Design Life-Cycle

assess.design.(don't)consume

Steven An

Professor C. Cogdell

Design 40A

14 March 2016

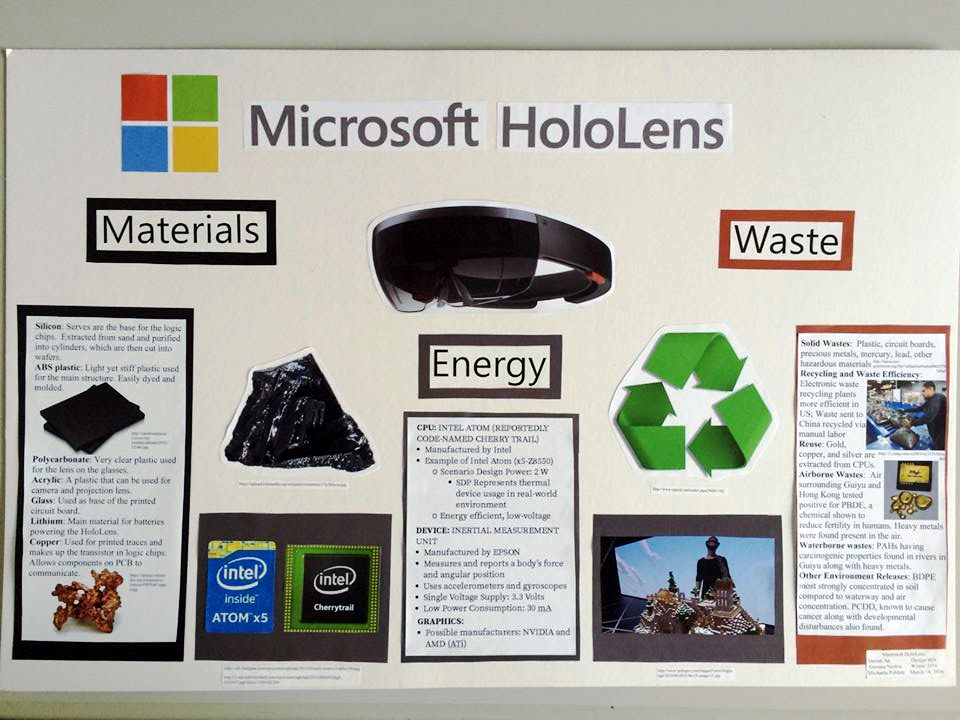

Materials in the Microsoft HoloLens

The HoloLens is a wearable device similar to glasses that is currently being developed by Microsoft. Similar to Google Glass, the device projects images for the user to see, but aims for a more ambitious goal, projecting a faux three dimensional image. Microsoft aims to change the workspace and gaming experiences with an augmented reality that can adapt to one’s surroundings. Microsoft believes that being able to see objects in real size can aid with training simulations. The Microsoft HoloLens is a revolutionary new product looking to change workflow. Even though it has not been released yet, its materials and their respective life cycles can be inferred.

Acrylonitrile butadiene styrene (ABS) is a recyclable, lightweight and stiff plastic that has many applications. It is likely that ABS would be chosen as the material for the framework and screws because it easy to color through pigmentation and easy to machine. This material is a “terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene”[1]. Butadiene and propene are made from a process called steam cracking which breaks down saturated hydrocarbons into smaller hydrocarbons from materials such as propane and butane[2]. Saturated hydrocarbons are usually variants of petroleum and crude oil. The styrene monomer is from the ‘dehydrogenation of ethylbenzene”[3]. Ammonia is produced by “combining hydrogen and nitrogen under high pressures” is combined with propene to make acrylonitrile[4]. The three chemicals needed to make ABS are secondary materials and the plastic itself can be considered as tertiary. The raw ABS is then colored and molded, which makes it ready for assembly. When ABS in the product is no longer needed, it is shredded and then combined with new ABS to produce a “desirable recycled plastic”[5]. Recycling ABS is a desirable course of action because it is cheaper to recycle than to synthesize new plastic.

Polycarbonate is another easy to machine and recyclable plastic that might be used in the HoloLens due to its finish. This would most likely be used as the lens material for the glasses due to its finish properties. Polycarbonate is made through “the reaction of bisphenol A [treated with sodium hydroxide and phosgene”[6]. The production of phosgene involves passing “purified carbon monoxide and chlorine gas through a bed of porous activated carbon”[7]. BPA is made by condensing one part “acetone with two equivalents [parts] of phenol”, while being catalyzed by a strong acid[8]. Both acetone and phenol are products from the cumene process. The main part of the process involves the reaction of “propylene and benzene in the process of acid-based catalysts” which is then converted to liquid form and then separated with “sulfuric acid” to make phenol and acetone[9]. Benzene and propene and made from crude oil. If the process starts at isolating the benzene and propene, polycarbonate can be considered to be a septenary product. Sodium hydroxide is made from an “electrolyzed” salt solution that produces it as a byproduct[10]. The BPA is treated with sodium hydroxide which makes diphenoxide. Polycarbonate is produced when the diphenoxide reacts with phosgene. Once the polycarbonate is molded into the correct shape, it can be polished with a vaporized solvent, giving the plastic its transparency. Similar to ABS, when polycarbonate is not needed anymore, it is cleaned, shredded and then turned into small granulates which are ready for a manufacturer to use again[11]. Polycarbonate and ABS are two strong and durable materials that would be suitable for the HoloLens’ frame and lenses.

Acrylic is a plastic made from petroleum that can be used as a camera or projection lens. The HoloLens is able to recognize the user’s surroundings and can also project images onto the lens which the user sees as holograms. Compared to glass, acrylic is easier to machine cheaper to manufacture, and lighter. This material is made from acetone, sodium cyanide and methyl alcohol. Acetone is made for the most part from the cumene process which accounts for about 90% of all acetone made. Sodium cyanide is made from the combination of ammonia and caustic soda, or sodium hydroxide[12]. Methyl alcohol is synthesized from a natural gas, which is “reformed” with steam and then distilled into a pure biodegradable alcohol[13]. One way to make acrylic is to first put the acetone with the sodium cyanide to make acetone cyanohydrin. Then the acetone cyanohydrin is put together with the methyl alcohol and the plastic is formed[14]. Starting from the beginning of the cumene process, acrylic can be considered as senary product. It is notable that if petroleum is used to make the plastic, it takes 2 kilograms of petroleum just to make one kilogram of acrylic. After the acrylic is made and shaped into the lenses, it needs to be coated to improve the light transmission and prevent internal reflections. Some lens designs require multiple lenses to be glued together which brings in lens cement. The recycling of acrylic is hard because it requires a lot of energy and the process might release “potential environmental hazard[s]”[15]. One of the ways to recycle it is called pyrolysis which is heating up the plastic to a very high temperature in the absence of oxygen. Depolymerization is the other way to recycle it, requiring the plastic to be heated until the monomers making up the structure separate. The use of acrylic for the camera and projector lens may not be very environmentally friendly, but is cost and weight efficient.

The Hololens will contain one or more logic boards which will most likely be printed circuit boards (PCBs) to carry out all of its functions. Even if the logic boards do not do all the calculations, it must be able to transfer power to the instruments such as the speakers, microphones, cameras and projectors while also being able to interpret and send back the data to the processing unit at the very least. The physical board is made from fiberglass, glass that has been elongated via gravity, which serves are the strengthening material in epoxy resin. Glass is created by melting various materials, such as silica, limestone and soda together[16]. This would be considered a secondary material because glass cannot be extracted from the ground. Copper traces are printed onto the board in order to provide connections between various parts. A variety of other metals can be used on the board including, but not limited to nickel, gold, lead, aluminum and tin lead, depending on the designer’s needs. The designer also has the choice of putting on integrated circuits, resistors, transistors, and many other electronic components. Many of these metals are extracted from mines, and then purified at a forge. When PCBs are recycled, the most valuable element on there is gold, which can be dissolved in sodium cyanide. Usually, a large amount of boards that contain trace amounts of gold are put into a vat of this acid to make recycling cost effective. When the board is recycled, it is likely that the only gold, silver and copper will be retrieved, and not any of the circuits or other components. Even though the integrated circuits and processing units on the PCB will not be fully recycled, they are needed to make the HoloLens work.

The HoloLens is able to work without having a connection to a power supply due to an internal battery. One of the most cost effective and most efficient battery types is the lithium ion battery. The physical battery will contain a compound that contains lithium which stores the electricity, a cathode, anode, insulation casing, and a charging chip. The pure lithium is “recovered from brine, or water with a high concentration of lithium carbonate”[17]. A combination of metals, including manganese, cobalt, vanadium and nickel, are combined with the lithium to form a cathode that has best possible properties[18]. The anode can be made from “lithium, graphite, lithium-alloying materials, intermetallics, or silicon”[19]. Electrolytes that compose the main portion of the battery can be liquid, solid or polymer. They are formed “from pastes of active material powders, binders, solvents and additives” which are put onto a foil. These are then stacked between in alternating layers in a “separator anode separator cathode” fashion. Once they have been tested, the battery is sealed. The charging circuit will most likely be on the logic board where the chips reside. Insulation on the outside of the battery will be made from plastic as it is a light, cheap and easy to shape insulator. Once the battery has reached the end of its lifespan, it is possible to recycle it, but it takes “five times the cost of lithium produced from … least costly … process”[20]. This statistic may not be true as there are many ways to extract the lithium including “mechanical, mechanochemical, thermal [and] electrochemical process [es]” that can be used[21]. The method the article referred to which produced the “five times” statistic is unknown and should not be trusted. As research into recycling methods continue, it may be feasible to extract and reuse most of the materials put into the battery. The more efficient the HoloLens is with its power, the less cycles the batteries will have to endure, increasing the battery’s lifespan. The part that will most likely consume the most power would be the processing units because of the sheer amount of tasks the HoloLens needs to complete.

Silicon is the main material used in the production of logic and computational circuits such as central processing units (CPU), graphical processing units (GPU), and integrated circuits (IC). The silicon acts as the base of the chip while extremely small copper traces are put above to make the actual transistors. The HoloLens needs all three of these chips in order to function correctly because in addition to interpreting the surroundings and rendering images, there may be some specialized tasks that would be best performed by ICs. The silicon is extracted from a particular type of sand that is taken off of the ground[22]. It is then purified and made into a cylindrical block which is then cut into flat circular plates. These plates serve as the base of the chip. The copper that is put onto the chip to make circuits is first extracted from the ground as an ore, which is then purified in a forge. Once the silicon has been etched and had a covering applied to it, the copper is put on and specific points are connected to each other[23]. The physical CPU and ICs are made in a similar process, albeit with different circuit designs. The chips can be considered as secondary products as the materials that went in were purified after being extracted from the earth. It should be noted that it would not be very efficient to recycle these components for their raw materials because of small they are. Furthermore, if they are soldered onto the logic board, it would be extremely cost inefficient to remove the chips for use on another system. The CPU and potentially the ICs may not need to be very powerful, and could not be used in the far future with other systems, but they are needed to process the data being received and create the data being outputted by the HoloLens.

The HoloLens is able to accept and interpret commands by the user as well as play sounds. It must have multiple microphones in order to gather sound accurately. The main similarity between microphones and speakers is the magnets, albeit the uses are quite different. A microphone’s magnet is moved by sound pushing on a diaphragm, generation current in the surrounding coils. A speaker moves the magnet via current applied to the coils which in turn moves the diaphragm which attached to the magnet, generating sound. The magnets are generally neodymium which is a rare earth metal that is mined from the ground. Coils surrounding the magnets are usually made of copper because of its high conductivity[24]. Accompanying most microphones and speakers are small circuits that regulate the voltage going into the speaker and a chip that amplifies the signal and reduces noise. In both, there are small wires that transfer the signal to and from the instruments. On the wire there is insulation made from petroleum which protects the pollution of signals from other wires. As these speakers and microphones all fit inside the HoloLens, they have to be really small and it would not be feasible to recycle. The amount of energy needed to recycle these small components would not be worth the amount of reclaimed materials. Microphones and speakers may be better suited for reuse rather than recycling because of this.

A majority of the HoloLens’ volume is occupied by the structures that contain the logic boards as well as the power supply. Materials were assumed to be used in the HoloLens because of their cost and properties. The majority of the materials include, but are not limited to ABS plastic, polycarbonate, acrylic, silicon, copper, and neodymium magnets. All of the materials that were stipulated to be used in the HoloLens are widely available to any company that would like to use them. It is possible to recycle most of the materials used, but it all depends on whether the recycler thinks that the recycled goods are worth his time and money. Even though it may take a considerable amount of energy to transform the materials mentioned into parts for the HoloLens, there may be some unknown material that requires more energy to make and transport than all the ones listed here combined. Until a HoloLens has been taken apart and examined, one can only speculate what materials compose the HoloLens.

[1] "Acrylonitrile Butadiene Styrene." Wikipedia. Wikimedia Foundation, n.d. Web. 30 Jan. 2016.

[2] "CIEC Promoting Science at the University of York, York, UK." Propene (Propylene). The University of York, 24 Nov. 2013. Web. 17 Feb. 2016.

[3] "Styrene (monomers)." Wikipedia. Wikimedia Foundation, n.d. Web. 14 Mar. 2016.

[4] Schmidhuber, Jurgen. "Haber-Bosch Process." HABER & BOSCH - Haber-Bosch Process. Nature, n.d. Web. 17 Feb. 2016.

[5] Faes, Eric. "Acrylonitrile-Butadiene-Styrene." PlasticsEurope. Plastics Europe, n.d. Web. 14 Mar. 2016.

[6] "Polycarbonate." Wikipedia. Wikimedia Foundation, n.d. Web. 30 Jan. 2016.

[7] "Phosgene." Wikipedia. Wikimedia Foundation, n.d. Web. 17 Feb. 2016.

[8] "Bisphenol A." Wikipedia. Wikimedia Foundation, n.d. Web. 17 Feb. 2016.

[9] "Acetone Production and Manufacturing Process." Acetone Production and Manufacturing Process. Reed Business Information, 1 Nov. 2007. Web. 02 Mar. 2016.

[10] AP-42, CH 8.11: Chlor-Alkali (n.d.): 1+. US EPA. EPA. Web. 17 Feb. 2016.

[11] "Polycarbonate Recycling." Plastic Expert. Plastic Expert, n.d. Web. 17 Feb. 2016.

[12] "Sodium Cyanide." Sodium Cyanide. Orica, n.d. Web. 14 Mar. 2016.

[13] "How Is Methanol Made?" Methanol Institute. Methanol Institute, 2011. Web. 17 Feb. 2016.

[14] "Acrylic Plastic." How Acrylic Plastic Is Made. Advameg Inc., n.d. Web. 30 Jan. 2016.

[15] "PMMA Acrylic Recycling." Plastic Expert. Plastic Expert, n.d. Web. 17 Feb. 2016.

[16] "About Glass." All. Brit Glass, 2003. Web. 02 Mar. 2016.

[17] "Lithium." Minerals Education Coalition. Minerals Education Coalition, n.d. Web. 17 Feb. 2016.

[18] Daniel, Claus. "Materials and Processing for Lithium-ion Batteries." Materials and Processing for Lithium-ion Batteries. TMS, Sept. 2008. Web. 30 Jan. 2016.

[19] See above

[20] Kumar, Aswin. "The Lithium Battery Recycling Challenge." Recycling. Waste Management World, 01 Aug. 2011. Web. 17 Feb. 2016.

[21] Xu, Jinqui, H. R. Thomas, Rob W. Francis, Ken R. Lum, Jingwei Wang, and Bo Liang. "The Recycling of Lithium-ion Secondary Batteries." The Recycling of Lithium-ion Secondary Batteries. ScienceDirect, 2 Mar. 2008. Web. 02 Mar. 2016.

[22] "Silica." Minerals Education Coalition. Minerals Education Coalition, n.d. Web. 30 Jan. 2016.

[23] Goodhead, Paul. "How to Make a CPU: From Sand to Shelf." Bit-tech. Bit Tech, 10 June 2010. Web. 30 Jan. 2016.

[24] Sibberson, Ernst S. "Microphone." How Microphone Is Made. How Products Are Made, n.d. Web. 30 Jan. 2016.

Bibliography

"About Glass." All. Brit Glass, 2003. Web. 02 Mar. 2016.

"Acetone Production and Manufacturing Process." Acetone Production and Manufacturing Process. Reed Business Information, 1 Nov. 2007. Web. 02 Mar. 2016.

"Acrylic Plastic." How Acrylic Plastic Is Made. Advameg Inc., n.d. Web. 30 Jan. 2016.

"Acrylonitrile Butadiene Styrene." Wikipedia. Wikimedia Foundation, n.d. Web. 30 Jan. 2016.

AP-42, CH 8.11: Chlor-Alkali (n.d.): 1+. US EPA. EPA. Web. 17 Feb. 2016.

"Bisphenol A." Wikipedia. Wikimedia Foundation, n.d. Web. 17 Feb. 2016.

Cavette, Chris. "Printed Circuit Board." How Printed Circuit Board Is Made. How Products Are Made, n.d. Web. 30 Jan. 2016.

"CIEC Promoting Science at the University of York, York, UK." Propene (Propylene). The University of York, 24 Nov. 2013. Web. 17 Feb. 2016.

"Cracking." Wikipedia. Wikimedia Foundation, n.d. Web. 02 Mar. 2016.

Daniel, Claus. "Materials and Processing for Lithium-ion Batteries." Materials and Processing for Lithium-ion Batteries. TMS, Sept. 2008. Web. 30 Jan. 2016.

Faes, Eric. "Acrylonitrile-Butadiene-Styrene." PlasticsEurope. Plastics Europe, n.d. Web. 14 Mar. 2016.

Goodhead, Paul. "How to Make a CPU: From Sand to Shelf." Bit-tech. Bit Tech, 10 June 2010. Web. 30 Jan. 2016.

"How Is Methanol Made?" Methanol Institute. Methanol Institute, 2011. Web. 17 Feb. 2016.

Kumar, Aswin. "The Lithium Battery Recycling Challenge." Recycling. Waste Management World, 01 Aug. 2011. Web. 17 Feb. 2016.

"Lithium." Minerals Education Coalition. Minerals Education Coalition, n.d. Web. 17 Feb. 2016.

"Phosgene." Wikipedia. Wikimedia Foundation, n.d. Web. 17 Feb. 2016.

"Polycarbonate." Wikipedia. Wikimedia Foundation, n.d. Web. 30 Jan. 2016.

"Polycarbonate Recycling." Plastic Expert. Plastic Expert, n.d. Web. 17 Feb. 2016.

"Poly(methyl Methacrylate)." Wikipedia. Wikimedia Foundation, n.d. Web. 30 Jan. 2016.

"PMMA Acrylic Recycling." Plastic Expert. Plastic Expert, n.d. Web. 17 Feb. 2016.

"Refining Silicon." Refining Silicon. PV Education, n.d. Web. 30 Jan. 2016.

Schmidhuber, Jurgen. "Haber-Bosch Process." HABER & BOSCH - Haber-Bosch Process. Nature, n.d. Web. 17 Feb. 2016.

Sibberson, Ernst S. "Microphone." How Microphone Is Made. How Products Are Made, n.d. Web. 30 Jan. 2016.

Sibberson, Ernst S. "Stereo Speaker." How Stereo Speaker Is Made. How Products Are Made, n.d. Web. 30 Jan. 2016.

"Silica." Minerals Education Coalition. Minerals Education Coalition, n.d. Web. 30 Jan. 2016.

"Sodium Cyanide." Sodium Cyanide. Orica, n.d. Web. 14 Mar. 2016.

"Styrene (monomers)." Wikipedia. Wikimedia Foundation, n.d. Web. 14 Mar. 2016.

Xu, Jinqui, H. R. Thomas, Rob W. Francis, Ken R. Lum, Jingwei Wang, and Bo Liang. "The Recycling of Lithium-ion Secondary Batteries." The Recycling of Lithium-ion Secondary Batteries. ScienceDirect, 2 Mar. 2008. Web. 02 Mar. 2016.

Anwana Ntofon

DES 40A – Professor Cogdell

March 14th, 2016

Power, Productivity, and Potential: The Microsoft HoloLens

In recent years, virtual and augmented reality have become rapidly growing industries. From a commercial and mainstream standpoint, they have been in constant competition, due to perceived advantages and disadvantages. Virtual reality technology generates computer simulations in order to create real-life or fabricated environments. In contrast, augmented reality technology generates computer images on top of real-life environments. This allows users to incorporate this technology into their daily lives.

A notable and upcoming device is the Microsoft HoloLens. It is a wearable headset that is capable of projecting 3-D holograms into the real world. For this reason, Microsoft states that the device captures mixed reality (combination of virtual and augmented reality). The level of power that the HoloLens will possess is a significant indicator in the amount embodied energy outputted by all of its components. Microsoft’s HoloLens is a revolutionary product that allows its users to visualize their ideas and maximize the productivity of certain tasks, taking place within an immersive and dynamic world. Its composition of sensors, chips, and other components undergo a lifecycle that entails the acquisition of raw materials, the manufacturing process, distribution and transportation, use and maintenance, recycling materials, and handling waste.

The raw materials of the HoloLens consist of copper, lithium, silicon, and many others. For example, copper is an element that can be used to transfer electricity, a key component for chip and circuit design[1]. It exists within copper ore, which is mined in open pit or underground mines[2]. Drilling machines and explosives are used to uncover copper ore. Most drilling machines use gas or oil as their fuel source, both of which are forms of primary energy. It follows that explosives such as ANFO (ammonium nitrate fuel oil mixture) also contain oil[3]. Other materials are taken from the ground by heating processes (i.e. heating sand to produce silicon) and chemical mixtures (i.e. melting of silica, limestone, ash, and other ingredients)[4]. Most of the raw materials that make up the HoloLens are extracted through primary energy processes, which use oil, gas, and coal fuel sources.

The primary energy processes align with the processes used to transport these raw materials to factories. Some materials are in different forms when they are extracted (i.e. liquid, ore), so they are handled by different methods. Ore that is extracted from mines is transported to factories by trucks, which use oil as their fuel source. Trains can also serve as transportation, using coal as their respective fuel source. Through these modes of transportation, the raw materials can be shaped into its final form so that different components are assembled into a working product. Theese steps include manufacturing, processing, and formulation of the device.

Before proceeding much further, I want to note that the Microsoft HoloLens has not yet been shipped to consumers or developers; shipping for developers exclusively begins March 30th, 2016. Therefore, issues arose when researching this product because major details have been withheld from the public and the press in order to divert attention from Microsoft’s current project. My group, as well as I, had to make educated guesses. We researched other technologies that shared similar characteristics, such as the Google Glass and the Samsung Gear Virtual Reality headset. Shared characteristics include: computer chips, processors (i.e. CPUs, GPUs), sensors, and other features. This is the reason for my speculation of how raw materials are processed and the length of time that goes into manufacturing certain components (glass, camera, etc.).

Nevertheless, I speculate that machines used to process the raw materials utilize thermal, electrical, chemical, and mechanical forms of energy. Revisiting the copper example, it goes through several processes (beneficiation, refining, smelting, etc.), which all use a variety of energies[5]. Another example is of fiberglass, whose quality is maintained by being transferred through an electric melter, ultimately using thermal heat to melt the glass and observe any potential flaws[6]. The fiberglass is speculated to be the visor that covers the eyes of a HoloLens user, similar to how sunglasses cover a person’s eyes. Large amounts of heat are added in melting process, such as with the heating of sand. The carbon in this process is able to reach temperatures close to 2200o C[7]. In addition, the glass mixture may take over 20 hours to obtain its desired form[8].

The length of particular processes can be overwhelming, as well as types of power used. These include coal-powered electricity and fossils fuels in machines. The reason that this is overwhelming is because that these resources are not sustainable and they are negatively affecting the climate. The more the HoloLens products will continue to ship, the more manufacturers have to utilize machines and methods that cause an increase in global warming and severe climate change. Due to the HoloLens’ global reach in materials, the amount of fuel is perceived to be severe as well.

The amount of fuel required to transport the product to stores as well as consumers must be speculated because of the product’s upcoming release date. However, if the HoloLens is expected to ship in the U.S. first, the amount of fuel is speculated to be thousands of gallons of gas, roughly 8,000-10,000 gallons. However, if these products are being distributed on a global level, the number may double or even triple. The global level is included because some devices within the HoloLens are located in different areas of the world, such as the inertial measurement unit from EPSON, a Japanese technology company[9]. Transportation may range from weeks to months respectively but there is no guarantee. The use of the product may inform superiors within the Microsoft and the HoloLens team if it is a smart move to ship out many products that may possess potential technology flaws (i.e. malfunctioning of processors).

The HoloLens will use energy constantly in order to render and display 3-D holographic images into a user’s reality. There is not a fixed amount of energy that will be used. Tasks such as image rendering, sensor functions, and graphic display will be working in a synergistic manner. Furthermore, the HoloLens, may be incorporating an unreleased Intel Atom chip in its design, noted for its small size (14nm). An example of such a chip is the Intel Atom x5-Z8550 Processor, which includes multiple cores and threads for multitasking applications and a 1.44 GHz Processor Base Frequency[10].

Although it is difficult to determine if the HoloLens can output more power with more advanced chips, the kind of energy most likely used is electric and electromagnetic energy. Other questions such as reuse and maintenance of the product are also tough to identify, for reasons mentioned above. In terms of the product’s longevity, this time will not be known until consumers have used it for a few years. Only then can a logical assessment be made about recycling certain materials.

I hypothesize that recycling will not take much energy because I do not believe that the hardware will be recycled freely or at all. It may turn out that the Microsoft HoloLens team may decide to dispose of any important components that make up the product as a precaution against their competition. However, if I were to observe the recycling process from another perspective, I believe that it would take quite a deal of energy to recycle materials from fiberglass, sensors, and the multiple chips involved. Each component may need to be handled in a specific manner, to raise its chances of reusability.

For the Microsoft HoloLens to end its life-cycle at an e-waste (electronic waste) location, an individual needs to assume that it can be processed there. If it can, then the waste machines would be capable of the decimation or modification of such a product. One company that handles e-waste is Krause Manufacturing, located in San Diego, California. It possesses optical and regular sorting techniques. Machines within the optical sorting equipment are the CIRRUS, L-VIS, and METALSORT[11]. The CIRRUS in particular has features that include an all-metal detector, a color sensor and a color touch-screen user interface. The machines appear to merely sort materials into categories such as scrap metals, plastics, and so on. The end of the lifecycle appears to be more relaxed and less harsh than one would have expected.

As its shipping date approaches, the Microsoft HoloLens is under major scrutiny from tech enthusiasts, critics, and consumers. Logical speculations can be made through the observation of other wearable devices and their corresponding raw materials. The true embodied energy of the HoloLens is yet to be determined, however; the device is still one of Microsoft’s most important products in the history of the company. Familiar software (i.e. Windows 10) and hardware components (i.e. CPUs) exist within the powerful wearable headset that seeks to revolutionize what it means to visually express one’s ideas. In addition, the level of productivity and connectivity between other users make it a promising device.

From raw materials to waste, the HoloLens’ journey through manufacturers and distributors allow the product to become a global, shared experience. The Microsoft HoloLens has designed a fresh concept of mixed reality, which has the potential to create an immersive and worthwhile experience.

[1] Hamilton, Jason. “Copper.” ScienceViews. 8 Aug. 2008. 12 Mar. 2016 <http://scienceviews.com/geology/copper.html>.

[2] “Copper.” How Products are Made. 12 Mar. 2016

<http://www.madehow.com/Volume-4/Copper.html>.

[3] “Explosives – ANFO (Ammonium Nitrate – Fuel Oil).” GlobalSecurity.org. 12 March 2016

< http://www.globalsecurity.org/military/systems/munitions/explosives-mining2.htm >.

[4] Bank, Eric. "Temperature Needed to Turn Silicon Into Glass." Seattlepi. 12 Mar. 2016

< http://education.seattlepi.com/temperature-needed-turn-silicon-glass-3715.html>.

[5] “Copper – From Beginning to End” Copper Development Association Inc. 12 March 2016

<http://www.copper.org/education/copper-production>.

[6] “Fiberglass.” How Products are Made. 12 Mar. 2016

< http://www.madehow.com/Volume-2/Fiberglass.html>.

[7] Kubach, Charles. “Silicon.” The Mineral Mine. 12 Mar. 2016

< http://www.mine-engineer.com/mining/mineral/silicon.htm>.

[8] Bank, Eric. "Temperature Needed to Turn Silicon Into Glass." Seattlepi. 12 Mar. 2016

< http://education.seattlepi.com/temperature-needed-turn-silicon-glass-3715.html>.

[9] “Epson Inertial Measurement Unit.” EPSON. 3 Feb. 2016

< https://www.epsondevice.com/download_e/imu/>.

[10] “Intel Atom x5-Z8550 Processor (2M Cache, up to 2.40 GHz).” Intel. 29 Feb. 2016 < http://ark.intel.com/products/93360/Intel-Atom-x5-Z8550-Processor-2M-Cache-up-to-2_40-GHz>.

[11] “eWaste Recycling Equipment.” Krause Manufacturing. 12 March 2016 <http://www.krausemanufacturing.com/recycling-equipment/optical-sorting-equipment/e-waste-recycling-equipment/ >.

BIBLIOGRAPHY

Hamilton, Jason. “Copper.” ScienceViews. 8 Aug. 2008. 12 Mar. 2016 <http://scienceviews.com/geology/copper.html>.

Bank, Eric. "Temperature Needed to Turn Silicon Into Glass." Seattlepi. 12 Mar. 2016

< http://education.seattlepi.com/temperature-needed-turn-silicon-glass-3715.html>.

Kubach, Charles. “Silicon.” The Mineral Mine. 12 Mar. 2016

< http://www.mine-engineer.com/mining/mineral/silicon.htm>.

“Fiberglass.” How Products are Made. 12 Mar. 2016

< http://www.madehow.com/Volume-2/Fiberglass.html>.

“Copper.” How Products are Made. 12 Mar. 2016

<http://www.madehow.com/Volume-4/Copper.html>.

“Intel Atom x5-Z8550 Processor (2M Cache, up to 2.40 GHz).” Intel. 29 Feb. 2016

< http://ark.intel.com/products/93360/Intel-Atom-x5-Z8550-Processor-2M-Cache-up-to-2_40-GHz >.

“Epson Inertial Measurement Unit.” EPSON. 3 Feb. 2016

< https://www.epsondevice.com/download_e/imu/>.

“Explosives – ANFO (Ammonium Nitrate – Fuel Oil).” GlobalSecurity.org. 12 March 2016

< http://www.globalsecurity.org/military/systems/munitions/explosives-mining2.htm >.

“eWaste Recycling Equipment.” Krause Manufacturing. 12 March 2016

< http://www.krausemanufacturing.com/recycling-equipment/optical-sorting-equipment/e-waste-recycling-equipment/ >.

“Copper – From Beginning to End” Copper Development Association Inc. 12 March 2016

<http://www.copper.org/education/copper-production>.

Michaela-Hope Poblete

Professor C. Cogdell

DES40

March 14, 2016

The Waste and Emissions of the Microsoft HoloLens

As each year brings us wider screens, clearer cameras, improved multi-touch, and higher definition, the consumers, creators, and scientists aspire towards holographic projection and the Microsoft HoloLens breaks ground in that field. Microsoft officially defined the HoloLens as “the first fully untethered holographic computer running Windows 10. It is completely untethered - no wires, phones, or connection to a PC needed. Microsoft HoloLens allows you to place holograms in your physical environment and provides a new way to see your world.” The computer was created to be worn on the head and looks similar to a pair of sunglasses. While many components of the HoloLens are still expected to make advancements, the old must be done away with by means of waste disposal and recycling. Like all other electronic products, the Microsoft HoloLens will eventually and unavoidably create emissions and waste from its manufacturing and disposal.

Because the Microsoft HoloLens has yet to be mass produced, my research of the potential waste and emissions from the Microsoft HoloLens is significant speculation based off of what has happened to previous electronic devices in its manufacturing and after serving its full life span. The materials composing the HoloLens include but are not limited to, silicon doped with boron or arsenic (for the Central Processing Unit), copper, a metal called hafnium, gold[1], aluminum oxide and ruthenium oxide for resistors[2], plastic that is chemically modified for the product, metal alloys[3], glass for the lenses, and a host of other chemicals and materials. Without doubt, the many materials composing the HoloLens takes effort to extract or produce. That effort will eventually produce waste and emissions. According to the Multilateral Investment Guarantees Agency Environmental Guidelines for Electronics Manufacturing, “Potential air emissions from semiconductor manufacturing include: toxic, reactive, and hazardous gases; organic solvents; and particulates from the process. Potential air emissions from the manufacture of printed circuit boards include: acids such as sulfuric, hydrochloric, phosphoric, nitric and acetic; chlorine; ammonia; and organic solvent vapors… Effluents (waste and emissions released into environmental waterways) from the manufacture of semiconductors may have a low pH from hydrofluoric, hydrochloric, and sulfuric acids, and may contain organic solvents… Effluents from the manufacture of printed circuit boards may contain: organic solvents, vinyl polymers, stannic oxide, metals such as copper, nickel, iron chromium, tin, lead, palladium and gold, cyanides, sulfates, fluorides and fluoborates, ammonia, and acids.[4]” A significant amount of waste and emissions are released into the surrounding environment with the manufacturing of these two components of the HoloLens alone. It is reasonable to assume that much more waste, emissions, and byproducts results in the manufacturing when one takes into account the rest of the components that must be manufactured for the HoloLens to fully function.

After the manufacturing process is over, the HoloLens will be shipped to Microsoft stores and headquarters around the world. With some hardware and most likely the HoloLens being manufactured in Asia[5], the products will inevitably take a long journey to North America for dispersion. The ways of transportation from Asia to North America will be via airplane or ship. Let’s speculate, for a moment, that the HoloLens will be made specifically in China, and that the product will be shipped on a Boeing 747 airplane. The 747 airplane burns 5 gallons of fuel per mile[6] and the distance between China and the US is approximately 7233 miles. That makes the total amount of fuel burned 36,165 gallons. Much carbon dioxide is released into the atmosphere. A plane releases 53 pounds of carbon dioxide per mile[7] which means that a whopping total of 383,349 pounds of carbon dioxide is released into the air from China to the US. Once the products arrive in North America, the electronics will be shipped around the US by different means of transportation including a semi-truck. Let’s say the HoloLens were to arrive at Redmond, Washington (the headquarters of Microsoft) and needed to be shipped to New York City by way of semi-truck. A semi-truck will burn 6.5 miles per gallon[8]. Google maps shows that the miles between New York City and Redmond, Washington totals to 2866. That’s 18,629 gallons of fuel burned on a one way trip. I was unable to find information on semi-truck carbon dioxide emissions per mile, but one can imagine the extent of carbon dioxide emitted during a single drive from Redmond to New York City based on the amount of gallons of fuel burned. The actual use of the device is expected to have a minuscule amount of emissions compared to its transportation.

The HoloLens is untethered which means that it won’t run from electricity through the power outlets that we commonly use for our other electronics. It’s safe to speculate that it will store power in a battery and can be recharged like any other electronic device. In a positive light, emissions during the HoloLens use is at its least amount during its entire life cycle which is what Microsoft actively seeks to improve in its own products. The high efficiency of the product during use will lead to little to no emissions and waste. The low emissions, low waste production during actual use will change to high emissions and high waste production once the HoloLens has served its entire life span and is ready to be recycled and/or disposed of.

Microsoft seems to have a strong recycling policy for its products and takes pride in the work it does to reduce its carbon footprint. Microsoft has explicitly stated in its environmental principles, “Microsoft actively works to protect our natural resources by doing the following:

Conserving, reusing, and recycling. When it is feasible, Microsoft conserves natural resources by using recycled materials and supplies, efficiently using energy, and participating in recycling programs for Microsoft products after they have served their useful life. Microsoft encourages and supports the sustainable use of renewable natural resources. Reducing and disposing of waste. Microsoft reduces and where possible eliminates waste through source reduction and recycling at company facilities. All waste is safely and responsibly handled and disposed of.

Developing safe and sustainable products. Microsoft develops, manufactures, and markets products that are safe for their intended use. Our environmental policies and practices aim to protect, conserve, and sustain the world's natural resources and also protect Microsoft customers and the communities where we live and operate.[9]” They act upon their environmental principles by incorporating a “Recycle for Rewards” program. In the program, the consumer can bring an outdated electronic and turn it in at a Microsoft store to receive credit towards a new Microsoft product. The company will then take the electronic and salvage any recyclable parts still in tact. There is no service charge[10].

There are two other ways in which the HoloLens will likely be disposed of. One possibility can be through e-waste recycling plants based in the United States[11]. Another possible disposal method would be through the mass shipping and disposal of old electronics in foreign continents and countries such as Africa[12] and China[13]. Although the process is not without flaws, recycling at e-waste recycling plants in the US proves to be a better way of disposing an electronic device. Once the electronics arrive at the e-waste recycling plant, it will be disassembled and circuitboards[14] will be separated from the product. CPUs will also be separated from the circuitboards and will be stripped of the gold, silver, and copper[15]. Other non-recyclable materials will be broken down to smaller pieces[16]. Metal alloys are melted down and the iron can be sold to different companies[17]. Not only does this method help the environment, but it also proves to be a benefit economically.

The second method would be through e-waste disposal in foreign countries. Electronic waste is disposed of in North America and will then be shipped to foreign countries. Notably Guiyu town located in China leads the way in waste collection[18]. Unfortunately, this is a largely inefficient method of disposal and is not environmentally friendly[19]. Because of the unregulated extraction methods and recycling methods, many toxins and harmful chemicals are released into the environment which even effects the health of the local people[20]. Fortunately Microsoft is taking active steps in increasing efficiency of the product itself as well as reducing the amount of wastes it produces[21].

Every product, whether organic or inorganic, will result in waste. Plants die and decompose, the iPhone 2 became obsolete, old food rots, buildings crumble, and the Microsoft HoloLens is no exception. Every product inevitably produces wastes and emissions, and the innovative product will do so like the preceding electronics although the amount of wastes the HoloLens will produce should be significantly less since Microsoft has designed it with efficiency and with the environment in mind. With that in mind, we can, in good conscience, look forward to the innovative product that will soon be released and explore the surreal experience of augmented reality.

[1] Free Documentary “HOW IT WORKS - Computer Recycling” Youtube Jan 29, 2014 Web. Mar 14, 2016 https://www.youtube.com/watch?v=zU62hh3DBfg

[2] PC Plus, “The Weird and Wonderful Materials that Make Up Your PC” July 22, 2012 Mar 14, 2016 http://www.techradar.com/us/news/computing/pc/the-weird-and-wonderful-materials-that-make-up-your-pc-1089510

[3] “ Gizmodo “Watch Your Dead Tech Get Demolished at an E-Waste Recycling Plant” Mar 20, 2015 Youtube. Mar 14, 2016 https://www.youtube.com/watch?v=EDVCldfYJ8k

[4] Multilateral Investment Guarantee Agency, Multilateral Investment Guarantees Agency

Environmental Guidelines for Electronics Manufacturing Mar 14, 2016 https://www.miga.org/documents/ElectronicsManufacturing.pdf

[5] Dignan, Larry “Microsoft moves Nokia manufacturing from China to Vietnam” July 17, 2014 March 14, 2016, http://www.zdnet.com/article/microsoft-moves-nokia-manufacturing-from-china-to-vietnam/

[6] How much fuel does an international plane use for a trip?” April 01, 2000 March 14, 2016 http://science.howstuffworks.com/transport/flight/modern/question192.htm

[7] “Airlines” March 14, 2016 http://blueskymodel.org/air-mile#

[8] Berg, Phil “10 Things You Didn't Know About Semi Trucks” August 08, 2012 Web. March 14, 2016

http://www.popularmechanics.com/cars/trucks/g116/10-things-you-didnt-know-about-semi-trucks/

[9] “ Microsoft “Corporate Social Responsibility” March 14, 2016 Web. https://www.microsoft.com/about/business-corporate-responsibility/environmental-sustainability/

[10] Microsoft “Don't throw away free money. Trade in before you upgrade.” March 14, 2016 Web. https://www.microsoft.com/en-us/store/locations/recycle

[11] “eWaste Recycling Equipment.” Krause Manufacturing. 12 March 2016 <http://www.krausemanufacturing.com/recycling-equipment/optical-sorting-equipment/e-waste-recycling-equipment/ >.

{12] SBS Dateline “E-Waste Hell” Sep 25, 2011 Youtube Mar 14, 2016 https://www.youtube.com/watch?v=dd_ZttK3PuM

{13} M.H. Wonga, , , S.C. Wua, W.J. Denga, X.Z. Yua, Q. Luoa, b, A.O.W. Leunga, C.S.C. Wongc, W.J. Luksemburgd, A.S. Wongd "Export of toxic chemicals – A review of the case of uncontrolled electronic-waste recycling” Oct. 11, 2006 Mar. 14, 2016 Web. http://www.sciencedirect.com/science/article/pii/S026974910700098X

[14] Free Documentary “HOW IT WORKS - Computer Recycling” Youtube Jan 29, 2014 Web. Mar 14, 2016 https://www.youtube.com/watch?v=zU62hh3DBfg

[15] Free Documentary “HOW IT WORKS - Computer Recycling”

[16] Sims Recycling Global “How Computers and Electronics Are Recycled” Youtube Nov 07,2012 Mar 14, 2016 https://www.youtube.com/watch?v=Iw4g6H7alvo

[17] Gizmodo “Watch Your Dead Tech Get Demolished at an E-Waste Recycling Plant”

[18] M.H. Wonga, , , S.C. Wua, W.J. Denga, X.Z. Yua, Q. Luoa, b, A.O.W. Leunga, C.S.C. Wongc, W.J. Luksemburgd, A.S. Wongd "Export of toxic chemicals – A review of the case of uncontrolled electronic-waste recycling” Oct. 11, 2006 Mar. 14, 2016 Web. http://www.sciencedirect.com/science/article/pii/S026974910700098X

[19] M.H. Wonga, , , S.C. Wua, W.J. Denga, X.Z. Yua, Q. Luoa, b, A.O.W. Leunga, C.S.C. Wongc, W.J. Luksemburgd, A.S. Wongd

[20] Journeyman Pictures “China's Horrendous Electronic Trash Dump” Youtube Oct. 27, 2007 Mar 14, 2016 https://www.youtube.com/watch?v=ZHTWRYXy2gE

[21] Microsoft “Corporate Social Responsibility”

Bibliography

Berg, Phil “10 Things You Didn't Know About Semi Trucks” Web. August 08, 2012

Dignan, Larry “Microsoft moves Nokia manufacturing from China to Vietnam” Web. July 17, 2014

Microsoft “Corporate Social Responsibility” March 14, 2016 Web. https://www.microsoft.com/about/business-corporate-responsibility/environmental-sustainability/

Microsoft “Don't throw away free money. Trade in before you upgrade.” March 14, 2016 Web.

https://www.microsoft.com/en-us/store/locations/recycle

Free Documentary “HOW IT WORKS - Computer Recycling” Online Video Clip

Youtube January 29, 2014 Web. Mar 14, 2016

Journeyman Pictures “China's Horrendous Electronic Trash Dump” Online Video Clip

Youtube Oct. 27, 2007 Mar 14, 2016

SBS Dateline “E-Waste Hell” Sep 25, 2011 Online Video Clip Youtube Mar 14, 2016

“Airlines” March 14, 2016 http://blueskymodel.org/air-mile#

“How much fuel does an international plane use for a trip?” April 01, 2000 March 14, 2016 http://science.howstuffworks.com/transport/flight/modern/question192.htm

PC Plus, “The Weird and Wonderful Materials that Make Up Your PC” July 22, 2012

Mar 14, 2016 http://www.techradar.com/us/news/computing/pc/the-weird-and-wonderful-materials-that-make-up-your-pc-1089510

Multilateral Investment Guarantee Agency, Multilateral Investment Guarantees Agency

Environmental Guidelines for Electronics Manufacturing Mar 14, 2016

Gizmodo “Watch Your Dead Tech Get Demolished at an E-Waste Recycling Plant” Mar 20, 2015 OnlineVideo Clip. Youtube. Mar 14, 2016 https://www.youtube.com/watch?v=EDVCldfYJ8k

M.H. Wonga, , , S.C. Wua, W.J. Denga, X.Z. Yua, Q. Luoa, b, A.O.W. Leunga, C.S.C. Wongc, W.J. Luksemburgd, A.S. Wongd "Export of toxic chemicals – A review of the case of uncontrolled electronic-waste recycling” Oct. 11, 2006 Mar. 14, 2016 Web. http://www.sciencedirect.com/science/article/pii/S026974910700098X

Sims Recycling Global “How Computers and Electronics Are Recycled” Online Video Clip Youtube Nov 07, 2012 Mar 14, 2016