Design Life-Cycle

assess.design.(don't)consume

Genesia Ting

DES 40A Fall 2016

Professor Cogdell

December 1, 2016

Vaseline: Raw Materials

Introduction

Vaseline is a widely distributed product that heals, rejuvenates, and moisturizes dry, cracked skin. It is a semi-solid, with a mixture of hydrocarbons mostly found in petroleum. Advertised to be 100% pure petroleum jelly, Unilever has continued to sit at the top of the skincare market for nearly 135 years.

Compared to the commercial giant it is today, Vaseline had small and humble beginnings. Vaseline, first known as the “Wonder Jelly,” was invented by Robert Augustus Chesebrough. He was intrigued by miners who would apply a byproduct from the oil drilling. This byproduct was unrefined petroleum jelly, also known as rod wax. The workers would apply the rod wax on their burns, and Chesebrough decided to research further into it. He performed many tests of refinery and distillation to help create a safer and better product. Even though Vaseline is a versatile fix-it solution, it is composed of unsustainable and unhealthy materials that are hazardous to the environment around it. Although Unilever is making small steps every year towards more sustainable products, we can see how environmentally destructive Vaseline is through examining its acquisition of raw materials.

Materials

Crude oil is the overarching umbrella material that all of the byproduct raw materials are created from. According to oilprice.com, crude oil is first created through the compression and heating of organic materials for many years. The formation of crude oil happens through a process called diagenesis, which melts the organic material and mud together through sediment compression. Crude oil, in terms of content percentage, varies greatly. Refineries will process the crude oil differently depending on its chemical composition and contents. Since the main ingredient, petroleum jelly, consists of varying amounts of both solid and liquid hydrocarbons, there are many methods for refinement.

For the extraction process, miners drill into the oil fields, which is highly detrimental to the environment, as petroleum is the residue from nonrenewable fossil fuels. Unilever’s site claims that their raw material extraction makes up a whopping 29% of the company’s greenhouse gas footprint. They understand that sustainability is important to both their customers and the rest of the community, and have implemented plans to become 100% agriculturally sustainable and renewable sources by 2030. However, Unilever skips over how they intend to transform their Vaseline with this plan, given that Vaseline consists of 100% petroleum jelly – a byproduct from nonrenewable fossil fuel sources.

I believe this is one of Unilever’s biggest roadblocks on their path to sustainability – because their mining and distillation is outsourced, they have less control over the processing. Although it is much further into the future – what is the fate of Vaseline when crude oil and other fossil fuels run out? There is no alternative to Vaseline that provides the same versatility while also being safe. Coconut oil comes to a close second, but it is also unsustainable.

According to U.S. Energy Information Administration, petroleum production in the U.S. alone (including crude oil, other petroleum liquids, and renewable fuels) is about 13,799,000 barrels per day. Crude oil production alone is about 9,431,000 barrels per day. This is only a small measure on the global scale of crude oil production. I was not able to get any exact numbers from crude oil production, because Unilever conducts its mining, extraction, and distillation in various parts of Africa.

Byproducts

After some processing, crude oil becomes petroleum oil through extraction of liquid hydrocarbons at petrolatum refineries. Vacuum distillation followed by filtration of the residue through bone char will then yield petroleum jelly, the primary ingredient in Vaseline.

Petroleum jelly, our main ingredient, makes up the highest percentage of product within the Vaseline mixture. It is mined in various factories scattered throughout Africa. Vaseline comprises of 6 main ingredients – petroleum jelly, paraffin oil, paraffin wax, lanolin, Vitamin E, and polypropylene for the packaging. Petroleum jelly, paraffin oil, and paraffin wax are all various byproduct forms of crude oil.

Primary Material: Petroleum Jelly

Although Chesebrough essentially had a foolproof recipe to start with for the clear and odorless semi-solid, the production and ingredients of Vaseline have changed slightly since its beginnings. The distillation and filtering process have remained relatively the same. Because of this, artificial Vaseline has several more materials than the advertised 100% pure petroleum jelly. The information on their website, as well as their product packaging, synthesize the amount of materials contained within the product. According to Unilever’s website, Vaseline is the only petroleum jelly product with a triple-purification seal. The purification process includes distillation, de-aeration, and filtration. This ensures that the waxy substance is free of air bubbles and as uniform as possible.

Paraffin Wax and Oil

Unmentioned by not unknown, paraffin wax and paraffin oil are two important ingredients to Vaseline. The term “paraffin” is often used interchangeably with alkane. Paraffin oil is used to adjust the consistency of the mixture. It is an oil that reduces thickness and has nourishing abilities, but on the other hand can serve as a flammable hydrocarbon or used as jet fuel. Paraffin wax is one of the other byproducts created from distillation, and is separated and refined to be mixed back together later on. It is found combined with slack wax, made of oil and wax, which is a byproduct from lubricating oil. Paraffin wax is purified through sweating and solvent refining. The wax often has things added to it in order to achieve a goal – for example, reaching a certain melting point, or trying to obtain a high viscosity.

Other Raw Materials

Lanolin is made of sheep wax. It adds a level of elasticity to the Vaseline. The extraction of crude wool to processing of lanolin is relatively simple – lanolin.com explains it thoroughly. First, the wool wax is refined by placing it in an aqueous acid solution which neutralizes the acids. It is placed through another process which has a much denser alcohol solution, in order to rid it of all impurities. It is then placed in a vacuum where it is dried, and reemerges as a pale, ointment-like substance. Vitamin E is the last raw material that goes into the mixture. It is typically extracted from wheat germ oil. Serving as an antioxidant, vitamin E helps with dry and cracked skin.

Polypropylene Containers

For Vaseline’s containers, Unilever uses type 5 plastic, formally known as polypropylene. Polypropylene is recycled and melted together with other types of plastic, created from propene in a Ziegler-Natta catalyst in a polymerization process. According to Guichon Valves Valco Group, for polypropylene production, “Various production processes exist with some general similarities. They are taking place either in a gas-phase (fluidized bed or stirred reactor) or a liquid-phase process (slurry or solution).” Unilever has been striving towards a more sustainable environment, and slowly using more and more recycled plastic with the help of new technology. By cutting down on the amount of plastic used, Unilever is saving energy and the amount of new plastic used.

Processing

According to Dooms-Goossens and Degreef, “natural petrolatum can be purified in several different ways, including treatment with sulfuric acid followed by neutralization with sodium hydroxide; filtration through bleaching earth, animal charcoal, silica gel, or aluminum silicate; selective solvent extraction; catalytic hydrogenation.” Goossen and Degreef weren’t specific about which petrolatum their paper covered, although white and yellow petrolatum are very similarly processed. The only difference between yellow and white petrolatum is that the white petrolatum has been processed much more, resulting in a more colorless semi-solid. To create the white petrolatum, the crude oil byproduct raw materials must be melted together. Vitamin E is added later on into the mixture, placed in containers made of polypropylene from machine molds.

Discussion

Generally speaking, extracting crude oil in its rawest form is harmful to the environment. The byproducts as a mixture, in Vaseline, may not seem like it has a direct impact in terms of its greenhouse gas footprint, but the productions to refine and purify the residue have CO2 emissions. Extracting the raw materials, separating them, refining them, melting them, and mixing them does not come without consequences. The only option I see possible for Unilever’s future would be to scrap Vaseline altogether and switch to coconut oil. As far as distribution, transportation, recycling, and waste management processes go, Vaseline has no new raw materials involved.

What does this mean for our future? Unilever’s vision is to ideally source 100% of their agriculturally raw materials sustainably. It is commendable that such a corporation as large as Unilever is taking steps towards a more sustainable future. They are making some headway – about 36% of their raw materials are now sustainable agricultural raw materials. Although Vaseline’s product qualities may seem too good to be true, they pose a risk to community health and have a much larger detrimental impact on its surroundings in the long run. Unfortunately, until a more sustainable option is developed, Vaseline production will continue to quietly make an impact on the environment.

Works Cited

Al Aboud, Khalid M., and Amor Khachemoune. "Vaseline®: A Historical

Perspective." Dermatology Nursing 21.3 (2009): 143. Web. 12 Oct. 2016.

Becker, Armin J., et al. "Petroleum jelly is an ideal contact medium for pain reduction and

successful treatment with extracorporeal shock wave lithotripsy." The Journal of urology 162.1 (1999): 18-22. 18 Oct. 2016.

"CIEC Promoting Science at the University of York, York, UK." Poly(propene) (Polypropylene).

N.p., n.d. Web. 24 Nov. 2016.

Chesebrough, Robert A. "Improvement in products from petroleum." U.S. Patent No.

127,568. 4 Jun. 1872. Web. 15 Oct. 2016.

Dept, Editorial. "What Is Crude Oil? A Detailed Explanation on This Essential Fossil Fuel."

OilPrice.com. N.p., 24 July 2009. Web. 20 Oct. 2016.

Dooms‐Goossens, A., and Hugo Degreef. "Contact allergy to petrolatums." Contact Dermatitis

9.3 (1983): 175-185. Web. 24 Oct. 2016.

Foldvari, M. "Effect of vehicle on topical liposomal drug delivery: petrolatum bases."

Journal of microencapsulation 13.5 (1996): 589-600. Web. 2 Nov. 2016.

Homan, P. G. "Vaseline: From trade mark to noun." Pharmaceutical Journal 281.7533

(2008): 754. Web. 12 Oct. 2016.

Lachampt, Felix, Andre Viout, and Guy Vanlerberghe. "New emulsions, and cosmetic products

made from such emulsions." U.S. Patent No. 3,846,546. 5 Nov. 1974. Web. 20 Oct. 2016.

"Lanolin Refinement." From Crude Wool Grease to Refined Lanolin. Lanolin.com, n.d. Web. 20

Nov. 2016.

Park, Eun-Kyoung, and Ki-Won Song. "Rheological evaluation of petroleum jelly as a base

material in ointment and cream formulations: steady shear flow behavior." Archives of pharmacal research 33.1 (2010): 141-150. Web. 14 Oct. 2016.

"Refining Crude Oil." Refining Crude Oil - Energy Explained, Your Guide To Understanding

Energy - Energy Information Administration. U.S. Energy Information Administration, n.d. Web. 2 Nov. 2016.

Rose, Walter, and Amy C. Zimmerman. "Petroleum jelly cream." U.S. Patent No. 5,407,678. 18

Apr. 1995. Web. 14 Oct. 2016.

Soma, Yoshinao, et al. "Moisturizing effects of topical nicotinamide on atopic dry skin."

International journal of dermatology 44.3 (2005): 197-202. Web. 20 Oct. 2016.

Strakosch, Ernest A. "Studies on Ointments I. Penetration of Various Ointment Bases."

Journal of Pharmacology and Experimental Therapeutics 78.1 (1943): 65-71. Web. 28 Nov. 2016.

Taheripour, Farzad, et al. "Biofuels and their by-products: Global economic and environmental

implications." Biomass and bioenergy 34.3 (2010): 278-289. Web. 25 Nov. 2016.

Treffel, P., and B. Gabard. "Skin penetration and sun protection factor of ultra-violet

filters from two vehicles." Pharmaceutical research 13.5 (1996): 770-774. Web 27 Nov. 2016.

Ulrich, G., et al. "Sensitization to petrolatum: an unusual cause of false‐positive drug patch‐

tests." Allergy 59.9 (2004): 1006-1009. Web. 22 Oct. 2016.

Matthew Lococo

Design 40A

Christina Cogdell

1 December 2016

Embodied Energy of Vaseline

Introduction

In 1870, Vaseline makes its debut as the latest and most innovative product on the American skin-care market. Wanting to learn more about petroleum and its uses, British chemist, Robert Chesebrough travelled to Titusville, Pennsylvania in 1859 where abundant crude oil reserves had been recently discovered. At the site of extraction, Chesebrough noticed how the oilmen would apply residue from the drill to help their cuts to heal. After his conclusion that this cure had validity, Chesebrough patented the production of petroleum jelly in 1870. Being such a long-existing product in the realm of skin care, Vaseline’s use of energy throughout its life cycle warrants better understanding. It is a common misconception to think of energy solely as part of a product’s actual processing and manufacturing, instead of viewing the involvement of energy in the life-cycle of a product from the acquisition of raw materials through its disposal. As the world increasingly needs to become more conscious of energy consumption and sustainability to avoid an impending energy blackout, there is a significance in looking at the energy involved in a product as arbitrary as Vaseline. An awareness of Vaseline’s energy consumption should be noted in particular because it is not a product in which its consumer use involves electricity or some other kind of power source. Throughout its life cycle, the energy involved in all aspects of the production of Vaseline serves to enlighten consumers of the composition of the product and the energy required for the existence of such a widely present and versatile skin-care product.

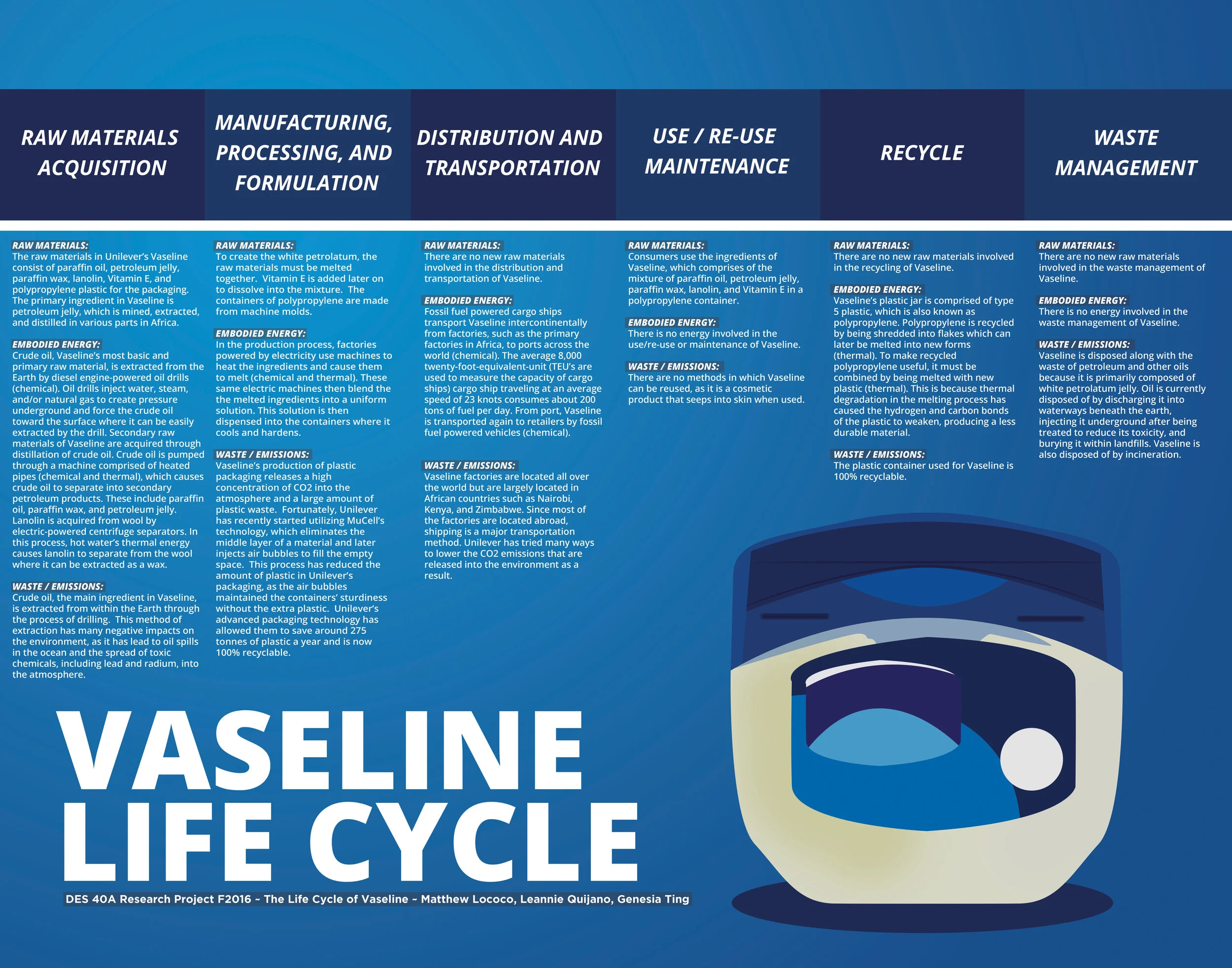

Energy’s role in Vaseline’s life cycle can be more clearly defined comprehensively beginning with the obtainment of the raw materials which form Vaseline’s ingredients, then the processing of these ingredients into Vaseline’s manufacture into a topical ointment, the international distribution of the product from factory to retailer, and ending with the recycling of Vaseline’s polypropylene container.

Raw Materials Acquisition

The primary and most basic raw material that makes up Vaseline is crude oil. Most of Vaseline’s secondary raw materials are derived from crude oil after its processing into separate petroleum byproducts, each having distinct properties. These are petroleum oil, petroleum jelly, paraffin oil, and paraffin wax, Vaseline’s only ingredient which is not originally derived from crude oil is lanolin.

Crude oil’s extraction from the Earth is Vaseline’s paramount, overarching beginning to which the product owes its existence. Deep below the Earth’s surface, housed under layers of impermeable rock, are crude oil reserves. After a reserve is located, the oil rig drills through the rock layer, entering the reserves. The oil rig then injects water, steam, or natural gas into the reserve, creating pressure and forcing the oil to the reserve’s surface. The crude oil is then pumped by the rig up to the Earth’s surface where it can be contained, and later processed. Chemical energy powers oil rigs with diesel, an unsustainable fossil fuel. On average, depending on the rig’s particular horsepower, an oil rig uses between 62.5 and 83.33 gallons of fuel per hour. This amounts to a total daily fuel consumption of 1500 to 2000 gallons of diesel. It is interesting how unsustainable fossil fuels are required at such great amounts to acquire more of Earth’s remaining fossil fuels.

After extraction, the next step toward bringing Vaseline to life is the distillation of crude oil. Distillation is the first step of processing the crude oil undergoes, which creates the petroleum byproducts that are Vaseline’s secondary raw materials. The distillation process of crude oil simply divides the matter into various petroleum byproducts separated by their concentration of hydrocarbons from light to heavy. The distillation column consists of a tall furnace, off of which several pipes extend off from top to bottom. The heated furnace that causes distillation is a source of both chemical and thermal energy. The burning of fossil fuels to heat the furnace is an example of chemical energy, while the energy embodied in the created heat is thermal energy. The products with least hydrocarbons flow into the higher pipes, while products with more hydrocarbons flow into the lower pipes.

Lanolin, an organic substance harvested from sheep wool, is an ingredient added to Vaseline for its moisturizing properties that are chemically similar to the oils naturally produced by human skin. Lanolin wax is extracted from the wool when it is boiled by a furnace. After the wool has boiled for some time, the lanolin wax rises to the surface of the water and the wet wool sinks to the bottom. The water is then allowed to cool and afterwards the lanolin is scraped from the surface. Burning of fossil fuels is required to bring the water to a boil and extract the lanolin. It is likely that in a mass-production and factory setting that wool is heated by electricity, a secondary energy source derived from fossil fuels. Both chemical and thermal energy are necessary to cause the lanolin to separate from the wool.

Manufacturing, Processing, and Formulation

The basic manufacture of Vaseline is the result of the combination of the individual ingredients into a melted uniform solution. The factories that produce Vaseline are powered by electricity. Machines that blend the ingredients into the solution that will later become Vaseline are powered by electricity. Electricity is the resultant secondary energy source derived from the burning of fossil fuels. Chemical energy is required to produce the electricity, and the heat provided by the electricity is the result of thermal energy. Unilever Kenya, the primary factory that produces Vaseline among other Unilever skin care products, operates 24 hours a day and 6 days a week. By percentage, the factory’s energy usage is 60% burning of furnace oil, 36% electricity, and 4% liquified petroleum gas; all of these energies are fossil fuels. In 2010 the factory demanded 1.8 mega volt amps of energy to operate. This great amount of energy required for a single factory’s operation is revealing of the tremendous rate at which unsustainable fossil fuels are being used.

Distribution and Transportation

The energy involved in transporting a product from the site of a factory, often abroad, to a local retailer is seldom thought of. Unilever, the company that owns Vaseline, primarily produces the product in its Nairobi, Kenya factory. While the company does not exactly disclose this, it can be assumed that the product arrives in the United States by cargo ship on either of the primary ports on the west and east coasts. Those ports would be the Port of Los Angeles and the Port of New York and New Jersey. Cargo ship sizes range from 4,000 to 10,000 twenty-foot-equivalent-units, which is a measurement of container capacity, and travel between 20 and 25 knots. It is important to note that cargo ship fuel consumption increases exponentially relative to their capacity and speed, hence their slow traveling speeds to maintain more efficiency. While the fuel consumption of a cargo ship is dependent upon both ship size and traveling speed, the average 8,000 twenty-foot-unit-equivalent cargo ship traveling at 24 knots consumes 225 tons of bunker fuel per day. Los Angeles and Nairobi are separated by 8395 nautical miles and New York and Nairobi are separated by 6397 nautical miles. Once arriving in the United States, Vaseline must driven to retailers across the country by fossil fuel powered vehicles to locations of varying distances from port. The distance from factories abroad to domestic retailers is revealing of the immense amount of energy simply used to transport the product to the consumer.

Recycle

After the contents of Vaseline’s container have been used, the type 5 plastic jar can be recycled. While not as commonly accepted by recycling facilities as plastic types 1 and 2, type 5 plastic, which is also known as polypropylene, is recyclable. Polypropylene’s durability and density are accompanied by a greater melting point; because of this, the plastic is not often recycled because of the heat and time needed for it to melt. The first step that polypropylene undergoes to be recycled is that it is shredded into flakes or compressed into pellets. When recycled polypropylene flakes or pellets are later melted to be remolded, the plastic undergoes thermal degradation, causing it to lose its sought after quality of being durable. Newly produced polypropylene has an embodied energy of 75 to 83 megajoules per kilogram and recycled polypropylene has an embodied energy of 35 to 45 megajoules per kilogram. However, in order for recycled polypropylene to be useful, it must be combined with newly produced plastic, making the recycled material not all that sustainable.

Conclusion

Examining Vaseline’s entire life cycle from an energy perspective is not only informative about the popular skin-care product itself, but is revealing of a much larger picture that is depictive of the embodied energy of a product outside of its appearance to the consumer. This life cycle assessment is also telling of prevalence and dependence upon fossil fuels in society. After assessing the life cycle of such a product, energy, and particularly fossil fuel sources of energy, are understood as more than just existent at the times which their use is visible. By this I mean that energy can be viewed as having contributed to the existence of any manufactured product, not just those which consume an energy source during their use, such as a gasoline powered vehicle or an electricity powered lamp. Most importantly, the life cycle of Vaseline can communicate society’s dependence on energy though a product that is unassociated with day to day energy use.

Bibliography

Abhari, Ramin. "Process for producing synthetic petroleum jelly." U.S. Patent No. 7,851,663. 14 Dec. 2010.

Kelly, Mike. "Energy: Exploration and Production." Prometheus Energy. Global Hunter Securities, 23 Apr. 2012. Web. 30 Nov. 2016.

Lavirotte, Francois. "Process of preparing petrolatum and the like and product obtained thereby." U.S. Patent No. 1,785,270. 16 Dec. 1930.

Mittal, V., J. Zhang, X. Yang, and Q. Xu. "E3 Analysis for Crude and Vacuum Distillation System." Chemical Engineering & Technology 34.11 (2011): 1854-863. Web.

Muriuki, John Peter. "Analysis of Energy Use and Improvement Opportunities at Unilever Kenya LTD." (2013): 4-5. Web. 30 Nov. 2016.

Rodrigue, Jean-Paule. "Fuel Consumption by Containership Size and Speed." Fuel Consumption by Containership Size and Speed. Hofstra University, n.d. Web. 01 Dec. 2016.

Thomas, G.P. "Recycling of Polypropylene (PP)." AZoCleantech.com. AZoNetwork, 25 June 2016. Web. 01 Dec. 2016.

Tooley, Jill. "Resource Center » The Different Types of Plastic and Their Number Classifications (Codes)." The Different Types of Plastic and Their Number Classifications (Codes) - Quality Logo Products, Inc. Quality Logo Products, Inc., n.d. Web. 01 Dec. 2016.

"About the Refinery." Processing & Refining Crude Oil | What We Do | About the Refinery. Chevron, n.d. Web. 01 Dec. 2016.

"Extracting Lanolin From Sheep's Wool." YouTube. YouTube, 20 Feb. 2015. Web. 01 Dec. 2016.

"Learn More about Vaseline®, the Original Skin Expert for over 140 Years." Read About the History of Vaseline and Our Skincare Products. Unilever, n.d. Web. 01 Dec. 2016.

"Unilever Opens $1.5M Vaseline Production Factory in Kenya to Meet Skin Care Demands." African Business Central. African Business Central, 08 Oct. 2015. Web. 01 Dec. 2016.

Leannie Quijano

Professor Cogdell

DES 40A

December 1, 2016

Vaseline: waste and emissions

Introduction

Vaseline, originally known as “Wonder Jelly”, is a unique multipurpose ointment that can be used to hydrate lips, soften skin, and protect skin from dryness. This multipurpose ointment gets its unique healing properties from the byproduct of distilled crude oil. Vaseline consists of ingredients that stem from petroleum, which is recovered from drilling deep into the earth. Its main ingredients are white petrolatum, paraffin oil, and paraffin wax. Due to its association with crude oil, Vaseline has become a controversial product in recent years, as consumers have become more aware of global warming and Greenhouse Gas (GHG) emissions. By analyzing all aspects of the life cycle of Vaseline and its production, we can see all the waste and emissions that subsequently come from the petroleum-based product and gain a better understanding on the effects its waste has on the environment.

Raw Material Extraction

The production of Vaseline begins with the extraction of petroleum from beneath the ground through the process of drilling, which happens until large pockets of oil are uncovered. The extractions process of raw materials for Vaseline and other products produced by Unilever make up 29% of Unilever’s Greenhouse Gas footprint. How could something like an ointment be the cause of such a high amount of greenhouse gas? Well first the crude oil is pumped out from the ground where the drilling occurred, and then it has to be transported to a site for it to be processed and distilled. The extraction of crude oil has lead to many waste and gas emissions, which contaminate the environment. Some of these toxic chemicals include Uranium, Thorium, Lead, and the most commonly found radioactive material (NORM) waste is Radium (Oil and Gas Waste). The waste that is produced from drilling is not only hazardous to the environment but is also dangerous to human health. The toxins such as Lead- 210 and Radium can cause neurological abnormalities, not to mention bone and lung cancer.

After petroleum is drilled from the earth it goes through multiple processes of distillation to reach the end result of differing substances. Some of these substances are used in cosmetic and other consumer goods. Petroleum must be distilled and purified by a process of "sweating" or solvent refining before being safe for consumers to use (Wax and Vaseline Plant 4). Heating up crude oil at different temperatures will produce varying types of wax-like substances. These processed substances secrete “slop oil sludge emulsion” which is treated by an acid demulsifier that can be made more acidic depending on the type and quality of the waste.

Manufacturing/ Packaging

Although plastic packaging only makes up 2% of Unilever’s GHG emissions, the process still releases a high concentration of CO2 into the atmosphere and a great amount of plastic waste into the environment. Fortunately, the company has formulated a new way to cut the amount of plastic it uses in its packaging by partnering with MuCell’s technology to more efficiently produce their containers with less plastic. MuCell technology eliminates the middle layer of a material, which is later injected with air bubbles to fill in the empty space. This process has reduced the amount of plastic in Unilever’s packaging, as the air bubbles maintain the containers’ sturdiness without the need for more plastic.

Unilever’s advanced packaging technology has allowed them to save around 275 tonnes of plastic a year and is now 100% recyclable. Unilever has made steady progress every year towards a more efficient and sustainable production process; in 2013, Unilever released the Sustainable Living Report stating that the company reduced the waste produced by the packaging process found in landfills by (-11%).

Transportation

Vaseline factories are located all over the world but are largely located in African countries such as Nairobi, Kenya, and Zimbabwe. Since most of the factories are located abroad, shipping is a major transportation method. Unilever has tried many ways to lower the CO2 emissions that are released into the environment and is attempting to reduce its dependence on fossil fuels.

According to Unilever’s company site, it has limited its GHG footprint and has managed to cut 40% of its CO2 emissions since 2008; however there is still a rise in the overall amount of the company's gas emissions. Due to a constant growth of consumerism its GHG waste footprint has increased by +6%. In the years 2014-2015 Unilever’s distribution of products/ transportation was 2% of their GHG footprint. Unilever produces approximately 59 million tonnes of CO2 a year (Our Greenhouse Gas Footprint), which has continued to increase annually.

Re-use/ Maintenance

Vaseline is a non-reusable material as it is a type of cosmetic product that is used for external use on the skin. Once it is placed on the skin it cannot be used for a different purpose since it seeps into the skin like lotion. The white petrolatum and paraffin wax used, as the main ingredients in Vaseline are non-renewable materials. Although there is very little to do for the maintenance of Vaseline there is a high amount of waste that comes from it.

Recycle

As Unilever has managed to cut down the amount of plastic it uses within its packaging the company began to focus on making it 100% recyclable. Unilever has begun to use new materials such as high-density polyethylene (HDPE) and polyethylene terephthalate (PET) in its plastic containers (Moving to a Circular Economy). According to an article on “Moving to a Circular Economy," Unilever is using more recycled materials into its manufacturing of packaging and have used approximately 4,9000 tonnes of recycled material. Unilever encourages their costumers to recycle and reduce plastic waste by rewarding them with incentives such as their own household product of Persil laundry detergent and PG tips which is a brand of tea produced by Unilever in the UK.

The company has partnered up with a few countries such as Argentina, Brazil, and the UK to work together in order to formulate new methods to increasing recycling around the world. Recently in Brazil they were able to “collect over 10,600 tonnes of recycled material in 2014 and continuing to gather more each year,”(Moving to a circular economy).

Waste Management

Vaseline is disposed along with the waste of petroleum and other oils because it is primarily composed of white petrolatum. Currently, discharging the waste into waterways beneath the earth, injecting it underground after being treated to reduce its toxicity, and burying it within landfills is how waste companies dispose of oil. Much of the chemical waste produced by crude oil is injected into the earth and discharged into bodies of water. Vaseline is also disposed of by incineration. While some pollutants are airborne and contaminate the atmosphere other wastes get injected into the ground where it gets absorbed into the soil. The contaminated soil reaches into waterways that feed to crops and livestock that are consumed by consumers and animals.

Vaseline is an overall unique product that can be used on hair, skin, and many other things; it is a multipurpose product. By looking at the waste section of this product’s lifecycle we can conclude that its extraction and disposal contaminate the environment and is a health risk for humans. Although CO2 and other waste are increasing every year, Unilever is doing its best to find new efficient methods towards reducing its GHG waste. As Unilever finds more sustainable ways to minimize its waste, not only will Vaseline become more environmentally friendly, but also will the rest of their products.

Works Cited

“Advanced Purification of Petroleum Refinery Wastewater by Catalytic Vacuum

Distillation”. Elsevier B.V

http://www.sciencedirect.com/science/article/pii/S0304389410001408. 24 Oct. 2016.

Bennett, James. Cosmetic and Skin Petrolatum/ Petroleum Jelly

http://cosmeticsandskin.com/bcb/petrolatum.php. 24 Oct. 2016.

Etim, Joyce. “How to produce Vaseline (Skin Jelly)”, JotSroll, 12 Oct. 2015,

http://www.jotscroll.com/forums/3/posts/117/how-to-produce-vaseline-skin- jelly.html. 24 Oct. 2016.

Iso Technology, and Kore Seoul. PETROLEUM WAX & VASELINE PLANT:

http://www.qiso.co.kr/new/pds/PETROLEUM%20WAX%20&%20VASELINE%20PLANT.pdf. 23 Oct. 2016.

"Moving to a Circular Economy." Unilever Global Company Website

https://www.unilever.com/sustainable-living/what-matters-to-you/recycling-and-moving-to-a-circular-economy.html. 30 Nov. 2016.

"Oil and Gas Wastes - Princeton University." N.p., n.d.

https://www.princeton.edu/~ota/disk1/1992/9225/922506.PDF . 7 Nov. 2016.

"Our Greenhouse Gas Footprint." Unilever Global Company Website. N.p., n.d. Web. 30 Nov. 2016.

Sears, Joi. “Unilever Develops Groundbreaking Sustainable Packaging.” Triple Pundit,

12 May. 2016, http://www.triplepundit.com/2016/05/unilever-develops-groundbreaking-sustainable-packaging/. 22 Oct. 2016.

Us Epa Oar, Office Of Air Quality Planning And Standards (Oaqps). AP-42, Section 5.1:

Petroleum Refining. 23 Oct. 2016.

Unilever. "What Is Petroleum Jelly & What Is It Used For? | Vaseline.

"What Is Petroleum Jelly & What Is It Used For? | Vaseline. 24 Oct. 2016.

"Unilever Launches Breakthrough Packaging Technology That ..." N.p., 24 Apr. 2014.

https://www.unilever.com/news/press-releases/2014/14-04-24-Unilever-launches-breakthrough-packaging-technology-that-uses-15pc-less-plastic.html. 25 Oct. 2016.

“Unilever Factories and logistics reduce CO2 by 1 million tones” 15 April. 2013,

https://www.unilever.com/news/press-releases/2013/13-04-15-Unilever-factories-and-logistics-reduce-CO2-by-1-million-tonnes.html. 20 Oct. 2016.