Design Life-Cycle

assess.design.(don't)consume

Ricky Ramirez

Khadijah Muhammad, Rachel Li

DES40A

Professor Cogdell

March 16, 2023

Demonia Swing 815 Boots: Materials

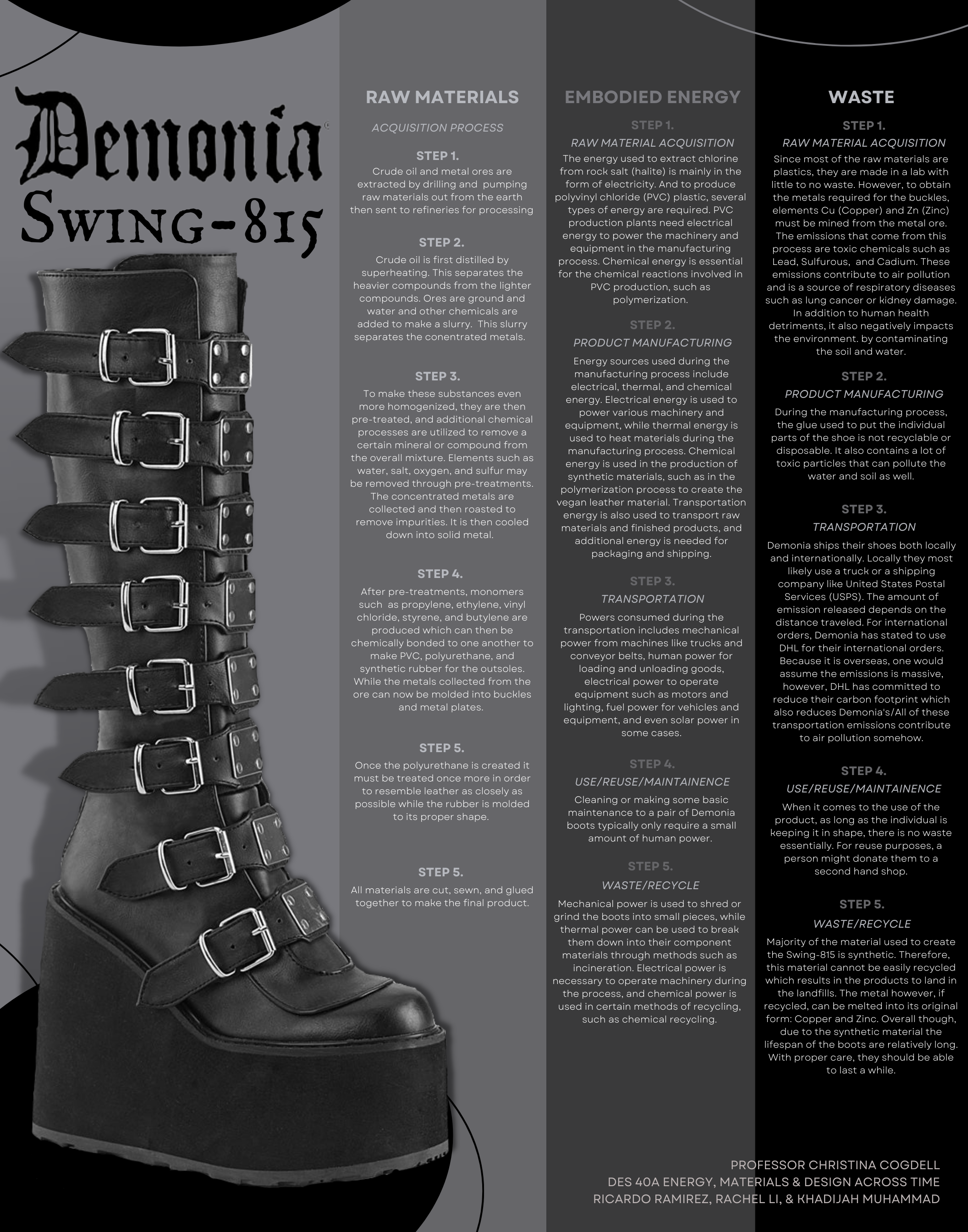

As consumerism is at an all time high, industries are attempting to take advantage of the global demand for easily accessible clothing. According to Van Rensburg, the average shoe utilizes 40 different kinds of materials in its construction and Demonia Cult is no exception. With their immensely wide range of maximalist footwear made from varying materials such as Suede, Leather, and a patented polyurethane, it is easy to identify the shear amount of varying materials needed to make a Demonia boot. They are well known for having vegan alternatives to leather which are used in many of their products. However, certain styles of boots feature decorative additions such as fur, and metal which require added chemicals and materials.. The production of Demonia shoes, particularly the “Swing-815'' style, utilizes a process which has been noted as highly unsustainable as it requires non-renewable raw materials and produces adverse effects on the environment. The Demonia Swing 815 boots are made from a polyurethane material created by purifying crude oils. From extraction of raw resources, to the disposal of the resulting materials, the lifecycle of polyurethane based products use many materials and chemicals even when compared to the already heavily resource reliant footwear industry.

The fast fashion industry implements designs that are meant to be easily produced and cheap, only using the cheapest and most readily available materials (Van Rensburg). This industry prioritizes quantity rather than quality, resulting in the production of countless materials and many side effects on the environment. The Demonia Cult website does not directly state which specific materials are used in order to create the Swing 815 boot, in which case, the materials discussed in this essay refer to industry standards. These materials are quite pervasive within the fast fashion industry and it is highly likely that these boots use the same if not similar materials(Van Rensburg). Demonia offers an immense range of materials primarily used in their products, from genuine leather, suede, vegan leather, and vegan suede. The Demonia Swing 815 boots however, are primarily made from a vegan polymer based leather, synthetic rubber, and zinc and aluminum for buckles and metal detailing. Generally, vegan leather is often cited as an environmentally friendly alternative to traditional leather as it does not require livestock in order to harvest. There are vegan leathers that are created from biomaterials that take less energy to dispose of or recycle at the end of their life cycle. However, the particular leather that Demonia utilizes for its products are made from polyurethane or polyvinyl chloride, more commonly known as PVC. When taking into account the synthetic rubber outsole, it is evident that this boot is manufactured primarily through means of crude oil refining (Wauquier).

Crude oils are extracted from the earth in a number of methods (CAAP). Variables such as the location, viscosity, and form which it takes determine the methods it is harvested and processed. Conventional methods of extraction apply to crude oil which is liquid at atmospheric temperatures and require traditional pumping and drilling methods (CAPP). Crude oil deposits which are not liquid or are located offshore require much more sophisticated techniques which depend on their specific location and require differing amounts of energy to operate. Once the crude oil is collected, it is refined into many different materials in order to produce a desired product. For plastic production, crude oil is first distilled by superheating. This separates the heavier compounds from the lighter compounds. To make these substances even more homogenized, they are then pre-treated, and additional chemical processes are utilized usually to remove a certain mineral or compound from the overall mixture (Liang, Chao, et al.). Pre-treatments aim at removing either of the following; water, asphalt, metals, nitrogen, oxygen, sulfur, and salt but not all batches of crude oil are subjected to the same treatments (Uchenna Babalola, Faith, and Alfred Akpoveta Susu.). From this, monomers such as propylene, ethylene, vinyl chloride, styrene, and butylene can be extracted for further compounding. Plastics have a chemical composition that has long strains of polymers that give it its malleable and versatile characteristics. In order to create polymers, monomers are needed as they serve as the building blocks which bond to each other to create different types of polymers. In order to bond monomers a catalyzer is needed to initiate the chemical reaction needed for monomers to bind with one another. Peroxides are commonly used as a catalyst (Liang, Chao, et al.). Polyurethane, PVC, and synthetic rubber are all materials that require polymerization in order to be manufactured. A process which produces numerous carcinogenic chemicals known to cause leukemia (Delzell, Elizabeth, et al.). Because each of these materials have different characteristics, different methods and proportions of monomers are needed in order to create each material for its intended use. This is a long and energy costly process which only begins here. The fabric and rubber must still undergo additional chemical procedures in order to reach its final form as a Demonia boot (Ali Shah, Aamer, et al.).

Vegan leather is often cited as a more environmentally conscious material for the purpose that it does not require any animal products to produce. Meaning that there is potential to dedicate land to other resources that don't carry the same adverse environmental impacts that come with cattle rearing. Oftentimes, companies utilize similar procedures to that of traditional leather making in order to produce an alternative that has similar qualities to that of genuine leather. For example, genuine leather receives its signature smell through the chemicals which are used to dye and tan and to give unprocessed leather desired characteristics. And for Demonias, once the polymer material for the fabrics have been created, they too undergo a tanning process that heavily relies on chromium based tannins (Van Resnburg). Chromium is a brittle heavy metal that is greatly resistant to ordinary corrosive agents (DCCEEW). Once tannins are used, the polymer takes on the smell and color, imitating the characteristics of natural leather and the chromium is infused into the polyurethane. Once the vegan leather has been treated the material only needs to be molded and treated in order to match the final design. While the synthetic rubber is physically transformed into its proper shape using heat and molding into a five and a half inch platform, the polyurethane is cut, sewn, and glued together to create the final design.

One of the stand out features of this boot are the 16 belt buckles that line the boot on either side and the metal plates that run down the front. The most commonly used metals in cheaply made garments in the fast fashion industry are primarily made by molding alloys primarily made from zinc. Zinc processing begins with the mining of zinc ores that are found within the Earth's crust at various depths (Pola, Annalisa, et al.). It is common practice to use cut and fill stopping in which main tunnels are excavated for transportation of ore at moderate depths, from which additional break out tunnels are excavated for further zinc ore collection. Once the zinc ore is collected, it is ground into small particles to which water and other chemicals are added. The slurry is then agitated with foam containing concentrated zinc particles where it can then be collected. This zinc is then roasted and cooled into solid zinc metal (Richards, Alan W.). From here it is combined with other metals such as copper or aluminum in order to produce the alloys needed for the metal detailing found on the boots.

The quality of material and construction of the boot highly informs the longevity of the product itself. Demonia carries roughly 400 unique styles of footwear alone. This number does not take into consideration the accessories and miscellaneous products such as enamel pins and hosiery that Demonia Cult also sells. It is evident that our economy is slowly turning to accommodate the quick turn over of fashion items in particular (Van Rensburg, Melissa L, et al.). Like the vast majority of shoes in the fast fashion market, the Demonia Swing 815 are made with less than ideal materials and construction. Because Demonia footwear is produced in mass and with low quality, their lifecycle is very short and there is very little one can do to elongate its shelf life. Plastics are notorious for their extremely long break down times. Once they have been disposed of, there is little done to recycle or reuse any of the material used. They have not been designed with the intent to reclaim and recycle materials at the end of their life cycle and more often than not end their life cycles in trash heaps. In the landfill, the many chemicals that were integral in the making of the Demonia Swing begin to seep into the surrounding environment, adding even more pollution caused by the overall production of these boots (Van Rensburg, Melissa L, et al.). Considering the vast number of products that are seemingly at the disposal of the consumer, it is clear that Demonia uses large amounts of resources to continue its operations.

Demonia boots are designed and advertised towards a very specific audience of individuals. Young adults in alternative subcultures are often mesmerized by Demonias counter culture aesthetic where weirdness is celebrated. Fast fashion as an industry, however, is not niche by any means. Demonia Cult takes advantage of the convenience and inexpensive qualities of synthetic materials in order to turn the most profit. For the vast selection of shoes and quantity in which they are available, it is important to bring into question whether or not an operation of this magnitude and type is sustainable. With countless other businesses just like Demonia Cult, the disastrous side effects that come from the processing of countless products from crude oil extraction and refining has become clear.

Works Cited

Ali Shah, Aamer, et al. “Biodegradation of Natural and Synthetic Rubbers: A Review.”

International Biodeterioration & Biodegradation, vol. 83, 2013, pp. 145–157., https://doi.org/10.1016/j.ibiod.2013.05.004.

“Chromium (III) Compounds.” DCCEEW, Australian Government Department of Climate

Change, Energy, the Environment and Water, 30 June 2022, https://www.dcceew.gov.au/environment/protection/npi/substances/fact-sheets/chromium-iii-compounds.

Delzell, Elizabeth, et al. “A Follow-up Study of Synthetic Rubber Workers.” Toxicology, vol. 1

13, no. 1-3, 1996, pp. 182–189., https://doi.org/10.1016/0300-483x(96)03443-9.

Liang, Chao, et al. “Material Flows of Polyurethane in the United States.” Environmental

Science & Technology, vol. 55, no. 20, 2021, pp. 14215–14224., https://doi.org/10.1021/acs.est.1c03654.

Oil Gas Canada. “Crude Oil Extraction and Drilling Methods.” CAPP, Canadian Association of

Petroleum Producers, https://www.capp.ca/oil/extraction/.

Pola, Annalisa, et al. “Review of Microstructures and Properties of Zinc Alloys.” Metals, vol. 10, no. 2, 2020, p. 253., https://doi.org/10.3390/met10020253.

Richards, Alan W.. "zinc processing". Encyclopedia Britannica, 12 Apr. 2019,

https://www.britannica.com/technology/zinc-processing. Accessed 16 March 2023.

Uchenna Babalola, Faith, and Alfred Akpoveta Susu. “Pre-Treatment of Heavy Crude Oils for

Refining.” Processing of Heavy Crude Oils - Challenges and Opportunities, 2019, https://doi.org/10.5772/intechopen.89486.

Van Rensburg, Melissa L, et al. “Life Cycle and End-of-Life Management Options in the

Footwear Industry: A Review.” Waste Management & Research, vol. 38, no. 6, 2020, pp. 599–613., https://doi.org/10.1177/0734242x20908938.

Wauquier, Jean-Pierre. “Introduction to Refining.” Petroleum Refining, Volume 1 - Crude Oil,

Petroleum Products, Process Flowsheets, vol. 1, Editions Technip, 1995, pp. 365–404.

Rachel Li

Team members: Khadijah Muhammad, Ricardo Ramirez

DES40A

Professor Cogdell

March 16, 2023

Embodied Energies of Demonia Swing-815’s life cycle

Introduction

Demonia is a footwear company located in southern California since 1993 and is a sub-brand under Pleaser USA Inc. The company is renowned for its punk platform shoes, with one of their top sellers being the Swing-815, which consists of metal plated vegan leather, synthetic rubber heels, and zippers. The Demonia Swing-815 is available in a range of colors, including black, white, and red. Other versions of the boot may also feature additional accents such as spikes, studs, or chains. Demonia primarily uses vegan leather, which are produced using PVC, polyurethane, and other plastic-based materials. The production process for a pair of shoes involves various energy usage stages, starting with the production of raw materials, then transformed into usable fabrics and parts. Then, power is consumed during the manufacturing stage, followed by packaging and other processes such as shipping.

Raw Materials Acquisition

The Demonia boots use PVC and synthetic rubber as their prime material. This kind of synthetic vegan material builds up the main structure of the boots, and they are all composite processed from the chlorine from rock salt and natural gas. The energy used to extract chlorine from rock salt (halite) is mainly in the form of electricity. The chlor-alkali process, which is used to produce chlorine, involves the electrolysis of a brine solution. In this process, an electric current is passed through the brine solution, which causes the salt ions to break apart into their constituent elements. Chlorine gas is produced at the anode, while hydrogen gas and sodium hydroxide are produced at the cathode. The production of this electric current requires energy, which is typically generated by burning fossil fuels such as coal, natural gas, or oil. The energy can also come from renewable sources such as hydropower, wind power, or solar power. The type of energy used to generate the electricity depends on the location, availability, and cost of the energy source.

The first raw material is rock salt, also known as halite, is typically mined from underground salt domes or areas where ancient seas once existed. Mining crews need to use heavy equipment to first excavate the rock salt, which is a process that may involve drilling, blasting, and machinery. Once excavated, the rock salt is transported to a processing plant where it is crushed, screened, washed, dried, and packaged for distribution. The mining and processing of rock salt require various types of energy. Electrical energy is used to power the heavy machinery and equipment, while fuel energy is used to run mining vehicles and equipment. Explosive energy is sometimes used to break up rock formations, and thermal energy is used during the drying process to evaporate moisture from the salt. Lastly, human energy is required for the physical labor involved in mining and transporting rock salt.

The other raw material required for making PVC plastic is natural gas. Extracting natural gas also involves several stages that require different types of energy. Mechanical energy is used during drilling to create the hole in the ground where the natural gas is located. Hydraulic energy is used to conduct hydraulic fracturing or fracking, which is a process that involves injecting a mixture of water, sand, and chemicals into the well at high pressure to fracture the rock and release the gas. Thermal energy is required to process the natural gas to remove impurities such as water, carbon dioxide, and sulfur. Electrical energy is used to power compressors, pumps, and other equipment in natural gas processing plants.

To produce polyvinyl chloride (PVC) plastic, several types of energy are required. Thermal energy is used to create the high temperatures needed to produce PVC resin, the raw material for PVC plastic. PVC production plants need electrical energy to power the machinery and equipment required in the manufacturing process. Chemical energy is essential for the chemical reactions involved in PVC production, such as polymerization, which releases heat, and the production of plasticizers that require energy-intensive chemical processes. Mechanical energy is also needed as the production of PVC plastic requires the use of heavy machinery and equipment powered by electricity or diesel fuel. In conclusion, PVC plastic production requires significant amounts of energy from the extraction of raw materials to final plasticization.

(The graphic of PVC plastic production)

Manufacture

The production of vegan leather boots involves the use of different types of energy sources. The specific energy sources used can depend on factors such as location and the type of machinery used. However, common energy sources used during the manufacturing process include electrical, thermal, and chemical energy. Electrical energy is used to power various machinery and equipment, while thermal energy is used to heat materials during the manufacturing process. Chemical energy is used in the production of synthetic materials, such as in the polymerization process to create the vegan leather material. Transportation also requires a lot of energy to transport raw materials and finished products, and additional energy is needed for packaging and shipping.

Transportation and Distribution

The process of transporting and distributing the final product of the Demonia Swing-815 from a factory to shops typically involves many different types of power such as the raw materials and manufacturing. Especially when most of the products from this brand now are outsourced to overseas factories. The overseas transportation from a overseas factory to a US shop required powers such as mechanical power that is used to move the product with machines like cargo ships, airplanes, trucks, and trains. Electrical power is necessary to operate heavy equipment such as cranes and conveyor belts during the transportation process. Human power is required to load and unload the product and operate equipment. Fuel power includes gasoline, diesel, or other fuels used to power vehicles and equipment. These powers work together to ensure that finished products are moved efficiently and safely from the overseas factory to US shops. With that being stated, now the Demonia makes most of their sales at their online shopping platform, which makes some differences in the use of power. For example, Lighting: In-shop shops require lighting to create a pleasant and inviting atmosphere for customers. However, online shops do not need to provide lighting for customers, as they can view products on a screen. Therefore, in-shop shops typically consume more energy for lighting. The other power that can be reduced from in-shop shopping to online shopping is Heating and Cooling. In-shop shops require heating and cooling to maintain a comfortable temperature for customers. This can be energy-intensive, especially during extreme temperatures. On the other hand, online shops do not require heating or cooling as there is no physical space to maintain a temperature.

Use and Maintenance

Cleaning or making some basic maintenance to a pair of vegan leather boots typically only require a small amount of human power. Instead, the process usually involves using cleaning solutions such as water or a simple mixture of mild soap and a soft cloth or brush to remove dirt and stains from the surface of the boots. In some cases, a conditioner may also be used to keep the material supple and prevent cracking or damage. Overall, the power needed to clean vegan leather boots comes from the manual effort of the person doing the cleaning, rather than from any external source of power.

Recycle

The process of recycling and disposing of vegan leather boots can involve different forms of power. Mechanical power is needed to shred or grind the boots into small pieces,then these small pieces can then be processed further for recycling. Thermal power can be used to heat the shredded plastic to high temperatures, which can cause it to break down into its constituent parts. Electrical power is necessary to operate machinery during the process such as the shredder and grinder that is used in the beginning of the recycle process. And last, chemical power is used in the chemical process to break down the PVC plastic into its component materials. This may involve using solvents or other chemicals to dissolve the plastic and separate it into its constituent parts. The powers used during the recycle process can vary depending on the method employed.

Conclusion

Overall, the life cycle from production to recycling a pair of vegan leather Demonia swing-815 requires a huge amount of power from chemical energy to human power. The power use might be reduced because of the main shopping platform being online rather than in-shop, but more power is consumed because of overseas factories.

Bibliography

Shintech: The World’s Largest PVC Manufacturer - Shin-Etsu Chemical. https://www.shinetsu.co.jp/wp-content/uploads/2019/04/AR2013_5.pdf.

“The Demonia Footwear Guide • Immoral Fashion.” Immoral Fashion, 3 June 2022, https://immoralfashion.com.au/the-demonia-footwear-guide/.

Wang, Jiahao, et al. “Life Cycle Energy Consumption, Environmental Impact, and Costing Assessment of Coal to Ethylene Glycol Processes via Dimethyl Oxalate and Formaldehyde - Environmental Science and Pollution Research.” SpringerLink, Springer Berlin Heidelberg, 28 Nov. 2022, https://link.springer.com/article/10.1007/s11356-022-24075-5.

Minh, Nhut Tran, and Ha Ngo Ngan. “Vegan Leather: An Eco-Friendly Material for Sustainable Fashion towards Environmental Awareness.” AIP Publishing, AIP Publishing LLCAIP Publishing, 20 Sept. 2021, https://aip.scitation.org/doi/abs/10.1063/5.0066483.

Sims, Alice. “Is Demonia Ethical, Sustainable or Fast Fashion?” Your Sustainable Guide, 27 Jan. 2023, https://yoursustainableguide.com/is-demonia-ethical/.

Yu, Xiaomin. “Impacts of Corporate Code of Conduct on Labor Standards: A Case Study of Reebok's Athletic Footwear Supplier Factory in China - Journal of Business Ethics.” SpringerLink, Springer Netherlands, 2 Aug. 2007, https://link.springer.com/article/10.1007/s10551-007-9521-2.

Bass-Modeling for Fast Fashion Lady's Shoes Based on Consumer Behavior. https://www.researchgate.net/publication/336583647_Bass-Modeling_for_Fast_Fashion_Lady's_Shoes_Based_on_Consumer_Behavior.

Kashyap, Divya. “Vegan Leather Manufacturers.” VeganAvenue.com, 5 Sept. 2022, https://veganavenue.com/vegan-leather-manufacturers/.

Clark, Devin. “Can PVC Be Recycled? A Foolproof Guide to PVC Recycling:” CleanRiver, 26 May 2022, https://cleanriver.com/blog-can-pvc-be-recycled/.

“Rock Salt Production Methods.” Salt Production Line, 11 Dec. 2019, https://www.saltproductionline.com/salt-production-methods/rock-salt-production-methods/.

Khadijah Muhammad

Rachel Li, Ricky Ramirez

DES040A

Professor Cogdell

16 March 2023

Demonia Swing-815: Life Cycle Analysis Through the Lens of Waste

Since the world was struck by the pandemic in 2020, society began embracing the idea of individuality. Defined by Cambridge Dictionary, individuality, not to be confused with individualism, is the “quality that makes a person different from others.” In this journey, an individual’s fashion style was one of the most common ways people began to express themselves. Because the world was on lockdown, many experimented with their closet, which many did not put much thought into before, leading to the rise of different styles that range from minimalism to maximalism (Picard). This increase in fashion interest caused a surge in online shopping and fast fashion products. Fast fashion is “a term used to describe the readily available, inexpensively made fashion of today” (Bick, et al). Due to the growth in globalization and the increase in the global economy, the process of creating these fashion products (tops, bottoms, accessories, and shoes) has become much cheaper (Bick, et al). But the societal and environmental consequences of fast fashion heavily weighs down its advantages.

Because of the normalization of the fast fashion industry due to its affordability, there has been an increase in consumer consumption of products such as footwear. In combination with individuals searching for their unique style came an increased interest in platform shoes like those sold by Demonia, an alternative footwear company based in Southern California. Despite being established in the early 1990s, Demonia became more popular in the last few years which has expanded their business from local to international. Their transition from animal-based leather to vegan leather has also increased their customer attraction. However, despite the usage of vegan leather, a cleaner alternative to animal leather, Demonia shoes are non-biodegradable and generate lots of emissions as a by-product of the life cycle, including material acquisition, manufacturing, transportation, maintenance, and disposal. This paper will look further into the waste by-products of the Demonia Swing-815.

The Demonia Swing-815 consists of vegan leather for the outer part of the boot, alloy metal buckles on the outside, a zipper in the back, and synthetic rubber for the platform of the boot. Since the Demonia Swing-815 is created out of vegan leather, the environmental impacts are not as high as they would be if created of animal leather, however, there are still environmental consequences due to the extraction of materials needed to create the leather. Vegan leather can come from many sources such as, “plastic-based Polyurethane Chloride (PVC) and Polyurethane (PU).. and products of natural origin such as cork, bark, pineapple leaves or apple peel” (Minh and Ngan). By far, leather made from natural materials is better for the environment than leather made out of plastic, but both have their disadvantages. Since “virtually all “vegan leathers” in products available in the market are in fact made from polyurethane (PU) and/or polyvinyl chloride (PVC),” it can be inferred that the vegan leather used in the Demonia Swing-815 is also created out of plastic. (Williams, et al). The main raw materials for PU are polyisocyanates, toluene diisocyanates, and polyols (Kemona and Piotrowska), and for PVC are rock salt and ethylene (Lewandowski and Skórczewska). While there is little to no waste throughout the acquisition process for vegan leather, the environmental impact of the extraction of the necessary metals needed for the buckles is huge.

In order to create the brass alloy for the metal buckles, copper and zinc are needed. The acquisition of the metal Copper, consists of mining, crushing, milling, ore concentration, smelting, and refining (Izydorczyk, et al). Overall, the metal ore mining industry accumulates over “10 billion tonnes of slags, dust, and aerosols as by-products, which are contaminated with metals and metalloids,” but, specifically, when copper is smelted, it “releases large volumes of SO2” and can lead to “excessive absorption of toxic elements..” that can cause “headaches, liver and kidney damage, and even cancer” (Izydorczyk, et al). During the smelting process, Copper releases “approximately 0.11 Mg of S per Mg of Cu produced in the USA” (Dudka). The emission of Sulfur is extremely harmful to the air quality in the surrounding area. It can lead to many respiratory and lung issues for human health and damage the environment with its toxic substance(Izydorczyk, et al; Dudka). For the acquisition of the metal Zinc, the waste products are similar to those for copper (Izydorczyk, et al; Dudka). In addition to similar processes, Zinc also emits “large quantities of Cd and Pb into the environment” (Dudka) which is damaging the air quality in its surrounding areas. Mining for Copper and Zinc has a detrimental impact on the contaminated soil and water of the environment and on human health.

For the zipper and the platform, there is no cleaner alternative than its synthetic alternatives. The Demonia Swing-815 continues to use a regular zipper created out of an alloy, which undergoes a process similar to the extraction of copper and zinc (Izydorczyk, et al), and polyester, a synthetic fiber formed with dihydric alcohol and terephthalic acid (Vigneswaran, et al). On the other hand, the platform utilizes synthetic rubber which is all processed and created in the lab from its “first ..manufacture of the monomer, [to the] second polymerization of the monomer” (Melville). Since polyester and synthetic rubber are both processed in the labs, the environmental and human health impact is very minimal.

The Demonia Swing-815 is originally a local selling brand. However now, they ship all over the United States and to every corner of the world. Through shipping, the brand accumulates a massive carbon footprint. During the last decade, “international shipping was responsible for approximately 2% of global annual CO2 emissions” (Selin, et al). Despite the emissions released during the shipping process, the company Demonia chooses to deliver internationally through, DHL, and actually claims to have “invested in more than 800 million liters of sustainable aviation fuel (“Sustainability”). They compare this amount of fuel with the annual “greenhouse gas emissions of some 400,000 passenger cars” (“Sustainability”) to display the improvement they have made. Their efforts to decrease their carbon footprint are visible, and DHL continues to decrease it further, not only reducing their carbon footprint, but also that of Demonia.

Since half of the raw materials used to create the Demonia Swing-815 were synthetic, their end-of-life is not that simple. These materials can be recycled, however, the process is long and not many go through the efforts to recycle the individual parts of the boot. This leads to the boot being sent off the landfills. This is considered a global issue (Rensburg) since it poses a threat to the environment since its lengthy lifespan prevents the synthetic material to be biodegraded easily (Davis). Vegan leather specifically has many negative consequences during its end-of-life. The synthetic materials it is made out of, PVC and PU, “release dioxins that are potentially dangerous to enclosed spaces or can lead to wildfires” (Minh and Ngan). This goes for the other synthetic components too. There is an abundance of plastic-based products yet no appropriate way to discard these products. Plastics are “considered a nonrenewable resource,” and while it is ideal to “recycle plastic, ..this has been proven difficult in practice since studies reveal that only 9% of plastic waste is recycled worldwide” (Rensburg, et al). Despite these challenges, it does not mean that recycling is not possible.

Efforts can be made to recycle properly. Vegan leather can be created out of more natural compounds so it would be able to biodegrade or recycle easily and without releasing a handful of emissions as plastics do. For the metal buckle, the recycling process of brass would allow for the recovery of its raw materials, copper and zinc (Maleki, et al) which can reduce the need to mine for copper and zinc in the first place. The synthetic rubber in the platform will not be able to be recycled completely or decompose at all (Fazli and Rodrigue). The only other way to get rid of it is by utilizing heat and pressure to blend the waste tires (Fazli and Rodrigue). The best technique, however, would be to ditch the synthetic rubber used in the platform for a greener alternative since synthetic rubber is not easily disposable with its long life span (Fazli and Rodrigue).

The increase in fast fashion has led to a growing consumer culture driven by finding one’s individuality. Demonia shoes are a benefactor of this trend with their platform shoes providing an alternative, non-practical look. However, what consumers are unaware of is that Demonia, despite being labeled as vegan, is not necessarily good for the environment either. Due to the heavy usage of synthetics, the shoes are non-biodegradable and generate lots of emissions as a by-product of the life cycle. From the material acquisition until its usage, synthetic material seems like a good idea. But once it has reached the end of its lifecycle, what’s next? To truly reduce their carbon footprint and help the environment, it is recommended to transition to a more natural organic material rather than relying on synthetics because of their affordability.

Besides the synthetic material, the acquisition of metals continues to be problematic when mining for these resources. During the acquisition, a lot of pollutants are emitted and contaminate the land, water, and air. These pollutants are harmful to, not only the environment but people as well. With the rate of production of fast fashion going out, the constant manufacturing toxifies the area of production and the people in that surrounding area. However, despite how damaging the acquisition of metals is, it is possible to recycle the material into its original materials. By recycling the used metals, they would be able to use the same original material without having to mine for these elements. Overall, the Demonia Swing-815 generates a lot of emissions that hinder the well-being of the people, and the environment.

WORKS CITED

Bick, R., et al., “The global environmental injustice of fast fashion.” Environmental Health 17, 92, 2018. https://doi.org/10.1186/s12940-018-0433-7

Davis, Jessica. “Is Vegan Leather Worse for the Environment than Real Leather?” Harper's Bazaar, Hearest, 13 Mar. 2021, www.harpersbazaar.com/uk/fashion/fashion-news/a30640996/vegan-leather-sustainability/

Dudka, S. and Adriano, D.C., “Environmental Impacts of Metal Ore Mining and Processing: A Review.” Journal of Environmental Quality, 26: 590-602. 1997. https://doi.org/10.2134/jeq1997.00472425002600030003x

Fazli, Ali, and Denis Rodrigue. “Waste Rubber Recycling: A Review on the Evolution and Properties of Thermoplastic Elastomers.” Materials (Basel, Switzerland) vol. 13,3 782. 8 Feb. 2020, doi:10.3390/ma13030782

Harvey, T.J., et al. “Selective Zinc Extraction from Complex Copper/Zinc Sulphide Concentrates by Pressure Oxidation.” Minerals Engineering, Vol. 5.9.975-992, 1992, Pergamon, 13 Feb. 2003, https://www.sciencedirect.com/science/article/abs/pii/089268759290125S.

“Individualism.” Cambridge English Dictionary, https://dictionary.cambridge.org/us/dictionary/english/individualism.

Izydorczyk, Grzegorz, et al. “Potential Environmental Pollution from Copper Metallurgy and Methods of Management.” Environmental Research, Vol. 197, Academic Press, 20 Mar. 2021, https://www.sciencedirect.com/science/article/abs/pii/S0013935121003443.

Kemona A, and Piotrowska M. “Polyurethane Recycling and Disposal: Methods and Prospects. Polymers (Basel).” National Library of Medicine. Aug 5;12(8):1752. 2020 doi: 10.3390/polym12081752. PMID: 32764494; PMCID: PMC7464512.

Lewandowski, Krzysztof, and Skórczewska, Katarzyna . “A Brief Review of Poly(Vinyl Chloride) (PVC) Recycling.” Polymers, vol. 14, no. 15, July 2022, p. 3035. Crossref, https://doi.org/10.3390/polym14153035.

Maleki, F., Ghasemi, S. & Heidarpour, A. “Recycling of brass melting slag through the high-temperature oxidation-leaching process.” Sustainable Environmental Research, 32, 24, 2022. https://doi.org/10.1186/s42834-022-00135-w

Melville, H. “Synthetic Rubber.” Nature 160, 851, 1947. https://doi.org/10.1038/160851a0

Minh, Nhut Tran, and Ha Ngo Ngan. “Vegan Leather: An Eco-Friendly Material for Sustainable Fashion Towards Environmental Awareness.” AIP Publishing, AIP Publishing LLCAIP Publishing, 20 Sept. 2021, https://aip.scitation.org/doi/abs/10.1063/5.0066483.

Picard, Lia. “For Some, the Pandemic Has Helped Them Find Their Style.” The New York Times, The New York Times, 19 Jan. 2022, https://www.nytimes.com/2022/01/19/style/pandemic-work-from-home-style.html.

Rensburg, Melissa, et al., “Life cycle and End-of-Life management options in the footwear industry: A review” International Solid Waste Association, Vol. 8.6, Sage Journals, 2020. https://journals.sagepub.com/doi/full/10.1177/0734242X20908938

Selin, Henrik, et al. “Mitigation of CO2 Emissions from International Shipping through National Allocation.” Environmental Research Letters, IOP Publishing, 24 Mar. 2021, https://iopscience.iop.org/article/10.1088/1748-9326/abec02.

“Sustainability.” DHL, 2023 https://www.dhl.com/global-en/home/about-us/sustainability.html#:~:text=DHL%20Express,of%20some%20400%2C000%20passenger%20cars.

Vigneswaran, C., et al. “Bioprocessing of Synthetic Fibres.” Bioprocessing of Textiles, Woodhead Publishing India, 17 Dec. 2014, https://www.sciencedirect.com/science/article/pii/B9789380308425500044.

Williams, E., et al., “Life cycle assessment of MycoWorks’ Reishi™: the first low-carbon and biodegradable alternative leather.” Environmental Science Europe 34, 120, 2022. https://doi.org/10.1186/s12302-022-00689-x