Design Life-Cycle

assess.design.(don't)consume

Thu Nguyen

Group Member: Patrick Trinh

DES 040A 03

Professor Cogdell

01 December 2021

Life Cycle of Aircraft Tires

Raw Materials

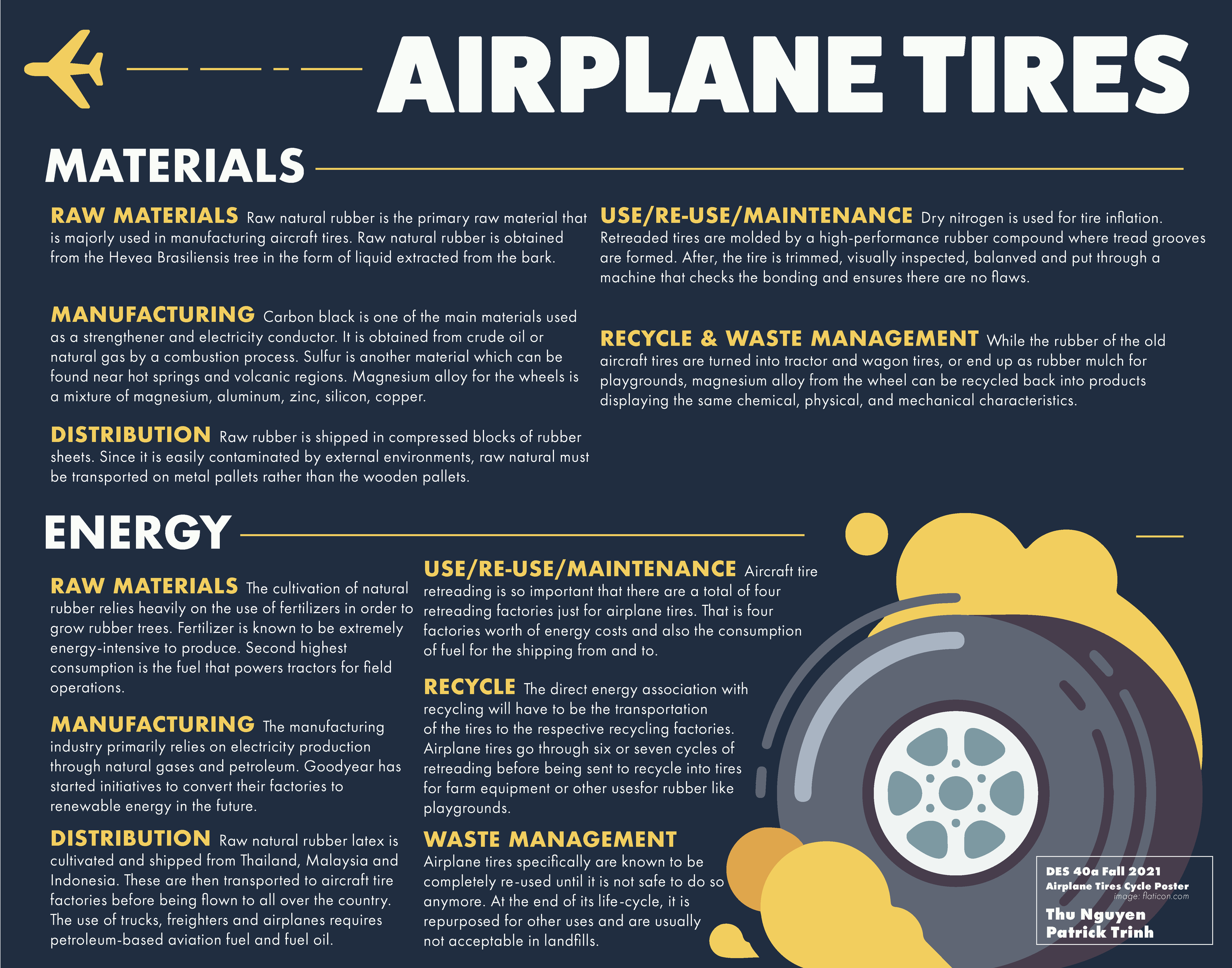

“Wastes from one industrial process can serve as the raw materials for another, thereby reducing the impact of industry on the environment” (Frosch and Gallopoulos, 1989) The author wants to focus on recycling products’ materials. The aging airplane’s end-of-service life has set off a hot topic in recycling management. Recycling retired airplane tires by environmental responsibility and retaining some valuable materials become a significant need. Airplane tires are used to operate at an extreme pressure, speed, and temperature. At first, airplane tires were designed to withstand extremely heavy loads for a short duration only, yet, due to the technology and society are increasing rapidly, airplane tires are developed to be stronger to adapt to human needs. An airplane tire contains many rubber compounds and other materials. To acknowledge how the process and product can affect our living environment , this paper is focused on taking a deep look into the raw materials that are used in a life cycle of an airplane tire from manufacturing to end-of-service life.

The primary raw material majorly used in manufacturing airplane tires is raw natural rubber. Raw natural rubber is an elastomer or hydrocarbon polymer that is known by the name of India rubber, gum elastic, and caoutchouc. Raw natural rubber is obtained from the sap of a tree called Hevea Brasiliensis. This tree grows best at temperatures of 21 to 28 Celsius degrees with annual rainfall such as Malaysia, Indonesia, and Thailand, etc. (Natural Rubber). Raw natural rubber is collected in a form of latex, a milky liquid, extracted from the tree’s bark. The properties of natural rubber include durability and abrasion resistance. It can be stretched but recovered back to its original shape and size. However, by itself natural rubber has limited properties, therefore, in order to increase the value of natural rubber, carbon black is an active material that plays a role in strengthening natural rubber to make airplane tires.

Carbon black is applied in the manufacture of the airplane tire as one of the primary elements that help to conduct electricity and strengthen rubber’s physical properties. Carbon black is a colloidal material that can be obtained from crude oil or natural gas. The crude oil is subjected to partial combustion under the limited supply of oxygen hence, which will become a huge layer of fine black soot (cbmadmin 2019). Carbon black is the most common type of reinforcing filler that is used in making rubber compounds, especially for airplane tires. The addition of carbon black will effectively improve the electrical conductivity of the aircraft tire and strengthen the rubber compound (Farida 2019). Beside carbon black, sulfur is also used to strengthen the rubber’s elasticity.

Sulfur is one of the key components in aircraft tire manufacturing. It is an odourless yellow powder that is produced by the production of sulphate and phosphate. Sulfur can be found nearby hot springs, volcanic regions, and underground deposits. It is currently mined in Indonesia, Chile, and Japan (Sulphur). Manufacture teams use a vulcanization accelerator to help build crosslinks between rubber, carbon black, and sulfur to make the tires hard and heat resistant. Vulcanization is a chemical process in which rubber is heated with sulfur, accelerator and activator at 140-160C (King 2019). This process helps to improve the rubber’s elasticity, resilience, tensile strength, and weather resistance. After mixing under pressure, the rubber is formed into thick sheets which can be further processed in calendaring and extrusion. Rubber is shipped as a compressed 75-pound block. Since it is easily contaminated by external factors, it must be transported on metal pallets rather than the wooden pallets (Bonney 2016). Moving on the aircraft tire manufacturing, the wheel's material also plays an important role in holding the pressure and temperature of the friction force.

Another valuable material that makes the wheel is magnesium alloy. It is a mixture of magnesium with other metals such as aluminum, zinc, silicon, and copper (Mathers 1942). The main purpose of using magnesium alloy is to reduce flamination and is highly resistant to impact and vibration. Beside that, magnesium alloy is lightweight, low density, and durable which does not stretch. After the initial processes have been carried out, in order to prevent the wheel from being rust, an anti-corrosive treatment is applied by using cellulose or epoxy resin paint. Depending on local regulation, it is the transportation and storage responsibility to ensure compliance with the airplane tire’s handler.

Proper storage is a must in order to avoid damaging the aircraft tire and lower the tire’s strength. Airplane tires should be stored in a cool and dry place out of direct sunlight with the temperature between 0 and 30 Celsius degrees (Aviation Tire Care 2020). Tires should be stored vertically on the tire rack and the weight of the tire rests should be flat and wide to minimize distortion. Age of an airplane tire is not a matter as long as all services or customer-imposed restrictions are met. Not only storing is important, but also transportation. Inflated tires are very dangerous which can lead to explosions, therefore, transportation must follow restricted rules. When tire assemblies are shipped, especially by air, the pressure inside the tire will be increased.

In order to use the airplane tire, the airline teams have to make sure the pressure should always be at the ambient temperature as they can rise to an excess of 93 degree Celsius and above during operation. Dry Nitrogen is used for tire inflation because it will not sustain combustion and help to reduce degradation from oxidation. Dry air may be used as long as the oxygen level is not over five percent of the total tire’s volume.

Nowadays, a typical airplane tire is built to last from 120 to 400 landing depending on a number of factors (Hydro 2018). Unfortunately, the Covid-19 pandemic has impacted the aviation industry negatively in 2020. With less flight activities, the airplane tire market stays quite low. However, everything is returning to normal, which means passengers are returning to their working routine and helping to grow the aircraft tire industry. Goodyear is a major tire supplier to the United States Department of Defense with an average annual contract worth 48 million USD (Aircraft Tire Market). There are many factors that can damage the tires, which lead to an uncountable number of tires that need to be replaced.

Mostly, tires are replaced for deterioration that is affected by sunlight and weather extremes. When the fabric or casing is exposed, the tire is not airworthy anymore. Southwest Airlines changes their airplane tires every 5-6 weeks (Liligo 2016). According to Conde Nast Traveler, the Southwest Airline used nearly 40,000 tires in a year (Summer 2016), which means a lot of rubber will be wasted. Retreading does not equal poor quality. Most airlines try to use airplane tires that can be reused or retreaded many times as possible before retiring them for service. Reusable airplane tires are retreaded by molding with a new high-performance rubber compound where tread grooves are formed (Simon 2013). After that, the tire is trimmed, visually inspected, and put through the shearography machine which will check the bonding and ensure that there is no gap or bubbles.

For non-reusable tires. they will be sent to recycle and waste management places. Gensco Tire is a company that specializes in turning all types of tires, especially airplane tires into tractor, wagon, and backhoe tires (Gensco Tire). For other airlines, their tires end up as rubber mulch for playground and sport fields. Different from the rubber of the old airplane tire, magnesium alloy from the wheel can be recycled back into products that have the same chemical, physical, and mechanical characteristics.

Tires are a very important part of the airplane, therefore, it is important that they are manufactured to withstand a wide range of conditions. The components that are used ensure that the airplane tires can provide enough stability to safely land. The society has reached to the point that it is in need of a large industrial production. By exploring the life cycle of the airplane tire, it is sure that a lot of material resources are invested and used in large quantities to satisfy the human need and environmental consequence caused through the production.

Bibliography

“Aircraft Tires Market: 2021 - 2026: Industry Share, Size, Growth.” Mordor Intelligence,

https://www.mordorintelligence.com/industry-reports/aircraft-tires-market.

“Aviation Tire Care 2020.” Goodyear Aviation Tires, https://www.goodyearaviation.com/

resources/pdf/aviation-tire-care-2020.pdf

Bonney, Joseph. “Despite Containerization, Breakbulk Carriers Still in Natural Rubber Game.”

Despite Containerization, Breakbulk Carriers Still in Natural Rubber Game | JOC.com,

24 Jan. 2016, https://www.joc.com/international-logistics/shipments-natural-rubber-

breakbulk-carriers-still-game_20160124.html.

cbmadmin. “Carbon Black: Successful Handling and Transportation.” Streamline Industries,

9 May 2019, https://streamlineind.com/carbon-black-successful-handling-

and-transportation/.

“Gensco Tire. Home of the No Flat Aircraft Tire.” Gensco Tire, https://www.genscotire.com/.

HYDRO, 11 Dec. 2018, https://www.hydro.aero/en/newsletter-details/

what-you-should-know-about-aircraft-wheels.html.

Farida, Erna, et al. “The Effect of Carbon Black Composition in Natural Rubber Compound.”

Case Studies in Thermal Engineering, Elsevier, 15 Nov. 2019,

https://www.sciencedirect.com/science/article/pii/S2214157X1930406X.

King, Helen. “Vulcanisation.” ScienceDirect, https://www.sciencedirect.com/topics/

earth-and-planetary-sciences/vulcanisation.

Liligo, and Federico Fioravanti. “What Really Happens to Old Airplane Tires?” Traveler's

Edition, 15 May 2018, https://www.liligo.com/travel-edition/what-really-happens-to-old-

airplane-tires-3495.html.

MATHES, JOHN C. “MAGNESIUM ALLOYS in the Aircraft Industry.” SAE Transactions, vol.

36/49, SAE International, 1941, pp. 76–80, http://www.jstor.org/stable/44438816.

“Natural Rubber.” Natural Rubber, Natural Rubber Properties, Natural Rubber Uses, Natural

Rubber Information, Natural Rubber Industry, http://www.industrialrubbergoods.com/

natural-rubber.html.

R. A. Frosch and N. E. Gallopoulos, “Strategies for Manufacturing,” Scientific American, 1989, http://www.umich.edu/~nppcpub/resources/compendia/IEORpdfs/IEOR_Reading.pdf.

Simon, Jeff. “What's so Special about Aircraft Tires? - AOPA.” AOPA, 15 Apr. 2013,

https://www.aopa.org/news-and-media/all-news/2013/april/15/whats-so-special-about

-aircraft-tires.

"Sulphur: Mineral information, data and localities". www.mindat.org.

Sumers, Brian. “Old Airplane Tires Are Turned Into...what?” Condé Nast Traveler, Condé Nast

Traveler, 27 May 2016, https://www.cntraveler.com/stories/2016-05-27/old-

airplane-tires-are-turned-into-what.

Patrick Trinh

Group Member: Thu Nguyen

DES40a 03 Cogdell

12/1/21

Airplane Tires Energy

The development and innovations of transportation has been tremendously impactful for our lives. The ability to reach anywhere on our planet in a matter of a day has changed the way human societies work. Globalization has only been made possible by the huge collective and accumulation of technology and the ideas of all the people in the world. From a simple screw to the fastest computer, the advanced world that we have built for ourselves requires the many resources on our planet in order to produce. The currency of the universe is time and energy. With energy, a whole new door opens for what is capable. To produce this energy, humans learned to harness the natural resources that occurred all around us. From the fossil fuels below our feet, to the wind all around us and to the sun above us. Our ability to be innovative and strive for always getting better than our best has led us to a future that relies heavily on the use of energy. Energy use is at an incomprehensible magnitude that it would be difficult to discuss what is happening all around the world, since energy is continuously being produced in an unfathomable scale. To start to understand how energy is used and the different instances of where it is used, we can start to comprehend how much we rely upon energy to produce and live. For this essay, we will focus on a somewhat niche product, which are airplane tires. We will discuss the life-cycle of the airplane tire and pay attention to the energy that is required at each stage of the airplane tire.

One of the main ingredients for airplane tires is the rubber. Rubber is made from a form of latex that comes from the rubber tree. This latex is almost like a sap which is white and sticky and is usually collected by draining the fluids of a rubber tree. The process of obtaining the raw material in order to convert to the rubber used in airplane tires, is the least mechanically demanding part. Still, this stage requires tractors and machinery in order to plant, maintain and harvest the rubber tree farms. The biggest energy consumer at this stage though, is surprisingly not the machines, but rather the fertilizer used. (Izaz, Jaiswal 2019) In order to produce fertilizer, a huge amount of energy is needed in order to manufacture. Machinery at this level relies mostly on diesel in order to run their equipment which is where their source of energy comes from.

Next, the latex is processed in these latex fields, where the latex is turned into dry rubber. This dry rubber will then be shipped via planes to processing plants in order to further develop this resource into a secondary material. This rubber is usually shipped in air-tight containers in order to avoid contamination or degradation of the material. Different processes like vulcanization are done in order to manufacture the right grade of rubber for tire manufacturing. Vulcanization is this process that is used within the industry in order to harden the rubber. More specifically, it pertains to the treatment of natural rubber with sulfur. (Akiba, 1997) The vulcanization process in addition to making the rubber stronger, also adds lifespan and more functionality into the material. Going into the energy aspect of vulcanization, the process is a chemical reaction using extreme heat in order to basically temper the rubber. The heat required for this stage of the manufacturing comes from the typical fire chambers powered by either coal or gas. There has been talks about becoming a bit more eco-friendly by using radiation instead of having to burn anything which would have emission byproducts. (Makuuchi, 1993) This offers low emission of certain chemicals being released into the air due to the lack of major combustions that fire would usually bring. This has been described as an environmentally friendly vulcanization technology.

Onto the actual production of the tires, we are starting to see the rubber mixed with other materials in order to deliver the right compound of materials to meet the guidelines and regulations. The aircraft tire is designed to hold a great amount of load in short bursts while also being capable of withstanding some wear and tear. The amount of tires needed for the aircraft also increases its weight which must be considered in the industry to save cost while bordering the line of safety for its customers. The surface design of aircraft tires are designed to aid stability in higher crosswind conditions, and material composition is the most important when we talk about possible occurrences of hydroplaning or extreme braking. Technically, the tire turns into a worn tire the moment it hits the tarmac. Tires undergo the change as the surface is degraded by resistance with the way layer over the course of usage. The recent tire goes out with some 10/32 inch of surface, and gradually starts to wear down at that point. When this surface level hits 2/32 inch, it is at the point where the surface is meeting critical wear and must be replaced. (Foelson 2018) There is a special manufacturing plant for airplane tires. This is because the quality and size of the tires require different equipment, machinery and processes which are not provided by the normal commercial manufacturing plants that make car tires. These plants are run by electricity and require a large amount of energy in order to power the different machines and processes that happen within the facility. As we know, electricity is generated by a different variety of sources. Most common is fossil fuels but as we are learning to become more eco-conscious, we are starting to use nuclear, biomass, geothermal, and solar energy in order to generate the great amounts of power we need in order to run our manufacturing industry. According to the U.S. Energy Information Administration, the U.S. primary energy source consumption is petroleum with 35%, natural gas with 34%, renewable energy with 12% which consists of geothermal, solar, hydroelectric, wind, biomass, biofuels and wood. Coal consists of 10% of the energy source we consume and lastly nuclear electric power takes up 9%. This energy is then used most by the industrial and transportation sectors which both take up around 25%. Residential and commercial sectors take up a significantly smaller amount of energy compared to the other sectors. Airplane tire manufacturing is already very energy consuming because of the different processes that need to be treated onto the tires in order for them to meet requirements. It is also interesting to mention that the three top tire manufacturers, Bridgestone, Goodyear, and Michelin only have one facility meant for manufacturing new airplane tires. Compared to the whole industry, this is miniscule but now we move onto transportation of these tires.

Once the airplane tires are formed and assembled, they get ready to be shipped to the airplane assembly factories. Since these facilities are all over the world, these tires are usually flown by plane to ports. From there, the transportation trucks take the shipment of tires and deliver them to the assembly facilities. Of course, the energy consumed at this stage has to do with the fueling of these transportation means with the small additional manufacturing of shipment supplies and equipment. This could include moving equipment like forklifts to packaging like boxes and paddings.

Retreading is a big deal for airplane tires. Since airplane companies have very strict policies when it comes to safety. They work with tire companies in order to determine the perfect amount of time an airplane tire could be used. This means that each tire is guaranteed for a number of flights before they are marked for retreading. Retreading is a process where new material is added on the wheels in order to restore the treading and worn material of the wheel. These are done a certain amount of times before tires are deemed too worn out and then therefore reused in other applications in the world. The retreading process happens in special airplane tire retreading facilities all over the country which means that there is the same energy consumption of transportation and material production. Airplane tires can be recycled into similar products such as tires for farming equipment which does not require the same level of intense requirements.

Bibliography

Akiba, M. “Vulcanization and Crosslinking in Elastomers.” Progress in Polymer Science, vol. 22, no. 3, 1997, pp. 475–521., https://doi.org/10.1016/s0079-6700(96)00015-9.

Ali, Izaz, and Ajay K. Jaiswal. “Energy Auditing and Production Planning for a Tire Manufacturing Plant.” 2019 7th International Youth Conference on Energy (IYCE), 2019, https://doi.org/10.1109/iyce45807.2019.8991559.

“Bridgestone Improves Energy Efficiency in Its Production Plant in Costa Rica.” Bridgestone Americas, Inc., https://www.bridgestoneamericas.com/en/newsroom/press-releases/2019/bridgestone-improves-energy-efficiency-in-its-production-plant-i#:~:text=Bridgestone%2C%20the%20world%20leader%20in,efficiency%20in%20the%20production%20process.

Ferrer, Geraldo. “The Economics of Tire Remanufacturing.” Resources, Conservation and Recycling, vol. 19, no. 4, 1997, pp. 221–255., https://doi.org/10.1016/s0921-3449(96)01181-0.

Fogelson, Jason. “Michelin Explores the Truth about Worn Tires.” Forbes, Forbes Magazine, 19 July 2021, https://www.forbes.com/sites/jasonfogelson/2018/04/28/michelin-explores-the-truth-about-worn-tires/.

Makuuchi, K. “Environmentally Friendly Vulcanization Technology of Natural Rubber Latex by Radiation.” Ecomaterials, 1994, pp. 721–724., https://doi.org/10.1016/b978-1-4832-8381-4.50172-4.

Roberts, Fred. “Old Made New: Airplane Tire Retreading and Reuse.” Tire Recappers, 8 July 2016, https://www.tirerecappers.com/tire-recappers-news/old-made-new-airplane-tire-retreading-and-reuse/.

“U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.” U.S. Energy Facts Explained - Consumption and Production - U.S. Energy Information Administration (EIA), https://www.eia.gov/energyexplained/us-energy-facts/.

“What Are the Major Sources and Users of Energy in the United States?” American Geosciences Institute, 4 Jan. 2019, https://www.americangeosciences.org/critical-issues/faq/what-are-major-sources-and-users-energy-united-states.

“Www.aalatex.com - Natural Rubber & Latex Distributor: Natural Rubber Latex Transportation & Packaging.” Www.aalatex.com - Natural Rubber & Latex Distributor | Natural Rubber Latex Transportation & Packaging, https://web.archive.org/web/20090404081944/http://www.aalatex.com/content/comments.asp?id=193.