Design Life-Cycle

assess.design.(don't)consume

Zeki Xu

Malia Serafin, Zicong Guan

DES 40A

Professor Cogdell

Material Costs of Beyond Meat

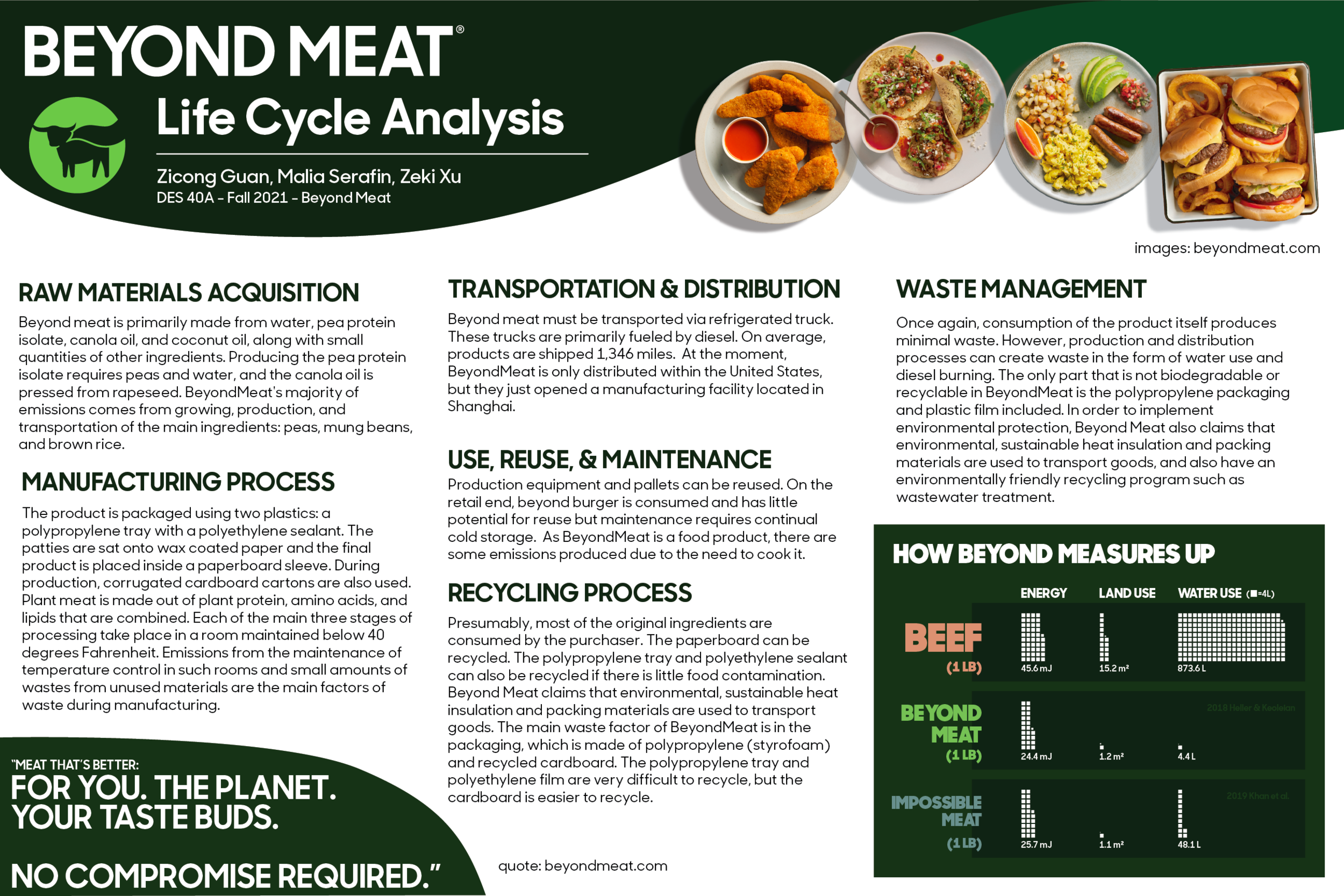

Beyond meat is a form of “plant-based meat”--an imitation meat that attempts to resemble the experience and nutritional profile of beef without the use of animals. Beyond Meat, the company that manufactures Beyond meat and other similar products, makes the claim that it is an eco-conscious alternative to eating real meat, a claim that we will examine through an analysis of their consumption and usage of raw materials. Ingredients for the plant food constitute the majority of emissions, energy, and water usage of the product’s lifecycle, followed by packaging materials and then production. Our life cycle assessment of their flagship alternative beef product demonstrates that collecting and processing the raw materials used to create Beyond meat, mainly peas, takes significantly less energy, creates fewer emissions, and is generally more sustainable compared to farming traditional beef.

In 2018, Beyond Meat commissioned the University of Michigan to perform an analysis on the lifecycle of Beyond meat products. This report, completed by Martin C. Heller and Gregory A. Keoleian, exposes most of what we know about Beyond meat’s operations and supply chain, despite a potential for bias from its funding (Wolf). Outside of this report, Beyond Meat has remained nearly completely opaque about its product lifecycle, earning it a 0% score on its weighted environmental disclosure ratio in an analysis by Trucost (Bitter and Tsao). More transparent and independent reporting is needed to verify whether these findings are accurate. Despite this, Heller and Keoleian’s report is peer-reviewed by independent sources and a window into where Beyond’s raw materials come from.

Beyond meat is primarily made from water, pea protein isolate, rice protein, canola oil, and coconut oil, along with small quantities of other ingredients, vitamins, and minerals (Beyond Meat, Ingredients). Producing the pea protein isolate requires peas and water, and the canola oil is pressed from rapeseed. Coloring is used in the form of beet juice extract. The product is packaged using two plastics: a polypropylene tray with a polyethylene sealant. The patties are sat onto wax coated paper and the final product is placed inside a paperboard sleeve. During production, corrugated cardboard cartons are also used (Heller and Keoleian). Their products aim to be vegan and do not feature animal ingredients or testing of any kind.

Beyond Meat has several production facilities in the United States (Cosgrove). The transportation of materials to these facilities create emissions and consume energy based on the distance they must be moved. In 2020, Beyond Meat opened new production facilities in China and the Netherlands, allowing them to reduce emissions and energy when distributing at these locations but increasing transport distance for some ingredients, especially those primarily produced in North America (Beyond Meat, News Release). As with many commercial food products, transportation and its associated emissions remains a major consideration when calculating the sustainability of Beyond meat.

The core of the Beyond meat product is its pea protein. This protein is mainly processed from yellow peas harvested from Saskatchewan or Manitoba in Canada, and growing peas is the primary source of land use for the product at roughly 1 acre per ton annually (Arnason). Production of peas accounts for 20% of Beyond meat’s total greenhouse gas emissions (Heller and Keoleian). At a production plant, the starch, fiber, and hull of peas are separated from the protein and sold in separate markets where their impact is harder to measure. Roquette, the company with which Beyond Meat contracts for plant protein, sells these byproducts to industries such as nutrition, pharmaceuticals, and pet foods (Roquette). A secondary protein used comes from brown rice and helps to form a complete protein profile.

Aside from water and pea protein, the remainder of the product is almost entirely oil. The rapeseed canola oil used is produced in Canada and the United States (Heller and Keoleian). However, the coconut oil must be produced and shipped by freight from Malaysia or Indonesia, a distance of over 20,000 miles to Beyond Food’s processing facilities in the United States. Despite this, coconut oil is considered by experts to be a more sustainable fat choice for the environment: “compared to a competing product like palm oil, coconut oil does not require heavy land use, i.e. no deforestation” (Wolf). Beyond Meat does not carry fair-trade certifications for its coconut or canola oil sourcing. Together, canola and coconut oil account for around 19% of Beyond meat’s greenhouse gas emissions (Heller and Keoleian). These oils are necessary to mimic the fat profile of beef.

Overall, the materials involved in Beyond meat paint a positive picture of sustainability compared to the beef consumption it aims to replace. Nutritionally, a 4 oz Beyond Burger patty provides similar amounts of protein, fat, and calories as the same quantity of beef patty (Beyond Meat, Ingredients). However, as a food, plants like peas and rice are a far more sustainable source of protein than animal meats. Farming 100 grams of protein from peas produces only 0.44 kilograms of carbon dioxide-equivalent of greenhouse gas emissions, compared to nearly 50 kilograms from beef. The same amount of beef requires 728 liters of water and 163.6 square meters to create compared to only 178 liters and 3.4 square meters for peas (Ritchie and Roser). Harvesting a quarter pound of beef uses roughly 11.4 MJ of energy while the same weight in Beyond Meat uses only 6.1 MJ.

As with all food production, the use of peas comes with its own impacts. The destruction of soil through tillage and agricultural chemicals for the purpose of industrial farming releases carbon trapped within, and is responsible for 30-40% of all atmospheric carbon (Yuko). Because of this, Beyond meat and other fake meat products produce a similar amount of emissions as chicken farming. However, producing beef involves a far greater amount of industrial farming, as much as 89 times. The majority of the energy, water, and land needed to produce beef comes from obtaining feed and raising cattle, concerns not shared by plant-based products like Beyond.

One area of concern comes from Beyond meat’s packaging. As previously mentioned, Beyond meat’s packaging mainly consists of a plastic thermoformed tray, a film covering, a cardboard-like sleeve, and waxed patty paper (Heller and Keoleian). The tray and the sleeve form more than 94% of the total packaging material by weight. The tray is made of polypropylene, a synthetic resin which, like most plastics, is made from petroleum (McGuire). The sleeve, made specifically from folding boxboard, is formed from several layers of pulp, most likely sourced from wood or scraps (Iggesund). Other materials used in the production process include corrugated cardboard, wood pallets, and polyethylene pallet racks for facility use (Heller and Keoleian).

Packaging is a significant use of resources and source of emissions. Packaging a quarter pound of Beyond meat uses up 1.64 liters of water, more than three times the amount of water used to produce the ingredients (Heller and Keoleian). In addition, it is responsible for a third of the energy used in the total lifecycle of the product and creates emissions that may not be completely necessary. In 2018, the University of Michigan study made a recommendation to switch to post-consumer polypropylene, calculating that it could reduce emissions by up to 2% and energy use by up to 10%. An additional concern is that the packaging is made from single-use plastics and as such is not biodegradable and does not effectively make use of recycling (Hollow). There is limited evidence that they have made significant changes to their packaging materials, apart from switching from their plastic tray to paperboard for specific Beyond Sausage products (Wolf). Since 2020, Beyond Meat claims they plan on moving towards lighter packaging in Europe with “30% less material overall by reducing paper and plastic use” (Beyond Meat, News Release). Beyond Meat is packaged with materials similar to many of the beef products it is designed to replace, and as such inherits the same sustainability issues (Hollow).

Based on an assessment of its ingredients compared to production of the beef alternative, Beyond Meat appears to live up to its claims of offering a more environmentally friendly alternative to meat. By going directly from plants to food, farming the ingredients needed to make Beyond Meat use roughly a third of the energy and significantly less resources than obtaining feed for cattle requires. However, its production processes, especially in sourcing pea protein and choice of packaging materials, are not without environmental impact and still show areas of unnecessary resource consumption or waste.

Sources

“2020 Activity and Sustainable Development Report.” Roquette, 2020, https://sustainability.roquette.com/wp-content/uploads/2021/09/2020-Roquette-Activity-and-Sustainable-Development-Report.pdf

Arnason, Robert, et al. “Beyond Meat Eyes Prairies for Pea Protein.” The Western Producer, 20 Jan. 2020, https://www.producer.com/news/beyond-meat-eyes-prairies-for-pea-protein/.

Bitter, Alexander and Stephanie Tsao. “Beyond Meat Trails Animal Meat Peers on Reporting Environmental Effects.” Market Intelligence, S&P Global, 5 Aug. 2020, https://www.spglobal.com/marketintelligence/en/news-insights/latest-news-headlines/beyond-meat-trails-animal-meat-peers-on-reporting-environmental-effects-59477986.

Cosgrove, Emma. “Beyond Meat Acquires Co-Packer to Tackle Unit Costs.” Supply Chain Dive, 11 Nov. 2020, https://www.supplychaindive.com/news/Beyond-meat-acquisition-copacker/588805/.

“General Technical Information: Paperboard.” Iggesund, 2008, https://web.archive.org/web/20110713004736/http://www.iggesund.com/Main.aspx?ID=d3f6ae98-6286-435d-bf6d-99a7ca881cab.

Heller, Martin C., and Gregory A. Keoleian. "Beyond Meat’s Beyond Burger Life Cycle Assessment: A detailed comparison between a plant-based and an animal-based protein source." Center for Sustainable Systems, University of Michigan, 2018. https://css.umich.edu/publication/beyond-meats-beyond-burger-life-cycle-assessment-detailed-comparison-between-plant-based.

Hollow, Michelle. “Plant-Based Meat Has a Packaging Problem.” LeafScore, 13 Jul. 2021, https://www.leafscore.com/eco-friendly-kitchen-products/plant-based-meat-has-a-packaging-problem/.

Hulley, Kate. “What is Corrugated Cardboard Made Of?.” Belmont Packaging, 21 Dec. 2017, https://www.belmontpackaging.co.uk/news/what-is-corrugated-cardboard-made-of.

“Ingredients: What Is Plant-Based Meat?: Beyond Meat.” Vegan Burger Meat, Crumbles, & Sausages, https://www.beyondmeat.com/about/our-ingredients.

McGuire, Maya. “Bioplastics vs. Petroleum Plastics.” University of Florida / Institute of Food and Agricultural Sciences, 14 May 2018, http://blogs.ifas.ufl.edu/flaglerco/2018/05/14/bioplastics-vs-petroleum-plastics/

“News Release: Beyond Meat® Opens World-Class Plant-Based Meat Manufacturing Facility in China to Accelerate Localized Production and Innovation.” Beyond Meat, Inc., 7 Apr. 2021, https://investors.beyondmeat.com/news-releases/news-release-details/beyond-meatr-opens-world-class-plant-based-meat-manufacturing.

Ritchie, Hannah and Max Roser. “Environmental Impacts of Food Production.” Our World in Data, Jun. 2021, https://ourworldindata.org/environmental-impacts-of-food.

Wolf, Jared. “Better Brands: Is beyond Meat Sustainable?” Sustainable Review, 29 Jan. 2021, https://sustainablereview.com/is-beyond-meat-sustainable/.

Yuko, Elizabeth. “The Downside of ‘Alternative Meat’ That No One's Talking About.” Reader's Digest, Reader's Digest, 14 July 2021, https://www.rd.com/article/downside-of-alternative-meat/.

Energy Essay

Malia Serafin

Professor Christina Cogdell

DES 40A: Energy, Materials, and Design Over Time

24 November 2021

Wastes and Emissions of Beyond Meat

It is well known that the consumption of meat is extremely damaging to climate change, especially regarding the high production of the greenhouse gas methane. Meat-alternatives have become popular recently, as many more people are cutting out meat of their diets or adopting the vegan diet entirely to lessen the consumption of animal products. Variations of meat-alternatives have been created including the Impossible Burger, which is based on soy and potato proteins. However, Beyond Meat carries a different approach, basing all of their products mainly on a variety of pea and bean proteins. BeyondMeat is a meat-alternative company that produces a wide variety of plant-based meat substitutes such as burger patties, sausages, and chicken tenders. Compared to a regular beef patty, Beyond Meat produces 90% less greenhouse gas emissions and has over 99% less impact on water scarcity (Heller and Keoleian). Though I will mention all six steps in the life cycle of BeyondMeat, I found that the most impacted steps were the acquisition of raw materials and the recycling process. Beyond Meat's majority of emissions comes from growing and production of the main ingredients: peas and brown rice. The main waste factor of Beyond Meat is in the packaging, which is made of polypropylene (Styrofoam), polyethylene film (plastic), and recycled cardboard.

Wastes from the packaging of Beyond Meat products itself mainly consists of the Styrofoam tray, which is not usually recycled, and a plastic film included in the recycled cardboard box. It is known that Styrofoam is usually thrown away and takes up space in landfills. Styrofoam is lightweight and is commonly used for food packaging, as it is with Beyond Meat, but the food residue must be washed first in order to be recycled, which it is often not (Chandra, Kohn and Pawlitz 15). If consumers would wash the Styrofoam packaging before disposal, Styrofoam could be recycled, and it would save a good portion of the wastes from Beyond Meat products. Styrofoam cannot biodegrade, so if a piece of Styrofoam is made, it will be around for a very long time. It will take up space in landfills and because of its lightweight properties, it can easily blown by winds and travel beyond designated landfills and enter ecosystems (Chandra, Kohn and Pawlitz). The inclusion of Styrofoam packaging in Beyond Meat is the second largest contributor of the product to the total greenhouse gas emissions (Heller and Keoleian). Styrofoam is created from styrene, which is created from petroleum or natural gas (Chandra, Kohn and Pawlitz). So not only is Styrofoam rarely recycled, it is created by fossil fuels which we know to be strong emitters of greenhouse gasses.

Another aspect of the packaging for Beyond Meat products is the cardboard box that it comes in, which is made of cardboard and a thin plastic film. The plastic film is made from fossil fuels and cannot be recycled. However, the cardboard box itself can be recycled or composted. Relevant to the recycling of packaging of Beyond Meat products, specifically, the city of Davis does accept both Styrofoam (as a plastic #5) and cardboard/paperboard for recycling (City of Davis). A majority of the wastes of Beyond Meat comes from the packaging of the product itself, however, a majority of the emissions released comes from the production of its main ingredients: rice, peas, and the fats canola oil and coconut oil.

Brown rice is one of the main ingredients of Beyond Meat, but rice grown in flooded fields is known to be a major emitter of methane, a very potent greenhouse gas. Flooded fields are the main method of growth for rice but contribute such a large amount of methane and have been absolutely integral for the production of rice across the world. “Anaerobic decomposition of organic material in flooded rice fields produces methane (CH4), which escapes to the atmosphere primarily by diffusive transport through the rice plants during the growing season (IPCC). Because of the way how rice paddies produce methane, it is the largest source of greenhouse gasses for the creation of the ingredients for Beyond Meat. If the rice used for Beyond Meat is grown in a different method, one that does not require flooding of the fields, the greenhouse gas emissions would lower significantly. Wastes from rice production, mostly rice straw and the husk, are typically either reintroduced to the soil or burned (Ricepedia). Returning the wastes to the soil, it decomposes and produces methane. Burning the wastes introduces more methane and other harmful particulates to the atmosphere. To look to reduce methane emissions from the growing process of rice, alternative technologies such as wetting and drying techniques could be implemented in future rice farms. “Water-saving technologies such as alternate wetting and drying reduce the amount of time rice fields are flooded and can reduce the production of methane by about 60-90% (Ricepedia). Alternate wetting and drying is the process by which the water level is controlled carefully, instead of the normal way of just flooding the entire field to a certain depth and leaving it as such for a period of time. Alternate wetting and drying techniques may reduce the amount of methane emissions for rice paddies, but it will increase the emissions of nitrous oxide (Climate Technology Center and Network). The growing process of rice creates methane gas, however there are other factors in the production of the other core ingredients of Beyond Meat, peas and canola oil, that contribute to the emissions of the products.

Peas don't need nitrogen fertilizer and growing them results in less air and water pollution (cite Just the tonic!). Pea production accounts for a majority of the greenhouse gas emissions from the production of Beyond Meat (20%) but is still significantly less than the amount of greenhouse gas emissions produced by creating a standard beef patty. Production of canola oil is second to the production of peas for Beyond Meat, accounting for 13% of the greenhouse gas emissions. One advantage of the main protein source of Beyond Meat products is their main ingredient: peas. Peas do not require nitrogen fertilizer, a fertilizer commonly used to grow grain crops. Nitrogen fertilizer contributes to climate change in that it can pollute water through the production of nitrates and pollute the atmosphere through the production of nitrous oxide, a potential greenhouse gas (Byrnes). Increased growth of pulse crops (legumes) could also potentially assist in CO2 emissions, but adding pulse crops into growth rotation with growth of other crops would result in a small but positive impact (R. L. Lemke). Another main ingredient in Beyond Meat is the fats: canola oil and coconut oil. Canola oil is produced by crushing through a cold press method or dissolved in a hexane solvent (Canola Council of Canada). Cold pressing rapeseed to get the oils has little effect on wastes and emissions, however hexane is one of the more commonly used methods to extract canola oil and the more dangerous method of the two. Hexane must be carefully managed because it is toxic to humans and can easily pollute the atmosphere (Gaber). Coconut oil is produced in a similar way to canola oil, but most of it is outsourced beyond the United States. A majority of coconut exporters are developing countries in Asia, particularly the Philippines, where poverty and climate change have impacted the country (Feinstein). This outsourcing introduces emissions through the shipment of products to Beyond Meat’s production facilities. During the production process of Beyond Meat, each of the main three stages of processing take place in a room maintained below 40 degrees Fahrenheit. Emissions from the maintenance of temperature control in such rooms and small amounts of wastes from unused materials are the main factors of waste during manufacturing. At the moment, Beyond Meat is only distributed within the United States, but they just opened a manufacturing facility located in Shanghai. Despite the wastes and emissions created from the production of peas and canola oil for Beyond Meat, there is a clear difference when comparing the emissions of Beyond Meat to a regular beef patty.

When comparing the beef industry’s impact on greenhouse gas emissions, the difference between beef and Beyond Meat are drastic. In a life cycle analysis done by the University of Michigan, production of a Beyond Meat burger patty produces only 10% of a standard beef patty’s equivalent of greenhouse gases; beef patties produce 3.7 kg. of CO2 eq. while Beyond Meat produces 0.4 kg. of CO2 eq. (Heller and Keoleian). I would infer that a majority of the greenhouse gas emissions come from the cows themselves, as well as the land needed to produce food for the cows. You would think that peas would take up more land to grow but compared to beef, Beyond Meat actually uses 7.8% of the land that beef would; beef uses 3.8 m2a eq. compared to Beyond Meat at 0.3 m2a eq. (Heller and Keoleian). The usage of peas as a protein alternative are rapidly developing, as many more companies are looking to using them because of their advantages over wheat, corn, and soy (Zimberoff).

Beyond Meat as an alternative to traditional meats such as beef, pork, and chicken stacks up against the latter as a more environmentally friendly in terms of wastes and greenhouse gas emissions and land and water use. The majority of wastes and emissions from the life cycle of Beyond Meat products is in the production process for the ingredients themselves and the packaging. The main ingredients of Beyond Meat are peas, brown rice, canola oil, and coconut oil. Brown rice shares a majority of emissions of the product production because of the methane that is released in flooded rice patties used. Peas on the other hand, compared to other grains, have the potential to mitigate nitrous oxide emissions from rice production due to their ability to grow without nitrogen fertilizers. Packaging of Beyond Meat products mainly consists of a cardboard box which can be easily recycled or composted, and a Styrofoam tray. The Styrofoam tray can be recycled, but it must first be cleaned from food residue which deters consumers from recycling it. Beyond Meat as a whole does well as a meat alternative in terms of wastes and emissions, but still has improvements to be made particularly within the growth of ingredients and packaging.

Bibliography

Baek, Chun-Youl, Kiyotaka Tahara, and Kyu-Hyun Park. "Parameter Uncertainty Analysis of the Life Cycle Inventory Database: Application to Greenhouse Gas Emissions from Brown Rice Production in IDEA." Sustainability 10.4 (2018): 922.

“Beyond Meat.” Vegan Burger Meat, Crumbles, & Sausages, https://www.beyondmeat.com/.

Byrnes, B. H. "Environmental effects of N fertilizer use — An overview." Fertilizer Research 26 (1990): 209-215.

Canola Council of Canada. Canola Oil. n.d. November 2021. <https://www.canolacouncil.org/about-canola/oil/>.

Chandra, Manu, et al. Real Cost of Styrofoam. Experiential Learning Project. Saint Louis: Saint Louis University, 2016.

City of Davis. Recycling. 2021. 18 November 2021. <https://www.cityofdavis.org/city-hall/public-works-utilities-and-operations/solid-waste-and-recycling/recycling>.

Climate Technology Center and Network. Alternate wetting and drying (rice). n.d. 22 November 2021. <https://www.ctc-n.org/technologies/alternate-wetting-and-drying-rice>.

Das, Neel. A review of the environmental impacts of meat and meat alternatives. Diss. Massachusetts Institute of Technology, 2020.

Feinstein, Asa. https://www.cocoasenso.com/blog/2017/8/23/do-you-know-where-your-coconuts-come-from. 24 August 2017. 24 November 2021.

Gaber, M.A.F.M., Tujillo, F.J., Mansour, M.P. et al. "Improving Oil Extraction from Canola Seeds by Conventional and Advanced Methods." Food Engineering Reviews 10 (2018): 198–210.

Heller, Martin C. and Gregory A. Keoleian. Beyond Meat's Beyond Burger Life Cycle Assessment: A detailed comparison between a plant-based and an animal-based protein source. CSS Report. Ann Arbor: University of Michigan, 2018.

IPCC. Revised 1996 IPCC guidelines for national greenhouse gas inventories. Paris, 1997.

R. L. Lemke, Z. Zhong, C. A. Campbell, R. Zentner. "Can Pulse Crops Play a Role in Mitigating Greenhouse Gases from North American Agriculture?" Agronomy Journal 99.6 (2007): 1719-1725.

Ricepedia. Climate change. n.d. <https://ricepedia.org/challenges/climate-change>.

Zimberoff, Larissa. The Rise of the Pea: How an Unassuming Legume Emerged as a Frontrunner in the Race to Replace Meat and Dairy. 15 August 2019. 24 November 2021. <https://time.com/5652178/pea-meat-dairy-alternative/>.

Zicong Guan

DES 040A

11/28/2021

Transportation energy of Beyond meat

Beyond Meat is the first listed company in 11 people in 11 people in the world. The company was founded in 2009. It is located in the United States. The main business is to use plant protein to synthesize "artificial meat", mainly sales targets for mainstream retail, caterers. As the global population increases, the consumption of meat also increases accordingly. At the current rate, the world's meat and seafood production will double by 2050, reaching US$1.66 trillion. But what follows is the destruction of the environment by industrialized farming under the traditional model: poultry emits methane and requires a lot of water for irrigation. According to the world counts estimates, on a global scale, humans will use 1,940,409,922,393 tons of water for meat production in 2021. Supplying the water, fuel, pesticides, and fertilizers needed for industrialized animal production at that scale is a great challenge for mankind (Fitzgerald & Hume, 2011, p.1886). It is also difficult for human beings to withstand the water pollution or damage to the ecological balance caused by this. In order to solve this problem, Beyond Meat turned out. Beyond meat meets our needs for animal protein-in large quantities and compared to traditional meat, there are almost no pathogens-industrialized animal production seems to be the only option at present. Therefore, this article will discuss Transportation Energy of Beyond Meat from the Production Beyond Meat, Transport Beyond Meat, Storage Beyond Meat, Beyond Meat Gets Energy for Raw Materials.

Plant meat and growing meat are two technological approaches to fake meat. Artificial meat may be classified into two types based on the idea and production process: plant meat and culture meat. Plant meat is made out of plant protein, amino acids, and lipids that are mixed together with fake meat created from botanic hemoglobin generated by yeast. The cultured meat is separated from the animal, a tiny number of stem cells are extracted, cultured in nutritional solution, and eventually, human meat is produced (Stein hart & Steinhart, 1974, p.311). Plant-based fake meat is created from peas, soybeans, and other ingredients. Plain meat with fresh meat tastes and the nutritional value contains trace minerals and vitamins. Artificial meat is made by taking all-in-range stem cells or angle cells from animals and culturing them in a nutritional solution, resulting in a tissue that looks like muscles, and then commercial processing and reshaping molding, resulting in a human flavor product. Stem cells arise from a multitude of places, including main animal muscles, embryonic stem cells, and multiple stem cells. As an example, consider the growth of fake beef: The first stage is to do a biopsy on the calf; the second step is to remove the stem cells from the cow's muscle tissue; the third step is to place the stem cells' stems into the biological Reactor, where they will proliferate and produce muscle fibers. Plant meat is now the most advanced production technology on the market, with Beyond Meat and Impossible Foods as its representative companies. The two businesses 1 pound of humans is worth about $12. (Elgasim, 1983). Memphis Meat and Mosa Meat are two meat-cultivating companies; Memphis MEAT manufacturing costs $ 9,000 in 2017. As a result, meat cultivation is still in the laboratory research stage, and large-scale commercial production is not possible. Plant meat is really vegetarian, since raising meat is a form of animal agriculture. Despite the fact that plant meat and meat culture are both classified as fake meat, there are differences in the key raw materials, technological methods, production costs, and the ability to achieve large-scale commercial production.

Transport Beyond meatCommercial large-scale transportation of artificial meat must meet at least two conditions: First, the taste of artificial meat is close to that of real meat. The second is to reduce the production cost to an acceptable range for people's daily consumption. Early vegetarians usually supplemented protein with products rich in plant protein, such as tofu and monks. According to the prospectus of Beyond Meat, customers of Beyond Burger also buy animal protein products at the same time, which means that most customers will not try artificial meat because they are vegetarians, and they really treat artificial meat as meat (Seller, 2015). A major disorder affecting vegetarian meat in the United States is the relatively limited number of stores. However, while Impossible Food has vigorously promoted to the grocery store, its competitor Beyond Meat also found a good way to expand the sales of sales - Online official website order page, express DC Consumers home. Both companies are well known to people with plant food-based artificial meat products, intended to replace a small part of the natural meat product market. Impossible Food and Beyond Meat's vegetarian meat have been sold in some grocery stores in the United States, and there are a variety of shapes and tastes, such as sausages and burger. But if you live in a small city in the United States, it is almost impossible to find the shelf of Beyond Meat in the store. The good news is that after the official website is online, consumers can directly choose the express delivery to the door. In addition to zero, Beyond Meat also provides a variety of package combinations, such as a $ 49.99 experience (Trial Pack), Hamburg, multi-taste sausage, chopped beef, and early meal intestines. In order to implement environmental protection, Beyond Meat also claims that environmental, sustainable heat insulation and packing materials are used to transport goods, and also have an environmentally friendly recycling program such as wastewater treatment.

The birth of a human meat product in the normal temperature and long-temperate period, subverting the public's awareness of the quality of the artificial meat products. Under the basis of zero-added zero preservatives, the artificial meat products of Yuanssen creatures are preserved at very 12 months at very temperature (Hart, 1997, p.68). Compared with the low-temperature short shelf life, there is no need for cold chain environments, which can greatly extend the product shelf life, reduce the cost of transportation, storage, etc., and enjoy the artificial meat anytime, anywhere. The artificial meat of low-temperature short-insured periods requires multi-processing, combined with the food habits of Chinese food, the frying method is most common, the oil temperature is too high, and the nutrients of the artificial meat are destroyed and harmful to the human body. Substances, the sale of healthy nutrients promoted by artificial meat products does not match, and it is impossible to achieve the purpose of eating meat to improve your health (Vermeulen, 2018, p.299). Every long-temperate period realizes the utility-of product of the product, and adds a variety of minerals such as calcium zinc selenium in Yuansen, and contains sufficient protein. The original nutrients are more likely to be absorbed. Snacking is a new proposition in the food market in recent years. With the rise of the fourth meal and night food economy, the demand for snacks is also increasing. Low-temperature short shelf life requires more time to cook, and it is also more suitable for the sight of the dinner, conflict with the concept of sanctification. And the eating people who are often temperate period is easy to eat, and it is easy to solve this problem based on convenience and fast. Yuanssen creatures make people flesh snacks into a big step forward by developing a normal temperature-long-temperate period. Artificial meat products in normal temperature and long supply are more advantageous compared to low-temperature short shelf-life products, and more advantages in storage, nutrition, and convenience, and also more in line with the development trend of today's food. Yuanssen creature is to see this, developed the world's first normal temperature and long-lasting period of artificial meat products. This is the core differentiation, and the source of the source is open to the new future of the people (Mejia & Sabaté, 2019).

Bill Gates once identified this as an essential drive for worldwide fake meat: "Plow and synthetic meat are the same as the world-changing breakthrough technology. The former ushers in the agricultural period, while the latter ushers in the bio-industrial era." The highest meaning of man, according to Gates, is environmental preservation. Artificial meat has the potential to lessen the negative influence on the environment at the macro level. Traditional animal husbandry is the primary producer of two major high-temperature greenhouse gases, methane and nitrous oxide, and the greenhouse gas generated directly influences global climate warming more than the aggregate of vehicles, trucks, planes, trains, and ships. Furthermore, increasing traditional animal husbandry would require a significant amount of natural resources, such as land, food crops, and water resources, resulting in resource waste. The first method involves extracting all-around stem cells or muscle cells from animals, culturing them in nutritional solution, and generating tissues through cell proliferation. The second method involves using muscle stem cells to produce human muscles in the laboratory. Material is available, however, the cost of this concept is too costly, at over 2,000 US dollars per pound. Another option is the current mainstream, which uses a vegetal protein as raw material and gives it a meat flavor and taste using physicochemical techniques. People's primary business focus is plant meat. Beyond Meat, Impossible Food, March Zero, and other well-known plant meat brands are currently available. The acquisition of soybeans and pea proteins, as well as the research and development of fundamental technologies like artificial plant meat firms, are the two most significant linkages in artificial plant meat (Cholette & Venkat, 2009, p.1403).

In conclusion, Beyond Meat transformed humans in general in order to get to the protein. Rather than using plant raising animals and then getting proteins from animals, people can acquire proteins straight from Beyond MEAT (Camp is, 2019). This not only increases the proportion of heat contained in crops that are absorbed by people, but it also decreases animal slaughter, has altered meat-eating habits, and has altered the meat-producing business. With the maturation of fake meat industrialization, it is expected that the future of Beyond Meat will spread to a bigger market, allowing top meat products companies to enter the artificial meat area, providing us with a rich protein supply.

References

Campos, M. (2019). A fork in the road for synthetic meat. Association for Computing Machinery (ACM).

Elgasim, E. A. (1983). Development of a commercial feasible application of a hydrostatic meat tenderizer and demonstration of its efficacy. Final report, June 24, 1980-March 1, 1983 (No. DOE/CS/15013-T1). Oregon State Univ., Corvallis (USA). Clark Meat Science Lab.

Steinhart, J. S., & Steinhart, C. E. (1974). Energy use in the US food system. Science, 184(4134), 307-316.

Fellet, M. (2015). A fresh take on fake meat.

Mejia, M., Fresán, U., Harwatt, H., Oda, K., Uriegas-Mejia, G., & Sabaté, J. (2019). Life cycle assessment of the production of a large variety of meat analogs by three diverse factories. Journal of Hunger & Environmental Nutrition.

Fitzgerald, W. B., Howitt, O. J., Smith, I. J., & Hume, A. (2011). Energy use of integral refrigerated containers in maritime transportation. Energy Policy, 39(4), 1885-1896.

Niles, M. T., Ahuja, R., Barker, T., Esquivel, J., Gutterman, S., Heller, M. C., ... & Vermeulen, S. (2018). Climate change mitigation beyond agriculture: a review of food system opportunities and implications. Renewable Agriculture and Food Systems, 33(3), 297-308.

Hart, S. L. (1997). Beyond greening: strategies for a sustainable world. Harvard business review, 75(1), 66-77.

Cholette, S., & Venkat, K. (2009). The energy and carbon intensity of wine distribution: A study of logistical options for delivering wine to consumers. Journal of Cleaner Production, 17(16), 1401-1413.