Design Life-Cycle

assess.design.(don't)consume

Tong Lor

Professor Christina Cogdell

Design 040A A02

8 November 2016

Raw Material for Sofa

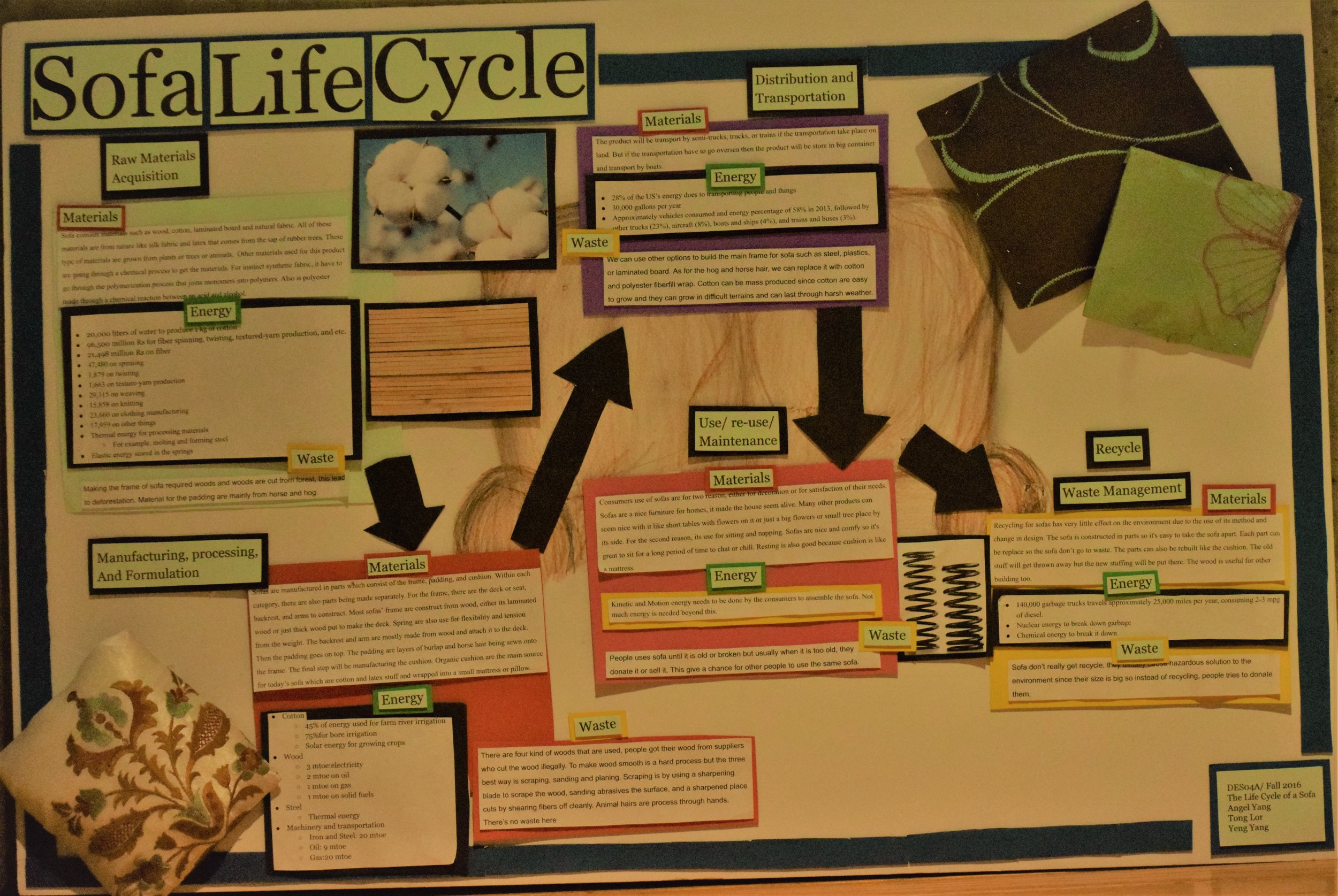

Furniture have accomplished many satisfaction in people's’ home with furniture like sofa. Sofa was originated from ancient Egypt which are mostly seen in royal or rich families’ home (“Sofa”). But the idea changes over time and with the manufacturing system of mass production, most people can afford to have a sofa in their home now, whether it's for decoration or the want of their needs. However, sofa have some bad affect to the environment like resulting in global warming and deforestation. Therefore, designer is trying to invent sofa that are more recyclable.

Throughout history designer have used many different materials to make sofa so it can have a different impact whether it's for consumers or environment. The format of building sofa is building each part separately. This idea will lead to an easier recycling process. Sofas have many sections that were build and put up together to form the product. One of the section is the frame which can be made from wood, plastic, steel, or laminated board. Another section is the padding, it can be constructed from animal hair, foam, or polyester fiberfill wrap. The last section of the sofa is the cushion that can be constructed from cotton, latex, or polyurethane foam. The finishing touch of this furniture is the cover sheet which can be a product from synthetic, natural, or blended fabric, (Sofa). All this items are from or made from natural resources.

Materials like wood and cotton are grown from earth so they are natural but this result in deforestation due to the cutting of trees and trees from land for cotton plantation. Laminated board are another type of wood use for building the product, which are made by combining layers of wood being bonded together. On the other hand, materials are either made from combining natural products physically or chemically. For example, plastic was made from combining cellulose, coal, natural gas, and crude oil. Also, foam is made from forming gas bubbles in plastic mixture which is a chemical process. Latex is a natural rubber made from the sap of a rubber tree. Natural fabric is made from cellulose, proteins, silk, or wool. This type of fabric is from nature which are formed physically but other fabric such as synthetics are different (“Sofa”). Synthetics are made chemically by people. The process of making synthetics fabric is called polymerization which is the joined of monomers into polymers. Synthetic and leather are also made from animals’ hair. The blended fabric is just a fabric made from combining two fibers together, (Xxxxx). Polyester are molecules formed from chemical reaction between an acid and alcohol. Sofa also consists of springs to support the sofa to hold up weight; this material is manufacture by human from the material of steel.

After consuming all the materials needed for the making of sofa, the manufacturing process begin. Like stated earlier, there are different section of the sofa that are manufacturing separately. Within the frame of the sofa, different parts of the sofa are made separately: seat, backrest, and arms. The frame has many options to choose which type of materials to use. Like wood, the wood should be thick enough to hold on heavy weights like human (“Sofa”). The arms, deck, and back are made from wood but in separately process and is attach later together to make the frame. This can be done by people or machines run by people. The deck will also be supported from spring to give tension and flexibility so the whole deck won’t be a hard-heavy wood or steel (Duncan). Overall, the frame is the most important part of the sofa because it’s the base foundation of the product.

When the frame is done, the padding process is next. The padding is the foundation of the cushion. It’s the only or the first materials sewn up with the frame. Again, each part of the frame is padding separately. The padding is placed in a pattern throughout each frame with layers of burlap and horse hair or a specific synthetic material (“Sofa”). But this is the base padding only, the second padding will be lay out on the first padding and sewn loosely and tightly in parts. The tighter part will resemble the separation of the platform and the front edge. Up until this process, the padding can be done by machines but after this step, the front edge will be sewn by hand to reshape the padding. Then a final padding will be added onto the whole padding to hide any stitches scars. The final step will be covering the paddings with a muslin sheet and sewn up in the brake of the platform and front edge (“Sofa”). This process of padding will also be done repeatedly with the arms. All the parts then will be attach to each other to form a sofa foundation.

Cushions are one of the factor that many consumers considered when purchasing sofas. Consumers may feel good but there are cons within it. According to “Nature Foam,” some old cushion is not organic, they went through a chemical process. Therefore, it resulted in bad health for users and workers. However, over time companies have change from chemical to organic cushion which doesn’t harm the environment as much. Organic cushion is like cotton and latex. These are materials made or pick from plants. Each of these materials goes through their own manufacture before it’s used in the sofa industries. Apart from the sofa the cushions will be manufacture by itself. But to fit right to the sofa there will be measurements needed to make the perfect fit for the sofa. The cushion will either be built for used of two purpose or just one. One purpose is to make a resemble of a pillow and is stuffed with cotton, latex, or polyurethane foam and wrapped with a thin or thick sheet of soft non-woven fibrous materials (Albecker). It will resemble a mattress but in a smaller size. The other uses are for cushion, so it will just be places on the padding but is still sewn up in separated parts; either sewn up to the deck or sewn into shape and is not sewn up with the sofa so it can be removable. These cushions can be designed in various forms or shapes depending on the satisfaction of the consumers. At this point the sofa is already a finish product.

The sofa will not be done there with some consumers. The sofa can be covered with a cover sheet. Some consumers prefer it to have a cover sheet but some don’t because the sofa a finished product itself without mentioning the cover sheet. A cover sheet can be ordered to manufacture to match the design of the sofa but not every sofa is design with a cover sheet.

After the product is finish it's time to put it on sale. The product will be transport by transportation truck known as semi-truck. These semi-trucks will use diesel as their fuel to run. Another transportation is train which also use diesel to run. For transportation around the world, sofas will be transported on water by ships in a big container. For consumers, either they use their own truck or have the store shipped it to them at home.

When the product reached the consumers at home it can be used in two way; as a beauty furniture or as a use for satisfaction such as sitting and sleeping on it. For the beauty, the sofa will be placed with some small tables in front of it for designing to elaborate the house more. Not only does the sofa be places with tables, it can also be decorated with flowers or plant next to it. Mostly, the sofas will be the main use for sitting to chat or just to chill or relax. There will also be product produced to keep sofas clean like vacuum. There is also water vacuum so it can wash and dry the sofa if it's made with leather. But some aren’t manufacture by leather but instead, they use synthetic fabric that are water proof for the sofa (Infoplease).

Recycling is an issue on the environment but sofas helped reduces its waste a little. After the use of the sofas, it can be used for others things such as fuel which is from the wood. Again, it stated earlier that the sofas are manufactured in separate parts, therefore, it can be remove easily and reuse. Only the fillings and fabric will be throw into the landfill which reduces CO2 emission (“From”). Like the padding, it can be replaced with a new one; as well as the cushion. But there are also parts that cannot be throw away without acknowledging the waste department because it consists of toxic chemical like upholstery foam (Pantsios). For the rest like the cotton, foam, and springs can all be dismantled and reused or taken to recycle (N.P). This whole recycling process means that the sofa can be reuse or rebuilt which resulted in less waste.

In conclusion, raw materials from the production of sofa have a big impact on the environment such as destroying and preserving it. It can be destructive because it needs the natural resources but it can also be preserving because after the use of the product, most items can be reuse or replace so there aren’t in use of new materials a lot every time. Also with the plantation of lumber trees, there are giving birth to nature again.

Works Cited

Albecker, III Walter J., and Iii; Walter J. Albecker. "Patent US5474362 - Cushions Having Internal Support Member." Google Books. N.p., n.d. Web. 23 Nov. 2016.

Duncan, Bob, Doug Gasal, Henry Panceri, Kevin Nguyen, and American Leather. "Patent US7040700 - Sofa and Method of Manufacturing Same." Google Books. N.p., n.d. Web. 23 Nov. 2016.

"From Reclining to Recycling - The Life Cycle of a Sofa." Sofa Bed Sofa Blog. N.p., 22 Dec. 2015. Web. 23 Nov. 2016.

Infoplease. Infoplease, n.d. Web. 23 Nov. 2016.

"Natural Foam." Organic Cushions, Natural Foam Made from Natural Latex, Organic Foam, Latex Foam. N.p., n.d. Web. 23 Nov. 2016.

N.p., n.d. Web. 23 Nov. 2016.

Pantsios, Anastasia. "What You Need to Know About Toxic Chemicals in Your Furniture." EcoWatch. N.p., 27 June 2016. Web. 23 Nov. 2016.

"Sofa." How Sofa Is Made - Material, Making, History, How to Make, Used, Parts, Product. N.p., n.d. Web. 23 Nov. 2016.

Xxxxx. "Textile Helpguide: What Is Blended Fabrics ? Advantage of Blended Fabrics & Example of Blended Fabrics." Textile Helpguide. N.p., n.d. Web. 23 Nov. 2016.

Angel Yang

Christina Cogdell

Sofa research paper

30 November 2016

Sofa Life-cycle: Energy

Sofa also known as couch is a main piece of furniture that is commonly found in a house. “The word ‘sofa’ dates back to 2000BC Egypt and derives from the Arabic word ‘suffah’ (which loosely translates as ‘bench’)” (10). The sofa is a family’s favorite place to sit back and relax to spend time and enjoy a movie. As a matter of fact, according to Sofa Workshop, “People sit on their sofa for an average of 4 hours each day” (10). Therefore the manufacturing has boomed ever since its existence came upon. The manufacturing of sofas has not only successfully fulfilled the needs of consumers but have also been innovate with regards to the various aspects of the life-cycle to impact the environment in a healthier and greener way.

The first thing that comes into play before the making of sofas is the gathering of the materials. These materials include cotton, springs, foam, and wood. The Wood industry energy consumption comes from chopping trees, loading logs onto saw chain, log debarking, log sawing, plank drying, plank sorting, and transporting them (Stages). Overall with all these factors the wood industry spends 3 mtoe (Million Tonnes of Oil Equivalent) on electricity, 2 mtoe on oil, 1 mtoe on gas, and 1 mtoe on solid fuels (Energy Consumption). One of the main materials used for sofas is cotton. Cotton has always played a significant role throughout history. For cotton, “irrigation typically accounts for 45 percent of all energy that is directly used on farm for river irrigation, and up to 75 percent for bore irrigation, with diesel use in tractors and machinery the next largest consumers of energy on farm” (Energy Use). Springs are made from steel. One of the main forms of energy used in the making of steel is thermal energy from fossil fuels. Fossil fuels produces the high temperatures of heat to melt and form the steel (Steel). Foam are made from Polyurethanes. “Polyurethanes, also known as polycarbamates, belong to a larger class of compounds called polymers” (Polyurethane). Polyurethane chemistry was first studied by the German chemist, Friedrich Bayer in 1937 and (Polyurethane). Springs are made from hardened steels that are coiled. According to FAO Corporate Steel production itself uses up to 20 mtoe on iron and steel, 9 mtoe on oil, and 20 mtoe on gas (Energy Consumption).

In order to impact the environment in a healthier way manufacturers are using alternative forms of materials that are more sustainable and renewable. One of the new renewable resources of materials that are proven to consume less energy that can serve as a sustainable resource is timber. “Timber has the lowest embodied energy compared to other conventional building materials”, for example, it takes “4 times more energy to produce bricks, 5 times more energy to produce concrete, 6 times more energy to produce glass, 24 times more energy to produce steel and 126 times more energy to produce aluminium” (Facts). According to the article of “Facts on Timber” timber is also “natural insulator and is 5 times better than concrete, 10 times better than brick and 350 times better than steel” (Facts). Besides timber sofa manufacturers are mastering sustainable cotton production because of high cotton demand.

Once the materials are gathered, they are then manufactured into various parts that contribute to the making of the sofa. One of the main materials used for sofas is cotton. Cotton has always played a significant role throughout history. Cotton consumes 20,000 liters of water to produce one kilogram of cotton” (Making). Cotton contributes to the overall Textile Industry. The Textile industry consumes a total of 96,500 million Rs on fuel for fiber production, spinning, twisting, textured-yarn production, weaving, dyeing, knitting, clothing, and etc. According to Energy Management in Textile Industry they also use up (units in million Rs) 21,498 on fiber production, 47,480 on spinning, 1,879 on twisting, 1,663 on texture-yarn production, 29,315 on weaving, 15,858 on knitting, 23,660 on clothing manufacturing, and 17,959 on other things (Sharma). The making of foam consists of five steps. These five steps include raw material conditioning, measuring out raw materials, trigger reaction, and growth verification (Administrator). All these materials are transported on large trucks and trains using oil and fossil fuel.

After it’s been manufactured the sofas get distributed. These items can be transported by boats, trucks, trains, and other transportational automotives. There are approximately 33,000 large trucks that transport furnitures on the road. These truck consumes about 30,000 gallons of oil a year (Table). In addition, 28% of the United States Energy goes to transporting people and their goods with the largest share consumed by cars, light trucks, and motorcycles—about 58% in 2013, followed by other trucks (23%), aircraft (8%), boats and ships (4%), and trains and buses (3%) (National).

Therefore due to such large consumptions new ideas have been proposed to decrease energy consumption. One of those is Packaging Optimization. Packaging Optimization is the method of having furniture unassembled sofas so that it takes up less space, decreases loads of transporting, and decreases the amount of trips it has to take. This also improves product handling, and reduces labor costs. As a matter of fact costs have declined by 23% (Supply). Another method that's been used to decrease use of sources and energy is by transporting sofas on trains instead of trucks (Supply). Large bundles of furniture are transported on trains to save oil and gas. Large trucks are used to transport the furniture to the consumers if wanted.

Once the sofa is distributed, it is in the hands of the consumer and become the owners responsibility. The best thing about a sofa is that the only amount of work and energy that a consumer uses to operate a sofa is when he/she assembles it. Once you assemble it, the sofa becomes your daily life-energy recharging place, the most comforting place to relax with your family after a long day.

At the end of a sofas journey of manufacturing and serving its consumer it goes to recycling. There are many ways in which you can recycle furniture. One way is to donate ror sell it to others such as charities, neighbors, friends, and etc. Another way to recycle it is to reuse the parts that you can. For example, you can use the wood frame of the sofa for other projects. Last but not least, you can recycle it at the dumpster. But a new method that has really improved the impact on the earth in a friendly way is by giving your furniture to companies that recycle furniture so that they can disassemble it and use it. One of the best ways to recycle sofas is by using an “environmentally friendly rubbish clearance company” (9 Modern). According to the article, “9 Modern Ways to Recycle Your Old Furniture”, “EnviroWaste is a removal and rubbish clearance company that focuses on environmentally friendly solutions for waste disposal, diverting 92% of waste from landfill” (9 Modern). Many companies who sell furniture, like Ikea and Home Depot, offer to take your old furniture for free when they ship you your new furniture. Along with the recycling process comes the machinery that contributes to the recycling process. The machines used in recycling are garbage trucks and bulldozers (Waste). According to Wake County’s Solid Waste management, 140,000 Garbage trucks, also known as Refuse trucks traveling approximately 25,000 miles per year, consuming 2-3 mpg of diesel, collect the materials and the bulldozers spreads the trash out evenly (O’Connor). One of the main type of waste that comes from sofas are its packaging which contibutesto approximately 1/7 of waste collected (Waste). Due to refuse truck’s diesel consumption and pollution a new proposal has been brought upon to contribute to an environmentally impact on the earth, Hydraulic Refuse trucks. Hydraulic trucks reduces fuel consumption of 30,000+ liters of fuel a year by 35 to 50 percent and “reduces carbon emissions by 48 tons per unit per year” (Garbage).

Overall, with continuous innovations and new renewable resources, the manufacturing of sofa has not only served consumers but also improved its eco-friendly impact on the Earth . New renewable resources are being made everyday to substitute and replace scarce materials and high energy consumption materials. Also, new forms of energy are being proposed to have a friendlier impact on the world to decrease greenhouse gases and pollution. In addition, many companies are working to positively sustain the environment by consuming less energy through packaging optimization. All these factors contribute to a sustainable industry that will not only satisfy consumers but impact the environment healthily. And believe it or not, “You will watch roughly 782 movies while sitting on your sofa” (10).

Works Cited

"9 Modern Ways to Recycle Your Old Furniture - Conserve Energy Future." Conserve Energy Future. N.p., 22 Oct. 2016. Web. 26 Nov. 2016.

"10 Interesting Facts About Sofas - Sofa Workshop." Sofa Workshop. N.p., 03 Dec. 2014. Web. 26 Nov. 2016.

Administrator. "Foam Production." Foam Production. N.p., 30 Nov. 2016. Web. 27 Nov. 2016.

"Aluminum Recycling Facts." Recycling Facts - A Recycling Revolution. N.p., n.d. Web. 24 Nov. 2016.

"Energy Consumption." 2. Energy Consumption. N.p., n.d. Web. 26 Nov. 2016.

"Energy Use Efficiency." Energy Use Efficiency | CottonInfo. N.p., n.d. Web. 26 Nov. 2016.

"Facts on Timber." Facts on Using Timber. N.p., n.d. Web. 26 Nov. 2016.

"Garbage Truck Halves Fuel Consumption." Miljnytta. N.p., n.d. Web. 26 Nov. 2016.

"Making Sustainable Cotton Mainstream: The Better Cotton Initiative." Triple Pundit: People, Planet, Profit. N.p., 15 Mar. 2015. Web. 26 Nov. 2016.

"The National Academies Presents: What You Need to Know About Energy." How We Use Energy, Transportation —. N.p., n.d. Web. 26 Nov. 2016.

O'connor, Megan H. "WakeGOV." WakeGOV: Wake County Government. N.p., n.d. Web. 26 Nov. 2016.

"Polyurethane." How Polyurethane Is Made - Material, Production Process, Making, History, Used, Processing, Parts, Steps. N.p., n.d. Web. 27 Nov. 2016.

Shandu, Gurdas. Real-World Activity and Fuel Use of Diesel and CNG Refuse Trucks. Riverside: U of Nebraska, 2014. Print.

Sharma, Sarita. Energy Management in Textile Industry. N.p.: Department of Fashion Technology, n.d. PDF.

"The Stages of the Wood Processing - Gascogne Bois." Gascogne Bois. N.p., n.d. Web. 26 Nov. 2016.

"Steel Manufacture." Steelconstruction.info. N.p., n.d. Web. 27 Nov. 2016.

"Supply Chain Optimizers : Packaging Optimization." Supply Chain Optimizers : Packaging Optimization. N.p., n.d. Web. 27 Nov. 2016.

"Table 4-5: Fuel Consumption by Mode of Transportation in Physical Units | Bureau of Transportation Statistics." Table 4-5: Fuel Consumption by Mode of Transportation in Physical Units | Bureau of Transportation Statistics. N.p., n.d. Web. 27 Nov. 2016.

Waste and Recycling Information Guide. Raleigh: Solid Waste Management Division, n.d. PDF.

Yeng Yang

DES 040A

1 December 2016

Sofa Wastes

Material can be found and energy can be produce but what about the leftovers after the materials are used and the energy is produced? Sofa originated in Ancient Egypt, it was meant only for royalties and social elites. However, in today world, it is a furniture that is affordable even to the poor. Making sofa demands a whole lots of human power however the materials aren't that difficult to find. Through the six steps in the product of life-cycle, we will learn about what we should consider to do with the waste products and try to preserve raw material making sofa.

Waste products can be potential dangers to the environments we lived in if not properly treat after used. The main material to make a stable sofa is woods. There are four kind of woods that can be use to make sofa but maple wood is preferred over fruitwood, mahogany, and walnut wood(made). Working with woods isn't all that complicate however the processes to make a smooth wood and to get those raw materials are hard. The consequences of making smooth woods is that the laborer or a person who is controlling the machine will be affected. Woods dust are so annoying, it is worse than dirt dust. Wood dust once got into my eyes, it stung really bad since it doesn't dissolve and the smell of wood dusts makes people cough and sneeze too. To protect the air we lived in from wood dust, wood has to be process in either a large inhabitant area or at least in a covered green house. However in today world, there's newer options such as steels, plastics, and laminated boards(made). Getting the raw materials to make sofa aren't too far away. Mahogany grows on the West Indian Island as far as the Bahamas, the Florida keys and parts of Florida. Black Walnuts, Juglans nigra, are found in the Eastern and Central United States but they occur in moderate numbers nearly everywhere in the U.S. east of the Great Plains, except for New England and south Florida. Maple woods grows throughout the eastern United States(Types). Fruitwood were readily available and fine-grained, fruitwood trees, such as cherry, apple, pear and plum, were often the wood of choice for cabinetmakers.Depending on a how a finish was applied, fruitwood colors could be extremely similar or vary widely across light and dark colors and shades including light honey-gold, cherry pear, light cherry and deep reddish brown and mahogany. This may be because cherry was one of the popular fruitwood materials used, as it provided a cheaper alternative to expensive light and dark mahogany woods.Because there is no set standard for the description of this type of fruitwood-color across stain and finish manufacturers, we can find samples identical to various light cherry samples or we might find samples that appear more reddish orange or pear-like with red streaks(Bertha).

The advantages of having four kinds of wood is that we can switch between the wood material when one gets too low. There's this time interval that we can afford to make sure the woods aren't used up. For example we can use the maple wood and let the walnuts wood grow, vice versa for the other woods. I previously wrote that we can use steel, plastic, and laminated board to make sofa. Sticking with woods to make sofa is better since it is a renewable source and growing it makes it more reliable than steel. Area where sofa are being mass produce are actually causing harms to nature.

IKEA is such a giant company, it got its wood from variety of suppliers. They are not responsible for the actual cutting down of trees, but rely on other companies to provide the wood for their products. According to Ellen Ruppel Shell, Ikea is the third-largest consumer of wood in the world and most of the wood comes from Eastern Europe and Russia, where wages are low and a large amount of logging is done illegally Forests in these areas, including birch forests, are rapidly waning. This is leading to deforestation, partially due to the high rate of logging that is going unchecked by forestry governance bodies. Deforestation’s negative impacts on the environment include loss of habitat for species, climate change from the disruption of water cycles and fewer trees to absorb greenhouse gases. While trees are renewable, the rates at which the forests are being logged are wiping out forests faster than they can be replenished. By being the third-largest consumer of wood and using questionable logging methods, consuming Ikea products promotes their detrimental effect on the environment(Ikea). This is just to prove that cutting to many raw material can lead to consequences.Although wood is used to make a stable sofa, we need padding and padding is made of animal hairs(made).

The padding is made of animal hairs such as horse and hog. Animal hairs shouldn’t be big deal but considering that it is from horse and hog(made), wouldn't that seem a bit off? Horse does not have a lot of hairs. Horse only liter one offspring and it happens in the spring and summer mostly. It is inappropriate to use horse hair when their hairs are their pride and the year it takes to grow is long, from the day it is born to the day it grow old just to have its hair taken off. As for hog, there are a lot of hairs, but it seem like once their hair is skinned off, it actually shows their skin. This raw material should be taken out of the formula and replace with another. Even though it is a bit inappropriate to use horse and hog hairs, I can see as to why they would use it. This are animal and they can be reproduce fast and hairs can grow back, the only problem though is that this cannot be mass produce. In order to mass produce padding, polyester fiberfill wrap and fiber can replace hog and horse hair(made). Another good thing about using the hog and horse is that they don’t make the supplier wait long comparing it to the tree raw materials. Trees takes 20-30 years to reach its highest and its most sturdiest. Animal hairs can be harvest thorough the year as long as it grow hairs.

There are still many other raw materials to replace animal hairs, in order to not waste animal hairs we can use wool, nylon, cotton, acetate, rayon, and polyester. Wool and nylon are natural synthetic fibers, but cotton, acetate, rayon, and polyester have their own functional properties. Some of the differences in feature between natural and synthetic fibers is that natural fibers are made from nature and the length is adjust by nature and it is more comfortable to wear. Synthetic fibers are man made and the length of the fibers is controlled by man however it is less comfortable to wear. Using cotton is more convenient since it can be mass produce in such a short time. Cotton are easy to grow and easy to harvest and it is renewable. There shouldn’t be any cotton being waste. Successful cultivation of cotton requires a long frost-free period, plenty of sunshine, and a moderate rainfall, usually from 60 to 120 cm(cotton). Soils usually need to be fairly heavy, although the level of nutrients does not need to be exceptional. In general, these conditions are met within the seasonally dry tropics and subtropics in the Northern and Southern hemispheres, but a large proportion of the cotton grown today is cultivated in areas with less rainfall that obtain the water from irrigation. Production of the crop for a given year usually starts soon after harvesting the preceding autumn. Cotton is naturally a perennial but is grown as an annual to help control pests. Planting time in spring in the Northern hemisphere varies from the beginning of February to the beginning of June. The area of the United States known as the South Plains is the largest contiguous cotton-growing region in the world. While dryland cotton is successfully grown in this region, consistent yields are only produced with heavy reliance on irrigation water drawn from the Ogallala Aquifer. Since cotton is somewhat salt and drought tolerant, this makes it an attractive crop for arid and semiarid regions. As water resources get tighter around the world, economies that rely on it face difficulties and conflict, as well as potential environmental problems(cotton). All the details of cotton makes it more qualify to make the padding then horse hairs.

The patterns and effects of choosing products can be considered harmful to the environment and people who make them. The environment and people’s wellbeing are of foremost concern, but it also has a social impact on lifestyle and individuality. The business model is to mass-produce products that are so low in price that as many people as possible can afford them. The result of this is where the same generic item is in thousands and thousands of homes, creating a kind of cultural standard in furniture. People compromise their personal taste and craftsmanship for the affordability of products like sofa. People buying aren’t decorating their homes with items that exactly reflects their personal style and preferences, they are given a finite array of options by the store and they have to find something they like the most. Buying mass-produced, impersonal, cheap things to decorate your home creates a homogeneous environment shared by thousands of other people. The sense of individuality and personalization of your most intimate surroundings is lost(Ikea).

When a sofa is broken and old, people usually try to advertise it or try to sell it to other people. Throwing a sofa away has to be on certain date and certain circumstance. The easiest way is to donate it. What about the recycle for the material? Furniture is more often reused than recycled, but there are companies that recycle furniture available that will break down old furniture to find new life as other products. Also, thrift stores, supply companies and charity organizations will accept furniture for resale and reuse(How).Not all household hazardous product leftovers can be shared or recycled. If the label indicates the product should be disposed of through a community collection program, St. Louis County participates in the regional Saint Louis Household Hazardous Waste program. Up to 85% of the material collected will be recycled or recovered as waste to energy through this program. The remaining material is managed as regulated hazardous waste and in accordance with applicable regulations(How).

Waste management are carefully executed. To reduce waste material, the left overs are used to make smaller size sofa. Animal hairs are use for the necessaries of sofa only not overly used. The excesses animal hairs are kept to make more sofa, same goes with polyester fiberfill wrap, cotton, etch. Cotton will never run out due to its growth rate and its flexibility in different weathers and terrains.

We must respect of how we treat the product that we use. If we do not respect how we treat our resources before use and after used, the result would be the same as today where our air are filled with carbon dioxide. The materials we recklessly use might run out due to lack of care for its capacity of growth rate. We must make the calculations so there will be no mistakes of material wasted.

"Ikea Case Study: Some Effects of Mass Production and Consumption". LTD. 2010 4.November <http://globalcitizens.pbworks.com/w/page/9036294/FrontPage>

"Types of Woods". LTD.2016 25.November <http://www.hoovedesigns.com/woods.html>

"Cotton". LTD 2016 25.November <https://en.wikipedia.org/wiki/Cotton>

Bertha. "What is Fruitwood Color and It Is Better Than Cherry"? What Exactly is Wood? LTD 2012 27. November <http://blog.kitchenmagic.com/blog/bid/165454/what-is-fruitwood-color-and-is-it-better-than-cherry>

"How To Recycle Furniture" LTD 2016 23. November <http://earth911.com/recycling-guide/how-to-recycle-furniture/>