Design Life-Cycle

assess.design.(don't)consume

Jessica McPeak

Christina Cogdell, Lauren Mabe

Design 040A A05

16 March 2023

Materials Life Cycle Assessment of the Fender American Vintage II 1957 Stratocaster

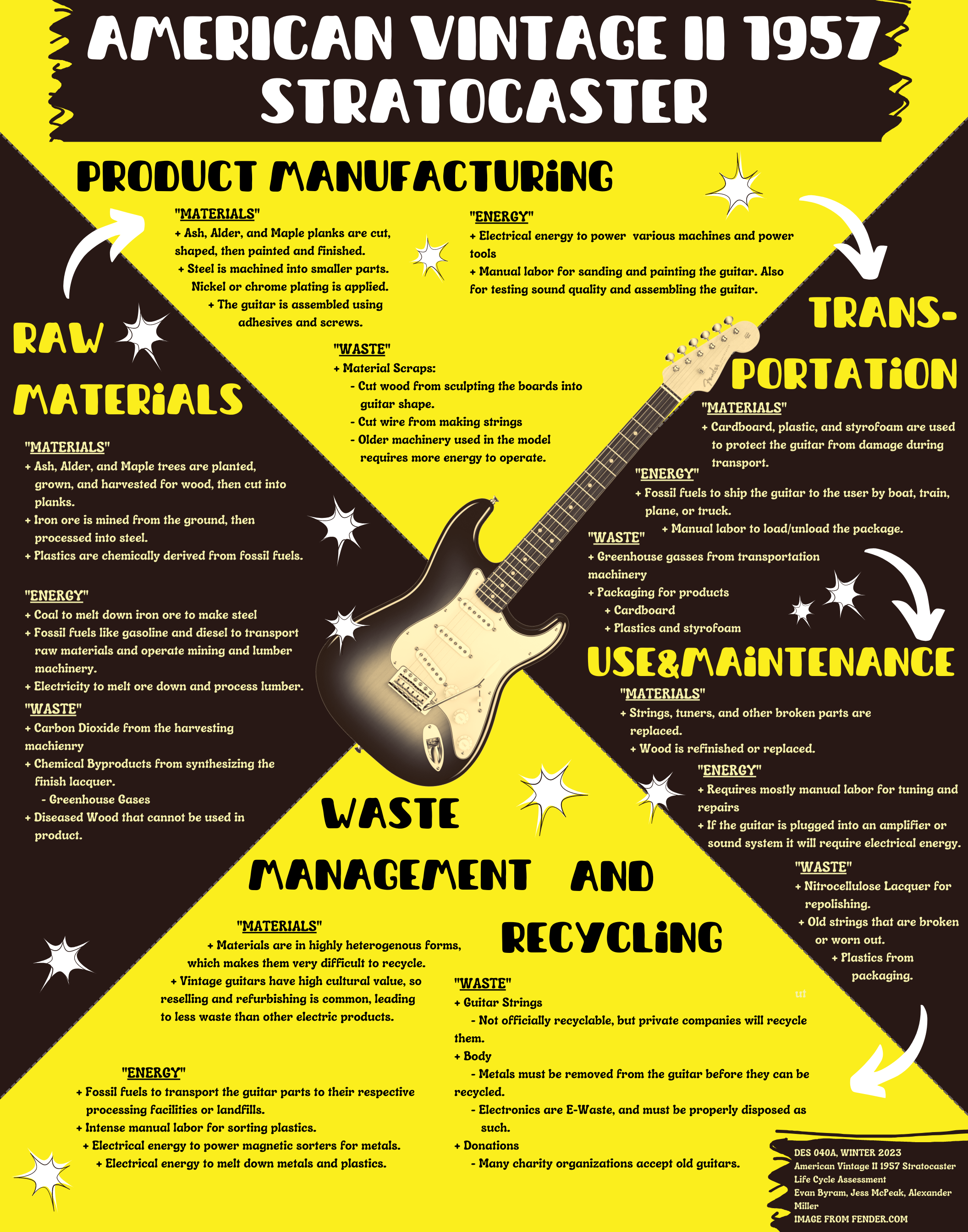

The American Vintage II 1957 Stratocaster is one of the mainline electric guitars manufactured by industry giant Fender. It’s a modern remake of the original Stratocaster model, whose introduction in 1954 highly influenced the development of Rock and Roll music from then on. This paper will focus on the primary and secondary raw materials used during the life cycle of the American Vintage II 1957 Stratocaster, which includes various woods, metals, plastics, finishes, and other materials. This paper will outline the journey of these materials throughout all the phases of the guitar’s life cycle, emphasizing the phases of raw materials acquisition; product manufacturing; and product use, reuse, and maintenance, as these phases are the most relevant to materials.

The life cycle of the Stratocaster begins with harvesting primary raw materials and processing them into secondary raw materials. The raw material that takes up the most volume of the guitar is wood. The body of an American Vintage II 1957 Stratocaster is made from alder or ash wood, depending on the color one buys, and the neck and fingerboard are made from maple wood (Fender, “American Vintage II 1957 Stratocaster”). The acquisition of wood involves planting trees, caring for them and waiting for them to grow, and eventually chopping them down, killing them. The wood is then cut into boards. Trees as a species are a renewable resource, but an individual tree is not. The next most prevalent material is steel, which is derived from iron. The strings, tuners, truss rod, tremolo block, and other small machine and electrical parts of the guitar are made from steel (Fender, “Super 250’s Nickel-Plated Steel Guitar Strings”; Fender, “Pure Vintage Guitar Tuning Machine Set”; Fender, “Pure Vintage Stratocaster® Tremolo Block”). Iron is mined out of the ground as iron ore, then smelted using a furnace, then heated up again while adding carbon in order to create steel ingots. Other metals are also used in smaller amounts. Nickel and chrome are used as hardware finishes (Fender, “Pure Vintage Guitar Tuning Machine Set”; Fender, “Super 250’s Nickel-Plated Steel Guitar Strings”). Copper is used in the wiring for the electronics, and a copper alloy is used for the frets (BRANDMADE.TV). These metals are mined out of the ground as ore, smelted, and processed into their useable forms. The copper alloy is then shaped into fret wire. Another material involved is various plastics. Plastics are used in wood finishes; the body finish for the Stratocaster is approximately 12% nitrocellulose (Saunders and Taylor). Plastics are also used for the pickguard, switches, and covers for electrical parts. Plastics are chemically derived from fossil fuels and colored and molded into the desired look and shape. The nut of the guitar is made from bone. An animal is killed in order to harvest its bones, which are then treated and cut to make the bone into its usable form. After these raw materials are collected and processed into their usable forms, they are most likely sent to Fender’s flagship factory in Corona, California (or possibly to its other factory in Ensenada, Mexico), to begin the next phase of the cycle (Fender, “About | Fender Musical Instruments”).

During the product manufacturing phase, the raw materials collected earlier are further processed and assembled into the Stratocaster. The alder or ash and maple are cut to size, shaped in a CNC machine, and sanded for smoothness, then, paints and finishes are applied to the woods (BRANDMADE.TV). A nitrocellulose finish is used for the body of the guitar to give it a highly glossy look (Fender, “American Vintage II 1957 Stratocaster”). The steel is cut and machined into smaller parts or wound into strings, and nickel or chrome plating is applied. The copper alloy fret wire is cut into fret-sized pieces which are then hammered into small grooves in the neck (BRANDMADE.TV). The plastic is cut for the pickguard and switches (BRANDMADE.TV). During assembly, adhesives and screws are used to permanently and semi-permanently attach the pieces to each other (more about the semipermanent attachments in the maintenance and repair section) (BRANDMADE.TV). After assembly, the Stratocaster is ready for the next phase of its life cycle.

During the transportation and distribution phase, the Stratocaster is taken from the factory to a storage facility for safekeeping until it is bought, then it is taken from the storage facility and shipped to a guitar store or directly to the buyer. To protect the guitar from damage during this phase, various kinds of packaging may be used, such as cardboard boxes for the outer packaging, cardboard sheets and Styrofoam molds to secure the guitar inside the box, and plastic bubble wrap to protect the delicate machine parts. Depending on the guitar’s destination, the transportation and distribution process may involve trucks, cars, planes, or ships, which are made mostly of steel and consume fossil fuels. After the buyer receives the Stratocaster, the next phase of the life cycle begins.

During this phase, the Stratocaster is played, modified, repaired, and maintained by the original buyer, then given away or resold in the secondhand market where it continues to be played, modified, repaired, maintained, and given away or resold. Vintage electric guitars are highly valued in the secondhand market, so there is a high incentive for owners to care for, maintain, repair, and recirculate their Stratocasters, unlike many other electric devices, which often get replaced and thrown away once damaged. The Stratocaster has a modular design, meaning that many of the parts, such as the neck, are semi-permanently attached and so can be taken out and replaced easily, which considerably extends the life span of the guitar (BRANDMADE.TV). Electric guitars are used in conjunction with amplifiers, speakers, effects pedals, recording devices, and other electronic machinery that is made of metals, plastics, and rare elements. Common repairs on Stratocasters include broken strings, broken tuners, which require replacement of the broken part, and wood refinishing. When the Stratocaster reaches the end of its usable life; when it is unable to be repaired or the owner simply doesn’t want to repair it or deems repair too expensive, the final phases of the life cycle begin.

During the waste management phase, the Stratocaster is disposed, and its used materials are dealt with. The alder or ash and maple, having been treated with paints and finishes, are no longer compostable (Think of the Pandas). Plastic takes 20 to 500 years to decompose, so it will sit in landfills unless it is recycled (Chariot Energy). The electronic components of the Stratocaster, while small, contribute to the 1.11-million-tonne e-waste problem when they are thrown away (Kiddee et al.). At the same time as waste management, another phase attempts to close the loop of the life cycle.

During recycling, used materials are processed and made usable again, returning them to the raw materials phase. For the Stratocaster, however, this is a very difficult process. The materials used in the guitar are all highly heterogenous: steel plated with nickel and chrome, woods painted and finished, plastics. This heterogeny is hard to undo without intensive processing, which may require raw materials of its own. However, there are private companies that are making efforts to close the loop. For example, the Playback program recycles used and broken guitar strings (D’Addario). Recycling and waste management represent the “end” of a product’s life, even though the raw materials remain in highly processed forms that can be difficult to reintegrate into the economy or nature.

Fender has been a leading manufacturer of guitars since the 1950s because of the original Stratocaster. Their practices reflect the industry’s standards. How they harvest and process their materials, how they encourage their customers to treat their guitars, and how they address the issue of closing the life cycle loop all influence the direction of the guitar manufacturing industry. Therefore, it’s important to examine how Fender handles this responsibility, and to think about how these practices can be made more environmentally sustainable for the future. While the high level of processing and heterogeneity of the Stratocaster’s materials makes reuse and recycling extremely difficult, some private programs are trying to recycle some of the Stratocaster’s materials. The long life span of the guitar helps offset the cost as well, as Richard McDonald, Senior Vice President of Fender (at the time of production), notes: “[he sees] guitars all the time, they’re 1954 Strats, they’ve been in service since the day they were made” (BRANDMADE.TV).

Works Cited

Chariot Energy. “How Long Does It Take for Plastic to Decompose?” Chariot Energy, 10 Feb. 2021, https://chariotenergy.com/blog/how-long-until-plastic-decomposes/.

D’Addario. Recycle My Strings | D’Addario String Recycling Program. https://www.daddario.com/playback/recycle/#@40.77027075200147:-95.93705549677736zoom:4. Accessed 15 Mar. 2023.

Fender. “About | Fender Musical Instruments.” Fender, https://www.fender.com/pages/about. Accessed 15 Mar. 2023.

---. “American Vintage II 1957 Stratocaster.” Fender, https://www.fender.com/en-US/electric-guitars/stratocaster/american-vintage-ii-1957-stratocaster/0110232803.html. Accessed 9 Feb. 2023.

---. “Pure Vintage Guitar Tuning Machine Set.” Fender, https://www.fender.com/en-GB/parts/tuning-machines/pure-vintage-guitar-tuning-machine-set/0992074000.html. Accessed 10 Feb. 2023.

---. “Pure Vintage Stratocaster® Tremolo Block.” Fender, https://www.fender.com/en-GB/parts/bridges/pure-vintage-stratocaster-tremolo-block/0019473049.html. Accessed 10 Feb. 2023.

---. “Super 250’s Nickel-Plated Steel Guitar Strings.” Fender, https://www.fender.com/en-US/accessories/strings/super-250s-nickel-plated-steel-guitar-strings/0730250403.html. Accessed 15 Mar. 2023.

How a Fender Stratocaster Guitar Is Made - BRANDMADE.TV. Directed by BRANDMADE.TV, 2015. YouTube, https://www.youtube.com/watch?v=eJ0fVGA0pOo.

Kiddee, Peeranart, et al. “Electronic Waste Management Approaches: An Overview.” Waste Management, vol. 33, no. 5, May 2013, pp. 1237–50. DOI.org (Crossref), https://doi.org/10.1016/j.wasman.2013.01.006.

Saunders, C. W., and L. T. Taylor. “A Review of the Synthesis, Chemistry and Analysis of Nitrocellulose.” Journal of Energetic Materials, vol. 8, no. 3, Aug. 2006, pp. 149–203, https://doi.org/10.1080/07370659008012572.

Think of the Pandas. “Is Wood Biodegradable? Can It Be Composted?” Think of the Pandas, 13 May 2022, https://thinkofthepandas.com/2022/03/10/is-wood-biodegradable-can-it-be-composted/.

Evan Byram

Dr. Christina Cogdell

DES 40A

16 Mar. 2023

Energy Used in the Lifecycle of a Fender American II Vintage ‘57 Stratocaster

No electric guitar has reached such legendary status as the Fender Stratocaster. Used by rock and roll legends such as Buddy Holly, Jimi Hendrix and David Gilmour this guitar born in the 50’s revolutionized the sound and play-style of electric guitars, and by extent, rock and roll itself. The more modern American Vintage II 1957 Stratocaster (AVS) is meant to replicate the sound and feel of the original Stratocaster released in 1954 (Fender, “American Vintage II 1957 Stratocaster”). These guitars are manufactured in Fender’s headquarters in Corona, California and distributed to guitar players all over the world, but this process—from pulling raw materials out of the ground to manufacturing the guitar, to holding it in your hands—requires energy. During its lifecycle, the AVS requires the most energy during the raw materials acquisition and manufacturing phases because of its use of lumber and the lack of recycling used in steel manufacturing. But the AVS is a sustainable product in terms of energy use overall because of its long lifetime and easy repairs during the use, reuse and maintenance phase of its lifecycle.

The design and layout of the AVS is quite standard. It has the iconic double-horned body made of alder wood, and a neck made of maple wood. On the neck of the guitar is the fret board and different notes are played when the strings are pressed against different frets. Inside the fretboard there is a steel truss rod that works to counteract the tension of the strings so the neck doesn’t bend. The vibration of the guitar strings is captured by three different pickups and converted into an electrical signal which can be amplified. Each pickup captures a certain type of vibration and adjusting the pickup that is being used by changing the position of the switch can produce a wide variety of sounds. The tone of the sound and the volume can also be controlled using three knobs on the front of the guitar. The guitar also has a tremolo which works to counteract the tensile forces of the guitar strings acting on the neck and body of the guitar. You can control the position of the tremolo using the tremolo arm which changes the tension of the stings to alter the pitch of the guitar. The electronic parts and the tremolo can be accessed by removing plastic plates on the front (the pickguard) or the back of the guitar, respectively. The pickups, the switch and the knobs are all wired together using vintage cloth-covered wire (Fender, “Pure Vintage ’57/’62 Stratocaster Pickup Set”) and connected to an output jack where the guitar can be plugged into an amplifier. Most electric guitars have a very similar layout because the Stratocaster became a standard model for other guitars.

That is how the AVS is put together in its final state, but every material used in the guitar came from the Earth at some point as a raw material. The acquisition of the raw materials for the guitar is the most energy intensive phase of the life cycle. One has already been mentioned, which is the wood used in the body and neck of the guitar. Energy has to be used to harvest the trees the wood comes from and also to process the wood into sheets that can be cut to the shape of the guitar. It requires a total of 6,430 MJ of energy to produce one cubic meter of cut hardwood from raw logs, 91% of which comes from burning fossil fuels or wood waste and the rest from electricity (Bergman and Bowe). Using a rough estimate, I will assume that the AVS is cut from about one twentieth of a cubic meter, so only 322 MJ are used to acquire the wood for one guitar. The next major material used in the AVS is steel, which is used in the guitar strings, the fret board, tuning knobs, the tremolo, and circuit components. The raw material for steel is iron ore, and about 60% of the steel that is produced does not contain any recycled steel (Harvey). Since this is the majority of steel that is produced and Fender’s source of steel was not information I could find, I will assume that the steel used in the AVS is not recycled steel. The process of mining and processing iron ore is also very energy intensive because tunnels need to be drilled into the mines, then the rock needs to be exploded to break apart, then they get transported to the surface where they are grinded down into fine particles to release the ore. Overall, these processes require 152.7 MJ per ton of ore, most of which comes from diesel fuel to run the mining machinery (Norgate and Haque). Then to make steel the ore need to be melted and purified in furnaces, which requires 15-24 GJ per ton of steel; and based on annual data from 2011-2015 the fuel use is about 87% coal and 13% electricity (Harvey) (these numbers include the energy used to make new steel from recycled steel, so they aren’t completely accurate based on the assumption made). Using more recycled steel could cut the energy cost by a significant amount, but currently there are many different alloys of steel that aren’t able to be sorted properly, so when they are being melted down they can’t always be combined into a usable product because they would have too many impurities. Again, an AVS will not require a full ton of steel and it is likely that it only used close to a pound which would require approximately 10 MJ of energy, including the energy to mine the ore. Overall, the processes of acquiring lumber and iron ore and processing them to a point where they can be used to manufacture the AVS are the most energy intensive parts of the life cycle of the guitar, but there are many other materials used in the guitar that would increase the total energy costs of collecting and processing raw materials.

After raw materials have been processed they get shipped to the Fender factory in Corona, CA where they can be put together to actually make the guitar where it can then be shipped to guitar players all over the world. This process is not too energy intensive as it’s more a matter of assembly than anything else. The main contributor of energy in this phase of the lifecycle would be the shipping of the materials into the factory and the guitars coming out of it. Inside the factory, the manufacturing of the AVS starts with the wood sheets for the body and neck of the guitar. These are cut to shape using a CNC machine to get a precise shape and it also leaves cavities where the circuitry and tremolo can be inserted later. The next step is sanding which is done using manual labor and belt sanders because of the irregular shape of the guitar (Brandmade.tv). Most of the manufacturing after this point is done manually with some assistance from machines for cutting parts to the right size and applying an even and precise layer of finish onto the guitar. It is most likely that all the machines used in the factories are powered by electricity. An estimate of how much energy manufacturing a guitar consumes is impossible based on the data available and due to how many different machines and tools are being used inside the factory. After the guitar has been tested for good sound quality and to make sure everything is working properly, it gets packaged and can then be shipped anywhere in the world. This makes a specific energy estimate difficult as well, but what can be said is that the guitar would be shipped by boat, plane, train or truck and would be sharing the fuel consumption of the vehicles across the other products that it's being shipped with, so the individual energy consumption of the guitar will be very small. However all the energy used in distributing the guitar would likely come from fossil fuels and maybe a little bit of manual labor to load and unload the package.

Once a guitar has been shipped and gets delivered to the user, either by online order or being bought at a store, it can begin its long life of producing music. The use phase of the AVS is the least energy intensive and contributes the most to the overall sustainability of the guitar. The guitar itself does not consume any energy on its own because it does not have an internal power supply, but it can be plugged into amplifiers to produce a clearer sound, and based on the amplifiers Fender recommends for their Stratocasters, they would require 180-660 watts (Fender, Anniversary Stratocaster 1954-1979). The use of an amplifier is completely optional, however, and really depends on how the buyer intends to use the guitar. If the buyer is in a band and plays frequent gigs they would consume more energy from using the guitar because it would be hooked up to amps and sound systems etc., but if they’re just learning guitar or only playing for themselves, the energy impact would be much less. Taking care of the guitar is simple due to the AVS being designed to make repairs easy for the user. There are two plastic plates of the guitar and they can be removed to access the tremolo and the circuitry of the guitar, so if anything breaks, parts can be easily replaced and it won’t compromise the functionality of the guitar. There are a lot of things that can be adjusted on the guitar too, which serve two purposes: they can customize the sound of the guitar to the user’s liking and fix anything that comes out of place or alters the sound in a bad way. For example, if the strings become too loose or too tight, the plate of the back of the guitar can be removed and the tension can be adjusted using the tremolo. If the strings break or the neck gets bent from the tension of the strings, they can be easily taken off and replaced with new parts. All the repairs and adjustments can be done with a simple screwdriver (Fender, Anniversary Stratocaster 1954-1979) which gives the user a lot of control over when to do them and greatly reduces their energy impact because they don’t require any heavy machinery. All of this means that the AVS is designed for a long lifetime which reduces the energy consumption of the guitar overall because they need to be manufactured less frequently since they aren’t designed for disposal. The only things that could really end the use phase of the guitar would be the body being damaged beyond repair or for stylistic reasons since the lacquer coating of the guitar yellows with age.

When the guitar reaches the end of its life the materials need to be disposed of or recycled if they can be. The main things that occur in this phase of the life cycle are the recycling of the steel and the PVC used in the plastics of the guitar, and the disposal of the wood body and neck. This phase of the lifecycle is also energy intensive relative to other phases of the life cycle because of the need to transport the guitar to processing facilities. Since the AVS is electronic, it should be disposed of as electronic waste. The electronic components are sorted by hand at special electronics recycling facilities, which requires a lot of manual labor for disassembling and sorting out recyclable materials. The main thing that would be recycled from the AVS would be copper wires used for wiring and the pickups. The process of recycling copper uses electrical energy for sorting the copper from other metals and melting it down, and overall uses one sixth the energy that is used to make copper from ore (Kang and Schoenung). Once the electronics have been sorted out, what is left is steel, wood, and PVC. These parts also have to be separated from each other and disposed of or recycled independently. The wood can not be recycled because it has been treated with a primer, paint and a lacquer finish during the manufacturing process and would likely end up in a landfill since it would be difficult to separate the layers. Steel is recycled by melting it down with raw iron ore to remove impurities and, unlike manufacturing steel from ore, most of the energy comes from electricity, totaling 1.3-6 GJ per ton of recycled steel (Harvey). Using the same assumption as before, the AVS would use about one pound of steel which would require 1.8 MJ of electricity. Recycling PVC follows similar steps to steel. It needs to be sorted by hand, ground down to small pieces and is then melted down with virgin PVC or other plastics to retain some of the original material properties, however the recycled product is not comparable to the original and has a limited range of uses (Sadat-Shojai and Bakhshandeh). Like steel, the sorting process is done by hand and the melting uses electricity. It is probable that the facilities that process and recycle all the different materials are located in different parts of the world, so they would need to be transported to the correct location which would require fossil fuels; which is why the recycling and waste management phase of the AVS lifecycle is energy intensive.

After disassembly and recycling, the AVS is no longer the iconic guitar it once was and its life cycle is over. The energy used throughout its lifecycle is concentrated in acquiring and processing the raw materials for the guitar but because the guitar is designed to be easily disassembled for repairs and uses durable materials like hardwood and steel the AVS has a long lifetime which works to minimize the overall energy impact of the guitar. In fact, some of the original Fender Stratocasters from the ‘50s are still in use today (Brandmade.tv). The parts of its life cycle that are the most energy, resource, and waste intensive—namely mining, and the use of fossil fuels and lack of recycling in steel production—can be made more sustainable by using more recycled steel which can be produced largely through electricity powered by renewable sources. This would consequently scale down mining operations and decrease energy and material inputs. With elements of sustainable design already present, and the legacy of other Fender guitars behind it, the AVS is set up for a long lifetime and a greener future where it can continue to shape music as we know it. .

Works Cited

Bergman, Richard D., and Scott A. Bowe. “Life-Cycle Inventory of Manufacturing Hardwood Lumber in Southeastern US.” Wood and Fiber Science, Jan. 2012, pp. 71–84.

Brandmade.tv. “How a Fender Stratocaster Guitar Is Made.” YouTube, 7 Dec. 2015, https://www.youtube.com/watch?v=eJ0fVGA0pOo.

Erlewine, Dan. Guitar Player Repair Guide: How to Set up, Maintain, and Repair Electrics and Acoustics. 3rd ed., Backbeat Books, 2007.

Fender. “A Strat Is Born.” YouTube, 26 Mar. 2012, https://www.youtube.com/watch?v=1MnylRaQC3w.

---. “American Vintage II 1957 Stratocaster.” Fender, https://www.fender.com/en-US/electric-guitars/stratocaster/american-vintage-ii-1957-stratocaster/0110232803.html. Accessed 9 Feb. 2023.

---. Anniversary Stratocaster 1954-1979. CBS Musical Instruments, 1979, https://fendercustomersupport.microsoftcrmportals.com/en-us/knowledgebase/article/KA-01959.

---. Fender Amer. Vin. Strat Pickups Set of 3 Wiring Diagram. Fender Musical Instruments, 19 Nov. 2013.

---. “Pure Vintage ’57/’62 Stratocaster Pickup Set.” Fender, https://www.fender.com/en-GB/parts/stratocaster-parts/pure-vintage-%E2%80%9957%E2%80%9962-stratocaster-pickup-set/0992117000.html. Accessed 10 Feb. 2023.

Glancey, Jonathan. Fender Stratocaster: A Design Icon at 60. https://www.bbc.com/culture/article/20140904-fender-stratocaster-guitar-hero. Accessed 6 Mar. 2023.

Harvey, L. D. Danny. “Iron and Steel Recycling: Review, Conceptual Model, Irreducible Mining Requirements, and Energy Implications.” Renewable and Sustainable Energy Reviews, vol. 138, Mar. 2021, p. 110553. DOI.org (Crossref), https://doi.org/10.1016/j.rser.2020.110553.

Kang, Hai-Yong, and Julie M. Schoenung. “Electronic Waste Recycling: A Review of U.S. Infrastructure and Technology Options.” Resources, Conservation and Recycling, vol. 45, no. 4, Dec. 2005, pp. 368–400. ScienceDirect, https://doi.org/10.1016/j.resconrec.2005.06.001.

Norgate, T., and N. Haque. “Energy and Greenhouse Gas Impacts of Mining and Mineral Processing Operations.” Journal of Cleaner Production, vol. 18, no. 3, Feb. 2010, pp. 266–74. ScienceDirect, https://doi.org/10.1016/j.jclepro.2009.09.020.

Sadat-Shojai, Mehdi, and Gholam-Reza Bakhshandeh. “Recycling of PVC Wastes.” Polymer Degradation and Stability, vol. 96, no. 4, Apr. 2011, pp. 404–15. ScienceDirect, https://doi.org/10.1016/j.polymdegradstab.2010.12.001.

Saeki, Y., and T. Emura. “Technical Progresses for PVC Production.” Progress in Polymer Science, vol. 27, no. 10, Dec. 2002, pp. 2055–131. ScienceDirect, https://doi.org/10.1016/S0079-6700(02)00039-4.

Smil, Vaclav. “The Rising Importance of Electricity.” Energy in World History, Westview Press, 1994, pp. 31–44.

Alexander Miller

DES 40A

Professor Cogdell

Lauren Mabe

16 March 2023

The Waste Produced by the Manufacturing of the American Vintage II 1957 Stratocaster

In 1954 Fender released their second model of electric guitar known as the Stratocaster. This new model built upon its predecessor, the Telecaster, by “boasting a comfort contoured body, advanced electronics and a built-in, pitch shifting vibrato system” (Duffy, Siegle, Fender) The Stratocaster has become a staple electric guitar in the industry, and is used by myriad popular musicians. Throughout the company’s history Fender has been committed to being the “Ford” of guitars ensuring that they are manufactured with cost effective materials while still maintaining quality (Harrington, The Washington Post). Additionally, despite the wood heavy nature of their guitars, Fender has managed to maintain a low amount of negative environmental impact in regards to wood cultivation by ensuring that the trees used in production are replanted after being cut down. Fender has created a “tonewood forest” consisting of trees solely for the purpose of being made into guitars (Gibson, Warren, The Conversation). However, despite attempts by Fender to incorporate more eco-friendly means of production for their electric guitars, the waste produced and the high amounts of natural resources harvested during the manufacturing process still poses harm to the environment.

For 70 years Fender has made their Stratocasters out of “swamp ash” wood found in wet areas in the Eastern United States; however, due to climate change causing many of the rivers where the wood was harvested to flood and an invasive insect known as the Emerald Ash Borer decimating a large amount of North American trees, Fender has had to switch to a different wood to maintain production. Currently Fender uses Alder as the model of wood for their guitars while still offering an Ash option, albeit at an increased cost due to its sourcing issues (Vlamis, Insider). Fender being so environmentally conscious has allowed for a very limited amount of waste to be produced from the wood harvesting process. The primary source of waste is wood that has rotted and any lumber that has some sort of defect that makes it out of line with Fender’s quality standards.

Ash and Alder are the wood options for the body of the guitar, at least for the American Vintage II 1957, but there is another wooden section on the guitar which uses a different type of wood than the previous options, the fingerboard. As the name implies, the fingerboard is the location where the guitarist puts their fingers and presses on the chords to fret the chords causing different notes to be played. For the American Vintage II 1957 model Stratocaster Maple wood is the only available option for the fingerboard. Primarily grown in the northeastern United States, though going as far south as Florida, Maple wood presumably follows the same guidelines and quality assurance practices that Alder and Ash do (Godman, Yawney, Tubbs, USDA). Thus, it is highly likely that there is minimal to no waste byproduct from the harvesting of the Maple wood. While the woods used in Fender’s Stratocasters may be sourced by them, it is unclear whether or not the finish used on the body, nitrocellulose, is produced by Fender or not.

Nitrocellulose, also known as Cellulose Nitrate, is produced from a combination of nitric and sulfuric acids. It does not appear to have any byproducts or losses in its synthesis (McKean, 293). Sulfuric and Nitric acids are made with an efficiency of 98%, only losing 2% percent in the chemical synthesis process (Cheremisinoff, Rosenfeld). Despite this high efficiency, both Nitric and Sulfuric acids are resource heavy and require high levels of sulfur to produce along with a myriad of other chemicals. Throughout the multitudes of chemical processes required to produce the two acids many harmful byproducts are produced including high levels of Carbon Dioxide and Nitrous Oxide, both of which are greenhouse gasses. Additionally, the fossil fuels used in the machinery that harvests the woods and sulfur would also produce high amounts of Carbon Dioxide emissions. The same can be said about the machines that harvest the metals used in the guitar strings as the strings are made out of nickel plated steel (Fender). Regardless of their eco-friendly model towards the harvesting of wood, the nature of gathering and producing the resources needed to manufacture the American Vintage II 1957 model Stratocaster still produce high amounts of waste.

The waste produced from the actual manufacturing process is not negligible either. According to Fender “much of the American Vintage II hardware is still manufactured on the original ‘50s and ‘60s era Fender factory machines” (Fender). It can be reasonably assumed that ,regardless of the fact that these machines are being continually maintained and ensured that they remain operational, they are much less efficient than modern hardware. Most likely they require more electricity for less output. Along with electricity, time is also a big component of the manufacturing process being wasted. The older machines being slower means that it will take longer for each individual guitar to be made, and considering that Fender guitars have handmade elements in conjunction with the machine made components a lot of time goes spent waiting for the automated components to finish production (Jones-Fielder, Blake, Insider). In addition to time and energy, there is also material waste to be considered during the manufacturing process.

In the factory, the lumber used in the guitar is sculpted to the shape of the guitar model. The wood cut off from the board becomes scrap and is not used at a different point in the manufacturing process. It appears that they do make a pen from the unused wood, but it seems to only be sold in Lichtenstein and cannot be purchased online (Fender). It does seem curious that they make or have made, depending on whether or not the pen is still sold, a product that addresses their waste issues and have decided to either limit its release or discontinue it all together. On the Fender website wooden bookmarks, bookends, and cutting boards are sold. These are all products that could utilize the extra wood left over from the carving process, but for some reason are not. Wood is not the only material that produces scrap during the production process, wire is a big scrap producer as well.

As wood gets lost when cut or shaved off the main plank, wire scraps are produced when cutting to get the ideal string length. However, unlike the wood scraps where there was at one point a use to them, the wire byproduct has no given purpose. Though not ideal, this makes sense. The Fender USA 250R Nickel Plated Steel .010-.046 Gauges strings that come with the American Vintage II are priced at $5.99 in a replacement package of six (Fender). With each string roughly the price of a dollar any small piece of scrap cut from the wire is likely worth so little that its loss is negligible to the company. The same thing could be said about the Nitrocellulose Lacquer that makes up the coating on the guitars. There is a loss as not all of the lacquer gets sprayed properly onto the guitar, but the amount that misses it is so little that it would probably cost more to make a machine that precisely coats the guitar. Once all of these processes have been completed the guitar is packaged and shipped to either a store or a client directly.

Fender’s guitars come packaged inside a recyclable cardboard box wherein the guitars are wrapped in a foam bag that is also recyclable. The packaging itself does not produce much waste as all of the parts included are easily recyclable. The greatest waste from this section would not come from the packaging, but rather the means of transportation to deliver the guitars. Considering that Fender ships domestically and internationally from their warehouse in Corona, California the emissions resulting from transportation must be sizable. Once the guitars arrive at their destination and are purchased by customers, the rest of the waste falls on the hands of the purchaser.

During the lifetime of a guitar for some reason or another it will need maintenance. A can of Nitrocellulose Lacquer spray can easily be disposed of once the can is empty as it is made of a recyclable metal. Difficulties arise when parts such as strings or electronics need to be replaced. Once a new set of strings are put on a guitar the old set should not be simply thrown away, but they also cannot be easily recycled either. The government does not recognize guitar strings as a recyclable substance, and thus most people instinctively throw them away. Companies such as D’Addario and Ernie Ball allow guitarists to send in their old strings so that they can be melted down and repurposed as new strings. D’Addorio even offers incentives such as discounts for people who send in their old strings to be recycled (Bell, KillerGuitarRigs). This is a great way for guitarists to reduce waste in an already wasteful industry. The electronic components are a little more complicated as they cannot simply be recycled as they are. When disposing of guitar electronics one must separate them from the guitar itself, and then remove the metals that are not part of the electronic components. The metals can then be recycled, but the electronics must be disposed of as E-Waste (Recyclist). All of these processes must also be used when disposing of the entire guitar itself, as whole guitars cannot be recycled as is and they should not be thrown away either.

While one could follow all of these procedures and dispose of their guitar, there are a multitude of charity organizations that would gladly accept donations of old guitars. Guitars Not Guns and Guitars 4 Vets are prime examples of these organizations, and they keep old guitars in circulation reducing their waste and allowing those who may not have the chance to get and play a guitar to do so.

Guitars are important pieces of the world’s musical culture, and they provide a lot of entertainment and enjoyment, but the guitar industry is much less enjoyable. The amount of waste created during the manufacturing process of Fender guitars, particularly the American Vintage II 1957 Stratocaster, is extreme and calls into question the ethical nature of the guitar industry. While the harvesting of the woods used is pretty sustainable it is the other materials required that raise concerns. The metals and chemicals used to make the guitars require large amounts of fossil fuels to produce and, in the case of the nitrocellulose lacquer, may even give off carbon emissions as byproducts. There does seem to be a saving grace with the ability to recycle a majority of the parts, but even then the waste caused by making those parts in the first place outweighs the offsets from recycling. What the guitar industry needs at the moment is a solution to the environmental issues caused by manufacturing, so that the industry can continue to thrive and allow for new products to be produced.

Bibliography:

“American Vintage II 1957 Stratocaster®.” Electric Guitars, https://www.fender.com/en-US/electric-guitars/stratocaster/american-vintage-ii-1957-stratocaster/0110232803.html.

Bell, Andrew. “Are Guitar Strings Recyclable?” Killer Guitar Rigs, 10 Oct. 2021, https://killerguitarrigs.com/are-guitar-strings-recyclable/.

Cheremisinoff, Nicholas P., and Paul Rosenfeld. Handbook of Pollution Prevention and Cleaner Production: Best Practices in the Agrochemical ... Industry. Elsevier, 2016.

Duffy, Mike, and Rich Siegle. “Infographic: Fender through the Years.” Fender Historical Timeline | Fender Guitars, Fender, 8 Mar. 2023, https://www.fender.com/articles/behind-the-scenes/fender-through-the-years-a-timeline-of-music-and-instruments#:~:text=Fender%20has%20been%20around%20for,Fender%20Play's%20debut%20in%202017.

“Fender™ Reclaimed Wood Pen.” Lifestyle, https://www.fender.com/en-LI/gifts-for-musicians/fender-reclaimed-wood-pen/9112020102.html.

Gibson Professor of Human Geography, Chris, and Andrew Warren Economic Geography. “Friday Essay: The Guitar Industry's Hidden Environmental Problem - and the People Trying to Fix It.” The Conversation, 12 Sept. 2022, https://theconversation.com/friday-essay-the-guitar-industrys-hidden-environmental-problem-and-the-people-trying-to-fix-it-159211.

Godman, Richard M, et al. “Sugar Maple.” Acer Saccharum Marsh, https://www.srs.fs.usda.gov/pubs/misc/ag_654/volume_2/acer/saccharum.htm.

Harrington, Richard. “Electric Experience.” The Washington Post, WP Company, 10 Nov. 1996, https://www.washingtonpost.com/archive/lifestyle/style/1996/11/10/electric-experience/83d06528-c5f4-46f1-8e39-140780bb2a65/.

Jones-Fielder, Mikala, and Conner Blake. “How Fender Guitars Are Made.” Insider, 3 Sept. 2019, https://www.insider.com/how-fender-guitars-are-made-2019-8.

McKeen, Laurence W. Permeability Properties of Plastics and Elastomers. Third ed., Elsevier, 2017.

“Musical Instruments.” South San Francisco Scavenger Recycling Guide, 4 Apr. 2022, https://ssfs.recyclist.co/guide/musical-instruments/?embeddedguide=true#:~:text=Most%20instruments%20are%20made%20from,are%20commonly%20made%20into%20jewelry.

“Super 250's Nickel-Plated Steel Guitar Strings.” Accessories, https://www.fender.com/en-US/accessories/strings/super-250s-nickel-plated-steel-guitar-strings/0730250406.html.

“Super 250's Nickel-Plated Steel Guitar Strings.” Accessories, https://www.fender.com/en-US/accessories/strings/super-250s-nickel-plated-steel-guitar-strings/0730250406.html.

Vlamis, Kelsey. “A Tiny, Invasive Bug and the Climate Crisis Are Changing How Guitars Are Made, and Shifting the Course of Music History.” Business Insider, Business Insider, 24 Apr. 2021, https://www.businessinsider.com/how-guitars-are-changing-climate-crisis-ash-wood-fender-2021-4.