Design Life-Cycle

assess.design.(don't)consume

Materials

Daniel, Sturman

Karla Chavarria, Ruben Montoya

DES 40A

Professor Cogdell

Life Cycle Paper

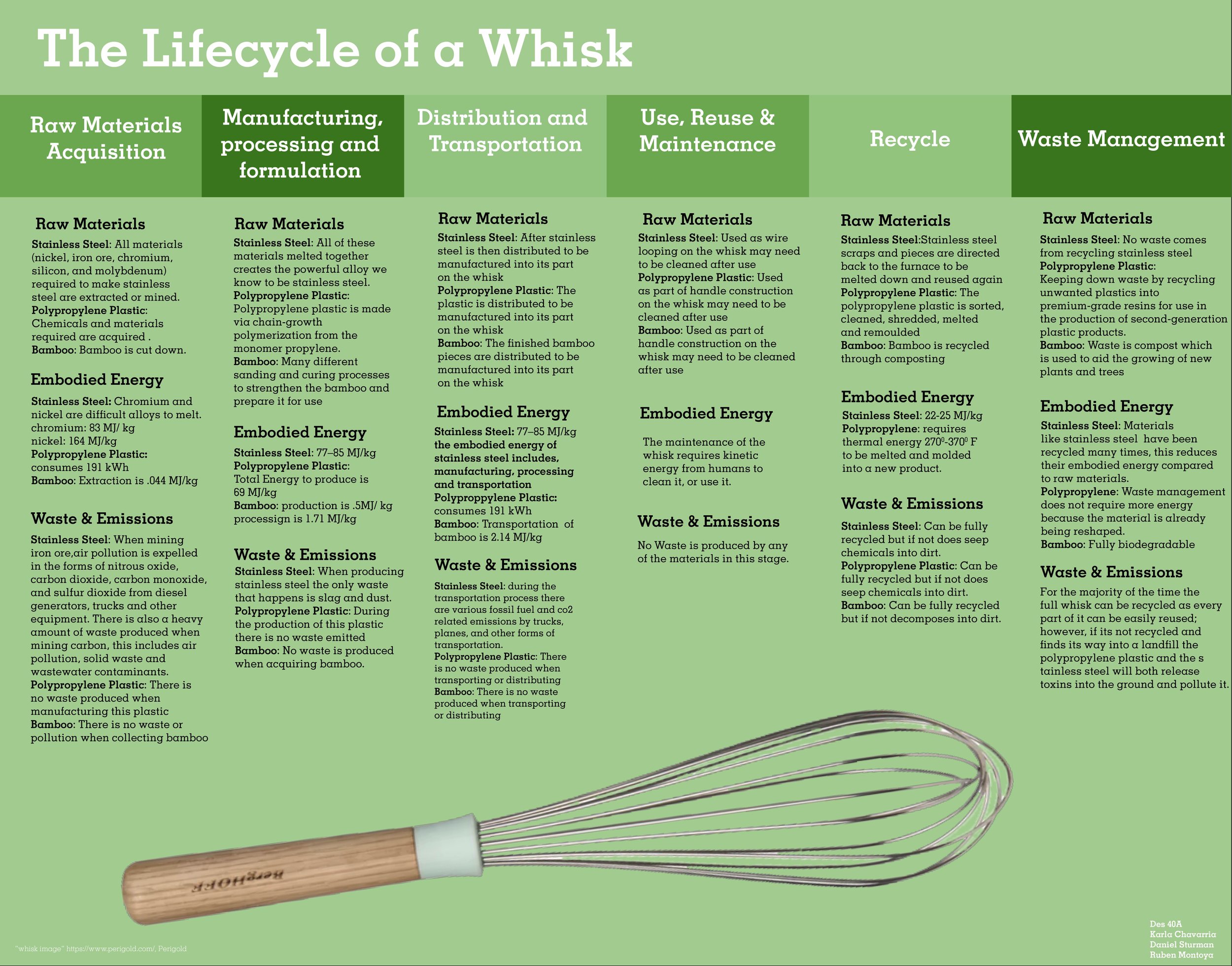

A whisk is a kitchen utensil that is used to mix different ingredients. It is such a simple product yet has to endure such a complex process to have both the look and functionality that it does. All raw materials used in the creation of the whisk consist of stainless steel, polypropylene plastic, and bamboo wood. My part in the project will involve going into detail discussing the processes each material endured to become part of the whisk. It all began with the extraction or creation of each material. Then those materials are taken to manufacturing factories to be formed into the parts that will soon make up the whisk. Soon after the completed part is distributed to stores where people can purchase them. Then after a product has been used and reused to its breaking point the whisk will then be recycled for the materials to then be used again.

Thinking about the whisk, it has 3 main materials to make up its construction, but only one of those are raw materials. For example, stainless steel comes from nickel, iron ore, chromium, silicon, and molybdenum. Most of the world's supply of nickel is mined in the Sudbury region of Ontario, Canada. It is believed that this large deposit of nickel ore is a result of an ancient meteor impact. Nickel is a hard, corrosion-resistant metal. Iron ore is mined in many different places around the world. Countries such as China, Brazil, Australia, Russia, Ukraine, India, the United States, Canada, and Kazakhstan make up 80 percent of the world's iron. Chromium is found mainly in chromite which is mined in many countries around the world. Chromium metal is usually produced by reducing chromite with carbon in an electric-arc furnace. Silicon is found in rocks, sand, clays, and soils, and it makes up 27.7 percent of the earth's crust by mass. The leading producers of silicon in the world are China, Norway, and Brazil with China accounting for 64 percent of it. The main molybdenum ore is molybdenite, but it can also be found in wulfenite and powellite. It is recovered as a by-product of copper or tungsten mining. Molybdenum is mainly mined in the United States, China, Chile, and Peru. All five of these materials are used in the production of stainless steel and are needed to make the whisk. Polypropylene plastic is also not a primary material. It comes from the monomer known as propylene. Propylene is a gaseous hydrocarbon of the alkene series and it is created by cracking alkanes. This is what is used to generate polypropylene plastic to soon be used on the whisk. Bamboo is its own primary material and is grown straight out of the ground and only requires a saw to harvest. With all of these materials we complete the list of what our whisk is made of.

As we know one major material that is present on the whisk is stainless steel. To be more specific, nickel, iron ore, chromium, silicon, and molybdenum are all melted together to create the powerful alloy we know to be stainless steel. Stainless steel has many desirable properties that contribute greatly to its widespread application in the making of parts and components across many industries. One of the main characteristics of stainless steel is its minimum chromium content of 10.5 percent, which gives it superior resistance to corrosion in comparison to other types of steel. Other favorable properties for consumers are its high strength and durability, its high and low-temperature resistance, increased formability and easy fabrication, low maintenance, long-lasting, attractive appearance, and is environmentally friendly and recyclable. After the stainless steel is manufactured it is then distributed to be made into its part on the whisk. They do this by melting and molding the stainless steel into the wire looping that gives the whisk its functionality. Once stainless steel is put into service, it does not need to be treated, coated, or painted, meaning there is very minimal maintenance required to upkeep stainless steel. After the whisk has been used, it comes time to recycle. Stainless steel scraps and pieces are directed back to the furnace to be melted down and reused again. With this process comes no waste of material because none is lost during the process.

Thinking about the construction of the whisk, it would be really difficult to use if there was no handle. One of the materials that make up the handle is polypropylene plastic. Polypropylene plastic is a thermoplastic polymer used for a variety of applications. It is made via chain-growth polymerization from the monomer propylene. It is a tough material with good heat resistance which is why it was chosen to be the handle of the whisk. Other properties like being lightweight and having a high strength-to-weight ratio can make it a more desirable material with the application of a handle. Just like stainless steel, this plastic is melted down to be molded into its optimal shape. Over time plastic won't maintain the same look and will develop some scratches from normal wear and tear. To keep it in its best condition the only maintenance necessary is to keep it clean. When it comes time to recycle the plastic is then sorted, cleaned, shredded, melted, and remolded for use again. Toxic waste can come from recycling certain types of plastics but there are ways of keeping down on the waste. People do this by recycling unwanted plastics into premium-grade resins for use in the production of second-generation plastic products. With all of this, the handle construction on the whisk is still missing one more material.

Bamboo wood completes the whisk and combined with the plastic creates the handle. A common theme between both handle materials would be their strong yet lightweight properties. Bamboo is a flexible, tough, high tensile, and lightweight material which makes it adequate for many different applications among kitchen utensils. Bamboo is a wood that is created and acquired like any other. Bamboo trees are cut down to be used on many different products such as the whisk. After it is harvested, the bamboo goes through many different sanding and curing processes to strengthen and prepare it for use. The finished bamboo pieces are distributed to be manufactured into their part on the whisk. Even with bamboo being as strong as it is, common wear and tear will leave the bamboo-part of the handle with some damage over time. When it comes to maintenance, bamboo itself does not require any special procedures to upkeep it. Keeping it clean along with other parts of the whisk would be the only maintenance required. After the whisk reaches its breaking point and gets thrown away the bamboo will be separated from it and recycled. This process is called composting which creates waste that is compost. This compost can be repurposed to grow new bamboo or other trees and plants. With the addition of bamboo, the whisk is now complete.

After thinking about how all the parts come into play with the life cycle of the whisk, let's think about the time they all spend together as the whisk. This takes place after each material has been mined or extracted and they have gone through each of their manufacturing stages to become their part of the whisk. After the whisk is created, it is then distributed among many different stores around the world. Once it has arrived at the store it may sit there anywhere from 1 day to months at a time before someone may buy it but nothing changes within that time frame. Only when someone decides to purchase the whisk will it be used and the materials begin to break down. Through different applications, the whisk is used and washed, and reused over a multitude of years. Once that time comes and it's either worn out or does not meet the standards of the consumer it will most likely be recycled. From here it will be taken to a recycling plant where the different recyclables will be sorted. Eventually, they will reach the whisk, and find the diverse materials on it and it will be sorted by material among the plants.

Once each material has been recycled the possibilities of what it can become are endless. Out of each material, stainless steel has the best-repurposed material because it's just as simple as melting it down and starting from the beginning. Any product made from strictly recycled stainless steel will be practically the same as any product made from fresh stainless steel. When it comes to polypropylene plastic it has a similar property to stainless steel in the sense that it can be melted down and remolded. Meaning a lot of new plastic products can come from the disposal and recycling of polypropylene plastic. Thinking about bamboo is a completely different story when it comes to recyclability. Yes, bamboo can be recycled but not in the same way that stainless steel and polypropylene plastic can. When we recycle bamboo we compost it which is shredding organic matter and letting it sit to absorb moisture, oxygen, and bacteria to over time be composted into a type of soil rich in ingredients plants thrive off of. Knowing this recycled bamboo can technically be used to grow more bamboo. It can also be used to grow many other different types of plants which in the interim is going back to the beginning of the process.

Given all the materials that make up the whisk and where they come from we can now understand the manufacturing and acquisition processes required to create such a kitchen utensil. Each material has its procedure to form into its part on the whisk and they all go their separate ways once it comes to recycling and reusing. Some are more complicated than others but most major materials are not primary and require some manufacturing. Then thereafter are they able to be formed into their part on the whisk.

Work Cited (bibliography)

Steel, Marlin. "How Is Stainless Steel Made?". Marlinwire.Com, 2021, https://www.marlinwire.com/blog/how-is-stainless-steel-made. Accessed 22 Oct 2021.

"Stainless Steel Characteristics: Grades, Properties & Applications". Eagle Stainless, 2019, https://eagletube.com/about-us/news/stainless-steel-characteristics/. Accessed 22 Oct 2021.

"How Stainless Steel Is Made - Material, Manufacture, Used, Processing, Parts, Components, Structure, Steps". Madehow.Com, 2021, http://www.madehow.com/Volume-1/Stainless-Steel.html. Accessed 22 Oct 2021.

Staff, Creative. "Everything You Need To Know About Polypropylene (PP) Plastic". Creativemechanisms.Com, 2021, https://www.creativemechanisms.com/blog/all-about-polypropylene-pp-plastic. Accessed 22 Oct 2021.

" Polypropylene (PP) ". Bpf.Co.Uk, 2021, https://www.bpf.co.uk/plastipedia/polymers/pp.aspx. Accessed 22 Oct 2021.

Plastics, Written. "Professor Plastics: What Is Polypropylene!". Plastics Make It Possible, 2014, https://www.plasticsmakeitpossible.com/about-plastics/types-of-plastics/professor-plastics-one-of-the-plastics-superheroes-polypropylene/. Accessed 22 Oct 2021.

"What To Know About The Toxicity Of Polypropylene". Webmd, 2021, https://www.webmd.com/a-to-z-guides/what-to-know-about-the-toxicity-of-polypropylene. Accessed 22 Oct 2021.

"Polypropylene (PP) Plastic: Types, Properties, Uses & Structure Info". Omnexus.Specialchem.Com, 2021, https://omnexus.specialchem.com/selection-guide/polypropylene-pp-plastic. Accessed 22 Oct 2021.

"Bamboo Harvesting And Growing". Home Guides | SF Gate, 2021, https://homeguides.sfgate.com/bamboo-harvesting-growing-21837.html. Accessed 22 Oct 2021.

"When And How To Harvest Bamboo". Guadua Bamboo, 2021, https://www.guaduabamboo.com/blog/when-and-how-to-harvest-bamboo. Accessed 22 Oct 2021.

Imadi, Sameen Ruqia et al. "Bamboo Fiber Processing, Properties, And Applications". Biomass And Bioenergy, 2014, pp. 27-46. Springer International Publishing, doi:10.1007/978-3-319-07641-6_2. Accessed 22 Oct 2021.

Energy

Karla, Chavarria

Group Members:

Daniel Sturman

Ruben Montoya

Des 40A

Professor Cogdell

Embodied Energy in the production of a whisk

Introduction

At first glance you would not think that the Whisk that we use for cooking would have to go through such a long process to look like a whisk. Every part of the process of making the whisk is essential, but what moves the process to the next step is the energy that is put into the whisk. The materials that are used for this specific whisk are stainless steel, Polypropylene plastic, and bamboo. In order to properly understand the energy that goes into producing this whisk we must look at each material separately. In the assembly of the whisk the embodied energy is what is overlooked in the production of each part of the whisk. Within the extraction process of the raw materials, the production, and the waste of each of the materials that compose the whisk the embodied energy shows the energy consumed in the process of making the whisk. Every material that composes the whisk has a very different embodied energy in each stage of its lifecycle; the embodied energy of stainless steel will tell us how much energy goes into making the upper part of the whisk, the polypropylene plastic will show the energy that goes into making the part between the handle and the upper part of the whisk, and the embodied energy in bamboo will tell us about the energy that goes into making the handle of the whisk. It is important to break apart the embodied energy of each of these components because knowing how much energy goes into making a product that we use in our everyday lives can change our perspective of how we see it.

Stainless steel Embodied Energy

The top part of the whisk is made of stainless steel, and stainless steel is not a primary raw material; stainless steel is made up of Chromium and Nickel. According to Harold M. Cobb, the process of making stainless steel is among one of the most difficult to melt because the chromium “gobbles” up. In the first 40 years of making stainless steel, stainless steel used to go through a three-step process that consisted of melting, decarburizing, and alloying(Cobb, 175). This means that compared to today, stainless steel used to have much higher embodied energy. The embodied energy of making chromium and nickel demonstrates the total energy in the extraction, manufacturing, and transportation of these materials. The Embodied energy of chromium is 83 MJ/ kg and Embodied energy of nickel is 164 MJ/kg (“The Inventory of Carbon and Energy”). Once the metals are melted stainless steel must go through a second process; this process is where stainless steel is transferred to a refining vessel to reduce impurities (Norgate, 841). The embodied energy of stainless steel is 77–85 MJ/kg and it shows the energy that goes into the production and transportation. Stainless steel can be melted and molded again, and the energy of recycled stainless steel is 22–25 MJ/kg (Ahmad, 1). When materials like stainless steel can be recycled many times, their embodied energy is reduced in comparison to virgin materials. (Crawford,1) It is essential to know how even the energy that goes into recycling the materials affect the overall embodied energy of the whisk because once the whisk has to be discarded, we know that the stainless steel will be melted again to make another product.

Polypropylene Plastic Embodied Energy

The energy that is consumed in the production of polypropylene plastic is 191 kWh (Alsabri, 369). The embodied energy in 1kg of polypropylene plastic is 69 million joules; the 69 million joules come from the addition of the 23 million joules that goes into the production of 1kg of polypropylene plastic and 45.8 million joules in calorimetric energy. This means that to make one kilogram of polypropylene plastic the production of Lastly, the thermal energy that goes into melting polypropylene plastic is between 270-379° Fahrenheit. (“Embodied Energy Polypropylene vs Copper”) This means that when recycling polypropylene plastic to reuse it it must go through the melting process to start its life cycle again. Polypropylene is also known as one of the most versatile polymer because it can go through a wide range of manufacturing processes. (Alsabri, 365) This explains polypropylene's versatility when we can commonly use polypropylene plastic in many of the products that we see in our daily lives. It is necessary to understand that even though polypropylene makes up a small part of the whisk, it must go through a long process that needs so much energy in order to be part of the whisk that we use to cook.

Bamboo Embodied Energy

To understand how much energy goes into the last part of the whisk, we must know about the energy that goes into the lifecycle of bamboo. The extraction of bamboo is 0.044MJ/kg. There are more stages in the life cycle of bamboo that require a lot of energy, especially the different stages in the extraction of the bamboo itself. The trimming is 1.32 MJ/kg, collection tractor is 18.96 MJ/kg, loading winch 5.63 MJ/kg, storing it is 15.56, and processing, boiling and kiln drying is 1967.35 MJ/kg. (Yu Dongwei et al., 2642). It is clear to see that the entire process of the production of bamboo relies on a lot of energy in every step, and as the bamboo goes through more stages more energy is needed. The energy that goes into the production of Bamboo is .5 MJ/kg, which is a very low energy requirement for production (Manandhar). In comparison to other materials that have a higher embodied energy in the production stage, bamboo has a very low embodied energy. energy that goes into processing bamboo is 1.71 MJ/kg, and the energy that goes into the transportation of bamboo is 2.14 MJ/kg (Yu Dongwei et al., 2642). Bamboo is a renewable resource that has no harsh effects on the environment once it decomposes (Wu, 20). It’s not surprising that bamboo’s ability to rapidly grow makes it a desirable and highly demanded material. It is important to understand the amount of energy that goes into every stage of the bamboo’s embodied energy because unlike other raw materials, the embodied energy in the production process of bamboo is much smaller than in comparison.

Conclusion

Overall, to understand the embodied energy of the whisk composed of stainless steel, polypropylene, and bamboo we must look at each of these materials separately. Each of these materials has an extraction process, manufacturing process, transportation process, and recycle process where energy is consumed to make them into what we know as the whisk that we use in our kitchens. The embodied energy of the whisk shows how there may be some processes that require more energy than others. The embodied energy of Bamboo, Stainless Steel, and Polypropylene plastic are different from each other in the sense that some of these are not primary raw resources and require a long process to get to what we know as their final form. Knowing the energy that goes into making a material can make us reflect on how we see these materials. It can also help us realize that there is a lot of energy that needs to be put into an essential home item that we may later discard not thinking much about its life cycle.

Works Cited

Cobb, Harold M.. History of Stainless Steel, A S M International, 2010. ProQuest Ebook Central, http://ebookcentral.proquest.com/lib/ucdavis/detail.action?docID=3002444.

Created from ucdavis on 2021-10-15 18:31:49.

Greenbuildingencyclopaedia.Uk, 2021, https://greenbuildingencyclopaedia.uk/wp-content/uploads/2014/07/Full-BSRIA-ICE-guide.pdf. Accessed 1 Dec 2021.

Ahmad, Nabeel, and Emmanuel Ugo Enemuoh. "Energy Modeling And Eco Impact Evaluation In Direct Metal Laser Sintering Hybrid Milling". Heliyon, vol 6, no. 1, 2020, p. e03168. Elsevier BV, doi:10.1016/j.heliyon.2020.e03168. Accessed 12 Nov 2021.

Alsabri, Amzan, and Sami G. Al-Ghamdi. “Carbon Footprint and Embodied Energy of PVC, PE, and PP Piping: Perspective on Environmental Performance.” Energy Reports, vol. 6, Elsevier Ltd, 2020, pp. 364–70, https://doi.org/10.1016/j.egyr.2020.11.173.

Energy Polypropylene Vs Copper – Community Engineering Services". Coengineers.Com, 2021, https://www.coengineers.com/embodied-energy-polypropylene-vs-copper/. Accessed 30 Nov 2021.

Yu, Dongwei et al. "A Future Bamboo-Structure Residential Building Prototype In China: Life Cycle Assessment Of Energy Use And Carbon Emission". Energy And Buildings, vol 43, no. 10, 2011, pp. 2638-2646. Elsevier BV, doi:10.1016/j.enbuild.2011.06.013. Accessed 29 Nov 2021.

Crawford, R. and Hall, M., 2020. Embodied energy. [online] yourhome. Available at: <https://www.yourhome.gov.au/materials/embodied-energy> [Accessed 29 November 2021].

Wu, Xiaoyan et al. "Effect Of Bamboo Sphere Amendment On The Organic Matter Decomposition And Humification Of Food Waste Composting". Waste Management, vol 133, 2021, pp. 19-27. Elsevier BV, doi:10.1016/j.wasman.2021.07.030. Accessed 2 Dec 2021.

Rashmi Manandhar, Jin-Hee Kim, and Jun-Tae Kim "Environmental, Social And Economic Sustainability Of Bamboo And Bamboo-Based Construction Materials In Buildings". 2021, p. ., https://www.tandfonline.com/doi/full/10.1080/13467581.2019.1595629. Accessed 12 Nov 2021.

Norgate, T.E. et al. "Assessing The Environmental Impact Of Metal Production Processes". Journal Of Cleaner Production, vol 15, no. 8-9, 2007, pp. 838-848. Elsevier BV, doi:10.1016/j.jclepro.2006.06.018. Accessed 2 Dec 2021.

Waste

Rubén Montoya

Daniel Sturman, Karla Chavarria

DES 40A

Professor Cogdell

Life Cycle Research Paper Waste

The BergHOFF International Leo Whisk is a whisk that has the option to be ordered in three different colorways; silver, mint green, and brown however regardless of which of the colorways is ordered by the consumer all three are made with the same three core materials. Manufactured and shipped out of China, the BergHOFF International Leo Whisk is used worldwide by consumers of all ages and backgrounds. The three raw materials that make up this product are polypropylene plastic, stainless steel, and bamboo wood. Throughout this paper there will be references to eco-friendly, green and environmentally friendly in the context of the materials used to make this BergHOFF International Leo Whisk, when referring to a product with these phrases keep in mind the Environmental Protection Agency’s definition of a green product: a sustainable product designed to minimize its environmental impacts during its whole life-cycle and even after it is of no use. Green products are usually identified by having two basic goals which are reducing waste and maximizing resource efficiency. The BergHOFF International Leo Whisk is one-hundred percent recyclable; however, this unfortunately does not mean it is recycled one-hundred percent of the time, due to its short lifespan, much of the polypropylene plastic ends up in a landfill and according to the United States Environmental Protection Agency accounts for twenty percent of solid waste. On the other hand, eighty-five percent of stainless steel and stainless steel products are recycled once they reach the end of their life and bamboo wood is one-hundred percent biodegradable so these two products do not produce much if any waste. Although the BergHOFF company may attempt to mislead a consumer with colorful descriptions of the product with the emphasis on the environmentally friendly and green materials that the company tries to put an emphasis on the BergHOFF International Leo Whisk cannot be confidently deemed a eco friendly or a waste free product in the slightest due to the amount of waste produced by the polypropylene plastics.

The BergHOFF International Leo Whisk itself can be split into three distinct parts; the handle, the series of loops that form the actual BergHOFF International Leo Whisk head part and the metal ring that connects the handle of the product to the BergHOFF International Leo Whisk head. The handle of this specific brand of BergHOFF International Leo Whisk is made out of pure bamboo wood which is fully recyclable and biodegradable. The bamboo is the most eco-friendly material in the entire BergHOFF International Leo Whisk due to the fact that not only can it be reused and recycled in many versatile ways after its life as a whisk is over, if it does somehow find its way into a landfill, due to it being a fully natural product, it will decompose into the ground without any release of wastes or chemicals into the soil and will actually fertilize the soil in many cases as many natural products do. This choice of material for the handle is easily the most eco-friendly option because the other options for material include either a type of metal or a type of plastic for the handle which both produce waste at some point of their lifecycle while on the other hand, bamboo produces zero waste when being produced, during its lifetime, and after use when disposed of. The amount of energy that is needed and amount of waste that is produced when harvesting and growing bamboo is much less than even a standard wood due to the fact that it grows to its adult size in a span of three to five years so it does not demand the same amount of resources and time that a normal wooden handle would expend which also greatly helps its case for being an environmentally friendly product. Often when bamboo wood is used as a handle for a product and even sometimes when it is used as flooring for houses, it is not fully recyclable and produces waste during production and after its life is over due to the fact that for preservation purposes there is sometimes a wrap of synthetic plastic that is put around the bamboo product which causes it to no longer be biodegradable. The appeal of wrapping the bamboo in the synthetic plastic is due to the fact that not only does it reduce the amount of splinters that the consumer is likely to get when using the product to almost zero it also extends the lifetime of the wood by a good amount; this, however is not the case with the BergHOFF International Leo Whisk. Therefore the handle can be deemed completely waste free and environmentally friendly because from the moment the seed of the bamboo tree is planted to after it is recycled or disposed of in a landfill it has zero negative emissions of any harmful waste or gas emissions.

The metal ring that connects the BergHOFF International Leo Whisk head to the handle is made out of stainless steel which is one-hundred percent recyclable and is considered a “green product” that is environmentally friendly by the Environmental Protection Agency (EPA). By the time that it reaches the end of its life cycle, eighty-five percent of stainless steel is recycled fully, however fortunately for the fifteen percent of the stainless steel that does somehow find its way into a landfill it will not release any toxins into soil or water. Throughout production of the product there is also very little waste being produced if any; while all of this sounds extremely environmentally friendly, the actual process of mining the iron and carbon that is needed to manufacture the stainless steel products produces a massive amount of wasteful emissions. The machines that mine the raw materials release an abundance of air pollution. The air pollution expelled while mining is in forms of nitrous oxide, carbon dioxide, carbon monoxide, and sulfur dioxide that come from the diesel generators and various other machines and equipment. In towns and cities that are near these iron and carbon mines with the machines releasing all of this air pollution into the atmosphere there are higher amounts of pneumoconiosis, asbestosis, and silicosis observed in humans living near the mines due to constant inhalation of these pollutants and fine particles that are released by common mining practices such as blasting and drilling. Overall the stainless steel ring is an environmentally friendly product throughout its life due to the fact that it produces next to no additional waste even after it is recycled or disposed of; however, due to the amount of air pollutants and harmful particles that are released into the atmosphere when collecting the iron and carbon from the mines offsets this and unfortunately when all of this is taken into account the stainless steel ring part of the BergHOFF International Leo Whisk cannot be deemed an environmentally friendly product.

The head of the BergHOFF International Leo Whisk, or the loops of what is most often a type of plastic or a type of metal that the actual whisking action is completed by in this case is composed of polypropylene plastic which is a very wasteful product. Even though polypropylene plastic is a recyclable product according to the American Chemistry Council, the rate of recycling of this specific type of plastic occurs at a rate that is less than a measly one percent for post consumer recovery. This recycling rate for the polypropylene plastic is the lowest amount for any other type of plastic. Even though the manufacturing process of polypropylene plastic produces zero toxic waste and zero toxic emissions, what happens after its life cycle has ended which is the problem for the environment. According to the US Environmental Protection Agency, out of all of the waste from all products in the world polypropylene plastic makes up twenty percent of that solid waste, to put this statistic into perspective, annually in the entire world there is over two billion tonnes of municipal solid waste produced, at the very least thirty-three percent of this is not taken care of in what would be deemed as an environmentally safe or healthy manner. Now twenty percent of that two billion tonnes of municipal solid waste that is being produced annually is just polypropylene plastics, which means an average of four-hundred million tonnes of that municipal solid waste is polypropylene plastics, and if thirty-three percent of this waste is not being managed in an environmentally healthy manner that would mean that one hundred thirty-two million tonnes of the solid polypropylene waste is not taken care of in a way that is environmentally healthy. When taking in all of these statistics about the waste that the polypropylene plastics produce annually one would be able to easily see that as a whole, the BergHOFF International Leo Whisk head can be deemed a wasteful product due to the sheer amount of waste that is produced after the polypropylene plastics life is over and is disposed of.

In conclusion, even though one third of the materials used to make the BergHOFF International Leo Whisk produces a net zero waste with the bamboo handle being fully biodegradable and recyclable, the BergHOFF International Leo Whisk head alone produces exponential amounts of waste and harmful emissions which completely counteract and negate how environmentally friendly and recyclable the rest of the BergHOFF International Leo Whisk not to mention the amount of harmful air pollution emissions that are produced when mining the carbon and iron that are used to make the stainless steel for the ring that connects the whisk head to the whisk handle is which is so bad that it leads to adverse health conditions in humans and animals like that live near these mines and breathe in the air that is polluted by them every day. Taking all of this information into account due to how unhealthy and environmentally insensitive the stainless steel ring and the polypropylene plastic head are it completely counteracts how eco-friendly the bamboo handle may be, therefore, overall the BergHOFF International Leo Whisk is not a clean or environmentally friendly product as a whole.

Bibliography

Kinney, Kerry Ann. “The Contribution of Plastic and Stainless Steel Constituents to Metal Emissions from Medical Waste Incinerators.” U. of Calif., Davis, 1993. Print.

LI QINCAN, LYU TAO, and NING XIAOYU. “Stainless steel solid waste recycling protection technology.” 2020: n. pag. Print.

LAI WEIJING. “Stainless steel waste material recovery device.” 2020: n. pag. Print.

Muralisrinivasan, Natamai Subramanian. Plastics Waste Management : Processing and Disposal . Second edition. Hoboken: Wiley, 2019. Print.

Rudolph, Natalie S. Understanding Plastics Recycling : Economic, Ecological, and Technical Aspects of Plastic Waste Handling . Second edition. Cincinnati, Ohio: Hanser Publications, 2020. Print.

Letcher, T. M. PLASTIC WASTE AND RECYCLING : Environmental Impact, Societal Issues, Prevention, and Solutions. Amsterdam: Academic Press, 2020. Print.

Lin, Zhen et al. “Potential for Value-Added Utilization of Bamboo Shoot Processing Waste—Recommendations for a Biorefinery Approach.” Food and bioprocess technology 11.5 (2018): 901–912. Web.

Ma, Lai et al. “Smart Colloid-Assisted Technique Prompts the Evolution of Bamboo Wastes into Nanometal-Inlaid Carbon Microfibers for Sustainable Ni–Fe Batteries.” ACS sustainable chemistry & engineering 7.21 (2019): 17919–17928. Web.

Choy, Keith K.H, John P Barford, and Gordon McKay. “Production of Activated Carbon from Bamboo Scaffolding Waste—process Design, Evaluation and Sensitivity Analysis.” Chemical engineering journal (Lausanne, Switzerland : 1996) 109.1 (2005): 147–165. Web.

Chen, Chuihan et al. “Thermogravimetric Pyrolysis Kinetics of Bamboo Waste via Asymmetric Double Sigmoidal (Asym2sig) Function Deconvolution.” Bioresource technology 225 (2017): 48–57. Web.

EPA, Environmental Protection Agency, http://www.epa.gov/.

“Environmental Impact of Steel and Carbon Mining.” The World Counts, https://www.theworldcounts.com/challenges/planet-earth/mining/environmental-impact-of-steel-production/story.