Design Life-Cycle

assess.design.(don't)consume

Lynn Yaguchi

Professor Cogdell

DES 040A

December 2, 2021

Electric Toothbrush Lifecycle Paper- Materials

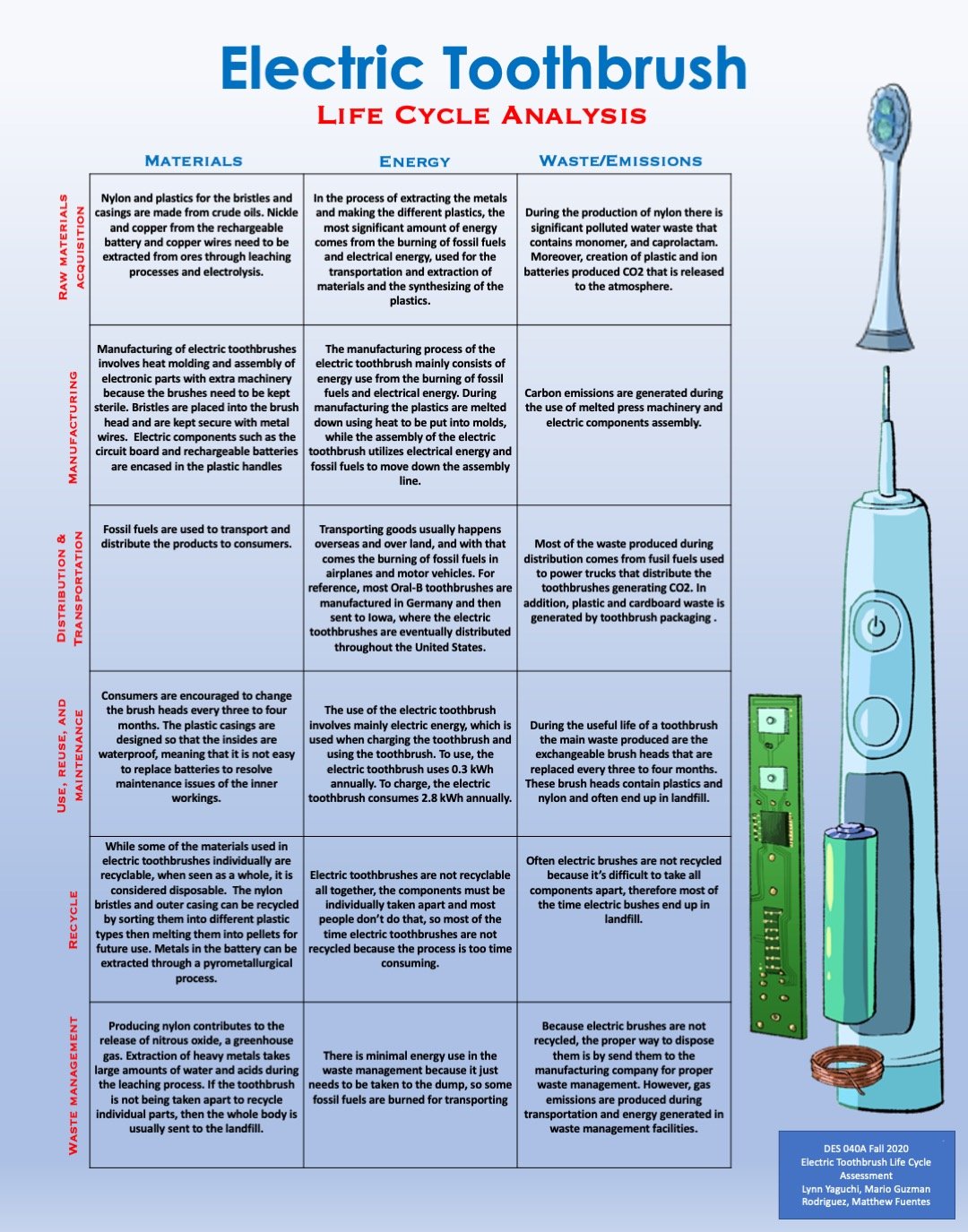

Electric toothbrushes have been advertised as a more effective way of cleaning your teeth than a traditional toothbrush by vibrating motions generated by an internal motor. At first glance an electric toothbrush seems to use the same materials as a normal plastic toothbrush, but examining the inside workings shows that one must consider more than the nylon bristles and plastic handle when it comes to the materials needed to produce one. The presence of rechargeable batteries that make the electric toothbrush lighter and more convenient for use than its predecessors with chunky bodies that had to be connected to a wire for electricity make it easier on the consumer to use but brings on a whole new facet of materials needed to keep people’s teeth clean. The extra complexity that the rechargeable battery brings to the electric toothbrush along with the use of nylon and plastics shows that the impact of the electric toothbrush goes farther than the bathroom it inhabits.

The outer casing and brush heads are primarily made of plastics and nylons. Most outer casings are made of heat molded plastic (polyethylene or polypropylene) that is recyclable. Polyethylene is made from crude oils (petroleum) that are heated until ethylene is released (Paxton). This material is used for its waterproofness, to keep the rechargeable battery safe from water. The nylon bristles are kept in place by a metal wire that is shoved into holes made in the brush head. Nylon 6-12 is the most commonly used type for toothbrushes because of the hardness and water resisting characteristics that make it durable for daily use (Ng). Nylon is a polyamide, which is a byproduct of different plastics and is made by forming a chain with amine, hexamethylenediamine, and adipic acid under pressure and heat (Bruce). The monomers that make up the chains are extracted from crude oils. Inside the plastic casing is the nickel-metal hydride (NiMH) battery. It can be recharged hundreds of times with a typical life expectancy of 2 to 5 years. Raw materials of NiMH batteries include neodymium, nickel, magnesium, carbon, potassium hydroxide, and lithium hydroxide. Nickel is extracted by crushing sulfide ores, then adding reagents to remove the sulfide particles. The nickel may then be leached with sulfuric acid or ammonia. Or they may be dried and smelted (in the range of 1350 C) which are then leached or electro-refined (Porvali). A copper wire sits at the base of the battery inside the toothbrush so that it can charge. Copper may be extracted from sulfide ores that contain about 2% copper. To extract pure copper, the ore is crushed into smaller pieces, then impurities are removed through a frothing process. The sulfur is then burned off as sulfide gas. Silica and limestone fluxes are added so that other impurities such as ferrous oxide bind to it, leaving it as copper sulfide. The remaining sulfur is burned off as sulfur oxide during an oxidation process. At this stage the metal is called copper blister. The blister copper is electro-refined to form pure copper cathodes (Bell). A printed circuit board controls the voltage in the electric toothbrush. Most electric toothbrushes use a 4-bit circuit board (Teschler) while a few may use an 8-bit circuit board. Copper foil is utilized as a channel that carries electrons in circuit boards (Sachin). Fiberglass is often used as a substrate in circuit boards with a resin-based laminate that sandwiches it. Fiberglass is made by forcing melting glass through small holes, making fibers that can be woven or added to resin to make a durable material that is light, strong, and electrically insulating. All the aforementioned components come together to form an electric toothbrush, even if the most crucial pieces won’t ever be visible to the consumer.

Manufacturing of electric toothbrushes involves heat molding and assembly of electronic parts with extra machinery because the brushes need to be kept sterile. Electric components such as the circuit board and rechargeable batteries are encased in the plastic handles and are checked by machines that the casing is waterproof (Ng). Bristles are placed into the brush head and are kept secure with metal wires and machines cut the tips of the bristles to get them into a desired shape. A final inspection makes sure that there are no pathogens on the body of the toothbrush by UV sterilization, and then they are ready to be shipped to distribution centers.

Assuming that the manufacturing process of electric toothbrushes occurs within the United States, transportation is heavily reliant on automobiles that use fossil fuels. According to the United States Environmental Protection Agency, the transportation sector took up 29% of the greenhouse gas emissions in the US and within that sector, 58% of greenhouse gas emissions came from light vehicles and 24% from medium and heavy-duty trucks. It is hard to say that the shipping of electric toothbrushes accounts for a large portion of the overall greenhouse gas emissions, but they still do contribute to the use of fossil fuels. After transportation, the product reaches the hands of the consumer.

Due to the design of the electric toothbrush, maintenance that involves producing waste is required for consumers. Consumers are encouraged to change the brush heads every three to four months (Ng). Due to health concerns and general wear, there is no working solution to maintain the use of a single brush head for more than that time period. There are no additional materials that can be used to repair or to upkeep the condition of the toothbrush. The plastic casings are designed so that the insides are waterproof, meaning that it is not easy to replace batteries to resolve maintenance issues of the inner workings. When the toothbrush no longer functions, repair is not the first thing that comes to the consumer’s mind.

While some of the materials used in electric toothbrushes individually are recyclable, when seen as a whole, it is considered disposable. The nylon bristles and outer casing are made of plastics, so they are not biodegradable. However, they can be recycled by sorting them into different plastic types then melting them into pellets for future use. NiMH batteries contain heavy metals that can be reused. These metals are extracted through a pyrometallurgical process or by dissolving them in mineral acids like hydrochloric, nitric, or sulfuric acids. The metals can be extracted out of its aqueous form through an electrolysis, precipitation, or calcination process (Sullivan). Printed circuit boards are broken into smaller pieces and are further sorted into specific materials. The copper in the printed circuit board is extracted by a leaching process where water and acid are added. Impurities are physically removed, and another leaching process takes place. Then during the precipitation process, a precipitation agent is added to the solution which converts the copper from a liquid to a solid state. The liquids and solids are separated. The solid copper can be sent for more refining and the liquid may go in for another round of the precipitation process (Ferguson). The complicated structure of electric toothbrushes makes it harder to recycle, much less access the components that contain the heavy metals that need to be recycled. Consumers can bring theirs to a recycling center after disassembly or participate in recycling programs launched by companies such as Oral-B, although they do not have a clear outline of how they deal with recycling the used products they receive.

Waste comes not only from the end product but from the early processes of extracting the materials and assembly. Nylon production requires large amounts of water to cool down the material after being heated to form the amide chains. Producing nylon also contributes to the release of nitrous oxide, a greenhouse gas. When the nylon bristles are cut in the production stages of the toothbrush, bits of nylon are lost in the process as well (William Anderson). Nickel content is very low in ores meaning that it takes more time and energy to extract and refine the metal to use in NiMH batteries. Same goes for the copper used in the copper wires. Extraction of heavy metals takes large amounts of water and acids during the leaching process. Fossil fuels provide the energy to process the metal, leading to emissions of greenhouse gases. On top of the waste that comes from production, when the toothbrush no longer works and the individual parts are not taken apart for recycling, then the whole toothbrush is usually sent to the landfill. This takes up space because none of the materials used are biodegradable. If nylon is not recycled properly then small pieces can enter the environment including water systems (Tang).

The materials used in an electric toothbrush is way more than meets the eye in terms of extraction, production, and waste. The crude oils used for the plastics produce greenhouse gasses and the metals needed for the rechargeable battery and printed circuit board require intensive leaching processes that use large amounts of water and acids. All the materials used are not biodegradable -- such as polyethylene, nylon, NiMH batteries, printed circuit boards -- making it very important that the components are properly recycled. However, because of the waterproof design, recycling can be a much bigger hassle than expected. If not recycled properly then there can be unintended consequences of micro plastics entering the environment. Although the additional component of a motor and a rechargeable battery is advantageous in oral hygiene, it relies on energy intensive methods to extract materials, and it makes it not suitable for maintenance and recycling.

Works Cited

“Fast Facts on Transportation Greenhouse Gas Emissions.” US EPA, 8 July 2021, www.epa.gov/greenvehicles/fast-facts-transportation-greenhouse-gas-emissions.

“Polyamides.” The Essential Chemical Industry, 2018, www.essentialchemicalindustry.org/polymers/polyamides.html.

Bell, Terence. “Manufacturing Process of Copper.” ThoughtCo, 26 Sept. 2019, www.thoughtco.com/copper-production-2340114.

Bella Bathrooms. “How Do Electric Toothbrush Chargers Work.” Bella Bathrooms Blog, 14 Oct. 2021, www.bellabathrooms.co.uk/blog/how-do-electric-toothbrush-chargers-work.

Ferguson, Anara. “The Processes of Circuit Board Recycling | RC.” Busch Systems Resource Center, 13 Nov. 2017, www.buschsystems.com/resource-center/page/the-processes-of-circuit-board-recycling.

Johnson, Todd. “Learn About the History of Fiberglass and How It Is Manufactured.” ThoughtCo, 3 Jan. 2020, www.thoughtco.com/what-is-fiberglass-or-glass-fiber-820469.

Lyne, A., Ashley, P., Saget, S. et al. Combining evidence-based healthcare with environmental sustainability: using the toothbrush as a model. Br Dent J 229, 303–309 (2020). https://doi.org/10.1038/s41415-020-1981-0

Mearian, Lucas. “Wireless Charging Explained: What Is It and How Does It Work?” Computerworld, 28 Mar. 2018, www.computerworld.com/article/3235176/wireless-charging-explained-what-is-it-and-how-does-it-work.html.

Moseley, Tomlinson. “Electric Toothbrush.” Google Patents, 13 Dec. 1937, patents.google.com/patent/US2196667A/en.

Ng, Clarence et al. “Safety and Design Aspects of Powered Toothbrush—A Narrative Review.” Dentistry Journal 8.1 (2020): 15. Crossref. Web.

Ordo Marketing. “How Long Do Electric Toothbrushes Last.” Ordo, 4 Nov. 2020, www.ordolife.com/blogs/ordo-life/how-long-do-electric-toothbrushes-last.

Paxton, Robert. "How to Make Polyethylene" sciencing.com, https://sciencing.com/make-polyethylene-10029798.html. 28 November 2021.

Porvali, A., Ojanen, S., Wilson, B.P. et al. Nickel Metal Hydride Battery Waste: Mechano-hydrometallurgical Experimental Study on Recycling Aspects. J. Sustain. Metall. 6, 78–90 (2020). https://doi.org/10.1007/s40831-019-00258-2

Sachin. “Printed Circuit Board (PCB) Materials.” Printed Circuits LLC, 2 Nov. 2020, www.printedcircuits.com/printed-circuits-materials.

Sullivan, J L, Gaines, L, and Energy Systems. A Review of Battery Life-Cycle Analysis: State of Knowledge and Critical Needs.. United States: N. p., 2010. Web. doi:10.2172/1000659.

Tang, Shuai, et al. “Pb(II) Uptake onto Nylon Microplastics: Interaction Mechanism and Adsorption Performance.” Journal of Hazardous Materials, vol. 386, 2020, p. 121960. Crossref, doi: 10.1016/j.jhazmat.2019.121960.

Teschler, Lee. “Teardown: What’s inside a Phillips Sonicare Electric Toothbrush.” Power Electronic Tips, 25 Feb. 2016, www.powerelectronictips.com/teardown-whats-inside-a-phillips-sonicare-electric-toothbrush.

Wells, Bruce. “Nylon, a Petroleum Polymer.” American Oil & Gas Historical Society, 10 May 2021, aoghs.org/products/petroleum-product-nylon-fiber.

William Anderson (Schoolworkhelper Editorial Team). “Nylon: Background, Dangers, Disposal.” SchoolWorkHelper, 6 Mar. 2021, schoolworkhelper.net/nylon-background-dangers-disposal.

Wise, Edmund Merriman and Taylor, John Campbell. "Nickel processing". Encyclopedia Britannica, Invalid Date, https://www.britannica.com/technology/nickel-processing. Accessed 14 November 2021.

Matthew Fuentes

Professor Cogdell

DES 040A

December 2, 2021

Electric Toothbrush Energy Consumption

Introduction

After waking up in the morning and before going to sleep, one of the key things to live a hygienic life is brushing your teeth. While many use normal manual toothbrushes, there is a growing percentage of electric toothbrush users – in Britain, it was estimated that around 67% of adults have started using electric toothbrushes (Oral Health Foundation, 2020) – due to their ease of use and convenience. With a growing number of users comes a higher environmental impact, especially in terms of the embodied energy throughout the lifetime of the electric toothbrush. A higher proportion of electric toothbrushes means that more need to be manufactured and delivered to different locations around the world, all of which involve a considerable consumption of fossil fuels. In addition to the beginning of its life, throughout the electric toothbrush’s time spent in use, charging is required, utilizing electrical energy for both the batteries and charger. Once reaching the end of its life, the toothbrush must be disposed of – and since its parts are all individually recyclable and not recyclable as a unit, more times than not they are just thrown away. Although an electric toothbrush may make life easier in the mornings and nights, the production process of an electric toothbrush comes with different components that quickly accumulate to create a considerable environmental impact. The overall energy consumption throughout the life cycle of the electric toothbrush makes it clear that we have come to have a strong dependence on high energy use, and while its functions may be beneficial and convenient to us personally, the damage their energy consumption causes to the environment makes them not worth it.

Manufacturing

Starting off with the manufacturing process of the electric toothbrush, they consist mainly of polypropylene and polyethylene for the body and head, nylon for the bristles (CariFree, 2019), and coils and nickel-metal hydride batteries to be recharged (Explain that Stuff, 2007). For the plastics that go into the electric toothbrush – with a focus on the polypropylene – it takes about “73 MJ with a range of values extending from 54 MJ to 94 MJ” to produce only 1 kg (Boustead, 2005). While I could not find the exact amount of plastic in an electric toothbrush, for reference I am using the amount of plastic in a regular toothbrush, which is 25 grams (Cooper, 2018). Based on this amount of plastic, it would take about 1.825 MJ to manufacture the necessary plastic for an electric toothbrush. Moving on to the nylon used for the bristles of the electric toothbrush, it typically takes 130 MJ to produce 1 kg (Schlesinger, 2018). For the specific amount of nylon that goes into the brush head I could not find an exact number but consistently saw that there is typically less than 0.1 ounces. Based off this number, it would take approximately 0.37 MJ to produce the necessary amount of nylon for a toothbrush. The electric coils that are used are “formed when a conductive metal wire is wound around an insulator” (Electric Coils). As for the specific amount of energy involved in making the electric coil, I could not find any definite numbers. Lastly, for the nickel-metal hydride batteries I could not find the amount of energy that goes into the manufacturing. Once all the materials are acquired and prepared, the assembly of the electric toothbrush begins.

After the individual components are manufactured, they must go through the assembly process of the electric toothbrush. To start off the assembly, the plastics that were made are melted down and injected into the mold of the electric toothbrush. This process involves the use of a hydraulic machine which uses “0.278 kWh per pound of plastic processed” (Socks, 2005). After being molded, “the hollow handle casings produced are then ready for the installations of electronics, in which a machine [clamps] a gearbox and motor together and fixes them in place” (Ng et al., 2020). From here, the two parts are welded together along with the nickel-metal hydride battery, and then lastly, they are all sealed together, completing the assembly of the electric toothbrush. The energy that is consumed in production lines like this, on average, is between 13 kW to 23kW (Desdouits et al., 2016). Once fully assembled, the electric toothbrush moves onto the next part of its life: distribution.

Distribution

After finishing being manufactured and assembled, the electric toothbrushes must be distributed throughout the world, with an even higher demand due to the increase in electric toothbrush users. In the case of the company Oral-B, electric toothbrushes are manufactured in Germany (Electric Teeth, 2021), meaning the distribution of electric toothbrushes requires both land and air travel – both of which use fossil fuels as energy sources. I could not find specific distribution facilities that the electric toothbrushes are sent to after being manufactured and assembled, so I will use Oral-B’s Iowa City facility to estimate the energy consumption. To calculate I will assume that electric toothbrushes are being commercially transported on a Boeing 777-280LR, which consumes about 6800 kg/hr (Saurabh, 2019). The distance between Iowa City, Iowa, and Germany is about 4,497 miles which would take around 9 hours to fly. Based off these numbers, air travel alone would burn 61,200 kg of fuel. Once being flown into the area, the electric toothbrushes must be transported to the Iowa City Oral-B facility, which would be a 3-mile drive. Assuming the electric toothbrushes are being transported on a commercial truck the approximate fuel burned is 1.17471 kg. Once at the facility ready to be distributed to the stores, the trucks set off once again. To calculate, I will use the closest Target to the Oral-B facility, a 2.5-mile drive. To get to the nearest Target, commercial trucks consume 1.4559 kg of fuel. While these last two numbers may seem small, one thing to keep in mind is that this is representative of one of many routes electric toothbrushes may be distributed. After being distributed, the electric toothbrush is sold – with more fossil fuels burned in the transportation to the consumers’ home – and continues to the next stage of its life: its use and maintenance.

Use and Maintenance

Electric toothbrushes typically come with a multitude of features, and with that comes a generous amount of energy consumption in the form of electricity. On average electric toothbrushes have the capacity to use 8-12W at a rate of around 5 minutes a day for 365 days, summing up to an annual consumption of 0.3 kWh (Energuide). In addition to the energy consumed during the use of the product, electric toothbrushes also require daily charging. Annually, Oral-B says in charging alone their electric toothbrushes consume 2.8 kWh – a reduced number that does not consider overcharging because Oral-B chargers are built to never overcharge their batteries. To be more specific on how the energy is being used wirelessly, electrical toothbrushes utilize close-range wireless transmission. The added electrical component of the electric toothbrush does reduce the amount of kinetic energy used to brush teeth but does not entirely do away with it; so, when taken together, electrical toothbrushes utilize both electrical and kinetic energy to function. Once the electric toothbrush has been used by the consumer, it must then move on to the final stage of its life: recycling, or in most cases, just being thrown away.

Afterlife

While the components of electric toothbrushes are recyclable individually, together they are not. To dispose of an electric toothbrush, it needs to be taken apart and recycled separately, which uses kinetic energy to be done. Once each part is separated from the rest and recycled, each of them are transported elsewhere, using fossil fuels as an energy source. After that, each recyclable component embarks on its journey of being recycled. However, this is merely an ideal example; most of the time electric toothbrushes are just thrown away after the consumer has finished using it. By throwing it away, the remaining energy that is consumed is fossil fuels – to be sent to the nearest dump where most will remain for the rest of their existence, unless burned.

Conclusion

To bring everything together, the electric toothbrush, although easy to use and convenient, consumes a considerable amount of energy, in turn having a significant effect on our environment. From the manufacturing process to the process of recycling, the electric toothbrush leaves a carbon footprint that is undeniable. One way that we could limit this impact – without getting rid of the electric toothbrush – would be to make all the components recyclable together, simplifying the process by getting rid of the time-consuming process of separating each component. An even simpler way of minimizing the impact on the environment is to revert to the use of a manual toothbrush on a grand scale, lowering the high demand for electric toothbrushes. The feeling of needing a more convenient way of living your day-to-day life does not make it a necessity; by following this hunger for a simpler life we are only perpetuating the mistake of consuming more and more energy. If we want to save our environment and attempt to reverse the effects of climate change, we should start at a smaller scale and cut our use of smaller electric appliances that could be done without the use of external sources of energy; our bodies have the capacity to do the work we choose to not do, we cannot continue being lazy, our environment and future civilization deserve better.

Bibliography

Oral Health Foundation. “12 Million Brits Move to Electric Toothbrushes,” June 1, 2020. https://www.dentalhealth.org/news/12-million-brits-move-to-electric-toothbrushes.

Boustead, I. “Eco-Profiles of European Plastics Industry.” PlasticsEurope: Association for Plastic Manufactures, March 2005.

Chris Woodford. “How Do Electric Toothbrushes Work?” Explain that Stuff, October 25, 2021. http://www.explainthatstuff.com/electrictoothbrush.html.

Cooper, Simon. “The Last (Plastic) Straw.” Grin Toothbrush, October 17, 2018. https://www.grinbrush.com/blogs/news/the-last-plastic-straw.

Desdouits, Chloé, Jean-Louis Bergerand, and Pierre-Alexis Berseneff. “Energy Study of a Manufacturing Plant.” . . ENERGY MANAGEMENT, n.d., 9.

“Electric Coil Manufacturers | Electric Coil Suppliers.” Accessed November 30, 2021. https://www.electriccoils.net/.

“How Long Do I Charge My Oral-B Rechargeable Toothbrush for? | Oral-B.” Accessed November 14, 2021. https://oralb.com/en-us/how-long-do-i-charge-my-oral-b-rechargeable-toothbrush-for/.

Energuide. “How Much Energy Do My Household Appliances Use?” Accessed November 14, 2021. https://www.energuide.be/en/questions-answers/how-much-energy-do-my-household-appliances-use/71/.

Love, Jon. “Oral Healthcare Products Not Made in China - Electric Teeth.” Accessed November 14, 2021. https://www.electricteeth.com/not-made-in-china/.

Lyne, Alexandra, Paul Ashley, Sophie Saget, Marcela Porto Costa, Benjamin Underwood, and Brett Duane. “Combining Evidence-Based Healthcare with Environmental Sustainability: Using the Toothbrush as a Model.” British Dental Journal 229, no. 5 (September 2020): 303–9. https://doi.org/10.1038/s41415-020-1981-0.

Mahmud, M. A. Parvez, Nazmul Huda, Shahjadi Hisan Farjana, and Candace Lang. “Comparative Life Cycle Environmental Impact Analysis of Lithium-Ion (LiIo) and Nickel-Metal Hydride (NiMH) Batteries.” Batteries5, no. 1 (March 2019): 22. https://doi.org/10.3390/batteries5010022.

Ng, Clarence, James Kit Hon Tsoi, Edward C. M. Lo, and Jukka P. Matinlinna. “Safety and Design Aspects of Powered Toothbrush—A Narrative Review.” Dentistry Journal 8, no. 1 (February 5, 2020): 15. https://doi.org/10.3390/dj8010015.

Saurabh. “Fuel Consumption of Popular Aircraft,” December 13, 2019. https://alliknowaviation.com/2019/12/14/fuel-consumption-aircraft/.

Schlesinger, Bill. “The Fabric for Our Lives.” Translational Ecology (blog), November 26, 2018. https://blogs.nicholas.duke.edu/citizenscientist/the-fabric-for-our-lives/.

Socks, Michael. “The Promise of All-Electric Injection Molding Machines: A Promise Kept?,” 2005, 12.

Staff, Creative Mechanisms. “Everything You Need To Know About Polypropylene (PP) Plastic.” Accessed November 14, 2021. https://www.creativemechanisms.com/blog/all-about-polypropylene-pp-plastic.

CariFree. “What Are Toothbrushes Made of? - CariFree Blog,” January 9, 2019. https://carifree.com/blog/what-are-toothbrushes-made-of/.

Wynes, Seth, and Kimberly A. Nicholas. “The Climate Mitigation Gap: Education and Government Recommendations Miss the Most Effective Individual Actions” 12, no. 7 (July 2017): 074024. https://doi.org/10.1088/1748-9326/aa7541.

Electric Toothbrush Lifecycle - Waste

Introduction

The Electric toothbrush is a product that is promoted as a better and efficient alternative to regular brushes, its rotative motor helps to clean teeth surfaces with ease and could be beneficial for people with motor deficits. In recent years, the use of electric-powered toothbrushes has increased in popularity, in the U.S. 36% of adults prefer and use electric brushes (Wadyka). However, electric brushes come with a great environmental impact, the amount of waste generated from the extraction of materials to the end of its life cycle does not justify its use. While the electric brush is a product beneficial for dental health, companies need to rethink the sustainability of electric brushes because much of the waste produced by the production, distribution, and use - electric brushes cannot be recycled, therefore the waste and byproducts generated are key contributors to the environmental decay in the long run.

Manufacturing

The manufacturing process starts by acquiring raw materials for the fabrication of plastics, nylon bristles, electrical components, and batteries. Generally, these materials are imported from China and later produced and assembled in local factories (Gutkowski). For example, Oral B is one of the leaders in dental care products, and they manufacture and assemble their line of electric toothbrushes in Germany, but they get sources of raw materials from China (Love). The main body of the electric toothbrush is made of polyethylene, which in its extraction process produces air emission of sulfur oxides, nitrous oxides (also produced by nylon production), methanol, and ethylene oxide that are toxic to the environment (Ecology Center). For instance, as Berkeley’s Ecology Center notes, “producing 16 oz. of polyethylene generates more than 100 times the toxic emissions to air and water than making the same out of glass”. Similar to plastic, the production of nylon generates toxic gases that are later released into the atmosphere. Although there is no defined data about emissions generated from nylon production specifically for the dental industry, it is important to note that nitrous oxide emissions of nylon production “from adipic acid plants in China may equal the greenhouse gas emissions of approximately 25 million automobiles” (McKenna and Pike). Moving on to the batteries production, electric toothbrushes use nickel-metal hydride batteries (NiMH) which “have a significant impact on global warming, human toxicity, marine aquatic ecotoxicity, and acidification” (Mahmud et al.). While taking a look at the materials necessary to assemble an electric toothbrush it is evident waste is generated even from the extraction of materials to create the individual components, so as the life cycle progresses more waste will be generated causing higher environmental impact.

Once all individual components are made, the assembly process starts by creating the main body of the toothbrush which will house all the electric components. The plastic is melted down and later injected into a mold press that gives the toothbrush its shape. Injection molding is one of the most efficient ways manufacturers create lots of products in a short period of time since the process can be repeated over and over. During this molding process, there are volatile organic compounds or VOCs emitted from the melted pallets of plastic (Yamashita et al.) the VOCs are generated from polymer degradation of the plastic, which are harmful to the environment and humans because high concentrations can cause irritation to the lungs and damage to the central nervous system and kidneys. Once the molding process is finished, the toothbrush will soon be sealed with all the rest of the components. This helps prevent damage to the electric components inside of it, especially to the battery. Moreover, the toothbrush heads are made separately using a similar process involving plastic molding, later “the nylon bristles are trim to the desired length, and special mechanisms are then inserted inside of the head for it to be able to rotate” (“From Scratch to a Large Batch”). I was unable to find information about specific waste produced during the production process of the toothbrush heads, but it can be inferred that some nylon bristles waste is generated during the trimming stage.

Finally, the assembled electric toothbrush requires packaging for its future distribution. Most companies use more plastic and cardboard to create the packaging of their products, and electric toothbrushes are not the exception. Usually, toothbrushes are packed in clear plastic boxes with some thin cardboard. This requires the use of more resources and increases the amount of waste generated.

Distribution

Once the electric toothbrush is assembled and packaged, now it's ready for the distribution process. During its distribution, the main waste generated is CO2 emitted by distribution trucks, cargos, and planes. To put in perspective, 29.4% of all CO2 generated globally is caused by freight distribution (Ritchie). Also, other byproducts emitted from transportation are “relatively small amounts of methane CH4 and nitrous oxide N2O emitted during fuel combustion. In addition, a small amount of hydrofluorocarbon HFC” (EPA)

Use and Maintenance

During the use of the electric brush, the biggest cause of waste is the exchange of the toothbrush rotating heads. The company Oral B recommends exchanging the toothbrush heads every three to four months, which means that in a year three to four brush heads will be used (Oral B). Usually, these toothbrush heads are not recycled, because it requires a complex and energy-demanding process, most of the time, toothbrush heads end up in landfill waste. Although three to four toothbrush heads per year does not sound like much it adds up in the long run. According to the American Dental Association, toothbrushes generate 50 million pounds of waste annually, and because the nylon bristles and plastic on them are not biodegradable, can cause great harm to the environment (Erskine). The accumulation of plastic is a significant concern because plastic is one of the main pollutants of oceans and coastal areas. Plastic can modify natural habitats, and damage wildlife.

Recycle

Recycling the electric toothbrush is the most complicated process of all the lifecycle of the product, not because the materials of the toothbrush are not recyclable, but because of its complex assembly. Electric toothbrushes as a whole cannot be recycled, they need to be separated into individual components to be processed properly. If an individual wants to dispose of their electric toothbrush correctly, they would have to disassemble all the components individually and then separate them and send them to their appropriate waste management service, but this is a complex process which consumers usually do not know how to do. The most adequate alternatives are recycling programs by manufacturers that encourage consumers to send back the electric toothbrushes for proper waste treatment. Once consumers sent their products, “the electric toothbrushes are dismantled and separated into metals/electrical components, batteries, and plastics, the plastics are then shredded and melted into pellets that can be remolded to make new recycled products while the metals are separated and recovered.” (Terracycle). Although, that is the ideal scenario, more often than not, electric toothbrushes are thrown into landfill waste contributing to environmental pollution.

Conclusion

The manufacture of electric toothbrushes is a damaging process to both the environment and indirectly human health. The process by which they are made results in the release of toxic substances into the atmosphere, and on top of that they generate a considerable amount of waste, leaving a significant carbon footprint. Having an electric toothbrush does not automatically entitle us to neglect regular brushing. They have benefits, such as removing plaque which manual toothbrushes cannot, but this only adds to the problem by creating more scrap materials to dispose of at our ends. Once broken, these items can be recycled but this has a high environmental impact, as this recycling process is extremely energy-intensive. Manufacturers should design electric toothbrushes to be easier to recycle, to reduce the amount of environmental impact of their products.

Works Cited

Wadyka, Sally. “Should You Use an Electric Toothbrush or a Manual Toothbrush?” Consumer Reports, 19 Jan. 2020, www.consumerreports.org/toothbrush/electric-toothbrush-or-manual-a3193343159/.

Love, Jon. “Oral Healthcare Products Not Made in China - Electric Teeth.” Electric Teeth, 13 July 2021, www.electricteeth.com/not-made-in-china/.

Gutkowski, Shirley. “The Hard Labor behind the Simple Toothbrush.” Rdhmag.com, 2021, www.rdhmag.com/patient-care/rinses-pastes/article/16405455/the-hard-labor-behind-the-simple-toothbrush.

Ecology Center. “PTF: ENVIRONMENTAL IMPACTS | Ecology Center.” Ecologycenter.org, 2021, ecologycenter.org/plastics/ptf/report3/.

Edwards, Summer. “The Environmental Impacts of Nylon - Tortoise & Lady Grey.” Tortoise & Lady Grey, Feb. 2016, tortoiseandladygrey.com/2016/02/01/environmental-impacts-nylon/.

EPA. “Sources of Greenhouse Gas Emissions | US EPA.” US EPA, 29 Dec. 2015, www.epa.gov/ghgemissions/sources-greenhouse-gas-emissions#t1fn2.

Erskine, Eliza. “Plastic Toothbrushes Add 50 Million Pounds of Waste to Landfills Every Year!” One Green Planet, One Green Planet, 4 Dec. 2019, www.onegreenplanet.org/environment/plastic-toothbrushes-waste/.

Mckenna, Phil, and Lili Pike. “A Chinese Chemical Company Captures and Reuses 6,000 Tons of a Super-Polluting Greenhouse Gas - inside Climate News.” Inside Climate News, 2 Oct. 2020, insideclimatenews.org/news/02102020/china-super-pollutants-nitrous-oxide-linggas-henan-shenma/.

Mahmud, M., et al. “Comparative Life Cycle Environmental Impact Analysis of Lithium-Ion (LiIo) and Nickel-Metal Hydride (NiMH) Batteries.” Batteries, vol. 5, no. 1, 18 Feb. 2019, p. 22, www.mdpi.com/2313-0105/5/1/22/htm, 10.3390/batteries5010022.

Oral B. “How Often Should You Replace Your Toothbrush.” Oral-B Connect, 2020, oralbconnect.com/blog/how-often-should-you-replace-your-toothbrush/#:~:text=If%20your%20brush%20head%20has,can%20even%20hurt%20your%20gums.&text=The%20American%20Dental%20Association%20(ADA,building%20up%20on%20the%20bristles.

Ritchie, Hannah. “Cars, Planes, Trains: Where Do CO2 Emissions from Transport Come From?” Our World in Data, 2020, ourworldindata.org/co2-emissions-from-transport.

Terracycle. “Electric Toothbrush Recycling Program.” TerraCycle, 2021, www.terracycle.com/en-AU/brigades/colgateelectric-au.

Yamashita, Kyoko, et al. “Compositions of Volatile Organic Compounds Emitted from Melted Virgin and Waste Plastic Pellets.” Journal of the Air & Waste Management Association, vol. 59, no. 3, Mar. 2009, pp. 273–278, www.tandfonline.com/doi/pdf/10.3155/1047-3289.59.3.273, 10.3155/1047-3289.59.3.273

“From Scratch to a Large Batch: The Production of Electric Toothbrushes.” Everyone Wants Pearly Whites, Everyone Wants Pearly Whites, 8 Dec. 2014, everyonewantspearlywhites.wordpress.com/from-scratch-to-a-large-batch-the-production-of-electric-toothbrushes/. Accessed 2 Dec. 2021.

VProPackaging. “Toothbrush Packaging Boxes | VProPackaging.” V-Packaging.com, 2021, www.v-packaging.com/industries-served/consumer-products/toothbrush-packaging-boxes/. Accessed 2 Dec. 2021.