 2023). Naturally, the farmers will need to provide it with energy until their slaughter date which can include up to 87 liters of water per day. Leather production is one of the most environmentally damaging industries in the world. It is responsible for deforestation, water pollution, and the release of greenhouse gases. Vegan alternatives, such as synthetic leather, are much more sustainable and have a smaller environmental impact. Considering the extremely short week-long lifespan of a pair of pointe shoes owned by a professional ballerina, it would be beneficial for Bloch to explore alternative types of leather such as mushroom and pineapple leaves, which have been seen in successful modern shoe designs. If vegan leather material can be developed free from the use of crude oils, microplastics, chemicals, and animals, the shoe– better yet– fashion industry, should seek out a termination of all animal leather together.

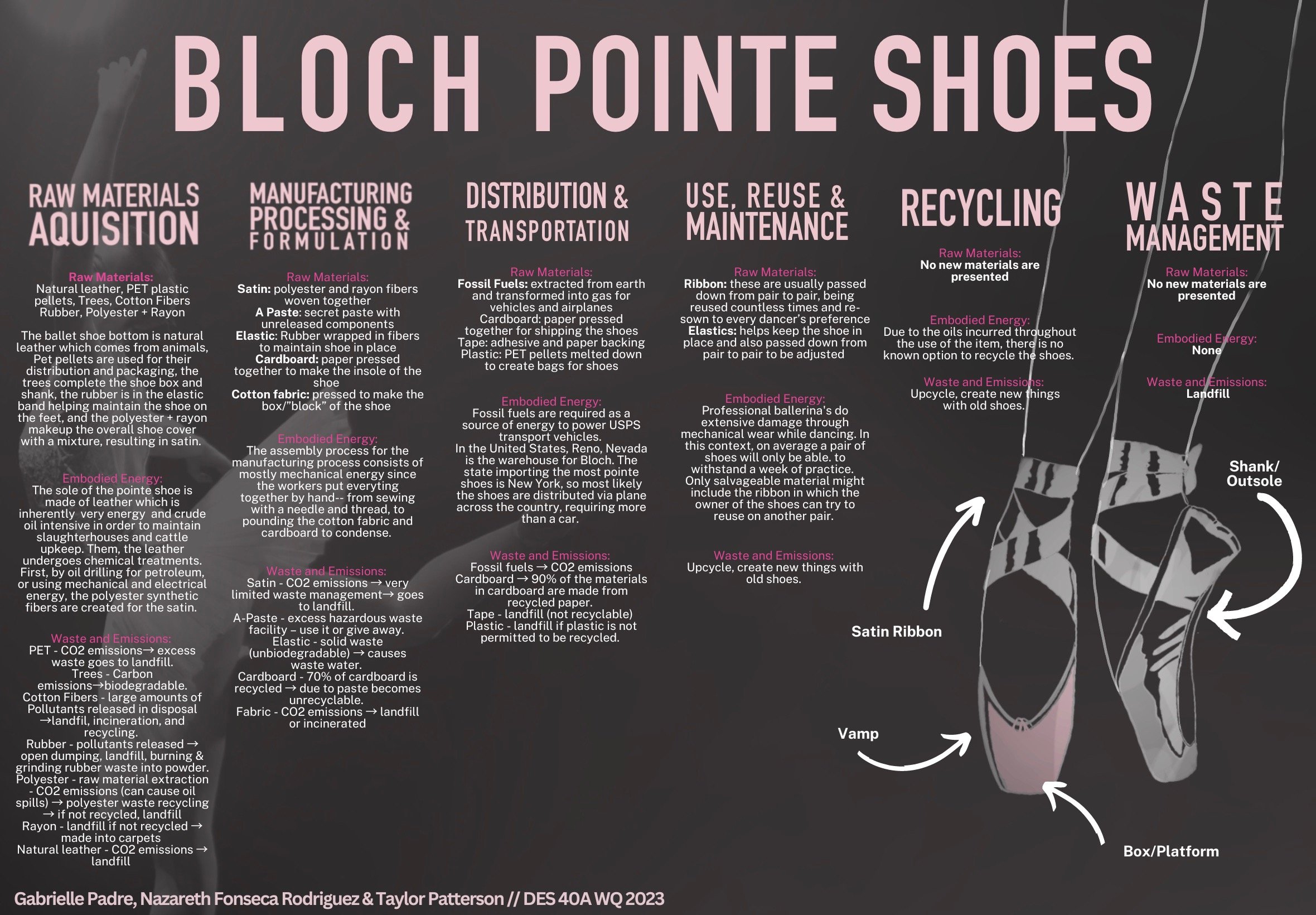

The image above depicts a pointe shoe taken apart, revealing each individual piece that is handsewn or glued together. On the far right, one of the most notable materials used in the manufacture of pointe shoes is satin. This fabric is used for the outer layer of the shoe, while the laces and shell are made of a blend of polyester or rayon. These synthetic materials are produced through a series of energy-intensive processes, requiring a large amount of resources. Polyester, in particular, is primarily made of polyethylene terephthalate and requires high amounts of energy to produce. In fact, the energy required to produce one kilogram of polyester is estimated to be 125MJ, with the greenhouse gas emissions reaching 14.2 kilograms of CO2 per kilogram produced (CDFA 2023). This is three times more than the emissions produced by cotton. It is a kind of plastic that is usually derived from petroleum, which is a non-renewable source. While there are alternatives to oil-derived polyester, such as recycled plastic or even agricultural crops, these options are not being prioritized by the large dance corporations. This lack of initiative means that waste reduction is not being addressed in the manufacturing process.

Lastly, there is the final assembly of all of the materials. Bloch is a company which takes pride in hand-making each shoe– from using their own physical force holding a block to hit down the layers of cardboard to creating the shank or box, to sewing elastics on with a needle and thread. Therefore, the manufacturing process includes mostly mechanical energy from the workers in the lines that put the pieces together.

The Transportation of the pointe shoes is an important aspect of the production life cycle that requires significant amounts of energy. Bloch is one of the most popular ballet brands in America, and its two biggest clients are the New York Ballet and the San Francisco Ballet (BLOCH 2023). Bloch's warehouse is located in Reno, Nevada, which is approximately 250 miles from San Francisco and 2700 miles from New York City. Shipping pointe shoes to their destinations requires a significant amount of energy, as fossil fuels must be extracted by drilling and electrical energy is used again when transporting via vehicles and airplanes. According to a report by the International Energy Agency, the transportation sector is responsible for approximately 24% of global carbon dioxide emissions. To reduce the environmental impact of shipping pointe shoes, Bloch could consider implementing more sustainable transportation methods, such as using electric vehicles or exploring the possibility of using renewable energy sources to power their transportation. Another option could be to establish regional warehouses closer to their clients to reduce the distance and energy needed for transportation.

In terms of use, once a dancer obtains a pair of pointe shoes, they begin the process of breaking in pointe shoes, which is a crucial aspect of ensuring the safety and comfort of the dancer. To achieve this, dancers will typically employ various techniques such as wetting or heating the box of the shoe, pounding it on hard surfaces, and wearing the shoe until it becomes more flexible and pliable. While most of these techniques require little to no energy, it is worth noting that the use of a blow dryer to heat the paste on the shoe could be a source of energy consumption.

However, it is important to keep in mind that the sweat and oils that incur in shoes during use can have a significant impact on their overall lifespan. While it may be possible to reuse elastic and ribbon components of the shoe, these are only a small fraction of the shoe and much of the remaining material may not be salvageable. As such, it is recommended that dancers invest in high quality pointe shoes and take proper care of them to ensure their longevity and continued use throughout their dance career. This can include storing them properly, regularly cleaning them, and consulting with a professional for any repairs or maintenance needs.

In conclusion, it is essential to consider the different stages of the Bloch pointe shoe production life cycle and the amount of energy required for each stage. Historically, pointe shoes were made from natural materials and designed to break down and mold to the dancer who wore them. This close relationship between the shoe and the dancer was a key element of dance tradition and informed the design of the shoe. However, with the rise of synthetic materials, the production of pointe shoes has become more complex, with a higher energy cost and more waste produced. It is therefore crucial to examine the environmental impact of its production cycle and ensure that the company is taking steps to reduce waste and energy consumption. For example, Bloch could explore the use of renewable energy sources in its factories, or look into alternative materials that are more sustainable. Additionally, they could implement recycling programs for their products, or even partner with environmentally-focused organizations to ensure that their production cycle is as green as possible. By taking these steps, Bloch can continue to innovate and produce high-quality technical dancewear, while also being responsible and mindful of its impact on the environment.

Bibliography

“Ballet Pointe Shoes.” BLOCH Dance US, https://us.blochworld.com/collections/adults-dance-shoes-pointe. Accessed 15 Mar. 2023.

CFDA. https://cfda.com/resources/materials/detail/polyester. Accessed 15 Mar. 2023.

How a Cow Works. https://www.petmd.com/blogs/thedailyvet/aobrien/2012/august/how_a_cow_works-26674. Accessed 16 Mar. 2023.

“How Long Do Pointe Shoes Last?” BLOCH Dance US, 17 Feb. 2023, https://us.blochworld.com/blogs/advice-and-education/how-long-do-pointe-shoes-last.

“Ivory Recycled Polyester Satin.” Offset Warehouse, https://www.offsetwarehouse.com/products/recycled-polyester-satin. Accessed 15 Mar. 2023.

Petit Pas New York – From Ballet Shoes to Bracelets. http://petitpas.nyc/. Accessed 15 Mar. 2023.

“The Environmental Impact of Cow Leather | Watson & Wolfe.” *Https://Www.Watsonwolfe.Com/*, https://www.watsonwolfe.com/2019/08/12/environmental-impact-of-cow-leather/. Accessed 16 Mar. 2023.

“The Point of Pointe Shoes.” Pittsburgh Ballet Theatre, https://www.pbt.org/learn-and-engage/resources-audience-members/ballet-101/pointe-pointe-shoes/. Accessed 16 Mar. 2023.

Taylor Patterson

Nazareth Fonseca Rodriguez,

Gabrielle Elyse Padre

DES40A

Professor Cogdell

Bloch Ballet Pointe Shoe: Waste & Emissions

The ballet pointe shoe is used in beautiful but demanding artistry, known as the ballet pointe dance. In this technique, individuals dance on the tip of their toes and rely on pointe shoes to execute their graceful movements. The dance form causes many dancers to form blisters, bunions, ingrown toenails, sprained ankles, and other health conditions if not appropriately managed. The pointe shoe, rigid when received, is essential in managing these health conditions if not properly broken in when receiving the shoe. These shoes are made with all-natural materials, breaking down quickly, depending on the dancer. Professional ballet dancers tend to go through many more pointe shoes than non-professionals in a given time. In fact, "The New York City Ballet goes through 8,600 pairs of pointe shoes per year for 47 dancers, and the Royal ballet goes through 12,000 pairs a year." (Becker, 2015a). This data shows the vast amount of waste contributed to the landfill based on only two ballet companies. The pointe shoe has been around for over 200 years and has had minor technological improvements with the turn shoe method, but overall, this hand-making process is the same. An Australian-based company, Bloch, continues with the traditional practice of using the turn shoe method to create the pointe shoe. Bloch ballet pointe shoe is a famously known brand used throughout the ballet world, by examining the materials, waste, and emissions released throughout the life cycle shows how the traditional handmade process can be inconsistent and cause large amounts of waste once ballet dancers have a dead pointe shoe.

Jacob Bloch founded the Bloch company in 1932, where he first created pointe shoes in a workshop in Sydney, Australia, for one customer at a time using the turn shoe method. The turn shoe method is when the shoe is put together inside out and turned right-side out once the shoe is completed; this method was first created for the turn shoe, a type of leather shoe from the middle ages (SoleScience, 2021). Jacob started noticing the ballet dancers struggling to stay en pointe during their performances and decided he would do something about it. He then devised a solution to their problems and improved the shoe. Once word got around about the pointe shoes, Bloch started creating them for famous ballet dancers like Helene Kirsova, a Russian ballerina. (BLOCH, 19). Furthermore, that is the start of a successful business. The minor improvements made since the beginning of the Bloch ballet company created the opportunity for ballet dancers to dance en pointe. He created the Pointe shoes to be uniquely crafted for an individual fit, so each element of the pointe shoe is hand sewn together to create the final product (BLOCH 19). However, without the improvements and changes to the materials used, precisely without sustainable materials, the global impact that pointe shoes create is large amounts of waste. By examining the making of the pointe shoe and the raw materials used, we can see the inconsistencies of the shoe and why it is time to move on to more sustainable materials for the pointe shoe.

The ballet pointe shoe is made to be and feel like an extension of the dancers' feet and is hand-crafted to the shape of the dancers' feet to bring all the support it can get. It is essential to know the anatomy of the pointe shoe to see the entire perspective of the shoe's life cycle. The shoe has many parts, starting with the toe box, which is the cup that encompasses the shoe, made from paper, cardboard, and fabric held together by the A paste or glue (Becker, 2016). Then, we have the elastic on the shoe made from rubber and fiber to secure the dancer's foot to the shoe. The vamp, which is the covering of the top of the shoe, is made from satin and fabric. The throat, which is the shoe's opening, is made from fabric and elastic. The ribbons, which are what the pointe shoes are known for, are made from satin. The outsole or inner shake is the hard material that reinforces the shoe's sole to support the point's arch while dancing; made from leather and cardboard. And the drawstring, which is used for aesthetics and refining the shoe's fit, is made from cotton and elastic. (DanceLine, 2021) Overall, this is what makes up a pointe shoe. Each raw material used in making a pointe shoe has its life cycle, and we must consider the waste and emissions they have produced and contributed to the lifecycle of the pointe shoe.

From their origins, most of the raw materials were created in an unsustainable process, emphasizing the waste and emissions caused by it. During the manufacturing process of the pointe shoe, we see how these materials coincide. Satin, made of polyester and rayon, has a minimal waste management system in developing countries and generates substantial waste and CO2 emissions. The excess waste will generally end up in landfills or be recycled through mechanical recycling (if permitted). The A- paste used to keep the overall shoe intact, specifically the layers of fabric on the cardboard on the toe box, is used predominantly in creating pointe shoes in Blochs' company. Still, they did not release the ingredients used in the paste. The excess waste of the paste can go to a hazardous waste facility to be disposed of appropriately (Adhesives and Glues, 2020). The elastic parts of the shoe, made up of rubber and fibers, create solid waste. This solid waste does not break down easily and can cause wastewater and release large amounts of pollutants, often in landfill. The cardboard used in the shoes is 90% made from recyclable paper, the most sustainable material used in the pointe shoe. But, due to the paste that revolves around the shoe, it becomes unrecyclable at the end of the lifecycle. The excess fabric used in the pointe shoe is dumped in the landfill or incinerated. Fabric is often found in a landfill; 73% of all fabric and clothing ends up there, while only 12% of all textiles are recycled (The Limitations of Textile Recycling, 2019). This data shows how the raw materials in the pointe shoes create a vast amount of emissions and waste that mostly goes to the landfill. By examining the making of the pointe shoe and how very inconsistent the lifespan of the shoe is with unsustainable materials, we can show how this handmaking process develops a large amount of waste yearly.

Despite the craftsmanship of the pointe shoe, examining its waste lifecycle shows its unsustainable practice and how thousands of these shoes go to waste every year. Not only are the raw materials used in the pointe shoe unsustainable, creating loads of emissions and waste yearly. But, once the pointe shoe is thoroughly used, they are disposed to landfills exponentially because they are unrecyclable. The pointe shoe only lasts for a short time, too, only about 10-20 hours for professionals (Huizinga, 2022). Because the shoes are made with natural materials, the constant use of these shoes and the sweat involved will break them down much faster. When the shoe breaks down, it is called a dead pointe shoe. It happens when the toe box is soft and can no longer support the dancers' feet. A dead pointe shoe occurs very often, and creating such an unsustainable shoe will have lasting effects on the waste problem. The waste that grows through the pointe shoes' lifecycle can directly reflect on the development of the shoe. Examining the shoes' raw material, emissions, and waste from start to finish will clearly understand the pointe shoes' entire lifecycle, but also the distribution and transportation of these shoes play a huge factor in the waste and emissions of the pointe shoe.

The distribution and transportation phase of the pointe shoe lifecycle also contributes heavily to the unsustainable process of creating the shoe. The raw materials used in packaging include cardboard, tape, and PET plastic pellets. The cardboard made by trees is the main component of the packaging; the box the pointe shoe comes in. Trees release carbon emissions into the air each time one is cut down. Although a sustainable material, the replenishment rate is prolonged, so there should be more environmentally safe ways to get the material needed for the packaging. The tape used in plastic packaging is not recyclable and often ends up in landfill. And finally, the plastic used in the packaging used mechanical energy to melt the plastic for the Bloch packaging, specifically the plastic bag in which the shoes will arrive. The process of shipping shoes worldwide causes lots of CO2 emissions. The transportation aspect of the shoes revolves around airplanes, cars, and trucks. The average flight CO2 emission is 90 kg per hour (Emissions of Carbon Dioxide in the Transportation Sector, 2022). Based on this, the flight from Australia to JFK in New York alone is about 1,890 kg CO2 for only one way; imagine how often they have flights going worldwide. Transportation to buy or transport the shoe must be accounted for, not only shipping worldwide. The average emissions released by vehicles, trucks, and cars account for 83% of CO2 emissions released in transportation (Emissions of Carbon Dioxide in the Transportation Sector, 2022). This data shows the inconsistencies of the ballet pointe shoe regarding the distribution involving the emissions released in this process. We can now discuss the waste management of the point shoe and what can be done once someone has a dead pointe shoe.

Once one has a dead pointe shoe, how should it be disposed of? The shoe itself is not recyclable or biodegradable, so it can often be a struggle for dancers to know what to do with their old shoes. Many dancers keep their shoes for a long time or upcycle them into something else. Many dancers keep the ribbon part of their shoe to add it to the newly purchased shoes. Without upcycling them, the pointe shoe will likely end up in landfills. This is why ballet shoe companies need to start incorporating more sustainable or biodegradable materials into their shoes, so they will not contribute to the waste problem.

The pointe shoe evolved as dancing en pointe in ballet became popular. Although painful, it is explicitly developed for the individual to move with fluidity, but the practice of making the shoe has mostly stayed the same since it was first introduced into the ballet world. By examining the entire lifecycle of the pointe shoe and the waste development throughout its life cycle, we can see why the handmade process is not sustainable and should move forward with more sustainable practices.

Works Cited

Palacios-Mateo, Cristina, et al. “Analysis of the Polyester Clothing Value Chain to Identify Key Intervention Points for Sustainability - Environmental Sciences Europe.” SpringerOpen, Springer Berlin Heidelberg, 6 Jan. 2021, https://enveurope.springeropen.com/articles/10.1186/s12302-020-00447-x.

SoleScience. “The History of Shoemaking.” SoleScience, 19 Feb. 2021, https://www.solescience.ca/history-of-shoemaking/.

BLOCH Dance US. “Bloch History.” BLOCH Dance US, BLOCH Dance US, 14 Oct. 2019, https://us.blochworld.com/pages/bloch-history.

Thomason, Abigail. “The Chemistry of Pointe Shoes (Ballet).” Www.ChemistryIsLife.com, https://www.chemistryislife.com/the-chemistry-of-pointe-shoes-ballet.

DanceLine. “Anatomy of a Pointe Shoe.” DanceLine, 8 May 2021, https://danceline.com/blogs/news/anatomy-of-a-pointe-shoe.

“Adhesives and Glues.” Metro, 16 Jan. 2020, https://www.oregonmetro.gov/tools-living/healthy-home/common-hazardous-products/adhesives-and-glues.

Becker, Kent G. “Pointe Shoes, Part I.” Ballet Focus, 10 Dec. 2016, https://balletfocus.com/pointe-shoes-part/.

“The Limitations of Textile Recycling.” Recovery, Recovery - Recycling Technology Worldwide, 10 Dec. 2019, https://www.recovery-worldwide.com/en/artikel/the-limitations-of-textile-recycling-3411757.html.

Huizinga, Madison. “What Is a Pointe Shoe?: A Guide to the Advanced Dance Footwear.” Dancewear Center, Dancewear Center, 18 Oct. 2022, https://www.dancewearcenter.net/blog/2022/8/19/whats-a-pointe-shoe.

“Emissions of Carbon Dioxide in the Transportation Sector.” Congressional Budget Office, Dec. 2022, https://www.cbo.gov/publication/58861.