Design Life-Cycle

assess.design.(don't)consume

Xeyla Huinac

12/01/2019

DES 40A - A01

Fall Quarter 2019

Professor C. Cogdell

Life-Cycle of Traditional Sports Bras: Waste and Emissions

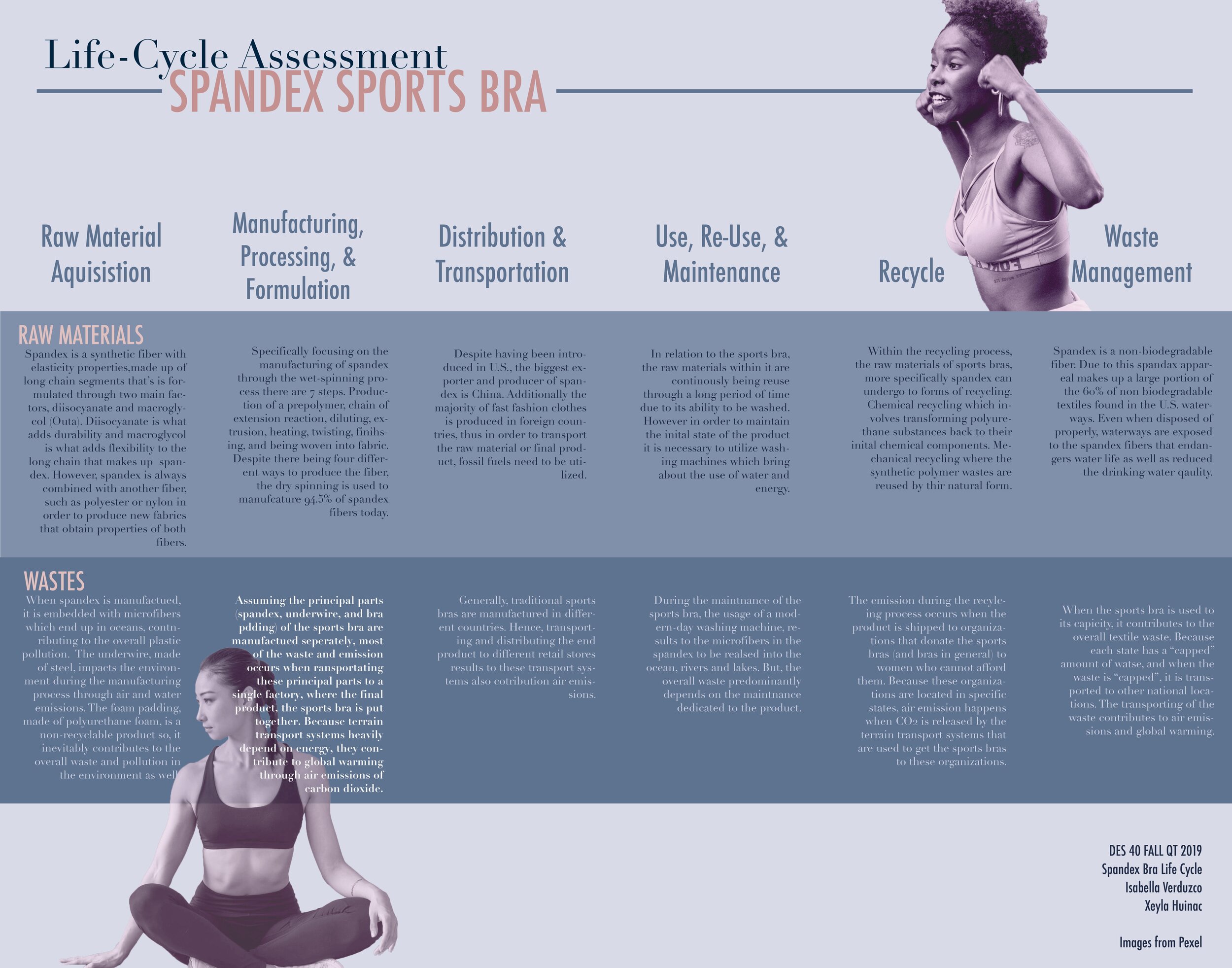

My partner and I focused on the traditional sports bra as the center of our life-cycle research project because we wanted to become knowledgeable of a product that was embedded in our daily lives. Although it is a product we come across daily, I found myself lacking knowledge of its life-cycle. After becoming familiar with the waste and emission of the sports bra’s life-cycle, it becomes evident that the spandex sports bra is not an environmentally friendly product due to its principal parts (that is the spandex fabric, the underwire made from steel, and the foam padding made from polyurethane foam) being made from internationally acquired raw materials, as well as the principal parts manufactured internationally. These factors are relevant as they pave the way for extreme air and water emission by plastic pollution and CO2 air emission.

Furthermore, when considering the mass numbers of sports bras being produced in order to meet consumer needs, it becomes evident that the product only contributes to environmental damages at faster, and extreme rates. The traditional sports bra is also a common product among women, which supports the importance of studying its life-cycle.

When researching the waste and emission of the raw materials used to make the traditional sports bra, I decided to focus on certain principal materials. These principal parts are narrowed down to the following parts: spandex, foam padding, and the underwire.

Beginning with spandex, it is defined as a synthetic fiber chemically made from a combination of polyurethane and diisocyanate. Additionally, spandex also contains microfibers and elastane. Both microfibers and elastane are important substances embedded in spandex because consequently when spandex is washed using modern day washing machines, the microfibers are released into the waste stream. After it is washed, these microfibers travel through wastewater treatment plants, which is a process used to remove contaminants from wastewater and sewage (James). Inevitably, these microfibers end up in rivers, lakes, and oceans where they contribute to the overall plastic pollution (James). Additionally, it is uncommon for spandex to be recycled. This is due to the synthetic fiber being initially combined with other fibers, making the recycling process tedious and also, not eco-friendly. Hence, spandex contributes to mass textile waste and to the overall pollution of the environment as well.

The second principal material is the underwire. This part of the bra is implemented in the design of the sports bra with the purpose of providing additional support during movement of the breasts (Underwire Bra). According to underwire manufacturer S&S Industries of NY, 70% of bra manufacturers use steel to create this part of sports bras. Although steel is one of the most recycled materials in the world, it is also important to acknowledge the environmental impacts of steel production. These impacts include the contribution to climate change, emissions to air, and emissions to water (Steel). More specifically, air emissions occur when coke oven gas and coke dust are released from coke ovens during the production of steel. Furthermore, the emissions to water occur when water is used to cool the coke after it has finished baking (Steel).

More specifically, the greenhouse gases from steel production stem from the carbon dioxide emissions related to energy consumption (Steel).

Finally, the third principal part of the traditional sports bra is the foam padding. These foam paddings are added in the design of the sports bras to define breasts and provide an additional layer for the nipples not to be visible. The most common foam used for bra padding is the polyurethane foam (Edmark). According to a study done by researchers at the University of Burgos, they found that polyurethane foam is a material that stays intact during high-pressure and high temperatures. This information is relevant because although it has a high resistance after the manufacturing process, after it is manufactured, the foam cannot be remodeled into different products. Hence, the foam is unable to be recycled. Inevitably, the polyurethane foam used to make the bra padding in the sports bra contributes to the waste and overall pollution (Nguyen).

The second part of the traditional sports bra’s life-cycle is the manufacturing phase. Because our research focuses on traditional sports bras rather than a specific brand, the research gathered in regards to where traditional sports bras are manufactured is dependant on the individual parts of the bras (such as the spandex, the foam pads, and the underwire) rather than the end product itself. That being said, according to How Products Are Made, the manufacturing process is described as cutting out the components, sewing the individual parts together, sewing closures and implementing the labels, and packaging. It is also important to note that while doing research on the waste and emission during the manufacturing process, I found there was an interrelation between the manufacturing phase and the third phase, the waste, and the emission of the distribution and transportation of the traditional sports bra. For this reason, in the following paragraph, I wrote about these two phases together.

As the principal parts of the traditional sports bra are manufactured separately and from different raw materials, it is safe to assume they are produced in different factories. For example, spandex is mainly manufactured in China. Additionally, China is not only responsible for manufacturing the majority of spandex, but in 2018, it also accounted for 51.3% of the world's steel production (Petroff). Although these products were manufactured in the same country, it is safe to assume that due to their different raw materials, they were manufactured in different factories. Hence, it becomes safe to assume that the transportation of these products to a single factory that puts together the end product of the traditional sports bra, also contributes to pollution. This becomes evident when accounting for the mass amount of energy transport heavily depends on. We utilize a massive amount of petroleum in order to meet the demands of energy necessary for transportation reasons. This also contributes to air pollution and at the same time, further paves the way for extreme global warming through emissions of carbon dioxide (Fuglestvedt). These environmental damages become inevitable since the end product is heavily consumed and the pieces to put the sports bra together are locally inaccessible.

The fourth part of the traditional sports bra’s life-cycle phase is the use, re-use, and maintenance of the product. Findings revealed that the maintenance of the sports bra serves as the foundation of how long the product will last. Also according to How To Wash Bras, a short informative article, if the maintenance of such garment is done correctly, the longer the sports bra’s life expectancy will turn out. Evidently, this results in consumers needing to purchase less of the product, less often. Generally, a sports bra’s lifetime lasts in between 9-12 months. This also mainly depends on factors such as the number of bras someone owns and, a consumer’s choice of washing their bras using a washing machine or choosing to wash them by hand. According to Sage Journals, washing or drying your bras using modern machines is the #1 way to ruin them. Additionally, the state, “using harsh soap will also cause the elastic to become brittle which will stretch out the band even faster than usual.”(How). Not only does washing your sports bra ruin the product quicker, but as previously mentioned, washing synthetic fibers will contribute to water emissions. Furthermore, modern washing machines generally use an average of 40 gallons of water per load (Eliott). A washing machine also uses a significant energy amount of 300 watts per load (How Much). Because such home appliances are generally used during the maintenance of the product, both the energy usage of the machine and the water usage per load are relevant key points when researching the waste and emission of the traditional sports bras.

The fifth phase of the traditional sports bra’s life-cycle is the waste and emission of recycling the product. Before presenting the research found in regards to the waste and emission during the recycling process, it is important to acknowledge the organizations that have attempted to recycle the product not only for environmental reasons but for ethical reasons as well. Some examples of these organizations are “The Bra Recyclers” and “The Bra Recycling Agency (BRA)”. These organization’s work mainly focuses on collecting wearable, used bras and giving them away to women who cannot afford them. Though these organization’s intentions are solely positive ones, minor non-eco-environmental collateral consequences exist during this recycling process. These consequences are due to these centers being located in specific states, and in specific cities. For example, “The Bra Recyclers” solely exists in Arizona so when an out-of-state donation wishes to contribute to the organization, they are left with their only option being to mail their products. Because the transportation process of recycling the product depends on various transportation systems such as, trucks and trains, air pollution is embedded in the environment as these terrain transport systems contribute to the CO2 emission in the air. Although these organizations only mean well by recycling the sports bras and providing them to women who are unable to afford bras, the unfortunate outcome is that it is not a locally accessible option to everyone.

Finally, we are left with the last phase, the waste management of the sports bra. In order to manage the waste of sports bras, we would need to radically change our consumer habits. That is, implementing the “waste hierarchy” into our lives (O'Conner). Although this hierarchy was designed for managing the waste of textiles in general, it remains a great and concise idea that is applicable and relevant to the idea of minimizing the waste of the sports bra. The waste hierarchy is described through the following steps: reduce, reuse, recycle, recover and landfill. The process begins by reducing the consumption of the product. That is, restocking the product only if we really need to. The following step consists of reusing the sports bra rather than buying a new one. An example would be purchasing the product from a thrift store, rather than purchasing it from a retail store. The waste hierarchy then suggests the recovery of textiles. Applying this step to the sports bra would be relevant in terms of using parts of the sports bra for any alternative projects. An example would be crafting a DIY project using either all or some parts of the sports bra. The article “7 Ways To Recycle Your Old Bras After Your Through With Them”, describes DIY projects such as using bra scraps in order to create shoe inserts, a purse, and even a headband (Waller). The last phase in the waste hierarchy is landfill. This is meant to be the last phase in order to promote using the product as much as possible before putting it away to landfill. Hence, the importance of the order of the waste hierarchy is extremely important as it allows us to realize that once a product’s life can go further than we believe it can. By searching for alternative ways to reuse and ultimately reduce the waste of a product, we are more than likely to find a way to make use of the product before characterizing it as a landfill.

It becomes clear that the traditional spandex sports bra is not an eco-friendly product. The raw materials of spandex, iron, and the polyurethane foam, are materials that are acquired internationally. Additionally, the product has three principal parts that are made from different raw materials, which results in these parts being manufactured in different factories. The transport process inevitably contributes to air emissions. Furthermore, spandex is embedded with microfibers that are released into oceans which contribute to water emissions through plastic pollution. Lastly, the sports bra is also a prominent product responsible for fast fashion. That is, consumers often purchase the product too often, and almost always end up going to waste after a couple or wears. Hence, the frequent and mass rates the sports bras are consumed at, contribute to the overall textile waste.

Work Cited

“Brassiere.” How Products Are Made, http://www.madehow.com/Volume-5/Brassiere.html.

Edmark, Tomima. “Bra Padding: What Are the Three Types of Bra Foam Padding?” YouTube,

YouTube, 10 Dec. 2018, https://www.youtube.com/watch?v=oA46aOCDIgg.

Elliott, Sara. “Washing Machine Water Usage.” HowStuffWorks, HowStuffWorks, 3 Oct. 2011,

https://home.howstuffworks.com/washing-machine-water-usage1.htm.

Fuglestvedt, Jan, et al. “Climate Forcing from the Transport Sectors.” PNAS, Edited by

Christopher B. Field and Carnegie Institution of Washington, 30 Mar. 2007, p. 1.,

https://www.pnas.org/content/pnas/105/2/454.full.pdf.

Hodakel, Boris. “What Is Spandex Fabric: Properties, How Its Made and Where.” Sewport,

Sewport, 30 Nov. 2019, https://sewport.com/fabrics-directory/spandex-fabric#h2_3.

“How Much Energy Does My Washing Machine Use?” Direct Energy,

https://www.directenergy.com/learning-center/energy-efficiency/how-much-energy-washi

ng-machine-use.

“How to Wash Bras.” How To Wash Bras: Your Bra Care Guide | True&Co.,

https://trueandco.com/how-to-wash-bras.

James. “The Environmental Impact Of Your Laundry - And What You Can Do.” Clean Home

Guide, James, 24 Oct. 2019,

https://cleanhomeguide.co.uk/environmental-impact-of-laundry/.

Nguyen, David H. “The Environmental Impacts of Polyurethane Foam.” Sciencing, 2 Mar. 2019,

https://sciencing.com/environmental-impacts-polyurethane-foam-20313.html.

O'Conner, Morgan. “The Monster in Our Closet: Fast Fashion & Textile Waste on the Rise.”

Center for EcoTechnology, 11 Oct. 2017,

https://www.centerforecotechnology.org/fast-fashion-textile-waste/.

Petroff, Alanna. “The Global Steel Industry by the Numbers.” CNNMoney, Cable News

Network,https://money.cnn.com/2018/03/02/news/economy/steel-industry-statistics-us-ch

ina-canada/index.html.

“Steel Production & Environmental Impact.” Greenspec,

http://www.greenspec.co.uk/building-design/steel-products-and-environmental-impact/.

“Underwire Bra.” Wikipedia, Wikimedia Foundation, 25 Sept. 2019,

https://en.wikipedia.org/wiki/Underwire_bra#cite_note-The-19.

Waller, Phoebe. “How To Recycle Your Old Bras.” Bustle, 1 Dec. 2015,

https://www.bustle.com/articles/126030-7-ways-to-recycle-your-old-bras-after-youre-thro

ugh-with-them.