Design Life-Cycle

assess.design.(don't)consume

Benjamin Narwold

Angel Rodas and Erika Jimenez

DES 40A

Christina Cogdell

4 December 2019

Life Cycle of a Samsung Refrigerator: Raw Materials

Refrigerators are a widespread technology, and this was enabled by their mass production by large companies such as Samsung. Refrigerators are composed of a variety of secondary materials, all of which are products of raw materials, namely metals extracted from ore and crude oil. The widespread implementation of the modern refrigerator was a product of post-WWII economic boom and the rise of suburban America and consumerism. This was a key development because due to the rise in the disposable incomes of American families, refrigerators and other appliances were now in every household. Since the popularization of the refrigerator, the design has remained fairly the same, however; the secondary materials that are used have changed due to environmental legislation. In the 1970s under the Nixon administration, many environmental laws were passed, namely, the Environmental Protection Agency, and this trend has since continued. Samsung, a major producer of electronics, has recently emerged as one of the leading manufacturers and supplies of refrigerators and other appliances. Therefore, Samsung is a pertinent company to analyze in the context of the life cycle of a refrigerator. Although Samsung refrigerators are composed of numerous secondary materials, I chose to focus my research on the raw materials used to produce steel, refrigerant, polyurethane, and polypropylene. Through my research, I have noticed the environmental problems associated with the acquisition, manufacturing and production, use, and disposal of these materials.

Steel is arguably the world’s most important engineering and construction material and consequently has a variety of uses. Steel is a secondary raw material because it produced from iron ore, which is physically mined out of the Earth. Large pits are dug where there is a naturally occurring iron ore deposit and the ore is crushed into smaller pieces and washed. The ore is then roasted to remove impurities and oxidize ferrous oxide and a blast furnace reduces iron from the iron oxide. The addition of coke and limestone completes the reduction reaction. (How Is Iron Extracted From the Earth). Blacksmiths originally hammered iron on charcoal to make steel, until the Middle Ages and the introduction of the blast furnace. Modern developments include the Bessemer process, which was developed in the 1850s and the first method that enabled the cheap, mass production of steel, as well as the basic oxygen process (BOP), which is currently used today. The BOP is an extension of the Bessemer process and pure oxygen is blown into the molten iron from the blast furnace, initiating a series of exothermic reactions. Carbon, silicon, phosphorus, and manganese are oxidized, and these impurities inhibit the durability and strength of steel if they aren’t properly removed (Basic Oxygen Process). There are many varieties, or grades of steel, that have different physical and chemical properties, and these are produced from the same molten iron. According to the World Steel Association, “Approximately 75% of modern steels have been developed in the past 20 years” (Worldsteel). Although steel production began during the iron age, almost 4,000 years ago, many technological advancements have since improved the strength to weight ratio of steel and catered the material to alternative uses. Steel production produces enormous amounts of carbon gas emissions due to energy consumption. Solid waste generated from steel production doesn’t reach landfills because the residual slag separated from the molten iron is sold to the construction industry. Additionally, electric arc furnaces generate gaseous emissions and metal dust (Steel Production & Environmental Impact). This process has some serious impacts, even though there aren’t any physical materials that need to be disposed of, and this is important when you consider the volume of steel being produced worldwide. Steel is a widely used material easily observable in everyday life, however; it merely provides structure for the refrigerator and doesn’t play a large role in the refrigeration process.

The types of chemicals used in refrigerant production have constantly evolved, but the same principle applies regarding refrigeration and this fluid is the driving force behind that refrigeration. Refrigerant fluids are produced from natural gases and these must be extracted by drilling holes in the Earth’s surface or through hydraulic fracking, which is less common because it requires an enormous input of water. These gases are then cooled to produce liquified natural gas (LNG), also known as refrigerant fluid (How Do You Gather and Harvest Natural Gas?). Due to the variety of natural gas available for extraction, there are numerous possibilities for different refrigerant fluids. The chemicals used in refrigerants have changed in recent years to comply with environmental standards and this has resulted in the phasing out of hydrofluorocarbons (HFCs), which served as the replacement for chlorofluorocarbons (CFCs). HFCs where the first installment of alternative refrigerants and promoted because they didn’t contribute to ozone depletion, however; they now face replacement by hydrofluoroolefins (HFOs) (What You Need To Know About the HFC Refrigerant Phase-Out). According to a patent outlining the manufacturing process of HFOs, “The process comprises two reactions, the first being a liquid phase, noncatalytic fluorination of the hydrochloropropene to form a hydrochlorofluoropropene (HCFO) and the second a catalyzed gas phase fluorination of the hydrochlorofluoropropene to form a hydrofluoropropene” (Elsheikh, Maher Y., Philippe Bonnet, and Benjamin Bin Chen). While these HFOs haven’t yet been implemented commercially and utilized in refrigerators, this indicates that they are an established alternative for the HFCs. A similar patent addresses why these HFOs are a sufficient alternative and states that “The inherent chemical instability of these materials in the lower atmosphere provides the low global warming potential and zero or near zero ozone depletion properties desired. However, such inherent instability is believed to also impact the commercial application of such materials which will degrade during storage, handling and use” (Elsheikh, Maher Y.). This indicates that HFOs present a great alternative and the challenge now is to solve the issue of commercial application so that we can shift to more sustainable refrigerant fluid. I struggled to find specifics regarding refrigerant and its role in the overall life cycle of a refrigerator, but this exemplifies that a priority is being placed on researching sustainable alternatives and the feasibility of using these new versions of refrigerant is currently the only hiccup in this process.

Refrigerators, like many other products today, are partially composed of plastics and the two primary plastics are polyurethane and polypropylene. The production of these plastics begins with drilling for crude oil, which is then distilled in an oil refinery. Plastics are produced through polymerization, where monomers, such as ethylene and propylene, link together to form a long polymer chain. Each polymer has its properties, structure, and size depending on the various types of basic monomers used (How Plastics Are Made). Both polyurethane and polypropylene are produced through this same general process. Oil refineries have enormous environmental consequences, producing copious carbon monoxide emissions, which trap heat within Earth’s atmosphere and thus contribute to global climate change. Additional toxic air pollutants, such as sulfur dioxide, are released and these pollutants are known to cause acid rain (Misachi). Despite these impacts, plastics continue to be widely manufactured because they are needed to supply consumers with products considered essential to everyday life. While refrigerators aren’t necessarily a part of this group of everyday essentials, they can be categorized as a product we take for granted in the household.

The differences between polyurethane and polypropylene are their varying properties, specifically how they are impacted by exposure to heat. Polyurethane is a thermoset, meaning it never softens once it has been molded, whereas polypropylene is a thermoplastic, meaning it softens when heated and then hardens again on cooling (How Plastics Are Made). Due to these properties, the use of a thermoplastic is ideal if the material will be exposed to high heat. Along with this difference, thermoset composites have a lower content of raw materials, specifically petroleum-based material, and per cubic inch costs than thermoplastics. Additionally, thermosets are precision molded so there is less waste and ideal for use in household appliances due to their durability (Poff). This is the reason why polyurethane is used as an insulator in refrigerators and is more widely used than polypropylene. This begs the question of why refrigerator manufacturers, like Samsung, use polypropylene for the interior, when they know it is more expensive, produces more waste, and is economically inefficient? I couldn’t uncover an answer to this question through my research but there must be some important factor, such that these refrigerator companies, who are driven to maximize profit margins, must use the more expensive material.

In the assembly process, additional secondary materials are introduced to manufacture refrigerators. Along with the secondary materials I have already discussed, refrigerators are also composed of copper, aluminum, PVC, and glass. Refrigerators consist of an exterior cabinet and door, an inner cabinet, insulation, cooling system, refrigerant, and interior fixtures. The outer and inner cabinet and door of the refrigerator are composed of sheet metal and copper and aluminum are key raw materials present in components of the cooling system, such as the compressor, condenser, and fins (Refrigerator). Polyurethane is used as an insulator and insulation is one of the primary determinants of cooling efficiency in a refrigerator. Refrigerators have glass shelves, PVC is used in refrigerator power cables, and polypropylene is used to form the interior of the refrigerator (Refrigerator - Eco-3e). These manufacturing plants require enormous amounts of electricity sourced from a coal-burning power plant and there is an enormous amount of raw materials needed to build the necessary infrastructure and machinery. These components are then assembled at the manufacturing plant to form the final products, which are then packaged-up and transported all over the world.

When analyzing the life cycle of a refrigerator, one can’t ignore crude oil and coal and their heavy usage even after the manufacturing and production of refrigerators. Both crude oil and coal must be extracted from the Earth and on top of that produce copious amounts of greenhouse gas emissions. Crude oil is needed to produce jet fuel and gasoline to power planes and trucks that ship the materials to the assembly centers, as well as the finished products. Additionally, electricity is needed to power refrigerators, which is likely generated at a coal-burning power plant. In some cases, this electricity is supplied by an off-grid, renewable source that doesn’t use raw material, however; raw materials are still needed to produce the solar panel or wind turbine generating electricity (Cogdell). Once the refrigerator is no longer functioning, it is then hauled to the landfill and the refrigerant and electronic components are removed before it is disposed of. However, most of the materials in the refrigerator can be recycled. The refrigerators are shredded, and the metal components are separated and recycled, whereas the glass, plastics, and polyurethane foam are sent to the landfill (Frequently Asked Questions). This exemplifies that we should be recycling refrigerators to the best of our ability, however; programs for this are limited. The consumer is required to take ownership and find recycling locations that accept appliances because appliances aren’t picked up by the recycling trucks that come around every week. In conclusion, refrigerators, even when they are being utilized, still lead to more raw material consumption and the input of raw materials is not limited to the acquisition and manufacturing of these materials.

Although I was unable to find any credible source on where Samsung assembles its refrigerators, some assumptions can be made to illuminate the manufacturing and processing and distribution and transportation components of the life cycle. In 2018, according to World Steel, China produced over 50% of the world’s crude steel (World Steel In Figures 2019). Based on the sheer percentage of the world’s output and the fact that Samsung’s superconductor manufacturing facilities are located in China, it likely that Samsung is sourcing their steel from China, however; ArcelorMittal, the largest steel-making company, is not based out of China. Additionally, Samsung has four chip fabrication centers in South Korea and one in Austin, Texas, indicating that Samsung doesn’t have a strong presence in the United States regarding the manufacturing of their products (Manufacturing-Centers). Therefore, it is safe to assume Samsung assembles their refrigerators outside the US, somewhere in China or South Korea. This logistically makes sense because Samsung is based out of Seoul, South Korea and would want shorter shipping distances for the necessary components, to maximize efficiency and cut costs. Additionally, China is a very attractive place for product manufacturing and assembly because of the economic advantage of low labor costs. This was an intriguing process to find what information I could on the topic and to do my best to deduce where Samsung is acquiring the refrigerator materials and sending them for assembly.

Throughout this research process, I have developed a fundamental understanding of what makes up a refrigerator, how refrigerators are produced, and how they operate, in the context of steel, refrigerant, polyurethane, and polypropylene. Additionally, I have noticed problems associated with the practices of large companies like Samsung and the need to move towards sustainable design solutions. Refrigerators are in nearly every household and since it is unrealistic to assume we can inhibit the consumption of refrigerators in the short-term, every attempt can be made to popularize the use of “eco-friendly” materials and fund research on developing methods of refrigeration that don’t use hazardous chemicals. Additionally, large companies like Samsung should take ownership of the environmental developments that have transpired over the last couple of decades and consider the use of alternative materials. The desire for profit and the ingrained ideal across the world of maximizing that profit has contributed to the opposition towards testing alternative methods in materials in production. This project has opened my eyes to the complexity of the world we live in today and the necessity to fund research in materials science to develop functional, sustainable materials for the future.

Bibliography

BGEAdmin. “What Is a Refrigerator Made Of?” BGE Smart Energy Savers Program, 2018, bgesmartenergy.com/residential/appliance-recycling/what-refrigerator-made.

“CFC Substitutes: Good for the Ozone Layer, Bad for Climate?” ScienceDaily, ScienceDaily, 24 Feb. 2012, www.sciencedaily.com/releases/2012/02/120224110737.htm.

Cogdell, Christina. "Electricity and Renewable Energy." UC Davis. Roessler Hall, Davis. 18 Nov. 2019.

Elsheikh, Maher Y., et al. "Stabilized hydrochlorofluoroolefins and hydrofluoroolefins." U.S. Patent No. 8,388,857. 5 Mar. 2013.

Elsheikh, Maher Y., Philippe Bonnet, and Benjamin Bin Chen. "Process for the manufacture of hydrofluoroolefins." U.S. Patent No. 8,076,521. 13 Dec. 2011.

“Frequently Asked Questions about Safe Disposal of Refrigerated Household Appliances.” EPA, Environmental Protection Agency, 26 Sept. 2016, www.epa.gov/section608/frequently-asked-questions-about-safe-disposal-refrigerated-household-appliances.

“From Ore to Steel.” ArcelorMittal, corporate.arcelormittal.com/who-we-are/from-ore-to-steel.

“How Do You Gather and Harvest Natural Gas?” Blog - KB Delta, SMG, 17 Nov. 2017, kbdelta.com/blog/gather-harvest-natural-gas.html.

“How Is Iron Extracted From the Earth?” Reference, Ask Media Group, 2019, www.reference.com/science/iron-extracted-earth-7df798ba77171fc7.

“How Is Steel Produced?” World Coal Association, World Coal Association, 22 Feb. 2019, www.worldcoal.org/coal/uses-coal/how-steel-produced.

“How Plastics Are Made.” PlasticsEurope, PlasticsEurope, 2019, www.plasticseurope.org/en/about-plastics/what-are-plastics/how-plastics-are-made.

Johnson, Alec. “Does R-134a Have a Phase Out Date?” Refrigerant HQ, Amazon Services LLC, 13 Dec. 2016, refrigeranthq.com/does-r-134a-have-a-phase-out-date/.

Manufacturing-Centers. “Manufacturing Centers Locations: Samsung Semiconductor Global Website.” Electronics & Appliances: Tablets, Smartphones, TVs, Samsung, 16 Aug. 2019, www.samsung.com/semiconductor/about-us/location/manufacturing-centers/.

Misachi, John. “What Is The Environmental Impact Of The Petroleum Industry?” WorldAtlas, WorldAtlas, 28 Feb. 2017, www.worldatlas.com/articles/what-is-the-environmental-impact-of-the-petroleum-industry.html.

Poff, Ron. “Benefits of Using Thermoset Composites.” Mar-Bal, Mar-Bal, 15 Sept. 2016, blog.mar-bal.com/blog/benefits-of-using-thermoset-composites.

“Polyurethanes.” Polyurethane Applications, American Chemistry Council, 2019, polyurethane.americanchemistry.com/Polyurethanes-Applications/.

“Refrigerator.” How Products Are Made, Advameg, 2019, www.madehow.com/Volume-1/Refrigerator.html.

“Refrigerator - Eco-3e.” Eco, 27 Nov. 2016, eco3e.eu/en/base/refrigerator/.

“... So Mankind Is Now Trapped by the Failure of Its Energies and by the Depletion of Those Natural Resources That Men Have Plundered Wantonly.” PictureQuotes.com, Picture Quotes, 2018, www.picturequotes.com/so-mankind-is-now-trapped-by-the-failure-of-its-energies-and-by-the-depletion-of-those-natural-quote-251052.

“Steel Production & Environmental Impact.” Greenspec, GreenSpec, 2019, www.greenspec.co.uk/building-design/steel-products-and-environmental-impact/.

The Editors of Encyclopaedia Britannica. “Basic Oxygen Process.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., 19 May 2017, www.britannica.com/technology/basic-oxygen-process.

“What You Need To Know About the HFC Refrigerant Phase-Out - Facilities Management Insights.” Facilitiesnet, TradePress, 10 July 2017, www.facilitiesnet.com/hvac/article/What-You-Need-To-Know-About-the-HFC-Refrigerant-Phase-Out--17286.

“William S. Burroughs Quotes.” BrainyQuote, Xplore, 2019, www.brainyquote.com/quotes/william_s_burroughs_132654.

“Worldsteel.” Worldsteel, Worldsteel, 2019, www.worldsteel.org/about-steel.html.

“World Steel In Figures 2019.” World Steel In Figures 2019, World Steel Association, 2019, www.worldsteel.org/en/dam/jcr:96d7a585-e6b2-4d63-b943-4cd9ab621a91/World%2520Steel%2520in%2520Figures%25202019.pdf.

Erika, Jimenez

Angel Rodas and Benjamin Narwold

DES 40A

Professor Cogdell

Samsung Refrigerators Energy

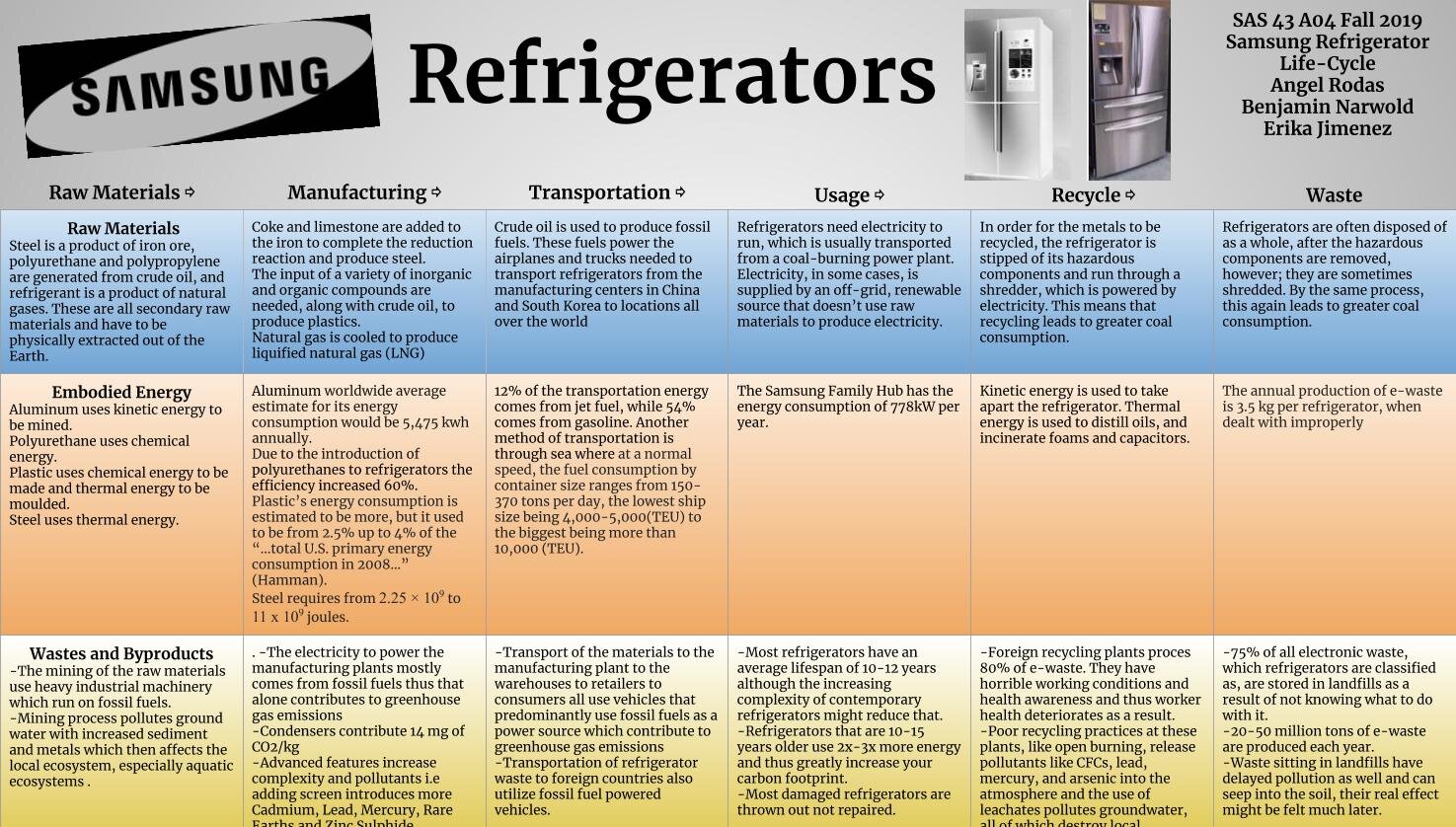

Every product has a life cycle starting with obtaining raw materials, and ending with the waste the product produces. This life cycle consists of six steps: obtaining the raw materials for the product, manufacturing, distribution and transportation, the use of the product, recycling, and waste management. The embodied energy that is consumed in this process helps understand the product’s overall energy usage. An example of the life cycle of a product is examining the life cycle of refrigerators. Refrigerators are the leading household item that consume up to 7% of America's electricity (Meier). Compared to other refrigerators that are commonly used, the Samsung Family Hub refrigerator requires less energy. Through my research of the life cycle of the Samsung refrigerators, it is found that the usage of Samsung refrigerators decreases the consumption of energy in the world. This paper focuses on embodied energy used to obtain the raw materials, to manufacture the product, the energy consumption used for this product to work, and the energy used to recycle or deal with the waste of this product.

It is important to take note of every step in the life cycle of the Samsung refrigerator and the energy consumption, because it helps us determine which products are more beneficial and friendlier to the environment. The main raw materials that the refrigerator is made out of are aluminum, polyurethane, plastic, and steel. To begin with, aluminum comes from bauxite which is usually “ found in the topsoil of various tropical and subtropical regions” (“Primary Production”). Therefore, there is kinetic energy being used to mine this raw material out of the earth. Another raw material used in the manufacturing of refrigerators is polyurethane, which “exist in a variety of forms, including flexible foams, rigid foams, chemical-resistant coatings, specialty adhesives and sealants, and elastomers” (“Introduction to Polyurethanes…”). Chemical energy is used to form polyurethane through the process of polyol reacting “with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives” (“Introduction to Polyurethanes…”). Plastic is also another raw material used to make refrigerators, and it is “derived from natural, organic materials such as cellulose, coal, natural gas, salt and, of course, crude oil” (“How Plastics Are Made”). Plastic has two procedures for manufacturing: polymerization and poly-condensation. Although they are different, they are made using chemical energy and molded using thermal energy. The last main raw material used in the production of refrigerators, is steel. There are two leading plans of actions when it comes to making steel which includes through a basic oxygen furnace and an electric arc furnace. Both of these methods require the use of thermal energy to produce steel, except that the basic oxygen furnace requires the combination of iron, steel scrap, and coal for thermal heat, while the electric arc only uses steel scrap and electrical energy to heat it up. Having obtained the raw materials for the Samsung refrigerators, various forms of energy are then employed in the manufacturing process.

In this paragraph, the many types of energy required in the manufacturing process will be discussed. Throughout my research it was difficult to see just how much energy was used in producing the Samsung refrigerator, so instead I focused on the amount of energy it takes to produce each of the raw materials. To start off with, aluminum uses the Hall-Héroult process, which at its best efficiency uses 13 kWh, while “the worldwide average is closer to 15 kWh/kg” (“Electricity consumption in…”). Assuming this process is nonstop, this uses up to 4,745 kWh annually and the worldwide average estimate would be 5,475 kWh annually. Polyurethane uses chemical energy which isn’t specified on how much energy is needed, however, “Because of the introduction of polyurethanes into refrigerators, ...today [they] are 60% more efficient than refrigerators 15 years ago” (“More facts and figures”). All types of plastic which use chemical and thermal energy overall consume “between 2.5% and 4.0% of total U.S. primary energy consumption in 2008 was due to the energy for plastic”(Hamman). Since this was about 11 years ago, the estimate is likely to be more than that now. And finally, steel, which uses thermal energy when using the basic oxygen furnace, requires 11 x 109 joules per ton, while the electric arc furnace “has significantly less energy required at 2.25 × 109 joules per ton” (Martelaro). With these materials, the manufacturing process of the Samsung refrigerators use kinetic energy to assemble the parts together finally finishing the product. According to the “Use of energy explained Energy use in industry”, metal-based products consume 4% of energy, while the iron, steel, and aluminum products consume 6% of energy in this type of industry. After assembling the refrigerators, they are now ready for consumers to use and the amount of energy consumption is less than the average refrigerator. The next step is transporting the finished product to their final stop at consumer homes or to companies that sell them.

This paragraph will focus on the types of energy necessary to transport and distribute the product. There is kinetic energy that is consumed in the transportation of these raw materials to the manufacturing places. Since refrigerators are assembled overseas, it is most likely they could also ship the refrigerators by boat. At a normal speed, the fuel consumption by container size ranges from 150- 370 tons per day, the lowest ship size being 4,000-5,000 TEU (twenty foot equivalent unit) to the biggest being more than 10,000 TEU (Rodrigue). According to “Use of energy explained Energy use for transportation,” “About 28% of total U.S. energy consumption in 2018 was for transporting people and goods from one place to another,” and 12% of the transportation energy sources/fuels is jet fuel, and 54% is gasoline (“Use of energy explained Energy use for transportation”). Jets and automobiles/ trucks are the main methods of transportation that companies use. After the transportation and distribution, the product is now ready to be used.

In this paragraph, it’s discussed that the amount of energy is lower for the Samsung Family Hub refrigerator than the average refrigerator. An average refrigerator’s energy consumption was measured through the fridge size, usually in liters. According to Halliday, a Samsung Family Hub is 825 liters of storage space (Halliday). As stated in the “Samsung Family Hub Refrigerator specs”, the Samsung Family Hub also has the energy consumption of 778 kW per year. As reported by Astbury, he reveals a chart categorizing refrigerators according to their size in liters and their estimated annual energy consumption; however, the highest fridge size it has is from 600 to 699 liters which annually consumes up to 1356 kWh (Astbury). This is almost two times more energy consumption than the Samsung Family Hub. This demonstrates that the Samsung Family Hub not only has a bigger storage, but it also requires less energy to function, whereas for typical refrigerators, larger storage means more energy consumption. Since it has less energy consumption, “Samsung’s new R-600a refrigerant is naturally occurring and climate-friendly, with no ozone depletion potential and very low Global Warming Potential (GWP) rating” (“Samsung Earns ENERGY…”). Once the refrigerators have malfunctioned or are no longer of use to the consumers, they then go through the process of recycling.

When Samsung refrigerators are done being used, they go through an extensive recycling process. In the recycling process, the whole refrigerator is taken apart in order to deal with the materials separately and send them to their designated stations to be dealt with accordingly; this uses kinetic energy. Thermal energy is used, on foam and “...capacitors that are suspected of containing PCB’s ... [are] shipped for destruction by a registered hazardous waste incinerator” (Koerner). Thermal energy is also used to distill oils that come from the compressor to be handled somewhere else or to be reused again. However, the annual production of e-waste is 3.5 kg per refrigerator, when dealt with improperly. It was a very interesting research in trying to find out the waste management of refrigerators, however the most I could dig out was that since this product is expensive, it is likely that the higher income areas would dump their e-waste in lower income areas which would take kinetic energy to do so (Robinson). Throughout the life cycle of Samsung refrigerators, there isn’t as much energy being used as the average energy consumption of regular refrigerators.

In comparison to regular refrigerators, the energy consumption was not as much for the Samsung refrigerators. Although it was hard to pinpoint exactly how much energy was being used at the start and end of the life cycle, the most important part where the energy consumption really matters is when the refrigerator is being used, and the Samsung refrigerator proved to have less consumption. Since refrigerators are a household appliance that are constantly in use, the annual consumption of energy shows how efficient the refrigerator is.

Bibliography

Astbury, Harrison. “The real cost of running your fridge.” Canstar Blue, Canstar Blue, 6 Jan. 2018, https://www.canstarblue.com.au/appliances

/how-much-energy-does-a-refrigerator-use/

“Electricity consumption in the production of aluminium.” MrReid.org, 15 July 2011, http://wordpress.mrreid.org/2011/07/15/electricity-consumption-

in-the-production-of-aluminium/

Ha, Dea Y. "Multi-purpose refrigerator having a door within a door." U.S. Patent No. 5,209,082. 11 May 1993.

Halliday, Fergus. “Samsung's fourth-gen Family Hub smart fridge is bigger, smarter and

Bixby-enabled.” PC World from IDG, IDG Communications, 13 Aug. 2019, https://www.pcworld.idg.com.au/article/665230/samsung-fourth-gen-

family-hub-smart-fridge-bigger-smarter-bixby-enabled/

Hamman, Curtis W. "Energy for Plastic." Energy for Plastic. Stanford University 24 (2010).

“How Do I Get Rid of an Old Refrigerator?” LoadUp, LoadUp Technologies, n.d.,https://goloadup.com/how-get-rid-old-refrigerator/

“How is Steel Produced?” World Coal Association, World Coal Association, 2019, https://www.worldcoal.org/coal/uses-coal/how-steel-produced

“How Plastics Are Made.” PlasticsEurope, PlasticsEurope, n.d, https://www.plasticseurope.org/en/About-plastics/what-are-plastics/how-plastics-

“Introduction to Polyurethanes: How Polyurethane Is Made.” American Chemistry Council, American Chemistry Council, n.d,

https://polyurethane.americanchemistry.com/How-Polyurethane-is-Made/

“Introduction to Polyurethanes: Polyurethane Applications.” American Chemistry Council, American Chemistry Council, n.d

https://polyurethane.americanchemistry.com/Polyurethanes-Applications/

“Introduction to Polyurethanes: Polyurethane Processing Equipment.” American Chemistry Council, American Chemistry Council, n.d,

Koerner, Allyson. “The Refrigerator Recycling Process.” Recycle Nation, ERI, 7 Mar. 2013, https://recyclenation.com/2013/03/refrigerator-recycling-

Martelaro, Nikolas. “Energy use in US Steel Manufacturing.” Energy for Steel,Stanford University, 4 Dec. 2016,

http://large.stanford.edu/courses/2016/ph240/martelaro1/

Meier, Alan. "Refrigerator energy use in the laboratory and in the field." Energy and Buildings 22.3 (1995): 233-243.

“More facts and figures.” Polyurethanes, ISOPA, n.d., http://www.polyurethanes.org/en/what-is-it/fact-figures/more-facts-and-figures

Park, Yong Pil, and Jong Su Jeon. "Dispenser and refrigerator having the same." U.S. Patent No. 7,958,742. 14 Jun. 2011.

“Primary Production.” The Aluminum Association, The Aluminum Association, n.d, https://www.aluminum.org/industries/production/primary-

Robinson, Brett H. "E-waste: an assessment of global production and environmental impacts." Science of the total environment 408.2 (2009): 183-

191.

Rodrigue, Jean-Paul. "Fuel Consumption by Containership Size and Speed." The Geography of TransportSystems (2015).

“Sales of Samsung's Side-by-Side Refrigerator Top 10 Million.” Samsung Global Newsroom,Samsung, 18 July 2011,

https://news.samsung.com/global/sales-of-samsung%E2%80%99s-side-by-side-refrigerator-top-10-million.

“Samsung Earns ENERGY STAR Emerging Technology Award for 20 Refrigeration Models in 2017.” Samsung Global Newsroom, Samsung, 2 Jan.

“Samsung Family Hub Refrigerator specs.” CNET, CBS INTERACTIVE INC., n.d.,https://www.cnet.com/products/samsung-family-hub-

Tackett v. Mid-Continent Refrigerator Co., 579 S.W.2d 545 (Tex. Civ. App. 1979).

“Use of energy explained Energy use for transportation.” Eia, U.S. Energy Information Administration, n.d.,

https://www.eia.gov/energyexplained/use-of-energy/transportation.php

“Use of energy explained Energy use in industry.” Eia, U.S. Energy Information Administration, n.d., https://www.eia.gov/energyexplained/use-of-

Wilmsmeier, Gordon, and Thomas Spengler. "Energy consumption and container terminal efficiency." (2016).

Wroclawski, Daniel. “CR Review: Samsung Family Hub 3.0 Refrigerator Our hands-on evaluation of Samsung’s latest smart fridge.” CR Consumer

Reports, Consumer reports, 24 Sept. 2018, https://www.consumerreports.org/refrigerators--french-door/samsung-family-hub-3-refrigerator-

Angel Rodas

Benjamin Narwold and Erika Jimenez

DES40A

Christina Cogdell

4 December, 2019

Waste and Byproducts: Samsung Refrigerators

Today mass consumer culture has caused an exponential increase in production and consumption capacity. This consumer culture has allowed almost everyone to have access to an unprecedented amount of individualized products. One such product is the refrigerator, just about every household has at least one of these products in their home, can you think of any of your friends who don’t? However, the full nature of refrigerators might not be self evident. In this paper I elaborate on the detrimental environmental impacts caused by the refrigerator industry through focusing on wastes and byproducts produced by the refrigerator industry. I also take a look at how companies like samsung propagate greener, energy efficient refrigerators while increasing the complexity of the design and lowering the recyclability through their choice of design and raw materials used.

When doing research into the particularities of the material acquisition portion of how companies like Samsung use to acquire their raw materials I could find very little if anything. Using logical reasoning, I can deduce that the use of heavy industrial equipment that runs off fossil fuels yields greenhouse gases like CO2 and the mining process can cause environmental damage like polluting ground water with more sediment or metal. This pollution can go on to find itself in crop fields or rivers and adversely affect the local population and ecosystem. That's about all I could find when it comes to byproducts and wastes of mining for materials to construct refrigerators.

When taking a look at the manufacturing process my research led me to discover the many levels of how different pollutants can all conglomerate into one product especially if that product is electronically feature rich and subsequently complex. Adding complexity to a product increases its carbon footprint and makes the recycling process a lot harder. One fact to note is that the manufacturing process can take harmless, naturally occurring elements and then create toxic and harmful compounds from those elements (Hasan). Some common parts and pollutants found in refrigerators are: condensers that produce 14mg of CO2 per kilogram. Cooling units and insulation foam, which generate CFCs, have a reputation for destroying the ozone layer, especially when burned . Cable insulation, used in the wiring of refrigerators, makes use of PVC, which is the most damaging of the plastics, and releases destructive chemicals, usually Chlorine based (Gaijadis). Also, the pollutants and risk of pollution increase when you introduce more complexity like adding a screen to a refrigerator, which the Samsung Family Hub Refrigerator does. This addition can bring with it elements like Cadmium, Lead, Mercury, Rare Earths and Zinc Sulphide. But this all pales in comparison to the damage done by the refrigerators at the end of their lifecycle. The system in place for waste management can be boiled down to countries like the US exporting their waste to foreign countries to have them deal with the problem of recycling and disposing of the waste.

The transportation of refrigerators include from manufacturing plants to warehouses to retailers to consumers homes. However, there is also another hidden transport needed towards the end of a refrigerators lifecycle. Refrigerators are classified as e-waste and, like all other forms of e-waste, they predominantly find themselves in foreign landfills. 80% of US e-waste is processed in China, India, or Pakistan (Hasan) and with 20-50 million tons of e-waste produced each year, that's a lot of waste to move. Since the majority of vehicles today use fossil fuels for power, that's a lot of greenhouse gas emissions just to move harmful waste to another landfill in a foreign country.

The reason we move waste to other countries is because they have more relaxed recycling and worker protection laws, which makes the recycling process cheaper. Also near the beginning of the electronic boom, many countries, like Indonesia, were eager to introduce the materials in e-wastes into their own material ecosystems, but contemporarily the waste has gotten out of hand and many countries are starting to reject our waste. Despite this, a large majority of e-waste recycling is still done in foreign countries with horrible working conditions. In these countries, workers have to dismantle items by hand in poorly ventilated workspaces using strong acids to retrieve precious metals like Gold. These recycling centers also routinely practice open burns to help manage waste. Burning the light bulbs and wiring boards present in Refrigerators releases Lead and Arsenic into the atmosphere. A 2004 study also found that the burning of wiring boards in electronics, for example refrigerators, leads to an increased concentration of dioxins in close proximity to where the open burns occurred. These Dioxins increase the risk of cancer as well as pollute the local crop fields which adversely affects the food chain and devastates the local ecosystem. Not only that, but the use of Leachates, strong acids, to recover valuable materials from e-waste, also finds its way into ground water and devastates the aquatic ecosystems.

Many companies are pledging to be more green. Companies like LG, Sony, Nokia, Samsung, Wipro, and Infosys have said they are going to eliminate toxic chemicals from their electronic goods. The Vice-president of Samsung Manufacturing in India said, “We encourage our vendors to ensure lead, cadmium, mercury, and chromium free components.” Yet 20-50 million tons of e-waste are generated every year, and 75% of e-waste sits in landfills because we do not know what to do with it (Hasan). Even with more “green” materials, the sheer amount of polluting and toxic waste sitting in landfills today are going to cause major problems in the future as they continue to deteriorate the environment due to improper disposal. So are companies doing enough to help curb this massive problem or are they just putting up a front so that their customers feel better about purchasing their products?

Today the refrigerator industry faces an environmental dilemma. The use of old refrigerators means that it uses up to 3x more energy than a modern one, yet modern refrigerators are being given the “smart” treatment that means more harmful compounds and elements are being used to make them. So then what is there to do? The more economical way to deal with refrigerators is to replace inefficient or broken components and repair or replace them with more efficient newer components (DENG). That way, your refrigerator is more energy efficient without having to go out and get a new refrigerator. There is a demand for refurbished refrigerators, especially in rural areas; however, dated or failing refrigerators are not usually refurbished. Rather, they are thrown out or recycled, but the recycling process by in large does not happen here in the US and it does not happen properly. Proper recycling is expensive because of all the regulations and proper recycling can only be done in developed countries. It becomes even more expensive to properly recycle complex items like smart refrigerators that are becoming more and more technologically advanced. So instead of footing the bill, countries like the US send their waste to developing countries where they continue to cause unbelievable environmental damage due to poor recycling practices and regulation. Even still, companies continue to push the narrative that their products are more environmentally friendly, purposely using ambiguous words like green or sustainable to help sell to consumers the idea that the product they are buying is not further contributing to the massive problem of unmanageable levels of consumer waste.

Bibliography

Borthakur, Anwesha, and Kunal Sinha. "Electronic waste management in India: a stakeholder’s perspective." Electronic green journal 1.36 (2013).

Deng, Jian-Jun, Xue-Feng Wen, and Yue-Min Zhao. "Evaluating the treatment of E-waste—a case study of discarded refrigerators." Journal of China University of Mining and Technology 18.3 (2008): 454-458.

Gaidajis, Georgios, Komninos Angelakoglou, and Despoina Aktsoglou. "E-waste: environmental problems and current management." Journal of Engineering Science and Technology Review 3.1 (2010): 193-199.

Hasan, M. Abul, et al. "E-waste management and hazardous effect on environment." Proceedings of the 4th National Conference. INDIACom, 2010.

“Household Appliances Emissions.” CleanAirTrust, 2017, www.cleanairtrust.org/Household-appliances.html.

Kahhat, Ramzy, et al. "Exploring e-waste management systems in the United States." Resources, conservation and recycling 52.7 (2008): 955-964.

Kollikkathara, Naushad, Huan Feng, and Eric Stern. "A purview of waste management evolution: special emphasis on USA." Waste management 29.2 (2009): 974-985.

Nnorom, Innocent C., and Oladele Osibanjo. "Overview of electronic waste (e-waste) management practices and legislations, and their poor applications in the developing countries." Resources, conservation and recycling 52.6 (2008): 843-858.

Prokopanko, Teresa. “The Hidden Polluters: White Goods Recycling.” Green Action Centre, 5 Dec. 2017, greenactioncentre.ca/reduce-your-waste/the-hidden-polluters-white-goods-recycling/.

Robinson, Brett H. "E-waste: an assessment of global production and environmental impacts." Science of the total environment 408.2 (2009): 183-191.

Williams, Eric. "International activities on E-waste and guidelines for future work." Proceedings of the Third Workshop on Material Cycles and Waste Management in Asia, National Institute of Environmental Sciences: Tsukuba, Japan. 2005.