Design Life-Cycle

assess.design.(don't)consume

Ryan Koski

Nvidia Founders’ Edition GPU Raw Materials Acquisition and Manufacture

A graphics card is made of four basic sections, a printed circuit board (PCB) on which all the components mount, the graphics processing unit (GPU), the heat sink with fins and heat pipes and the injection molded shroud with fans. These major components each require individual environmentally detrimental resource collection and refining methods. Both the acquisition of raw materials and manufacture of chemical components for graphics cards are toxic to the environment and should be mitigated with processes such as chemical recycling. Not only is the acquisition of the necessary raw materials unethical and harmful to the environment, but so are the manufacturing and formulation processes required to assemble the Nvidia RTX 30 Series GPUs.

The basic anatomy of a graphics card is as follows. All graphics cards fundamentally have the same general, overall design: a highly specialized processor, on a circuit board filled with … chips and electronic opponents.” (Evanson, Techspot, 2020.) Most graphics cards have some kind of cooling system, most commonly “copper pipes coming off of [the copper block] into multiple rows of aluminum fins” (Evanson, Techspot, 2020.) These aluminum fins direct the heat generated from the graphics processing unit into the shroud of the card where, “the fan just directs air down into the fins.” (Evanson, Techspot, 2020.) Under the cooling system is the printed circuit board or “PCB” made from FR-4 non-metallic substrate with resin insulation. This substrate is made out of fiberglass filaments and epoxy to make sure that it is non-conductive whole being strong, lightweight, and heat-resistant. On this board is where the GPU and other components like the RAM (random access memory) are located. The GPU is made up of 1.7 billion transistors, “some [of which] just do set math operations, like multiplying and adding two numbers; others read values in memory and convert them into a digital signal.” (Evanson, Techspot, 2020.) As for the RAM, it must “be directly wired to the GPU itself, to ensure the best possible performance” (Evanson, Techspot, 2020.) with something called traces. This is the same way all other transistors, chips and semiconductors communicate with one another. Lastly is the power supply, which uses a new proprietary 12-pin standard for delivering the required +12v from the PSU in your system. These +12v pin connectors are molded out of abs plastics that are highly thermally resistant in order not to deform under the operating temperatures of graphics processing, which can easily exceed 75°C.

With a basic understanding of the makeup of a graphics card, we can look at the environmental impact of these components. “GPUs are silicon layered with tantalum and palladium transistors and capacitors for better storage on a smaller chip … made from a mind-boggling array of chemicals and copper, boron, cobalt, tungsten, for starters.” (engineering.com, 2021.) These rare earth metals that mainly originate from Southeast Asia are known as conflict-materials due to their involvement with unjust labor regulations and practices as well as their high associated environmental impacts such as the release of GHGs thousands of times more potent than CO2. This has been caused by a lack of regulation in the rare earth metal mining industry. Not only this, Miller (Penke, 2021.) said, “Their production process is pretty toxic.” Unfortunately, “China is not the only country with low environmental standards … for example, a thriving illegal gem and metal mining sector has been linked to rainforest depletion and destruction of natural lemur habitats.” (Penke, 2021.) This issue is not contained to a single country with bad regulation, but seems to be an industry-wide practice. The environmental impact of the mining of rare earth metals for the manufacturing of graphics cards is exorbitantly high, with greenhouse gasses (GHGs) being released making up around 50% of emissions. Something needs to be done in order to manage these impacts.

The creation and manufacture of the chemical components necessary (resins and plastics) in the manufacture of graphics cards are toxic to the surrounding environment. “Although CCLs come in numerous types, they primarily come in epoxy resin base CCL that accounts for over 7% of all CCLs … FR-4 [is] used for HDI (High Density Interconnect) substrate,” such as what is used within Nvidia graphics cards. Because CCLs (copper clad laminates) are the building blocks of PCBs they are in all modern electronic devices from smartphones to tvs, there is a large push to reclaim these materials to reduce the inherent toxicity of the production process. The more waste material we are able to reclaim and reuse, the less new materials we will have to source directly from the earth. “Chemical recycling is considered by Guo et al. (2009) the most effective method to take full advantage of all the elements and eliminate all hazardous and toxic components contained in the NMFs. Unfortunately, the studies are limited and relatively few data are available.” (Marques et al., 2013.) From the data about NMF chemical composition, we can see that “hazardous substances in NMFs are mainly BFRs (tetrabrombisphenyl-A (TBBA), etc.) and traces of heavy metals (lead, chromium, cadmium, mercury, etc.) (Dimitrakakis, 2008)” (Marques et al., 2013.) These heavy metals are released into the environment and eventually make their way into the food chain, causing a multitude of adverse health effects, such as kidney dysfunction and nervous system disorders. Though the creation and manufacturing of resins and plastics is detrimental to the environment, there are proven methods to reduce this waste that are being integrated into the industry, mitigating the environmental impact and increasing the sustainability of the production of these materials.

A graphics card consists of a printed circuit board base, copper and aluminum cooling fins and heat pipes surrounded by an injection molded shroud. This shroud holds fans which direct air down onto the metal fins cooling the chips on the PCB underneath it. This FR-4 resin coated PCB is where the GPU and other important chips like the RAM are located, as well as where the power supply terminals are connected to. These components require rare earth metals such as lead, chromium, cadmium, and mercury. These metals are harmful to the environment to acquire, and chemical components that are toxic to produce, although measures are being put in place to manage the toxic pollution. More regulations are being proposed to limit the releases of greenhouse gasses and other toxic materials into the environment, and efforts are being made to introduce chemical recycling to the wider industry as a first line of defense.

References

“Epoxy Resin Used for CCL in PCB and Its Development Trend.” PCBCart, 2021, www.pcbcart.com/article/content/epoxy-resin-used-for-ccl-in-pcb.html.

Evanson, Nick. “Anatomy of a Graphics Card.” TechSpot, TechSpot, 16 Mar. 2020, www.techspot.com/article/1988-anatomy-graphics-card/.

“FR-4.” Wikipedia, Wikimedia Foundation, 22 Sept. 2021, en.wikipedia.org/wiki/FR-4.

James, Dave. “How Your Nvidia and AMD Graphics Cards Are Made.” PCGamesN, PCGamesN, 23 Mar. 2021, www.pcgamesn.com/how-nvidia-amd-graphics-card-are-made.

“Student Educational Resources.” Aluminum Facts and Education Resources| The Aluminum Association, 19 Oct. 2021, www.aluminum.org/aluminum-advantage/student-educational-resources.

Taiwan Union Technology Corporation. “Technology.” Manufacturing - Taiwan Union Technology Corporation, 2019, www.tuc.com.tw/en-us/technology2.

“What Is Copper Clad Laminate (CCL)? .” What Is Copper Clad Laminate (CCL)?, PCBBogo, 29 June 2019, 11:16:25, www.pcbgogo.com/blog/What_Is_Copper_Clad_Laminate__CCL__.html.

Wheeler, Andrew. “What Raw Materials Are Used to Make Hardware in Computing Devices?” Engineering.com, Engineering.com, 28 Sept. 2018, www.engineering.com/story/what-raw-materials-are-used-to-make-hardware-in-computing-devices.

“Introduction of Thermal Conductivity Silica Gel Classification Materials and Production Process and Heat Transfer Principle.” Introduction of Thermal Conductivity Silica Gel Classification Materials and Production Process and Heat Transfer Principle-Corporate News-Shenzhen Union Tenda Technology, Union Tenda Technology, 1 Aug. 2019, www.szutd.com/en/corporatenews/58-58.html.

Sharafian, Amir, et al. “Thermal Conductivity and Contact Resistance of Mesoporous Silica Gel Adsorbents Bound with Polyvinylpyrrolidone in Contact with a Metallic Substrate for Adsorption Cooling System Applications.” International Journal of Heat and Mass Transfer, vol. 79, 2014, pp. 64–71., doi:10.1016/j.ijheatmasstransfer.2014.07.086.

(www.dw.com), Deutsche Welle. “Toxic and Radioactive: The Damage from Mining Rare Elements: DW: 13.04.2021.” DW.COM, www.dw.com/en/toxic-and-radioactive-the-damage-from-mining-rare-elements/a-57148185.

National Center for Biotechnology Information, nrd.gov/resource/detail/14039611/National+Center+for+Biotechnology+Information.

Atlas Brito

NVIDIA FE GPU Life Cycle

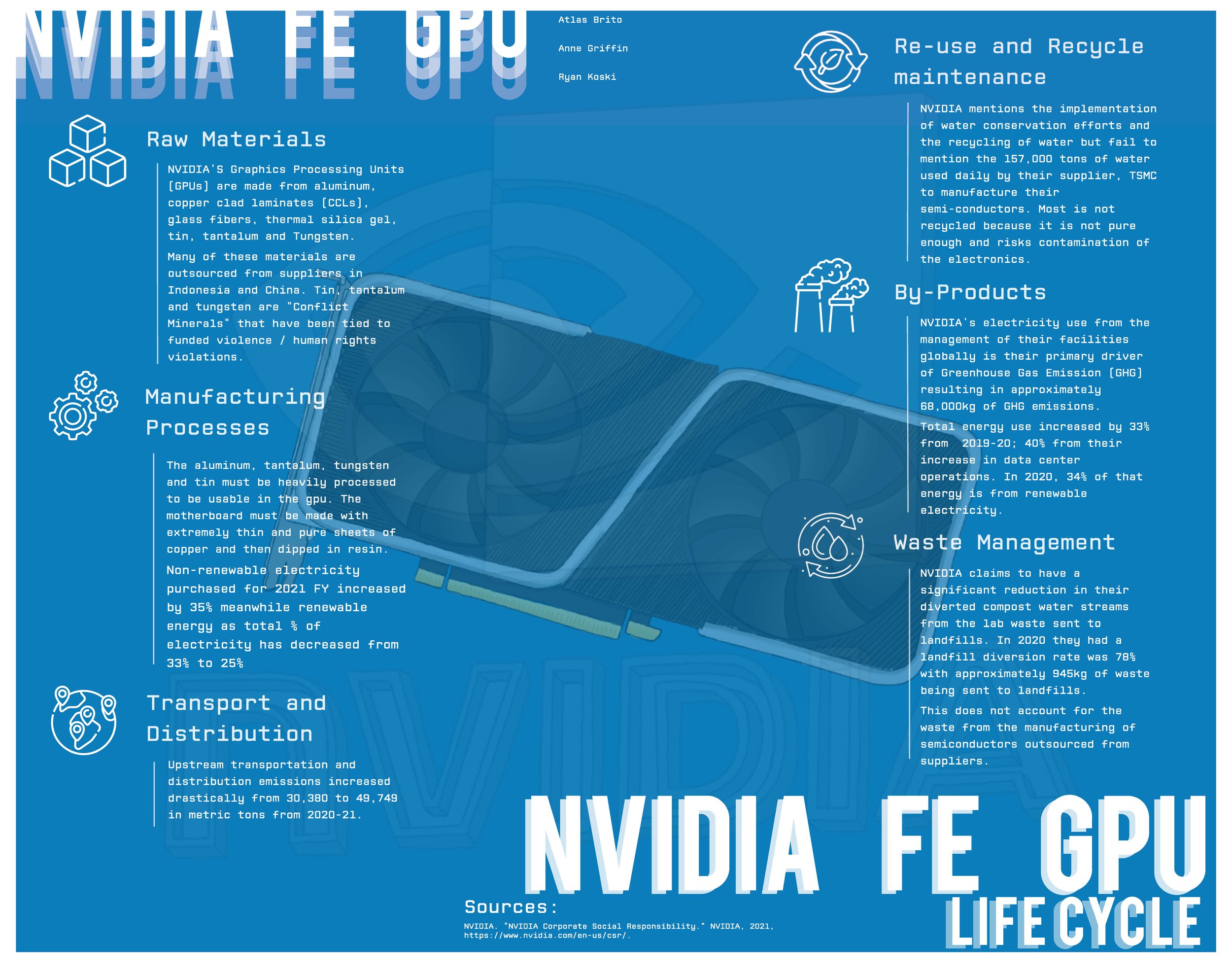

This report will primarily focus on the embodied energy that is utilized for the manufacturing of Nvidia’s Graphics cards. These Graphics Processing Units (GPUs) are not completely manufactured by Nvidia, many components of the product are outsourced from other corporations. The companies that Nvidia outsources their semiconductors from have issues with sustainability in their chip manufacturing. The ‘sustainable efficiency’ that Nvidia proudly claims is called into question with the investigation on their partners “sustainability”.

NVIDIA claims NVIDIA AS A CUSTOMER - Environmental:

Calculated carbon, water, and waste data of all silicon manufacturers and systems contract manufacturers to determine carbon emissions and water consumption per product and per financial outlay.

Required compliance with environmental standards.

NVIDIA’s 2020 CSR Report - Social, Performance with the RBA Code of Conduct

They outsource from Taiwan Semiconductor Manufacturing Company Limited (TSMC) and Samsung Electronics Co. Ltd, to produce semiconductor wafers for their GPUs. The company, TSMC uses about 157,000 tons of water a day and has claimed to “reuse” some of it in their Corporate Social Responsibility Report for 2019, but most of the water that is used is not pure enough to reuse for chip manufacturing. Large quantities of ultra-pure water are needed to manufacture semiconductors in order to avoid the contamination of electronic devices. Much of the water used contains toxic solvents and heavy metals which contribute to groundwater contamination in their water treatment facilities when the water is discharged. Other byproducts that are caused from unrenewable electricity use are not accurately accounted for in their Corporate Social Responsibility Report.

What Does Nvidia Claim?

Nvidia claims that they are on track to reach their goal to source sixty-five percent renewable energy by year 2025. Nvidia’s GPU revenues increased from $9,465 to $10,175 (FCC Form 10-K, in millions) thus increasing their total energy use by 24% from 2019 -2020 and then by 33% in 2021. Seventy-eight percent of this increase is due to Nvidia’s growing data center operations and are responsible for almost half of their total energy use in 2021 (Nvidia’s Corporate Social Responsibility Report 2020 / 2021). Non-renewable electricity purchased for 2021 FY increased by 35% meanwhile renewable energy as total percentage of electricity has decreased from 33% to 25%. Nvidia’s electricity use is one of its primary drivers that contribute to Greenhouse Gas emissions (GHG) footprint. In Scope 3, Purchased goods and services increased by 751,771 metric tons of tCO2e meanwhile conveniently the waste generated in operations decreased by 175 metric tons.

Suppliers

TSMC is the primary supplier of semiconductors for Nvidia and produces specialized 14-nanometer technologies for them. They claim that they have seen significant progress in the renewable energy market but are unable to suppress the growth of carbon emissions despite the implementation of industry-leading standards because of their growing capacity. They had 24 on-site audits in factories of critical high-risk suppliers in 2020 by RBA-certified third party institutions, 46% of violations being major violations containing supply chain risks. (TSMC Corporate Social Responsibility Report 2020). These supply chain risks include: the lack of comprehensive electricity and water backup plans in response to climate change, lack of safety stock for raw materials or finished goods and lack of human resources to navigate unexpected events such as the COVID-19 pandemic. Other Environmental protection concerns such as the lack of establishing effective rainwater systems were discovered during these audits. One of TSMC’s achievements in 2020 according to their sustainability report is the introduction of a low-energy consumption system for pipeline heating that reduces the pipeline surface temperature for the development of their 12-inch wafers. TSMC’s Scope 3 GHG emissions surprisingly show a decrease in purchasing energy meanwhile there is a large increase in waste generated in operations by 16,420 metric tons for the 2020 year. 88% of the GHG emissions in 2020 alone were caused by the usage of non-renewable energy.

What does this Mean?

In Emanuela Barbiroglio’s article, “No Water No Microchips: What is Happening in Taiwan?” (Forbes 2020) they write about the drought in Taiwan that has caused chip manufacturers to compete with locals for water use. TSMC, one of the largest global chip manufacturers, uses more than 150,000 tons of water a day, which is approximately 80 swimming pools. They have been reliant on the implementation of water trucks in order to maintain their operations and productions; they are estimated to spend more than their initial budget plan on these water trucks. Although TSMC has had a decrease in the purchase of energy in their Scope 3 GHG emissions, the same cannot be said for their purchased energy of water. Since the ultra-pure water used to develop semiconductor wafers cannot be recycled because of the risk of the contamination of electronic devices, the water then may contain hazardous waste that pollutes our water streams. (The Guardian 2021) There have been green carbon measures that have started to become implemented by the UN and have established tariffs for corporations that do not satisfy the criteria of these green measures. One problem with this is that these chip maker corporations generate millions of dollars and can easily afford the cost of turning a blind eye to the efficient implementation of green carbon technologies throughout their supply chains.

Nvidia’s Sustainability report only reports what energy consumption is used in Nvidia facilities to manufacture their GPUs, but does not account the energy resources used to manufacture their semiconductors, which are critical components of the system. Nvidia has seen substantial growth from their 2020 FY period to their 2021 FY period, thus increasing the amount of energy usage in order to sustain operational activities. Nvidia’s values on “Sustainability” as a corporation seem to only extend to the ban of disposable paper cups and plastics in their offices in India and not their business partners who deplete tons of water daily and battle their locals for water resources for the sake of profit. They account for the energy and waste that happens in their operational facilities and data centers, but not their custom-made 14 nanometer technologies that they baptise before entering Nvidia grounds. This close-knit relationship between Nvidia and Taiwanese Semiconductor Manufacturing Company is really interesting to research, it really makes you think about the issues that we cannot see under the surface of these two tech giants.

Bibliography

NVIDIA. “2021 NVIDIA Corporate Social Responsibility Report.” Social Responsibility Report, JENSEN HUANG, 2021, https://images.nvidia.com/aem-dam/Solutions/documents/FY2021-NVIDIA-CSR-Social-Responsibility.pdf.

Nvidia. “Nvidia Corporate Social Responsibility.” NVIDIA, 2021,

https://www.nvidia.com/en-us/csr/.

Nvidia. “Redefining Green: Sustainability at Nvidia.” NVIDIA, 2021,

https://www.nvidia.com/en-us/csr/product-recycling/.

Nvidia. United States Securities and Exchange Commission, Washington DC, DC, 2021, FORM SD Specialized Disclosure Report for NVIDIA CORPORATION.

https://d18rn0p25nwr6d.cloudfront.net/CIK-0001045810/bf30112b-f1fa-4303-83eC-0434aa6a1c4b.pdf

Nvidia. United States Securities and Exchange Commission, Washington, D.C., 2020, FORM 10-K Annual Report Pursuant to Section 13(d) of the Securities Exchange Act of 1934.

https://www.sec.gov/Archives/edgar/data/1045810/000104581020000010/nvda-2020x10k.html

Global Tungsten & Powders Corp. “Global Tungsten & Powders Corp.. Public Due Diligence Report.” Public Due Diligence Report , https://www.globaltungsten.com/fileadmin/user_upload/GTPStep5Report-FY2018-19.pdf.

Campbell, Charlie. “Inside the World's Largest Semiconductor Chip Manufacturer.” Time, Time, 1 Oct. 2021, https://time.com/6102879/semiconductor-chip-shortage-tsmc/.

Campbell, Charlie. “Taiwan Semiconductor Manufacturing Company Is One of the 2021 TIME100 Most Influential Companies.” Time, Time, 26 Apr. 2021, https://time.com/collection/time100-companies/5950050/taiwan-semiconductor-manufacturing-corp/.

Barbiroglio, Emanuela. “No Water No Microchips: What Is Happening in Taiwan?” Forbes, Forbes Magazine, 1 June 2021, https://www.forbes.com/sites/emanuelabarbiroglio/2021/05/31/no-water-no-microchips-what-is-happening-in-taiwan/?sh=1e0faa2c22af.

“The Computer Chip Industry Has a Dirty Climate Secret.” The Guardian, Guardian News and Media, 18 Sept. 2021, https://www.theguardian.com/environment/2021/sep/18/semiconductor-silicon-chips-carbon-footprint-climate.

Anne Griffin

Waste and Emissions from the Nvidia GPU

Computers make our lives easier and we wouldn't be where we are today without their invention. While the fancy shell and keyboards are nice to look at, the important part of the computer is the GPU. The GPU, short for graphics processing unit, start out as printed circuit boards (PCB) that then have solder screen printed onto them. “The PCB then goes through a process called reflow soldering, which finally bakes the unit to ensure they’re all attached firmly”(1) The boards then go through a rigorous cleaning process to get them ready to be used in the GPU. Every step along this path, wastes and emissions are being put out into the world. In order to make the Nvida GPU, metals and materials must be processed from raw materials to a usable part of the machine, creating emissions and waste products throughout the processing and manufacturing. A lot of work goes into the creation of these machines, and with it comes a lot of waste and emissions.

To begin, the materials must be mined from the ground before they are processed. The main materials are tungsten, copper, tin, aluminum, and gold. Nividia has multiple sources of all these materials, with one of their sources being the Global Tungsten & Powders Corp. In their public due diligence report they make the statement “as it is not possible to smelt tungsten in the same way as for other metals because the processing of tungsten concentrates in metal requires extensive processing, GTP and the tungsten industry as a whole, considers all tungsten containing scrap as out of scope for responsible sourcing of minerals.”(2) This results in the major risks being that they are being sold and are processing scrap tungsten, which they claim is a minor possibility. Copper is an entirely different situation, and the EPA has specialized regulations for it. “Calcium sulfate wastewater treatment plant sludge from primary copper processing” and “Slag from primary copper processing”(3) are covered in the Mining Waste Exclusion bill passed in 1991. This means that the wastes coming from the processing of copper are not considered hazardous by the EPA.

In addition to the other materials a large part of the GPU and of its casing is made of aluminium. While in general, aluminum is a stable and versatile material, the processing of it can result in dangerous byproducts. This can especially be seen when “grinding, polishing, sawing, cutting, sanding and scratch brushing of aluminum generate fine aluminum particles known as “fines”, “dust” or “powder” - some of which are potentially explosive.”(4) Even with the extensive handling regulations, this aluminum dust can stay in the environment indefinitely because of its small size. An apt simile would be getting glitter in a dog's fur. There's no real way to get rid of it all and even after a lot of cleaning up, there will still be a small residue of it. The aluminum must also be processed which can be done in a variety of ways including “the Deville process, which involves direct reaction of metallic sodium with aluminum chloride, was the basis of aluminum production in the late 19th century, but it has been abandoned in favour of the more economical electrolytic process.”(5) After studying the electrolytic process and how aluminum is currently being processed, researchers have found “the current carbon footprint of the global aluminum industry is estimated at 500 million metric tonnes carbon dioxide”(6) and while the Nividia GPU does not account for the entirety of those emissions, the emissions of aluminum processing must be factored in as well.

Next, after the raw materials are processed and the base of the circuit is manufactured offsite, the boards are placed into machines to be soldered. Instead of having each piece be soldered by hand, there is a machine that superheats the solder paste in order to create precision joints for the electronics.Currently the best reflow soldering used is lead based solder. There have been studies into reworking the lead based solder to a lead free solder paste however “The 30oC higher temperatures required to rework lead-free connections place thermal stress on the materials that expand at different rates, potentially causing failure of the solder joint.”(7) Lead is especially toxic and dangerous for humans and for plants. “If released or deposited on soil, lead will be retained in the upper 2-5 cm of soil, especially soils with at least 5% organic matter or a pH of 5 or above.”(8) These soils retaining lead can allow it to leach into the organic matter that is laying on or in the soil. As the lifecycle continues, whatever is in the soil slowly gets incorporated into the life around it, resulting in lead in the wildlife and even into the human population. The soldering process is necessary however steps must be made to ensure that the lead based solder is reworked into a less toxic material.

Once the board is soldered it moves to perhaps the most toxic part of the entire process: the PCB cleaning. In order to operate smoothly the board must be entirely clean of dust that could cause it to malfunction or short circuit. Extra dust would also result in a shorter life span for the machine. Usually a product called d-Limonene is used to clean the boards. Extensive research has been made into the toxicity concerns of d-Limonene. “The primary health and safety concerns with the use of d- Limonene in the PCB cleaning operation are combustibility and toxicity. d-Limonene has introduced a fire hazard into the PCB cleaning operation due to its low flashpoint. This risk is made manageable through proper equipment safeguarding. d-Limonene also raises concern about toxicity to humans. Toxicological studies performed on animals and humans indicate that human toxicity may be low to moderate”(9). While it seems harmless in stating that it has a low to moderate toxicity, there has been testing done on animals. Still, the researcher claims “d-Limonene should not pose a significant threat to human health. Although it induced kidney toxicity, reproductive and developmental effects, and dermal effects in animals, the prediction of toxicity in humans based on these results is uncertain.”(9) It is obviously not a very safe material that can be handled lightly, and there is a real threat to humans, despite being thoroughly brushed aside. Factory workers can come into contact with d-Limonene through inhalation during production and through dermal contact should any get onto their skin. Workers are at an increased risk of contacting this material as they are exposed to it daily.

Furthermore Nvidia has also looked into their social responsibility and is making steps to be more sustainable in the future. They have already taken some measures and they claim that “100% percent of the technology NVIDIA employees are issued is reused or recycled through certified e-waste vendors.”(10) This shows a willingness to reuse old technology rather than constantly having to have the newest devices for their employees. They are also making long term goals to help move the process forward and have been fairly successful so far and “Achieved a 78 percent diversion rate in calendar year 2019”(11) for waste going to landfill. Even during a large scale construction project Nvidia was able to divert 90% of waste from the landfill. However, things do look bleaker when you look at their CO2 reports. In the year 2020, they produced 2,698 metric tons of CO2, a number that has been slowly but steadily increasing throughout the years. While they are very focused on the physical side, the company itself should recognize the impact CO2 emissions have on the environment.

In conclusion, a lot of wastes and emissions come from the production and manufacturing of the Nvidia GPU. These wastes come from everything from the mining processes to the manufacturing and even the cleaning of the boards. However, steps are being taken to reduce these emissions throughout the digital and electronic world.

Chipmaker TSMC (Taiwan Semiconductor Manufacturing Co Ltd) “which counts Apple Inc and Qualcomm Inc amongst its major clients, will "set related mitigation measures" and actively adopt the use of renewable energy”, in addition they have set a goal for “zero emissions growth by 2025.”(12) This decision came from pressure from activists who lobbied the Taiwanese government to take action in the climate crisis. Taiwan is a leader in electronic production and hopefully their example will lead other countries and companies to follow suit. Now that the problem is being addressed and looked at clearly, steps are being made to try and combat the emissions that are produced.

Biography

(1) James, Dave. “How Your Nvidia and AMD Graphics Cards Are Made.” PCGamesN, PCGamesN, 23 Mar. 2021, https://www.pcgamesn.com/how-nvidia-amd-graphics-card-are-made

(2) Global Tungsten & Powders Corp. “Global Tungsten & Powders Corp.. Public Due Diligence Report.” Public Due Diligence Report , https://www.globaltungsten.com/fileadmin/user_upload/GTPStep5Report-FY2018-19.pdf

(3) EPA “Mining Waste.” EPA, Environmental Protection Agency, 2016, https://archive.epa.gov/epawaste/nonhaz/industrial/special/web/html/index-5.html

(4) Aluminum Association. “Student Educational Resources.” Aluminum Facts and Education Resources| The Aluminum Association, 19 Oct. 2021, https://www.aluminum.org/health-safety

(5) Bridenbaugh, Peter R. “Aluminum Processing.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., https://www.britannica.com/technology/aluminum-processing

(6) Das, S. Achieving Carbon Neutrality in the Global Aluminum Industry. JOM 64, 285–290 (2012). https://doi.org/10.1007/s11837-012-0237-0

(7) EPA “Solders in Electronics: A Life-Cycle Assessment Summary” EPA-744-S-05-001, August 2005 https://www.epa.gov/sites/default/files/2013-12/documents/lead_free_solder_lca_summary.pdf

(8) Jennings, Gerard “ AN INVESTIGATION INTO THE USE OF LEAD-FREE SOLDERS IN THE ELECTRONICS INDUSTRY” Institute of Technology, Sligo. September, 2002 https://research.thea.ie/bitstream/handle/20.500.12065/1505/Jennings%2CGerard%202002.pdf?sequence=7&isAllowed=y

(9) Missick, Peter “Health and Safety Impacts of Citrus-Based Terpeness in Printed Circuit Board Cleaning.” The Toxics Use Reduction Institute University of Massachusetts Lowell, June 1993 https://www.turi.org/content/download/3762/46108/file/techreport6.pdf

(10) Nividia. “Redefining Green: Sustainability at Nvidia.” NVIDIA, 2021, https://www.nvidia.com/en-us/csr/product-recycling/

(11) NIVIDA. “2021 NVIDIA Corporate Social Responsibility Report.” Social Responsibility Report, JENSEN HUANG, 2021, https://images.nvidia.com/aem-dam/Solutions/documents/FY2021-NVIDIA-CSR-Social-Responsibility.pdf

(12) Blanchard, Ben. “Chipmaker TSMC Aims for Net Zero Emissions by 2050.” Reuters, Thomson Reuters, 16 Sept. 2021, https://www.reuters.com/technology/chipmaker-tsmc-aims-net-zero-emissions-by-2050-2021-09-16/