Design Life-Cycle

assess.design.(don't)consume

Grace Goodfriend

Lauren Mabe

DES 40A

March 16, 2023

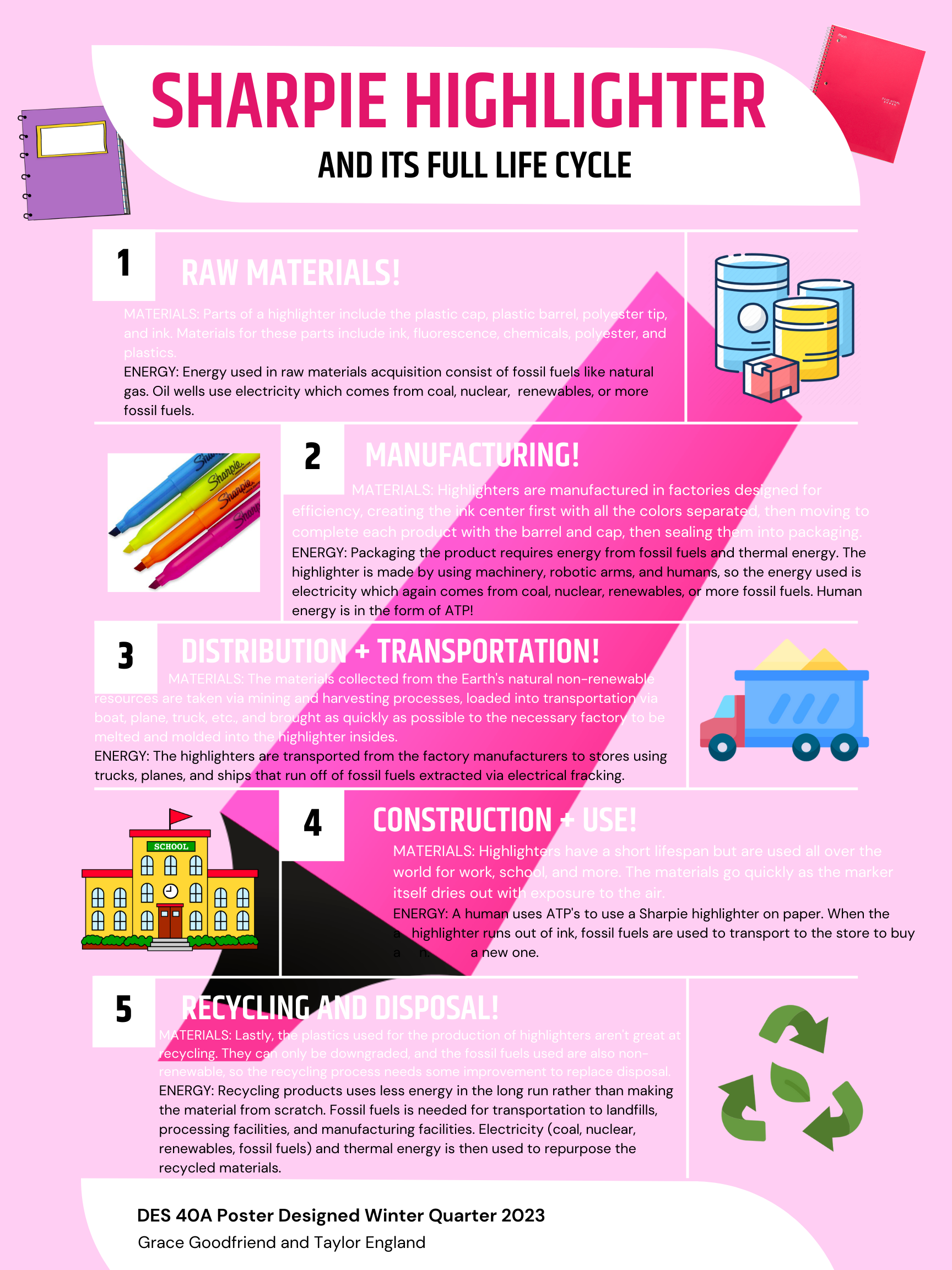

Raw Materials of Sharpie Highlighters

When one thinks of school and work supplies, their mind does not automatically jump to the in-depth description of how they are made, or to the thought-provoking question of where do they come from? This is something that requires a great deal of deep diving into research to find information from proper sources. Many separate conversations can be discussed about the parts of the process that make up these products. The one helpful and well-known product that this essay will focus on is the highlighter, and more specifically from Sharpie, with its many colors and fluorescent design. The highlighter itself was originally created in 1963, on accident, by Francis J. Honn, then vice president of technology at Carter's Ink, while trying to create a new nonpermanent marker for children. To specifically explain the life cycle of a Sharpie highlighter, materials are first gathered raw from many different places around the world, then altered in a factory using machines, working with plastic and neon elements, to finally create the luminescent color that is necessary in order to produce this product.

The primary part of the highlighter creation process is gathering the raw materials. There are many different materials that come both straight from Earth’s deposits, and from the factories that turn the raw materials into secondary materials so they are usable for multiple purposes. The first material is the physical ink + color in the pen/marker. Ink comes from dyes, either from artificial compounds or natural sources, as a chemical liquid. This is a secondary resource that is taken from plants that are planted, grown, and harvested. These plants are used for other purposes, and then the colorful parts of them are taken into a factory to be pressed into endless colors of dye. The ink in a highlighter isn’t black as it is in a pen or regular Sharpie, it actually has a fluorescent component to it, regardless of whether it is a primary or secondary color being infused into the marker. This fluorescence is the emission of light by a substance that has absorbed light or other electromagnetic radiation. It can come from kidney wood, and a lot of it actually originates in Japan, and is then transported around the world via plane, boat, train, truck, etc. The chemical that aids this fluorescence in making the ink glow is called Phosphor. It is a substance that exhibits the phenomenon of luminescence. Coming from phosphate rock, the process to make this essentially heats phosphate rock in the presence of carbon and silica in a furnace. Combining these chemicals and elements to form the inside part of the highlighter lead to discussing the outside parts and packaging of it.

A couple other chemicals that are of notable importance in standard-sized Sharpie highlighters are n-butanol, n-propanol, and diacetone alcohol. The larger highlighter markers may have, in addition to these three, cresol and xylene. All of these chemicals follow the limits set by the The Occupational Safety and Health Administration (OSHA) to keep an eye on human exposure. Most highlighter ink also contains fluorescein, as a part of the fluorescence, which is an organic compound and dye that is soluble in water.

Sharpie highlighters are composed of a plastic cap, a plastic barrel, and a tip for writing made of polyester. These two both come from non-renewable fossil fuels, making the beginning of this production not as eco-friendly as some may think. Polyester is a synthetic fiber derived from coal, air, water, and petroleum. Fibers of this material are formed from a chemical reaction between an acid and alcohol, and the cost is about $3 per yard, being cheaper in certain countries over others. The plastics that make up the outer shell of the highlighter, or the cap and barrel, come from oil and natural gases. To create the caps, Alyssa Mertes explains the exact process that occurs in a Sharpie factory. Mertes writes, “A vacuum siphons plastic pellets into a large container. These are dyed in the eventual color of the highlighter’s barrel. The plastic pellets are heated and melted down into a liquid form at about 240°F. A mechanical steel screw pushes the liquid plastic down into premade pen molds. Lastly, the highlighter barrels are cooled down by water and stored in a container.” (Mertes 4) This process creates flawless highlighter caps and barrels out of plastic. Regarding the most important part of the entire marker, the tip, it is made from beads of polyester, which falls under the lightweight types of plastic. So essentially, highlighters contain a lot of materials but they can be condensed into 2 groups: plastic and chemicals.

School supply markers and highlighters are mass dispersed for sale, as they are widespread, easily accessible, cheap items used in schooling all around the world. The yearly shopping spree (usually each August) for brand new school supplies always includes highlighters, and this is when the majority of the productions skyrocket and line the shelves of stores. These markers are dispersed throughout the world from the factories where they are created and packaged. They are loaded into all different modes of transportation, whether it be over water by boat, through the skies on planes, or over land through many different ways.

Once the collection of materials, production of products, dispersion and sales of the highlighters, and use of the actual object are all over, the last step in this entire life cycle of the highlighter marker is to essentially get rid of it. Sharpie highlighters are a piece of plastic and ink materials that have a relatively short lifespan. This is because for each second that the chemicals in the tip + ink are exposed to air, they start to dry out. After a certain amount of time the ink will eventually dry up. When a cap is kept on, it will extend the lifespan, but without one, the Sharpie highlighter would dry up and only have a full lifetime of one day, maybe even less than 24 hours, before it is unable to be used and must be discarded. When discussing the final method of disposal and/or recycling and where the plastic goes, it is important to note that it really should go somewhere better than where it goes now, as it isn’t very efficient. For now, the plastic is able to be recycled about half-way. It is only able to be downgraded instead of being entirely recyclable as soda cans are. A solid statistic about the inefficiency of the process to gather this plastic for proper recycling reads, “Eighty-six percent of plastic packaging produced globally is never collected for recycling, according to a 2016 World Economic Forum report.” (Lemonick 3) Even if this mass amount of plastic were able to be collected and gathered into one space, the technology today doesn’t have enough knowledge about the properties of recycled as well as downgraded plastic to be able to get 100% efficiency out of it once it is all used. All in all, right now in time, plastic simply does not recycle well. A lot of it even ends up in landfills.

The thought and effort for the future of recycling directly affects how long our Earth and its natural but non-renewable resources will be able to support the creation of products such as Sharpie highlighters, and all of the other products that Sharpie creates and sells on a yearly basis. One way to improve the life-cycle would be to find chemicals that don’t dry out as easily to put into the ink, so the lifespan of each individual highlighter marker can be longer. This would potentially lead to less resources being used, both in the plastic and chemical industries.

Wrapping up these parts of the Sharpie highlighter and how the materials and resources from our planet are used to create it, the process is a long but also simple one. There are many different chemicals that can be included in the process, especially to produce the different colors and add fluorescence. The plastic cap, barrel, and polyester tip are all created using resources that must be taken care of in order to preserve the process of the highlighter and its life cycle. Sharpie has found so many purposes for these highlighters, ending up in so many different places. In schools starting all the way down at elementary, then through college, and even into the workforce, they will always have a manufacturing process that will continue to increase in efficiency, simplicity, and eco-friendliness.

Bibliography

Dani, Riya. “Plastic Processing: Upcycling, Recycling, Downcycling and More.” Earth5R, 8 July 2020, https://earth5r.org/plastic-and-what-to-do-with-it/#:~:text=While%20the%20plastic%20is%20processed,which%20do%20not%20recycle%20well.

Dodge, Tony. “What Chemicals Are in Highlighter Markers?” What Chemicals Are In Highlighter Markers?, https://snippets.com/what-chemicals-are-in-highlighter-markers.htm.

Legare, Danielle. “Ed Artifact - Brightening the School Year: The History of the Highlighter.” Ed Artifact - Brightening the School Year: The History of the Highlighter - Graduate School of Education - University at Buffalo, University of Buffalo Graduate School of Education, 22 June 2022, https://ed.buffalo.edu/magazine/issues/spring-2022/ed-artifact.html.

Lemonick, Sam. “Recycling Needs a Revamp.” Cen.acs.org, https://cen.acs.org/environment/pollution/Recycling-needs-revamp/96/i25.

Mertes, Alyssa. “What Chemicals Are in Highlighters & How Are They Made?” Promotional Products Blog, 24 Jan. 2023, https://www.qualitylogoproducts.com/blog/what-chemicals-in-highlighters/.

Nakaya, Rion. “How Does Faber-Castell Make Highlighters?” The Kid Should See This, 26 Jan. 2022, https://thekidshouldseethis.com/post/how-does-faber-castell-make-highlighters.

Nexus102rah, Engineering World, director. YouTube, YouTube, 2 Apr. 2021, https://www.youtube.com/watch?v=zjopKHGuu7A. Accessed 3 Feb. 2023.

Palm, Kristin. “Marker Highlighters.” How Products Are Made, http://www.madehow.com/Volume-3/Marker.html.

Pearltreessays, Consumer Products, and Anxoidesays. “The Chemistry of Highlighter Colours.” Compound Interest, 22 Jan. 2019, https://www.compoundchem.com/2015/01/22/highlighters/.

Rinkesh. “Can You Recycle Highlighters? (and Are They Bad for the Environment?).” Conserve Energy Future, 29 July 2022, https://www.conserve-energy-future.com/can-you-recycle-highlighters.php.

“What Makes a ‘Fluorescent’ Highlighter so Bright?” Science Questions with Surprising Answers, https://www.wtamu.edu/~cbaird/sq/2015/05/15/what-makes-a-fluorescent-highlighter-marker-so-bright/.

Writer, Staff. “What Is Highlighter Ink Made of?” Reference, IAC Publishing, https://www.reference.com/science-technology/highlighter-ink-made-210b58777f80353c.

Taylor England

3/1/2023

Des 40A

Lauren Mabe

Sharpie Highlighters Life Cycle: Energy

“The Sharpie brand highlighters have been in the hands of millions of students, teachers and people everyday since they were made in 1964.” (Sharpie) They can be found in a classroom, office, backpack, pencil case, desk, and the junk drawer of a kitchen. The Sharpie highlighter comes in many colors, giving papers a bright neon translucent finish over text. Millions of Sharpies are made and sold each year which means there are factories working with many forms of energy to make the highlighters. The materials acquisition, manufacturing, distribution, maintenance, and disposal of Sharpie highlighters use many forms of energy including electrical, human, thermal, and the burning of fossil fuels.

To start, raw materials are needed to make the highlighter’s shell, tip, cap, colorful dye, and packaging. The acquisition of these materials requires energy in a few forms. First, plastic is used in the highlighters shell, tip, cap and packaging. “Plastics are produced from natural gas, feedstocks derived from natural gas processing, and feedstocks derived from crude oil refining,” (Energy Information Agency) Natural gas is an energy source fossil fuel, and to extract it from the earth also takes energy. Oil wells drill into the earth to capture the natural gas. In the process of fracking, “all the equipment that's being used to do the actual hydraulic fracturing process is electric,” (Ozuna) Electricity comes from what is being extracted, natural gas, as well as coal, and nuclear energy. (Alternative Fuels Data Center). Next, the highlighter inks contain chemicals like Fluorescein, pyrene, triphenylmethane, xanthene, coumarin and rhodamine. (Mertes) Lastly, cardboard is used in the packaging which comes from trees. Trees get cut down using electrical and human energy, ATP, and then are shipped using fossil fuels to be manufactured into cardboard. The process starts by pulping pine tree chips and then being put through a fourdrinier machine. These steps use electrical and thermal energy. (Moses) After the cardboard is made, fossil fuels are used again to ship the materials to the Sharpie manufacturer for packaging its highlighters.

Next, once all the materials needed are in the factory, the highlighters can be put together by machines, robotic arms, and a little help from a human chemist. The product manufacturing requires energy like electricity for the machines and arms, and then throughout the process thermal energy, ultraviolet radiation and human energy, ATP, is used. The manufacturing starts with a vacuum siphoning pellets into a container and melting them with thermal energy heating to 240 degrees Fahrenheit. Steel screws push melted plastic into pen molds with a force that's equal to 350 elephants. Molds are then dropped into a conveyer and robotic arms use electricity to put caps on.. A human chemist then puts concentrated dye in a beaker of water until the right color and consistency is correct. Following that, a robotic arm pushes needles in reservoirs to inject them with ink. Then, mechanical vibrations and compressed air drive the conveyor belt with pen nibs. They then fall into a clutch of mechanical claws which drops them to be shoved into the pen. Mechanical machine slides the cap on and positions it to get the log pressed. Once the logo is on, an ultraviolet light chamber bonds the ink to the pen. Once the highlighter is made, it is then tested by mechanical grippers which press the pen to paper and rotate in circles. At the very end, the highlighters are put into their packaging with more mechanical parts. (Insider)

After the highlighter is made in the factory, it's ready to be distributed to stores. There are numerous Sharpie manufacturers, one in the United States in Tennessee and others in Mexicali, Baja California, Mexico. (Sharpie) These manufacturers ship off highlighters to stores all around the world. In the United States you can find them at Target, Walmart, many grocery stores, and office supply stores. A lot of energy is used to do all this shipping across multiple stores around the planet. The main energy used in transportation and distribution is fossil fuels. “Transportation is almost entirely reliant (90%) upon petroleum products.” (Rodrigue) Petroleum products are used to power trucks, ships and planes that transport the highlighters.

You might pick up a Sharpie when reading a book, doing schoolwork or office work. Energy in the human body, ATP of course, is used to glide the highlighter across paper. You can’t add more ink into a Sharpie highlighter or fix one. When your Sharpie runs out of ink, you throw it away and go buy a new one. Energy in this step of the life cycle just comes from the human throwing the highlighter away and going to the store to buy a new one. Once again when you get in your car to buy a new one, you are most likely using fossil fuels to power the engine of your car. If you're using an electric car to make your trip then you are using electricity which again, comes from natural gas, coal, nuclear power plants, or renewable sources. (Energy Information Agency)

After opening a new highlighter package you can recycle the packaging because it's plastic and cardboard. When it comes time to throw away your dead highlighter, it can either be thrown away or mail them to a company called Terracycle which can recycle them. To recycle a highlighter on your own you have to take the ink reservoir out, the tip off and wash the inside plastic with water. If thrown away in the trash it will be carried and dumped to a landfill by a truck using fossil fuels. When recycled, a truck, again using fossil fuels, carries it to a processing facility where they are sorted, cleaned and then transported by trucks to a milling or manufacturing facility. (Environmental Protection Agency) Recycled material is then shredded into flakes by electrical energy and/or melted with thermal energy to form pellets before being molded into new products. (Recycle Now)

An important note to add is that using energy to make highlighters and other things that people use everyday affects our climate drastically. “Worldwide, in recent years, billions of tons of carbon dioxide and more than 120 million metric tons of methane, the two key greenhouse gasses, have been emitted annually into the atmosphere from the production and burning of fossil fuels for energy and transportation.”(Perera) Since pre-industrial times the global temperature has gone up by about 2 degrees Fahrenheit the Intergovernmental panel concluded we must limit the global temperature to not going above 2.7 degrees Fahrenheit to minimize global consequences. So just in the last two centuries we have risen 2 degrees in the global temperature and with the demand from the world population of about 8 billion people we will continue to see a rise in global temperature. “In the wake of concerns raised by many researchers over the ever increasing demand for energy from emerging economies and the projections for a huge shortage of fossil fuels in the not-too-distant future, the goal of achieving increased energy efficiency has taken an even greater significance.”(Mukherjee) The earth's supply of fossil fuels is finite and it’s not a sustainable resource. Not only does the greenhouse gasses emitted from the burning of fossil fuels cause climate change, they also pollute the air and cause health concerns to people.

The life cycle of a Sharpie highlighter includes materials acquisition, manufacturing, distribution, maintenance, and disposal which use many forms of energy in each step including electrical, human, thermal, and the burning of fossil fuels. The number one form of energy used in the life cycle of Sharpie highlighters are fossil fuels. Extracting fossil fuels also takes energy and they are used to make plastic, power machines in factories, and transport materials and products through every step of the lifecycle from materials acquisition to disposal. “One ton of recycled plastic saves 5,774 Kwh of energy, 16.3 barrels of oil, 98 million BTU's of energy, and 30 cubic yards of landfill space.” (Stanford University) Recycling Sharpie highlighters, their packaging, and any other recyclable materials you use in your life saves energy which also saves our planet from greenhouse gas emissions that cause climate change. Do your part and always remember to reduce, reuse, and recycle.

Sources

-Alternative Fuels Data Center, U.S. Department of Energy, “Electricity Production and Distribution,”https://afdc.energy.gov/fuels/electricity_production.html#:~:text=According%20to%20the%20U.S.%20Energy,biomass%2C%20wind%2C%20and%20geothermal.

-Conserve Energy Future, “Can You Recycle Highlighters? (And Are They Bad For The Environment?),”https://www.conserve-energy-future.com/can-you-recycle-highlighters.php#:~:text=Yes%2C%20your%20highlighters%20are%20recyclable.&text=You%20can%20always%20recycle%20highlighters,of%20the%20favorite%20recycling%20materials.

-Environmental Protection Agency, The U.S. Recycling System,

-Insider, “How Highlighter Pens Are Made,” Youtube, July 21, 2018, https://www.youtube.com/watch?v=gyKTUmnHH-M

-Made How, “Marker,” How Products are Made, volume 3 http://www.madehow.com/Volume-3/Marker.html

-Mertes, Alyssa, “What Chemicals are in Highlighters and How Are They Made,” Quality Logo Products Blog, January 24th,2023 https://www.qualitylogoproducts.com/blog/what-chemicals-in-highlighters/

-Moses, Clara, “The Pulp And Paper Making Process,” Springfield Printing, November 18, 2022

https://blog.springfieldprinting.com/the-pulp-paper-making-process

-Mukherjee, Kankana, Energy use efficiency in U.S. manufacturing: A nonparametric analysis,Energy Economics,Volume 30, Issue 1,2008,Pages 76-96,ISSN 0140-9883,

https://doi.org/10.1016/j.eneco.2006.11.004. (https://www.sciencedirect.com/science/article/pii/S0140988306001411)

-Ozuna, Jesus, S&P Global, The Potential of Electric Fracking, September 11, 2019,https://www.spglobal.com/commodityinsights/en/ci/research-analysis/the-potential-of-electric-fracking.html#:~:text=When%20people%20hear%20it%2C%20they,hydraulic%20fracturing%20process%20is%20electric.

-Perera, Frederica, “Climate Change, Fossil-Fuel Pollution, and Childrens Health,” The New England Journal of Medicine, June 16, 2022, https://www.nejm.org/doi/full/10.1056/NEJMra2117706

-Recycle Now, “How is Plastic Recycled,”

https://www.recyclenow.com/how-to-recycle/plastic-recycling

-Rodrigue, Jean-Paul, “Transportation and Energy,” The Geography of Transport Systems, Chapter 4.1 https://transportgeography.org/contents/chapter4/transportation-and-energy/

-Sharpie, “Sharpie-About Us A Brief History,”

-Stanford University, “Frequently Asked Questions: Benefits of Recycling,”

-U.S. Energy Information Administration, “How Much Oil is Used to Make Plastic,” June 1, 2021

-U.S. Energy Information Administration, “Natural Gas Explained,” December 27, 2022,

https://www.eia.gov/energyexplained/natural-gas/

-U.S. Energy Information Administration,“Use of Energy Explained, Energy Use For Transportation,” June 12, 2022 https://www.eia.gov/energyexplained/use-of-energy/transportation.php