Design Life-Cycle

assess.design.(don't)consume

Jada Ferguson

Paulina Uytiepo, Yiqing Zhao

3/15/2023

Des 40A Winter Quarter

Professor Cogdell

The Raw Materials of the Grandmaster Chime

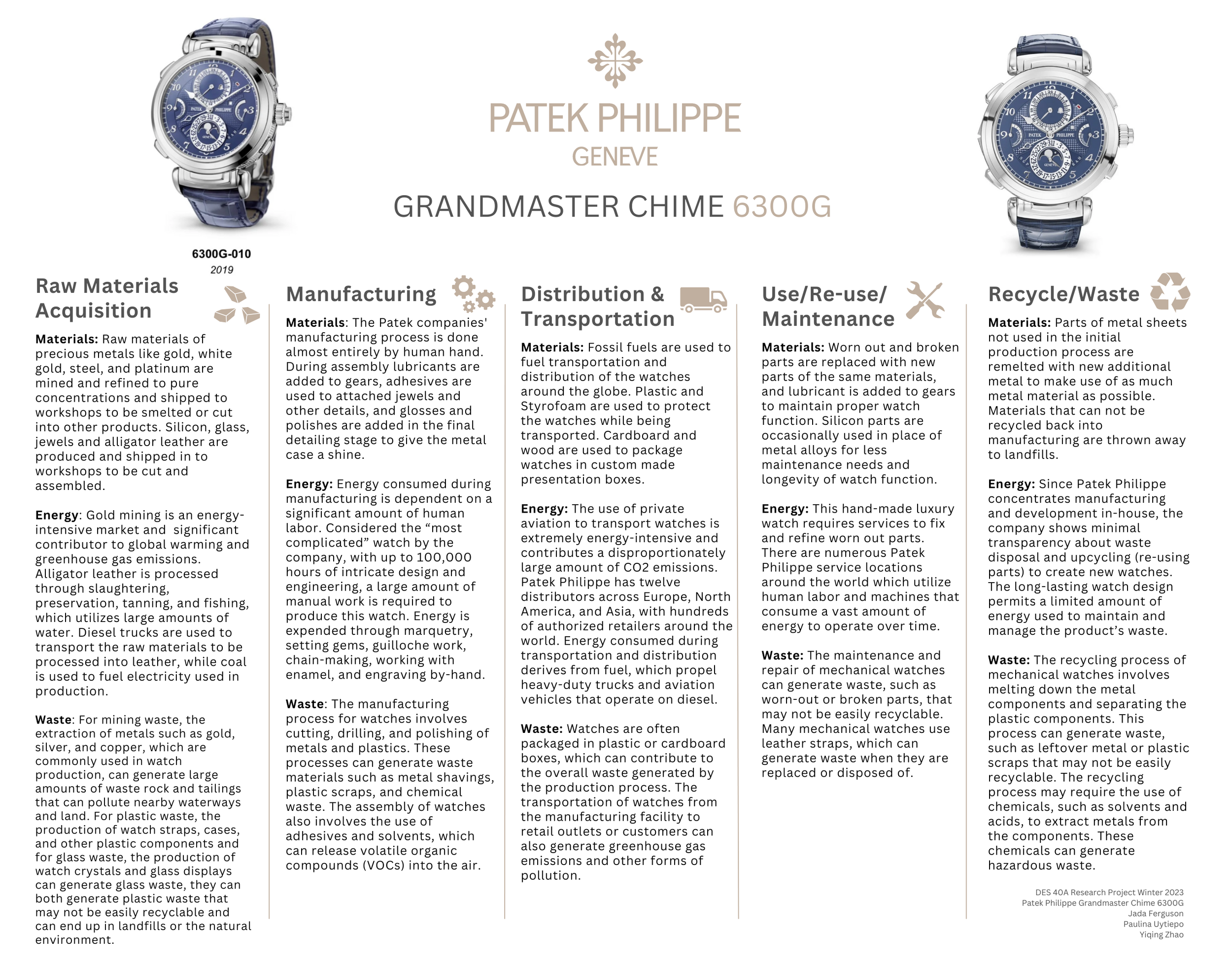

Owning a watch from a luxury brand is a symbol of wealth, and signals to your colleagues that you are someone of importance. Luxury watches have a social factor of high status and wealth that make them desirable to the public. Patek Philippe is a luxury watch company from Switzerland founded in 1839. Patek Philippe watches are exclusive and expensive to make, watches made by Patek Philippe are considered a luxury to own. The Patek company prides itself on its heritage and producing quality over quantity. Every watch is made by an experienced watchmaker and quality checked after every stage of the production process (Patek Philippe SA). For the company's 175th anniversary a special watch called the Grandmaster Chime was made. The Grandmaster chime is the most complex watch Patek has ever made, the watch is so complex only 6 were made (Clerizo, 2014). The Patek Philippe Grandmaster Chime limited edition watch has large amounts of expensive and finely detailed raw materials used through its lifecycle that limits the amount of watches that can be made.

Many materials make up the Grandmaster Chime, the main materials to focus on in the raw material acquisition stage are various precious metals like gold, white gold, steel, and platinum. Other materials used are glass, jewels, opaline, alligator leather, and silivnar and other silicon based materials. 18k solid gold is used for the watches' dial plates and other decorative details. 18k gold is 75% gold and 25% another alloy like palladium. The outer case of the grandmaster chime is made entirely of white gold. White gold is gold combined with another alloy like nickel to make a white or silvery gold color (Henderson and Dippal, 2005). To make 18k gold and white gold, palladium, gold, and nickel are mined from their respective ore and then smelted to remove any impurities. The cooled metals are then refined through chlorination or acid leaching to become 99.9% concentrated, which is the industrial standard for metals. The pieces of gold are then combined with nickel pieces to make white gold or combined with pieces of palladium to make 18k yellow gold (Education, 2018). The metals are smelted together and made into sheets that can then be shipped to the warehouse to be used.

The gears and watch mechanics of the grandmaster chime are made in house and made of mostly platinum and stainless steel. The mining and refinery of platinum is a similar process to gold. Platinum is mined from platinum ore, or as a byproduct of other ores. The platinum is refined to 99.9% concentration and the pieces are then sent to the warehouse to be cut or melted into the specific parts needed for the watch to work (Education, 2018). Stainless steel is made of many metal alloys and comes in several different types. The most common elements used in stainless steel are iron ore, chromium, silicon, nickel, carbon, nitrogen, and manganese. These materials are melted together at intense heat, then casted in rods or sheets. The sheets are then sent out and cut into the parts needed for gears or other watch parts (Stainless steel, 2006). The jewels used in watches are bearings, their smooth frictionless surface makes movement of gears easier (Smith). Patek uses synthetic rubies for its watches, synthetic rubies are aluminum oxide dyed red by chromium and have the same structure as a naturally made ruby (Arem, 1986). The rubies are cut and polished to the correct shape and ready to be used in the watch.

Silivnar and silicon are used for some of the gears and springs of the watch. Silivnar is a silicon base material that is used by Patek to replace some of the metal alloys that would normally be used. It is a lightweight and smoother material causing the watch to use less lubricant and schedule less maintenance appointments (Patek Philippe SA). Silivnar is a silicon based material and shares a close production process with silicon. Silicon is made from quarts or gravel that is infused with carbon and heated at high temperatures. At high temperatures oxygen is removed and it creates liquid silicon. It is refined to improve its purity concentrate then heated and casted into whatever pieces are needed for the watch (silicon, 2009).

Patek watches use sapphire crystal glass as a covering in the watch face. Sapphire crystal glass is made similarly to synthetic rubies, aluminum oxide is crystallized at high temperatures making a scratch resistant glass (Arem, 1986). Blue opaline; a milky opaque glass dyed blue is also made and used in the watch face. Blue opaline is made from silica sand, limestone, soda ash, and cobalt oxide to give a blue tint, the materials are mixed and fired in a furnace at high heat. The glass is cooled then scored to be the needed size and shape.

The wrist straps of the grandmaster chime are made of dyed alligator leather. An Alligator raised in a leather farm is killed and skinned of its underbelly hide then scraped using a dull tool to remove some of the flesh and fat. The skin is washed then hung up to dry, once dried salt is applied 2-3 times to dry out the skin and stop decomposition of the skin. The skin is then cured through brining the hide in a mixture of bleach, borax and salt mixture for around 48 hours. The hide is then washed to remove any remaining fat from the hide and hung to dry again. The leather then moves to the dying stage and is rewet and chemically treated for different colors. The leather is added to a drum filled with the color dye for a few hours, then given a raised scale pattern using a dry shaving machine. Finally the leather is given a gloss and a glazing to make the leather harden and waterproof (Jiwa, 2021). These raw materials are collected and transformed into the parts needed before being shipped to the Patek assemble workshops where they are cut and assembled together.

In the manufacturing stages human energy, polishes, glosses, benzine lubricant, and adhesive materials are added to assemble and prime the watches. The manufacturing process at Patek is largely done by hand and workers are needed to assemble and create the watches. When screws or joinery is not used to hold pieces together chemical adhesives are used. Adhesive is used in gem setting, for the watch jewels and other attachments like gold foil decoration on the watch face. The synthetic lubricant Benzine is used while assembling the gears and mechanics of the watch. Lubricant is an important part for ensuring the complex watch mechanisms are all working (Patek Philippe SA). In the final stage of production, chemical polishes and glosses are applied to give the watch a bright and clean shine before being shipped to consumers or set on display.

Resources used for transportation and distribution of the Grandmaster Chime were few, because of the limited on the amount of watches made but used excessive packing than necessary and energy intensive travel. Patek Philippe used fossil fuels to fuel transportation and distribution of the watches around the globe to displays and special customers who got the customized watch. Cardboard and wood boxes were used to package watches in custom made presentation boxes. Inside the boxes plastic and styrofoam were used to protect the watches while being transported and have a clean presentation for when the box first gets opened. The packaging used more materials than necessary by focusing on presentation over how much was actually needed to protect the watch.

Patek Philippe emphasizes the quality of their work and limits the amount they produce by ensuring that all of their materials are the best quality and hand making the product causing longevity of the product and good maintenance practices. The Patek Philippe company has a repairing policy, so parts of the watch that are worn out and broken can be replaced or repaired with the company allowing the lifespan of the watch to live longer. Silicon parts are occasionally used in place of metal alloys for less maintenance needs and increasing longevity of watch function (Patek Philippe SA). Patek watches are meant to have a long lifespan and to last for generations so the materials used are constructed to last a long time.

The Grandmaster Chime includes waste prevention through limited numbers of watches produced and recycling materials post production where it can. The watch itself is not meant to be recycled but the excess materials left over from production can sometimes be reused again. Parts of metal sheets not used in the initial production process are remelted with new additional metal to make use of as much metal material as possible. Materials that can not be recycled back into manufacturing like alligator leather scraps are thrown away to landfills (Patek Philippe SA). Making less watches limits waste from the materials that can not be recycled back into production. The production of Patek watches being a handmade process instead of automated, also means Patek uses mostly an animate prime mover of energy and avoids using more fossil fuel or inanimate producers of energy.

Luxury Watches are not meant to be thrown out but passed down from generation to generations, or kept as a collectors item. Patek Philippe emphasizes quality from the raw materials through the manufacturing process and repairing policies. Other luxury brands like Rolex mass produce as quickly as possible to increase as much profit as possible creating more waste and using more energy to mass produce. Patek is not the most sustainable company but Patek adopts practices and methods that are more sustainable in the long run of their products life span by trying to limit waste of production and maintenance needs (Scholz, 2021).

References

Arem, Joel E. “Understanding Gem Synthetics, Treatments, and Imitations.” Gems and Jewelry, 3rd ed., Batam Books, Toronto, 1986.

Clerizo, Michael. "Patek Philippe's Best-Kept Secret; A First Look at the Swiss Watchmaker's Oh-so Limited-Edition 175th-Anniversary Timepiece, the Grandmaster Chime." Wall Street Journal (Online), Oct 16, 2014. ProQuest, https://www.proquest.com/newspapers/patek-philippes-best-kept-secret-first-look-at/docview/1612625466/se-2.

Education. “An Overview of Precious Metal Mining and Refining Techniques.” Education, Education, 28 Jan. 2018, https://www.thenaturalsapphirecompany.com/education/precious-metal-mining-refining-techniques/.

Henderson, Steven, and Dippal Manchanda. “White Gold Alloys:” Gold Bulletin, vol. 38, no. 2, 2005, pp. 55–67., doi:10.1007/bf03215234.

Jiwa, Val. “Leather Making Process Using Crocodile Skin.” Kenya Wildlife Safaris, 8 June 2021, https://www.safari-center.com/leather-making-process-using-crocodile-skin/.

Joy, Annamma, et al. “Fast Fashion, Sustainability, and the Ethical Appeal of Luxury Brands.” Taylor & Francis, 21 Apr. 2015, www.tandfonline.com/doi/abs/10.2752/175174112X13340749707123.

Patek Philippe Sa. “Patek Philippe: Grand Complications Ref. 6300G-010 White Gold.” Patek Philippe SA, www.patek.com/en/collection/grand-complications/6300G-010.

Patek Philippe Sa. “Patek Philippe: Savoir-Faire: Advanced Research.” Patek Philippe SA, https://www.patek.com/en/company/savoir-faire/advanced-research.

Patek Philippe Sa. “Patek Philippe: Savoir-Faire: Attention to Details.” Patek Philippe SA, www.patek.com/en/company/savoir-faire.

Scholz, Felix. “Watches Go Green.” Revolution, Revolution, 13 Dec. 2021, https://revolutionwatch.com/watches-go-green/.

“Silicon.” How Products Are Made, 2009, http://www.madehow.com/Volume-6/Silicon.html.

Smith, Emily. “What Are Watch Jewels & Are They Necessary?” WatchBox, https://www.thewatchbox.com/blog/watch-jewels-101.html#:~:text=in%20Watch%20Movements-,Jewels%2C%20or%20jewel%20bearings%2C%20are%20synthetic%20rubies%20or%20sapphires%20that,metal%20components%20to%20move%20freely.

“Stainless Steel.” How Products Are Made, Advameg Inc, 2006, http://www.madehow.com/Volume-1/Stainless-Steel.html.

“Walkthrough Patek Philippe Finishing Workshops.” YouTube, Watches TV, 6 Sept. 2017, www.youtube.com/watch?v=ZSk2a91nh-s. Accessed 10 Feb. 2023.

Paulina Uytiepo

Jada Ferguson

Yiqing Zhao

DES 40A

Professor Cogdell

Patek Grandmaster Chime 6300G Life Cycle: Embodied Energy

In 2014, to celebrate the company’s 175th anniversary, Patek Philippe released a complex masterpiece that embodies the company’s values of precision, elegance, and innovation: The Patek Philippe Grandmaster Chime 6300G. This timepiece features a distinctive case crafted from 18k white gold, boasts 20 complications with five chiming functions, a blue opaline dial, two time zones, a calendar, a stopwatch, and a strap composed of alligator leather (Patek Philippe SA). While the energy consumption of the Patek Philippe Grandmaster Chime 6300 watch considers the processes of raw materials acquisition, manufacturing, transportation/distribution, use, and recycling/disposal, research demonstrates that the extraction of raw materials and transportation/distribution prevail as the phases with the greatest energy footprint due to the complex and intricate mechanical components used in processing, refining, and burning fuel during transport, while the manufacturing and use/reuse/recycling phases account for a smaller but moderately significant amount of energy consumption.

The production of the Patek Philippe’s Grandmaster Chime 6300G watch involves the extraction and acquisition of high-quality primary materials, which are essential for creating a timepiece that meets the company’s elevated standards of precision and reliability. The predominant materials used in creating the watch are white gold, platinum, blue opaline, alligator leather, and jewels. Specifically, a vast amount of research has been conducted on the energy consumed during the extraction and production processes of gold and animal leather. Initially, research demonstrates that gold mining contributes to global warming and is an energy-intensive market. According to the Journal of Cleaner Production, greenhouse gas emissions from gold mining amount to 28,700kg CO2-e per kg of gold (Ulrich et al., 2022). Similarly, gold production has an estimated expenditure of 200,000 GJ/t atomic units, 18,000 t CO2 e/t atomic units, 260,000 t water/t atomic units, and 1,270,000 t waste solids/ t atomic units (Norgate & Haque, 2012). The evidence suggests that gold mining is a significant contributor to global warming due to its high energy consumption and greenhouse gas emissions. Additionally, the data highlights the environmental impact of gold mining on water resources and underlines the immense amount of waste generated after the extracting process. On the other hand, alligator leather is processed through slaughtering, preservation, and tanning/fishing. Diesel trucks are mainly used to transport the raw materials (hide, water, salt) to be processed into leather, while coal is used to fuel electricity used in production. Accordingly, the energy expended in processing equates to approximately 423kWh for 100 square meters of finished leather, along with an estimated fuel consumption of 17.8L (Joseph & Nithya). This evidence suggests that the production of alligator leather is an energy-intensive process that relies on fossil fuels. Additionally, the evidence provides specific figures which demonstrate that the production of alligator leather has a relatively high energy cost. Once the raw materials have been acquired and transported into Patek Philippe’s manufacturing facility, the process for engineering the Grandmaster Chime 6300G begins, where skilled artisans and technicians work meticulously to transform the raw materials into a highly complicated and sophisticated wristwatch.

Essentially, the Patek Philippe Grandmaster Chime 6300G is an extremely complex and luxurious piece that is manufactured through the efforts of detail-oriented craftsmen. Patek Philippe’s manufacturing sector is vertically integrated, independent, and assembles watches in-house. Moreover, the company manufactures products independently and utilizes its own research and development department in Geneva, Switzerland (Patek Philippe SA). Energy expenditure during the manufacturing process is dependent on a significant amount of human labor for crafting the Grandmaster Chime 6300G. In fact, Patek Philippe described this product as the “most complicated” watch by the company, with up to 100,000 hours of intricate design, engineering, and enhancement (Patek Philippe SA). This implies that a considerable amount of manual work and energy is required to produce this watch. Moreover, processes within the manufacturing sector of Patek Philippe include marquetry (cutting and gluing wood), setting gems, guilloche work (operating a rose engine), chain-making, working with enamel, and engraving (Patek Philippe SA).

Essentially, the evidence indicates that the production of Patek Philippe’s most complicated watch requires a great amount of human labor and a high degree of skill and expertise. After the Patek Grandmaster Chime 6300G watch has completed its complex manufacturing process, it is then carefully transported and distributed to authorized retailers and dealers worldwide.

A critical component of the energy analysis of the life cycle of this specific watch is the process of transporting and distributing the finished product, specifically due to the large amount of energy needed to input security measures and power vehicles for transport. Luxury watches like the Patek Grandmaster Chime 6300G are typically transported to the distributors using secure and specialized methods to ensure their safe delivery. This includes and is not limited to armored vehicles, courier services, private jets, depending on the distance and urgency of the delivery. Of course, the greater the distance, the more energy expended. Patek Philippe has many global retailers, which means that masses of fuel are consumed in transporting the watches through numerous vehicles. Additionally, Patek Philippe’s strict standards may prompt them to implement GPS tracking systems and other security measures to monitor the location and status of their products during transit (Adams). According to the article "Jet-setting during COVID-19:

Environmental implications of the pandemic,” private aviation is “the most energy-intense form of air travel.” Additionally, the research article includes a graph illustrating an increase to approximately 23 megatons of CO2-equivalent emissions from private jet flights within one month (Sobieralski et al., 2022). This evidence shows that Patek Philippe’s potential use of private aviation to transport watches is extremely energy-intensive and contributes a disproportionately large amount of CO2 emissions relative to other forms of travel. Furthermore, Patek Philippe’s website lists twelve distributors across Europe, North America, Asia, in addition to hundreds of authorized retailers around the world (Patek Philippe SA). Given Patek Philippe’s significant number of branches on a global scale, it can be considered that a large amount of energy consumed during transportation and distribution derives from fuel, which propel heavy-duty trucks and aviation vehicles that operate on diesel and fuels. With the completion of the energy-intensive process of transportation and distribution, using and recycling the Patek Philippe Grandmaster Chime 6300G consumes a moderately significant amount of energy compared to other phases in the life cycle.

As one of the most exclusive and highly coveted watches in the world, the Patek Grandmaster Chime 6300G watch is designed to be used and last for generations. Eventually, the watch is managed responsibly at the end of its life through reuse, refurbishment, and recycling. Since Patek Philippe handles manufacturing in-house, the company shows minimal transparency about waste disposal and up-cycling (re-using parts) to create new watches. Furthermore, the long- lasting watch design permits a limited amount of energy used to maintain and manage the product’s waste; however, these hand-made luxury items may require services to fix and refine worn out parts. There are numerous Patek Philippe service locations around the world which utilize human labor and machines that consume a vast amount of energy to operate over time (Patek Philippe

SA).

To conclude, the life cycle of the Patek Grandmaster Chime 6300G watch is a complex process that moves through various stages, from obtaining raw materials, manufacturing the watch in-house, and eventually recycling. Certainly, the energy expenditure of the Patek Philippe Grandmaster Chime 6300 watch encompasses various stages in its life cycle, it is apparent that the extraction of raw materials and transportation/distribution of the product are the phases with the largest energy consumption due to the extensive processing of raw materials, immense amount of human labor involved in manufacturing the watch, and the heavy amount of fuel used in transportation and maintaining security measures. Moreover, the use and re-use phase accounts for a smaller but moderately significant amount of energy consumption due to the potential up-cycling of parts and available services to repair and maintain the watch. Throughout this energy-intensive process, sustainability plays an increasingly important role in ensuring the longevity and responsible management of luxury watches. By implementing eco-friendly and transparent practices in manufacturing, efficient logistics and distribution, and responsible waste management, the luxury watch industry can reduce the environmental footprint and contribute to a more sustainable future. Essentially, the strict management of high-end watches like the Patek Grandmaster Chime 6300G watch is crucial not only for preserving the quality, value, and elegance of these luxury goods, but for promoting a more sustainable and responsible approach to high-end consumption.

Works Cited

Adams, Ariel. “The Logistics of Transporting Luxury Watches.” Forbes, 2016,

https://www.forbes.com/sites/arieladams/2016/04/22/the-logistics-of-transporting-luxury-

watches/?sh=1679b9c57c2d.

Barrick Gold Corporation, 2020, Barrick Sustainability Report 2020. Accessed Mar. 2023.

Bossi, Tania, and Johannes Gediga. "The environmental profile of platinum group metals."

Johnson Matthey Technology Review 61.2 (2017): 111-121.

Buza, Jan, Annina Luterbacher, and Pascal Sennhauser. "Patek Philippe Watches." (2012).

Fernandez, Jessica, and Christie Klimas. "A Life Cycle Assessment of Jewelry." DePaul

Discoveries 8.1 (2019): 6.

Jasiński, Dominik, James Meredith, and Kerry Kirwan. "The life cycle impact for platinum

group metals and lithium to 2070 via surplus cost potential." The international journal of life

cycle assessment 23 (2018): 773-786.

Joseph, Kurian, and N. Nithya. "Material flows in the life cycle of leather." Journal of Cleaner

Production 17.7 (2009): 676-682.

Norgate, Terry, and Nawshad Haque. "Using life cycle assessment to evaluate some

environmental impacts of gold production." Journal of Cleaner Production 29 (2012): 53-63.

“Patek Philippe: About Time: The Grandmaster Chime.” Patek Philippe SA,

https://www.patek.com/en/company/about-time/the-grandmaster-

chime#:~:text=The%20Grandmaster%20Chime%20is%20the,covered%20a%20staggering%201

00%2C000%20hours.

“Patek Philippe: Company: The Manufacture.” Patek Philippe SA,

https://www.patek.com/en/company/the-manufacture#patek-philippe-key-points.

“Patek Philippe: Savoir-Faire: Unique Watchmaking Crafts.” Patek Philippe SA,

https://www.patek.com/en/company/savoir-faire/rare-handcrafts/the-crafts.

Sobieralski, Joseph B., and Stacey Mumbower. "Jet-setting during COVID-19: Environmental

implications of the pandemic induced private aviation boom." Transportation Research

Interdisciplinary Perspectives 13 (2022): 100575.

Ulrich, Sam, Allan Trench, and Steffen Hagemann. "Gold mining greenhouse gas emissions,

abatement measures, and the impact of a carbon price." Journal of Cleaner Production 340

(2022): 130851.

Weber, David, and Haute Ecole Arc Ingénierie. "Case study of the ecological impact of a typical

mechanical Swiss watch."

Yiqing Zhao

Des040A -- Winter 2023

Professor Christina Cogdell

March 15th 2023

Patek Philippe Geneve Grandmaster Chime 6300G: Waste and Emissions

When it comes to famous and luxury watches, what brand do you think of? Rolex? But in fact, there are many mechanical watch brands more expensive than Rolex in the world. Patek Philippe is one of them. Patek Philippe is a Swiss luxury watch brand founded in 1839 by Antoni Patek and Adrien Philippe. The brand has a reputation for producing high-quality timepieces with intricate designs and technical precision. It is also known for its classic and timeless designs and is considered one of the most prestigious watchmakers in the world.

The brand has many iconic models, including the Nautilus, Calatrava, and the Grand Complications collection. Patek Philippe is also known for its limited edition and special edition watches, which can fetch millions of dollars at auctions. Patek Philippe watches are handmade and assembled by skilled craftsmen, with each watch taking several months to produce. The brand is committed to using the finest materials and employing traditional watchmaking techniques, which ensures that each watch is a unique work of art. The product that I want to research about is the the watch called Patek Philippe Grandmaster Chime Ref. 6300. It is designed and produced both by Patek Philippe. Moreover, Grandmaster Chime Ref. 6300 is the first grande-sonnerie wristwatch ever added to the company’s current collection. Featuring a reversible case in white gold decorated with manufacture’s typical hobnail pattern, this opus showcase 20 complications, including five chiming modes, two of which are patented acoustic world debuts.

The part I focus is about waste and pollution . Through a detailed investigation of the waste and emissions that are produced during the life cycle of the Grandmaster Chime watch made by Patek Philippe, this article will specifically investigate how the Ref. 6300 make waste and pollution and how to reduce waste and pollution from five parts — raw materials extractions, manufacturing and assembly, packaging and transportation, using/reusing and maintenance, and recycling, they are also the life cycle of the production of this watch.

First, for raw material extraction, The production of watches requires a variety of raw materials such as metal, plastic, and glass. The extraction and processing of these materials can lead to environmental damage, including land and water pollution, deforestation, andhabitat destruction. The waste generated during the extraction and processing of raw materials for watch production can vary depending on the specific materials used and the manufacturing processes employed. For mining waste, the extraction of metals such as gold, silver, and copper, which are commonly used in watch production, can generate large amounts of waste rock and tailings (ground-up rock and chemical waste) that can pollute nearby waterways and land. For plastic waste, the production of watch straps, cases, and other plastic components can generate plastic waste that may not be easily recyclable and can end up in landfills or the natural environment. Glass waste can be produced during the manufacturing of watch crystals and glass displays, but this glass trash may not be readily recyclable and may instead wind up in landfills or the environment. The extraction may also cause chemical waste, that is the processing of raw materials can involve the use of chemicals that may be harmful to human health and the environment. These chemicals can end up as waste products that may require special handling and disposal.

The article titled Heavy Metal Pollution in the Environment and Their Toxicological Effects on Humans; provides an overview of the sources and toxicological effects of heavy metal pollution on human health. The authors (Briffa, Jessica, et al 1) draw attention to the fact that heavy metals are naturally occurring substances that can be found in a variety of environmental sources, including food, soil, water, and air. However due to human activities like industrialization, mining, and agriculture, there are now more heavy metal pollutants in the environment, which can be dangerous for human health. The effects of numerous heavy metals, such as lead, cadmium, mercury, and arsenic, on various human organs and systems, including the neurological, cardiovascular, and reproductive systems, are covered by the writers. The article focuses on the significance of putting measures in place to control and reduce heavy metal pollution in the environment, like better waste management, regulating industrial operations, and encouraging sustainable practices. The raw materials for Patek Philippe Grandmaster Chime 6300G includes heavy metals like lead, hence, the methods for reduce pollution stated before can be used in this process.

Second, the manufacturing process for watches involves cutting, drilling, and polishing of metals and plastics. These processes can generate waste materials such as metal shavings, plastic scraps, and chemical waste. The assembly of watches also involves the use of adhesives and solvents, which can release volatile organic compounds (VOCs) into the air. Metal shavings: Cutting and drilling of metal components can generate metal shavings as waste. From plastic scraps, the cutting and drilling of plastic components can generate plastic scraps as waste. And for chemical waste in manufacturing, the use of solvents and adhesives in the assembly process can generate chemical waste, which may be hazardous and require special handling and disposal. One special pollution and waste in this process is VOC emissions. The use of adhesives and solvents in the assembly process can also release volatile organic compounds (VOCs) into the air, contributing to air pollution. The manufacturing process must use water. Therefore, water waste is produced. The production process may generate wastewater, which can be contaminated with chemicals, metals, and other pollutants. And energy waste in the manufacturing process can consume a significant amount of energy, resulting in greenhouse gas emissions and contributing to climate change.

According to the review to Environmental Impacts of Metal Ore Mining and Processing. The authors (Dudka, Stanislaw, and Domy C. Adriano 3) highlight that metal ore mining and processing can result in significant environmental damage, including soil and water pollution,deforestation, and habitat destruction. The article reviews various environmental impacts of metal mining, including the release of heavy metals, acid mine drainage, soil erosion, and land degradation. The authors discuss the effects of these environmental impacts on human health and biodiversity. The article emphasizes the importance of implementing measures to minimize the environmental impacts of metal ore mining and processing, such as using environmentally sustainable technologies and waste management practices. The authors conclude that a multidisciplinary approach, including collaboration between scientists, policymakers, and the mining industry, is necessary to address the environmental impacts of metal ore mining and processing.

Third, packaging and transportation can also produce waste. Watches are often packaged in plastic or cardboard boxes, which can contribute to the overall waste generated by the production process. To be more specific, The use of plastic or cardboard boxes to package watches can generate waste that may not be easily recyclable and can end up in landfills or the natural environment. For shipping waste, the transportation of watches from the manufacturing facility to retail outlets or customers can generate waste, such as packing materials, which may not be easily recyclable. That is to say, it can also generate greenhouse gas emissions and other forms of pollution. Energy and water waste are also produced in transportation. The transportation of watches also requires energy consumption, such as fuel for vehicles or electricity for shipping facilities, which can contribute to greenhouse gas emissions and other forms of pollution. And when watches are transported, wasted water from cleaning or maintaining shipping facilities may be produced. This wasted water may be contaminated with chemicals, metals, and other pollutants.

Fourth, the use and reuse of watches can have both positive environmental impacts and seldom produce waste. The watch that is designed to last longer and can be repaired or maintained can reduce waste and pollution associated with the production of new watches. The recycling or repurposing of watch components can reduce the need for new raw materials and reduce waste. For example, metal components can be melted down and reused in new products, and leather straps can be repurposed into other products. Although the maintenance and repair of mechanical watches can generate waste, such as worn-out or broken parts, that may not be easily recyclable, the influence is too small.

Finally, the recycling process of mechanical watches involves melting down the metal components and separating the plastic components. This process can generate waste, such as leftover metal or plastic scraps that may not be easily recyclable. The authors (I.D.,Gadaskina, and Ryzik L.A. 3) explain that gold is extracted from ore through various methods, including cyanide leaching and gravity separation. The gold refining process involves smelting the gold to remove impurities, which is usually done in large-scale industrial settings. The article reviews the potential occupational health hazards associated with gold smelting and refining, including exposure to toxic fumes and chemicals, high temperatures, and physical hazards such as noise and vibration. The authors discuss the measures that can be taken to minimize these risks, such as using personal protective equipment and implementing proper ventilation and waste management practices.

In conclusion, to reduce waste and pollution in watch production, companies can implement sustainable practices such as using recycled materials, reducing packaging waste, and implementing responsible disposal and recycling programs. Additionally, consumers can reduce their environmental impact by choosing watches made from sustainable materials, repairing watches rather than buying new ones, and properly disposing of old watches.

Works Cited

Briffa, Jessica, et al. “Heavy Metal Pollution in the Environment and Their Toxicological

Effects on Humans.” Heliyon, vol. 6, no. 9, 2020,

https://doi.org/10.1016/j.heliyon.2020.e04691.

Dudka, Stanislaw, and Domy C. Adriano. “Environmental Impacts of Metal Ore Mining and

Processing: A Review.” Journal of Environmental Quality, vol. 26,

no.3,1997,pp.590–602., https://doi.org/10.2134/jeq1997.00472425002600030003x.

Geneve, Patek Philippe Sa. “Patek Philippe: Grand Complications Ref. 6300G-010 White

Gold.” Patek Philippe SA, https://www.patek.com/en/collection/grand-

complications/6300G-010.

Geneve, Patek Philippe Sa. “Patek Philippe: Savoir-Faire: Attention to Details.” Patek

Philippe SA, https://www.patek.com/en/company/savoir-faire/attention-to-details.

I.D., Gadaskina, and Ryzik L.A. “Gold Smelting and Refining.” ILO Encyclopaedia of

Occupational Health and Safety, 16 Mar. 2011,

https://www.iloencyclopaedia.org/part-xiii-12343/metal-processing-and-metal-

working-industry/item/671-gold-smelting-and-refining.

Ltd., Belton China. “How the Watch Industry Is Embracing the Circular Economy?” BCL |

Italian Watchmakers, BCL | Italian Watchmakers, 13 Apr. 2022,

https://www.beltonchinalimited.com/news/how-the-watch-industry-is-embracing-the-

circular-economy.

Reference 6300 - Patek Philippe Grandmaster Chime.

https://static.patek.com/pdf/instructionsforuse/PatekPhilippe_6300G_010_en_fr.pdf.

Smith, Emily. “5 Things about Patek Philippe.” WatchBox,

https://www.thewatchbox.com/blog/patek-philippe-history.html.

Swisswatches. “Baselworld 2019: Patek Philippe Grandmaster Chime Rare Handcrafts Ref.

6300G-010.” Swisswatches Magazine, 9 June 2022, https://swisswatches-

magazine.com/blog/patek-philippe-grandmaster-chime-rare-handcrafts-ref-6300g-

010-baselworld-2019/.

Watches, Time and. “Patek Philippe - Grandmaster Chime Ref. 6300G-010.” Time and

Watches | The Watch Blog, 16 June 2019,

https://www.timeandwatches.com/2019/06/patek-philippe-grandmaster-chime-

ref.html?m=1.