Design Life-Cycle

assess.design.(don't)consume

Victor Barajas

Group Members: Emily Reed, Mia Guo

DES 40A

Professor Cogdell

Life Cycle Research Paper – Plastic Debit Card Raw Materials

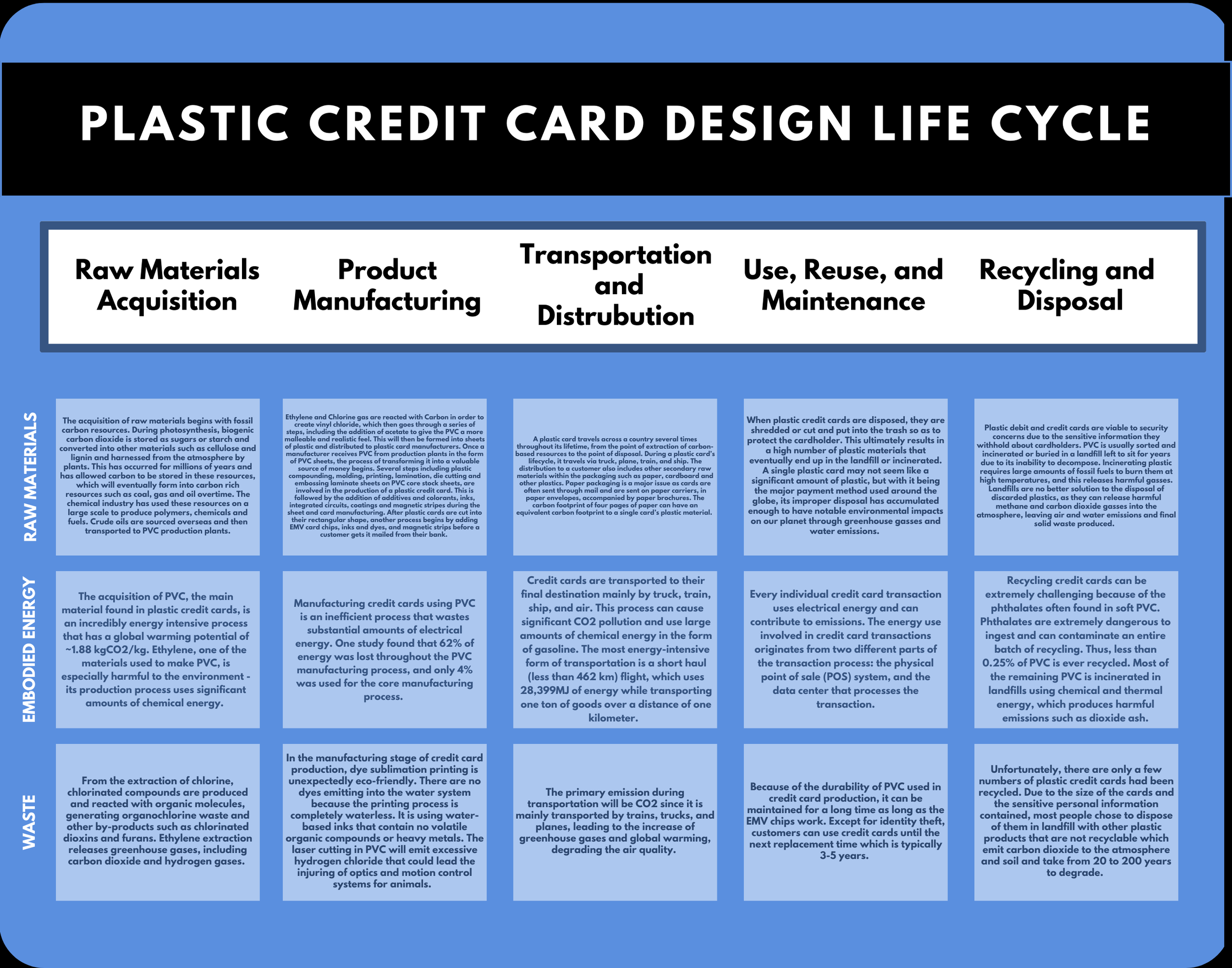

For a majority of human existence, coinage, cash or barter were the main forms of making transactions and currency. As we further developed and advanced, we eventually began manufacturing plastic cards connected to our banks and associated accounts. An ever-growing population has resulted in increases in demand for plastic products. This need to manufacture more plastics, such as debit cards, has caused surges in the number of the raw materials we use to produce consumer plastic products. Moreover, this need has resulted in harmful waste allocation of dumping in landfills or by means of incineration. Large amounts of these plastics have caused significant environmental damage to our planet. The necessity for carbon-based resources that are essential for producing plastics such as PVC have impacted the entirety of the plastic card lifecycle and aspect of its manufacturing, transportation, and disposal. Technological advances and modernization in currency have gradually transitioned us from utilizing cash and coinage to plastic. Unfortunately, improper disposal and overreliance on plastics have adversely impacted our planet through increases in energy use and harmful gasses in our environment.

The discovery of plastics came as a result of WWII as they were manufactured for the war. After war efforts were over, prior, extensive research of these materials allowed for a subtle transition of plastic products into consumer’s lives. The acquisition of raw materials that begins the life cycle of a debit card with a magnetic strip and chip starts with fossil carbon resources. During photosynthesis, biogenic carbon dioxide is stored as sugars or starch “or converted into other materials such as cellulose and lignin, altogether known as biomass” (ICMA, 2010) after being harnessed from the atmosphere by plants. This has occurred for millions of years and has allowed carbon to be stored in these resources, which will eventually form into carbon rich resources such as coal, gas and oil overtime. The chemical industry has been using these resources “on a large scale to produce polymers, chemicals and fuels” (ICMA, 2010). From this process, we know that these crude oils are most likely sourced overseas and transported to PVC production plants. The method for creating PVC is majority chemistry based as it is also not a single, primary raw material that comes from the Earth. The lifecycle of a plastic card first begins “with the extraction of resources from the earth, such as crude oil and gas” (ICMA, 2010), which is used for “the production of the raw materials for the card body from fossil or bio-based resources” (ICMA, 2010). The use of fossil fuels to create PVC requires substantial amounts of embodied energy in order to convert raw materials into plastic prior to the card’s production.

Once at the plant, Ethylene and Chlorine gas are reacted with Carbon in order to create vinyl chloride, which then goes through a series of steps, including the addition of acetate to give the PVC a more malleable and realistic feel. This will then be formed into sheets of plastic and distributed to plastic card manufacturers who will continue the journey to creating the final product. Once a manufacturer receives PVC from production plants in the form of PVC sheets, the process of transforming it into a valuable source of money begins. Several steps including plastic compounding, molding, printing, lamination, die cutting and embossing laminate sheets on PVC core stock sheets, are involved in the production of a plastic credit card. This is followed by the addition of additives and colorants, inks, integrated circuits, coatings and magnetic stripes during the sheet and card manufacturing. After plastic cards are cut into their rectangular shape, another process begins of adding EMV card chips, inks and dyes, and magnetic strips before it looks familiar to what a customer receives from their bank. Overall, the production of synthetic materials such as PVC is more complicated as they are fossil-fuel based. PVC production is achieved through chemical and artificial means, and later distributed to other manufacturers to continue the process of creating these plastic cards. This process also includes the embodied energy used to transport these materials to different manufacturers, producers, distributors, banks, and consumers. This embodied energy is greater than what is utilized during the final production of a plastic card, however, the process of transforming carbon-based resources into the final product still embodies a great deal of energy.

The transportation and distribution that is involved in the debit/credit card lifecycle is one of the largest forms of its embodiments of energy. A plastic card travels across a country several times throughout its lifetime, from the point of extraction of carbon-based resources such as crude oil, gas, and coal to the point of disposal. Plastic cards and its raw materials must travel to various other locations and distributors before this once cheap piece of plastic is considered extremely valuable and in the hands of the consumer. During a plastic card’s lifecycle, it travels via truck, plane, train, and ship. The distribution to a customer also includes other secondary raw materials within the packaging such as paper, cardboard and other plastics. Paper packaging is a major issue as cards are often sent through mail and “sent on paper carriers, in paper envelopes, accompanied by paper brochures. The carbon footprint of four pages of A4/letter format paper can have an equivalent carbon footprint in the range of the individual card’s plastic material” (Trüggelmann, 2012). The global industry of plastic cards only further exacerbates the embodiment of energy and negative environmental impacts that come from plastic cards. A report by the International Card Manufacturer’s Association stated that “the fact that there are multiple raw materials, sheet producers, card manufacturers and distributors significantly increases the complexity of the life cycle of cards” (ICMA, 2010). Debit and credit cards have become universally known and one of the most commonly used forms of currency in a majority of developed countries. Usually, a country will have national manufacturers and distributors of plastic cards, but this is only impacted when considering that it is occurring in almost every country. A plastic card travels across a country several times before making it into the hands of the cardholder.

The average credit/debit card is in use for about 2-3 years before it is either lost, reported stolen, or replaced entirely. The average American also has four credit cards in their possession at a time, not to mention several other plastic cards they may also have in their wallet. When plastic debit or credit cards are disposed of, they are heavily recommended to be shredded or cut and put into the trash so as to protect the former cardholder, and this is exactly what most frequently occurs. This ultimately results in a high number of plastic cards in use, and that eventually end up in the landfill or are incinerated. A single plastic card may not seem like a significant amount of plastic, but with it being the major payment method used around the globe, its improper disposal has accumulated enough to have notable environmental impacts on our planet.

Unfortunately, PVC is a form of plastic that makes it difficult to be recycled, or “downcycled” easily but it is possible. Plastic debit and credit cards are also viable to security concerns due to the sensitive information they contain about their cardholders. This makes the composting and recycling of plastics such as PVC that much more difficult, and, due to this, PVC is more often than not sorted and incinerated or buried in a landfill left to sit for years with due to its inability to decompose. Incinerating plastic requires large amounts of fossil fuels to burn them at high temperatures and this releases harmful gases. Landfills are no better solution to the disposal of discarded plastics, once buried in landfills, these piles of dirt can release harmful methane and carbon dioxide gases into the Earth’s atmosphere. This is further explained in the International Card Manufacturer’s Association, as they state, “The materials entering this system are the raw materials extracted from the earth; the final materials leaving this system are air and water emissions and final solid waste produced.” The fossil fuels used to produce PVC products such as plastic cards are present throughout its entire lifecycle. Even after its disposal, plastics such as PVC, through landfills and incineration, emit greenhouse gases and liquid pollutants into the environment and atmosphere. Proper waste management must be urgently addressed in order to combat any further damage to our environment as “inadequate disposal of plastic waste is the main driver of global plastic leakage” (OECD, 2019). More responsibility should be placed on the manufacturers of these plastics in order to ensure the safe disposal of fossil-fuel based materials, and not let it solely rest on the consumers of their products.

To conclude, although plastic cards are much more convenient and portable than normal currency, its benefits do not fully account for the large amounts of embodied energy that goes into its manufacturing, distribution and disposal. The extraction of fossil fuels is not sustainable due to only a limited amount of these carbon-based resources that take millions of years to replenish. The chemical industry’s utilization of these resources to produce different plastics, chemicals and fuels since the beginning of the twentieth century has proven itself detrimental to our environment due to the improper disposal and maintenance of these harmful raw materials and respective products. Overall, although recycling can be an option when disposing plastic cards, however, there are overarching security concerns regarding personal and financial information. Proper waste management spearheaded by the corporations that produce these harmful products is necessary, as well as a greater emphasis on the educating on the topics of pollution and recycling and composting.

Bibliography

Magnetic Stripe

Tang, Michael. “Fic 1 Production Flow Of Cards Method 1 Method 2 Initial Printing Magnetic Tape Application Die Cutting Card Separation Magnetic Encoding Variable Printing/FOL Application. (n.d.),” “United States Patent Application: Singlepass Plastic Card Manufacturing System”, Dec. 20, 2007, pp. 1-3.

Microchip and Radio Frequency

R. Leighton, Keith. “Radio Frequency Identification Card and Hot Lamination Process for the Manufacture of Radio Frequency Identification Cards. (2001),” United States Patent. Apr. 10, 2001. pp. 5-6.

2. Apparatus and Method for Developing Plastic Cards

Melzer, R. “Application Data 63 Continuation-in-part of Ser,” “United States Patent: Apparatus and Method for Manufacturing Plastic Cards,” Vol. 593, Issue 779, May, 6 1987, pp. 5-6.

3. Plastic Waste Management

Faraca, Giorgia. Astrup, Thomas. “Plastic waste from recycling centres: Characterisation and evaluation of plastic recyclability, Waste Management.” Volume 95, pp. 388-398, 2019,

ISSN 0956-053X. https://doi.org/10.1016/j.wasman.2019.06.038.

4. Plastic Solid Waste Recycling

S.M. Al-Salem, P. Lettieri, J. Baeyens. “The valorization of plastic solid waste (PSW) by primary to quaternary routes: From re-use to energy and chemicals.” “Progress in Energy and Combustion Science”, Volume 36, Issue 1, 2010, pp. 103-129, ISSN 0360-1285, https://doi.org/10.1016/j.pecs.2009.09.001. (https://www.sciencedirect.com/science/article/pii/S0360128509000446).

5. Environmental Impacts of Debit Card Payments

Lindgreen, E. R., van Schendel, M., Jonker, N., Kloek, J., de Graaff, L., & Davidson, M. “Evaluating the environmental impact of debit card payments”, International Journal of Life Cycle Assessment”, (2018), pp. 2-3. https://doi.org/10.1007/s11367-017-1408-6

6. Energy Used in Plastic Production

Schlüter, B. A., & Rosano, M. B. “A holistic approach to energy efficiency assessment in plastic processing.” Journal of Cleaner Production, Volume 118, 2016, pp. 19-28, ISSN 0959-6526,

https://doi.org/10.1016/j.jclepro.2016.01.037. (https://www.sciencedirect.com/science/article/pii/S095965261600072X)

7. Plastic Card Recycling/Landfill

Erik, R. L., Milan, v. S., Jonker, N., Kloek, J., de Graaff, L., & Davidson, M. “Evaluating the environmental impact of debit card payments.” “The International Journal of Life Cycle Assessment”, (2018), pp. 1-3. Vol. 23, no.9, 1847-1861. doi:https://doi.org/10.1007/s11367-017-1408-6

8. Polymers and Plasticizers

Beach, E. S., Weeks, B. R., Stern, R., & Anastas, P. T. “Plastics additives and green chemistry.” “Pure and Applied Chemistry.Chimie Pure Et Appliquee”, vol. 85. no.8, 2013, pp. 5-6. 1611-1624. doi:https://doi.org/10.1351/PAC-CON-12-08-08

9. Patent for Card with Magnetic stripe

Foote, F. C. “Production of Laminated Card with Printed Magnetically Encodable Stripe,” United States Patent, July 11, 1978, pp. 3-4.

10. Plastic Waste Management for Cards

Dr. PIYUSH GUPTA. “Plastic Waste Management,” “Industrial People Management, vol.29, 2016, pp. 253-255, ISBN: 978-81-948131-0-1.

11. PVC

Wypych, George. “PVC degradation and stabilization”, ChemTec Publishing, 2008, 2015, 2020. 4th edition. ISBN 9781927885628.

12. White, Alexandria. “Americans Have an Average of 4 Credit Cards-Is That Too Many?” CNBC, CNBC, 10 May 2022, https://www.cnbc.com/select/how-many-credit-cards-does-the-average-american-have/.

13. “Plastic Leakage and Greenhouse Gas Emissions Are Increasing.” OECD, https://www.oecd.org/environment/plastics/increased-plastic-leakage-and-greenhouse-gas-emissions.htm#:~:text=Throughout%20their%20lifecycle%2C%20plastics%20have,to%20global%20greenhouse%20gas%20emissions.

14. Trüggelmann, Uwe, and TruCert Ltd. Carbon Footprint of the Card Industry. 2012. Special Events II, ICMA Card Manufacturing, https://www.icma.com/ArticleArchives/CarbonFootprint_SE2-12.pdf.

15. International Card Manufacturers Association. Indicators for the Environmental Impact of Cards. 2010. ICMA Ecolabel Indicators Criteria Doc, https://icma.com/wp-content/uploads/2014/10/ICMAEcoIndicatorsCriteria.pdf.

______________________________________________________________________________________________

Emily Reed

Victor Barajas and Mia Guo

DES 40A

Professor Cogdell

16 March 2023

The Life Cycle of a Credit Card: Embodied Energy

Modern credit and debit card technology has made it incredibly efficient to pay for goods and transfer funds. With a credit card, you can easily pay for goods in-store, purchase goods online, and transfer money between people without ever having to meet face to face. Almost everyone carries at least one of these cards in their wallet and most use them much more frequently than printed currency. However, the materials used in credit card development and technology have had detrimental effects on the environment. Materials used - especially PVC plastic - and the transportation, manufacturing, and recycling of credit cards can cause significant environmental harm. As credit cards have become more widely used and their technology has developed further, their negative impacts have increased. These detrimental effects derive mainly from the significant use of electrical energy as well as the use of PVC, a type of plastic that can be harmful to the environment.

Modern credit cards are made up of many materials including various plastics, opaquing agents, plasticizers, and laminate sheets (Foote). The main and most researched material listed here is PVC (polyvinyl chloride) plastic. PVC is not a naturally occurring substance and thus has to be manufactured using chloride gas and ethylene. These substances are combined to form vinyl chloride, which then goes through a series of manufacturing processes to become PVC (Wypych). This acquisition of these chemicals involves high levels of embodied energy that can be harmful to the environment. Ethylene production, specifically, is a major part of the U.S. petrochemical industry and uses large amounts of chemical energy. The most energy-intensive step of the ethylene acquisition process is the cracking of hydrocarbon feedstocks, in which a gas mix (made up of ethylene and other gasses) is heated up and then rapidly cooled, creating liquid ethylene that can then be extracted. Waste and fuel gas are used to provide the chemical energy needed for this reaction. In 1990, the energy consumption of the ethylene production process was thought to be about 1 quintillion joules/year. Since then, ethylene has become even more widely used, but no further energy estimates have been provided, so the current estimate could be even higher (Worrell). According to the International Card Manufacturers Association, non-renewable primary energy (NRPE) consumption in the entire PVC production process is equal to about 55.45 MJ/kg and has a global warming potential (GWP) of about 1.88 kgCO2/kg. Essentially, this means that PVC production uses a high level of non-renewable primary energy, and produces a potential for global warming 1.88 times higher than releasing 1kg of CO2 (Indicators for the Environmental Impact of Cards). Once processed, these primary materials move on to be manufactured into the final product, a credit card.

No two manufacturers create credit cards the exact same way, so information on the energy used in this process can be difficult to ascertain. However, it seems that generally cards are manufactured using two separate layers - a core stock layer and a thermoplastic surface laminate layer. In cards with magnetic stripe or EMV chip technology, these materials are placed between the two layers (Foote). Plastic compounding and molding, in which the plastic used for these layers is processed into the correct form, uses significant electrical energy. Plastic processing is incredibly energy intensive and can take up a significant percentage of a country’s entire energy demand, which results in increased energy costs and greenhouse gas emissions. In a study done on a plastic production plant in Germany, it was found that only about 4% of energy in the core plastic production process actually goes toward making the material. The rest of the electricity involved is used for powering machines not involved in the core process and for powering infrastructure such as coolers, heaters, and computers. The entire process was found to be incredibly inefficient - kinetic energy losses in the form of electricity made up for 62% of the entire demand (Schlüter). Not all of the energy involved in making a credit comes from its manufacturing process, however. Once the card is made, it must be transported to its final destination and, once there, used and eventually disposed of. These processes also involve significant energy usage.

The most popular methods for transporting credit cards after they are manufactured are by truck, train, ship, and air. These processes can cause significant CO2 pollution and use large amounts of chemical energy in the form of gasoline. Air transport both uses the most energy and produces the most emissions. A short haul flight (less than 462 km) uses 28,399MJ of energy and releases 1,936 grams of CO2 while transporting one ton of goods over a distance of one kilometer. Container ships use 144MJ of energy and release 10 grams of CO2 for every ton of goods transported one kilometer. Trucks use 1,728MJ of energy and release 120g CO2 for the same weight and distance. Trains are the most energy-efficient transportation option, but still require 468MJ of energy to transport one ton one kilometer, and release 32 grams of CO2 (Indicators for the Environmental Impact of Cards). Once they reach their destination, credit cards are used and reused by the consumer.

According to an article by CNBC, the average American has a total of four credit cards, and likely countless other plastic cards, in their wallet. Though these cards typically last 3-5 years before they expire and need to be replaced, they are used almost daily. The energy used in these transactions can cause harm to the environment. A study done on the environmental impact of card transactions in the Netherlands illustrates this point - transactions for an entire year resulted in an “environmental burden” of approximately 1.5 million Pt. This measurement was obtained by weighing three different results for damage done to an environment: impacts on human health, ecosystem quality, and resources. This translates to a global warming potential of about 12.2 million kg CO2. The climate change potential of each individual credit card transaction is calculated to be ~3.78 grams of CO2 equivalents. The energy use involved in credit card transactions originates from two different parts of the transaction process: the physical point of sale (POS) system the customer completes the transaction at, and the data center that processes the transaction. It is advised by many corporations that POS systems are not shut off when not in use in order to create a more efficient work environment. Thus, POS systems are always using electrical energy. Greater amounts of energy are used to perform specific tasks such as completing a transaction or printing a receipt. A POS system requires about 0.0063Wh to complete a transaction and 0.0240Wh to print a receipt. As a customer completes a transaction at a POS, information about their identity and purchase is transferred to a data center. Data centers serve as hubs for processing transactions, which includes routing the consumer’s information to the appropriate bank, contacting banks to reserve the transaction amount on the consumer’s account, and communicating with acceptant payment service providers (APSPs) to handle the card payment on behalf of the merchant. In this study, energy use at these data centers was conglomerated into renewable and non-renewable categories. It was found that in the Netherlands, data centers using non-renewable energy used 2,142,306 kW h of energy in one year, and data centers using renewable energy used 916,060 kW h of energy in one year (Lindgreen). Consumers typically carry out thousands of credit card transactions each year, making their total contribution towards climate change potential a significant amount. After using their card for 3-5 years, the consumer then disposes of it.

Once disposed of, credit cards can either end up in landfills or their plastic can be reused, which is a more environmentally friendly option that reduces CO2 emissions and fossil fuel use. However, the high concentration of phthalates found in the soft PVC used for credit cards can make them difficult to recycle. Phthalates are highly toxic chemical compounds added to credit cards that give them flexibility and durability (Faraca). If ingested, they can cause human developmental or reproductive harm (Heudorf). Recycling a credit card is thus a slippery slope because one can run the risk of contaminating an entire batch of recycling with phthalates. One study found that products made from recycled plastic had a significantly higher phthalate concentration than those made from virgin materials (Pivnenko). Thus, according to the Environmental Protection Agency, though over 910,000 tons of PVC waste is generated annually, less than 0.25% is ever recycled (Murphy). Most of the remaining PVC is incinerated in landfills using chemical and thermal energy, which produces harmful emissions such as dioxide ash (Napierska). There are however some alternative methods to PVC recycling, such as chemical recycling. Chemical recycling is a process by which PVC is broken down molecule by molecule, allowing the harmful additives to be removed and the usable material to be recycled. The facilities and machines required to do this are especially costly, however, so the process is not widely used (Murphy). If chemical recycling were to become more accessible, it could significantly reduce emissions caused by the incineration of PVC and other materials.

Creating, manufacturing, and disposing of plastic credit cards are incredibly energy-intensive processes that can be harmful to the environment. The main environmental issue caused by credit card consumption is the use of PVC plastic. The utilization of ethylene in PVC production gives the process a significant global warming potential. Recycling PVC is also an incredibly difficult process due to the presence of phthalates in the material, so most PVC that ends up in landfills is incinerated, contributing to global warming by increasing carbon emissions. Besides the use of PVC, the electrical energy involved in making and using credit cards can also add to global warming. A significant amount of electrical energy is used in the credit card manufacturing process and in processing transactions at POS systems and data centers. Changes to the credit card manufacturing process such as using PVC alternatives as well as decreasing electricity usage in POS systems or data centers could significantly reduce the harmful effects of credit card manufacturing, use, and disposal.

Bibliography

Faraca, Giorgia, and Thomas Astrup. “Plastic Waste from Recycling Centres: Characterisation and Evaluation of Plastic Recyclability.” Waste Management, vol. 95, 25 June 2019, pp. 388–398., https://doi.org/10.1016/j.wasman.2019.06.038. Accessed 15 Mar. 2023.

Foote, Frances C. Production of Laminated Card with Printed Magnetically Encodable Stripe. 11 July 1978.

Heudorf, Ursel, et al. “Phthalates: Toxicology and Exposure.” International Journal of Hygiene and Environmental Health, vol. 210, no. 5, 31 Oct. 2007, pp. 623–634. Elsevier, https://doi.org/10.1016/j.ijheh.2007.07.011.

Indicators for the Environmental Impact of Cards - ICMA. https://icma.com/wp-content/uploads/2017/11/icma-indicators-for-the-environmental-impact-of-cards-document-final-2020.pdf.

Lindgreen, Erik Roos, et al. Evaluating the Environmental Impact of Debit Card Payments.

Murphy, Melissa. “PVC Recycling.” Home Guides | SF Gate, 17 Nov. 2020, https://homeguides.sfgate.com/pvc-recycling-79771.html.

Napierska, Dorota, and Ruth Stringer. “Briefing/Opinion - Why PVC and PTFE Should Not Be Placed on OECD Green List of Waste Shipment.” Www.noharm-Europe.org, Oct. 2019, https://noharm-global.org/sites/default/files/documents-files/6108/2019-10-09_HCWH_feedback_PVC_PTFE_FINAL.pdf.

Pivnenko, K., et al. “Recycling of Plastic Waste: Presence of Phthalates in Plastics from Households and Industry.” Waste Management, vol. 54, Aug. 2016, pp. 44–52. Elsevier, https://doi.org/10.1016/j.wasman.2016.05.014.

Schlüter, B. Alexander, and Michele B. Rosano. “A Holistic Approach to Energy Efficiency Assessment in Plastic Processing.” Journal of Cleaner Production, vol. 118, 25 Jan. 2016, pp. 19–28. Elsevier, https://doi.org/10.1016/j.jclepro.2016.01.037.

White, Alexandria. “Americans Have an Average of 4 Credit Cards-Is That Too Many?” CNBC, CNBC, 10 May 2022, https://www.cnbc.com/select/how-many-credit-cards-does-the-average-american-have/#:~:text=While%20there's%20no%20perfect%20answer,credits%20and%20interest%2Dfree%20financing.

Worrell, Ernst, et al. Energy Use and Energy Intensity of the U.S. Chemical Industry.

Wypych, George. “PVC Manufacture Technology.” PVC Degradation and Stabilization, ChemTec Publishing, Toronto, 2020.

______________________________________________________________________________________________

Mia Guo

Victor Barajas, Emily Reed

DES 40A

Professor Cogdell

The Recycling and Waste Emission of Plastic Credit Cards

With the advancement of technology, we live in a world that has gradually abandoned the use of paper money and started using small plastic credit cards for all payment operations for over 100 years. All payments can be controlled with plastic cards, which brings great convenience to people, leading to a huge growth in the credit card production industry.

However, along with all the benefits brought by credit cards, there comes a significant number of harmful effects on the environment. From the beginning process of raw material extraction to producing process of plastic credit cards, there comes emissions and pollutants to Earth. More than that, there are also concerns regarding recycling and waste management in its life cycle. Because credit cards are so small, people often overlook their recycling value and bury them in the ground with other landfill, releasing toxic substances that pollute water, soil, and air constantly.

The Emission and Waste for PVC: One Essential Material in Plastic Credit Card Production Process:

There are waste and emissions already in the first process of manufacturing a plastic credit card, raw material extraction. Polyvinyl chloride, also known as PVC, is the main material for making plastic credit cards. It needs both the extraction of salt and fossil fuels for chlorine which is acquired from salt and ethylene obtained from oil and natural gases in order to produce the PVC boards for credit card production (Polyvinyl Chloride PVC).

Chlorine is extracted from salt during PVC production by splitting sodium chloride from seawater using a specific technological process, which results in the emission of chlorine gases. Chlorine is a strong oxidant with a suffocating odor that is dangerous to human health if inhaled in large quantities. Furthermore, it is toxic to both air and water, and its effects, such as birth defects, are long-lasting. Chlorine produces chlorinated compounds when it reacts with organic molecules, resulting in organochlorine waste and byproducts such as chlorinated dioxins and furans. These toxic substances have the potential to contaminate local ecosystems, affecting fish, wildlife, and humans, as well as causing a variety of negative health effects. Furthermore, chlorine gas emissions from PVC production can pollute local environments and ecosystems, and when the gases react with other molecules like carbon tetrachloride, contributing to global warming (The Polyvinyl Chloride Debate: Why PVC remains a problematic material, 2021).

Ethylene is a crucial component in the manufacturing of Polyvinyl Chloride (PVC). It is procured through naphtha or crude oil cracking, which is associated with highly energy-intensive procedures that release greenhouse gases, including carbon dioxide and hydrogen gases. However, the extraction of crude oil also results in the discharge of various metals, nonmetals, and organic chemicals into the surrounding environment, such as copper, selenium, zinc, arsenic, and polychlorinated biphenyls (Ghanta et al. 173).

The most PVC production process will combine the two primary essential feedstocks into vinyl chloride monomer in order to manufacture PVC board and produce them in the form of plastic credit cards in life. During the converting process, there is highly toxic waste comes along and recognized as dioxins, furans, polychlorinated biphenyls, and hexachlorobenzene (The Polyvinyl Chloride Debate: Why PVC remains a problematic material, 2021). After the extraction and production processes of raw materials, the vinyl chloride monomer is polymerized into PVC board and awaiting final production in the plastic card market.

The Waste and Emission for EMV Chip: The Functioning Part in Plastic Credit Cards

To manufacture a well-functioning plastic credit card in daily life, the EMV chip is indispensable in the process. In the manufacturing process of EMV chips and integrated circuits, the factories are actually producing silicon substrates on the nano and micrometric scale. During production, there are two types of plants involved: the front-end and back-end plants. The front-end plants produce wafers and silicon-based semiconductor chips and the back-end plants are for the packaging, which will protect and integrate chips on circuits (Villard et al. 4, 2014). During EVM chip manufacturing, there are emissions and wastes related in the fields of raw material masses, chemical, gas, water, and machine power. In the aspect of water pollution, there are liquid substances containing metals and toxic compounds, acids such as chlorine, fluor, nitrogen, and phosphorous compounds, silica compounds, and fluor compounds generated into wastewater and discharged into seas which degraded water quality for animals and plants. Another polluted part that will be considered in chip production will be the air on the planet. The organic compounds such as VOC formation, doping gases like silane, phosphine, and diborane, and etchants like nitrous oxide and boron trichloride are also emitted into the air, leading to more greenhouse gases released which degrade the air quality and accelerate global warming (Villard et al. 11, 2014).

Sustainable and Emission in Card Manufacturing: Printing, Dyes, and Laser Cutting Technology

After the two essential parts, PVC boards and EMV chips, are ready; here comes the final card production next. Since credit cards are always presenting and advertising branding and marketing information, there are designs needed to print on the card with messages promoted for different companies. The most common technology used in plastic card printing is called dye sublimation printing. Unexpectedly, this technique is eco-friendly. There are no dyes emitting into the water system because the printing process is completely waterless. It is using water-based inks that contain no volatile organic compounds or heavy metals, creating a sustainable part of card production (Ross, 2016).

The following step after embedding chips, lamination, and printing is laser cutting the PVC boards into final products. Laser cutting had been widely used in the industries of plastic cards instead of mechanical-based methods, creating a much more efficient and stable way for factories. However, laser cutting in PVC will emit excessive hydrogen chloride that could lead the injuring the optics and motion control system for animals (Elsheikh et al., 2021).

The Transportation of Credit Cards

The process of manufacturing and distributing credit cards involves several steps, one of which is the transportation and preparation of the cards for customers. To transport credit cards, there are various packaging materials are used in the process, such as paper envelopes, brochures, plastic wrappers, and boxes. The production of paper requires the use of trees, water, and energy, which can contribute to deforestation and air pollution. Furthermore, the transportation of credit cards by plane, train, ship, and truck worldwide also contributes to carbon emissions. Every 10,000 km of shipping by air for a plastic card can emit over 25 grams of carbon dioxide into the atmosphere. These emissions can accelerate global warming and negatively impact air quality, potentially leading to health problems for humans and wildlife (Trüggelmann, 2012).

Usage and Maintenance of Credit Card

Although PVC is known for its durability in the banking market for regular card usage, frequent and prolonged use can still lead to the card becoming weakened, unreadable, or even cracked, resulting in new plastic card needs in the market. Another reason to renew a card is to avoid fraud and identity theft, so banks usually set the expiration date from three to five in order to provide the best user experience to the customers. However, this practice leads to environmental degradation by generating more waste and emissions. Currently, there are approximately 24.56 billion cards in circulation globally, with the industry producing approximately five billion new cards annually for use, reuse, and maintenance (Trivedi, 2021). The production of each PVC-based credit card is estimated to contribute to approximately 20 grams of CO2 emissions and the cumulative effect in the industry is estimated to be over 40,000 tons (Trüggelmann, 2012).

The Recycle of Plastic Credit Cards

Unfortunately, there are not much of plastic credit cards will be recycled in their end-of-life cycle. One of the reasons is that there is no regulation of card recycling to the public, and since they are containing sensitive personal information and are also small in size, people would tend to cut them and throw them away. Another reason is that the specific type of PVC that is commonly used for credit cards, polyvinyl chloride acetate, also known as PVCA, is difficult to recycle. Even though most community recycling centers won’t accept this type of PVC products, there are still some cooperations that are willing to recycle them. During the recycling, the cards will be ground up to make other plastic products such as vinyl flooring, window frames, or piping (FitzGerald, 2020). In addition, there are emerging recycling practices developing that specifically target plastic cards. During their recycling process, they will separate the plastic and metals which comes from the EMV into two parts, incinerate plastic waste into thermal energy, and use the heat from plastic to purify and refine gold, palladium, and copper. Then the metals will be used in other industries for a second life such as jewelry and electronic markets (What to do with old credit cards? A quick review).

Common Way of Credit Card Disposal in its End-of-Life Cycle

Despite efforts in recycling to reduce the negative impact of plastic cards, the most common method of disposal of plastic credit cards is still through landfilling for the public. Once the cards are discarded into landfills, plastic credit cards require from 20 to 200 years to biodegrade, leading to the release of harmful chemicals and additives such as chlorine, carbon dioxide, and carcinogens. These substances can emit into the soil and air, potentially causing harm to the surrounding ecosystem (SF Gate Contributor, 2020).

Incineration is an alternative disposal method that poses environmental concerns. Since there are a lot of other chemicals were added during the production of PVC, more hazardous concerns are shown in the process of incineration. PVC will release highly corrosive hydrochloric acid gas and produce ash that contains heavy metals such as cadmium and lead, contaminating both the air and groundwater (SF Gate Contributor, 2020). Recycling plastic cards is a more eco-friendly option when considering the environmental impact as opposed to disposing of them in landfills. It is imperative to initiate and enhance recycling practices to minimize the detrimental effects of plastic waste on the planet.

Credit card payment brings people convenience and a great number of benefits, but we are also paying the advantages it provided us back with the environmental condition. Throughout the life cycle of plastic credit cards, it produces an excessive amount of CO2 in the carbon footage, emitting a great number of hazardous chemicals into water, air, and soil, leading to the degradation of the environment and human health. However, the pollution is not only happening in the stage of raw material extraction and card production, it is also showing in the disposal phase at the end of the life cycle. Recycling is not common and requires new technology, fund, and cooperation from the public. It has not been standardized to recycle this very widely used product, instead, landfilling is people’s first choice, which resulting more CO2 and other toxicants emissions to the place humans and wildlife live.

Bibliography

Elsheikh, A.H., Muthuramalingam, T., Abd Elaziz, M. et al. Minimization of fume emissions in laser cutting of polyvinyl chloride sheets using genetic algorithm. Int. J. Environ. Sci. Technol. 19, 6331–6344 (2022). https://doi.org/10.1007/s13762-021-03566-x

FitzGerald, Ray. “Can Credit Cards Be Recycled? Plastics Expert Keith Vorst Answers a Question That Is More Difficult than You May Think.” CardRates.com, CardRates.com, 19 Oct. 2020, https://www.cardrates.com/news/how-to-remain-eco-friendly-by-recycling-old-credit-cards/.

Ghanta, M., Fahey, D. & Subramaniam, B. Environmental impacts of ethylene production from diverse feedstocks and energy sources. Appl Petrochem Res 4, 167–179 (2014). https://doi.org/10.1007/s13203-013-0029-7

“Polyvinyl Chloride PVC.” British Plastics Federation, https://www.bpf.co.uk/plastipedia/polymers/PVC.aspx.

Ross, Charlie Bradley. “The Sublimation Printing Process; What Is IT & Is It Eco Friendly?” The Sustainable Fashion Collective, 8 Jan. 2016, https://www.the-sustainable-fashion-collective.com/2016/01/08/what-is-sublimation-printing-process-ecofriendly.

SF Gate Contributor. “PVC Disposal and Recycling.” Home Guides | SF Gate, SFGATE, 3 Dec. 2020, https://homeguides.sfgate.com/pvc-disposal-recycling-79234.html.

“The Polyvinyl Chloride Debate: Why PVC Remains a Problematic Material.” HCWH Europe, June 2021.

Trivedi, Vaidik. “Card Companies Go Green, but Hurdles Remain.” Payments Dive, 22 July 2021, https://www.paymentsdive.com/news/payments-companies-look-towards-greener-future-roadblocks-lie-ahead/602847/.

Trüggelmann, Uwe, and TruCert Ltd. Carbon Footprint of the Card Industry. 2012. Special Events II, ICMA Card Manufacturing, https://www.icma.com/ArticleArchives/CarbonFootprint_SE2-12.pdf.

Villard, Aurélie, et al. Drawing a chip environmental profile: environmental indicators for the semiconductor industry. Journal of Cleaner Production, 2015, 86, pp.98-109. ff10.1016/j.jclepro.2014.08.061ff. ffhal-01063777f

“What to Do with Old Credit Cards? A Quick Review.” Thales Group, https://www.thalesgroup.com/en/markets/digital-identity-and-security/banking-payment/inspired/old-credit-cards.