Design Life-Cycle

assess.design.(don't)consume

Wendy Atriano Pacheco

Maya Kornyeyeva, Ethan Emana

DES 40A, Professor Codgell

March 16, 2023

Design the Life Cycle of a Soccer Ball (Raw Materials)

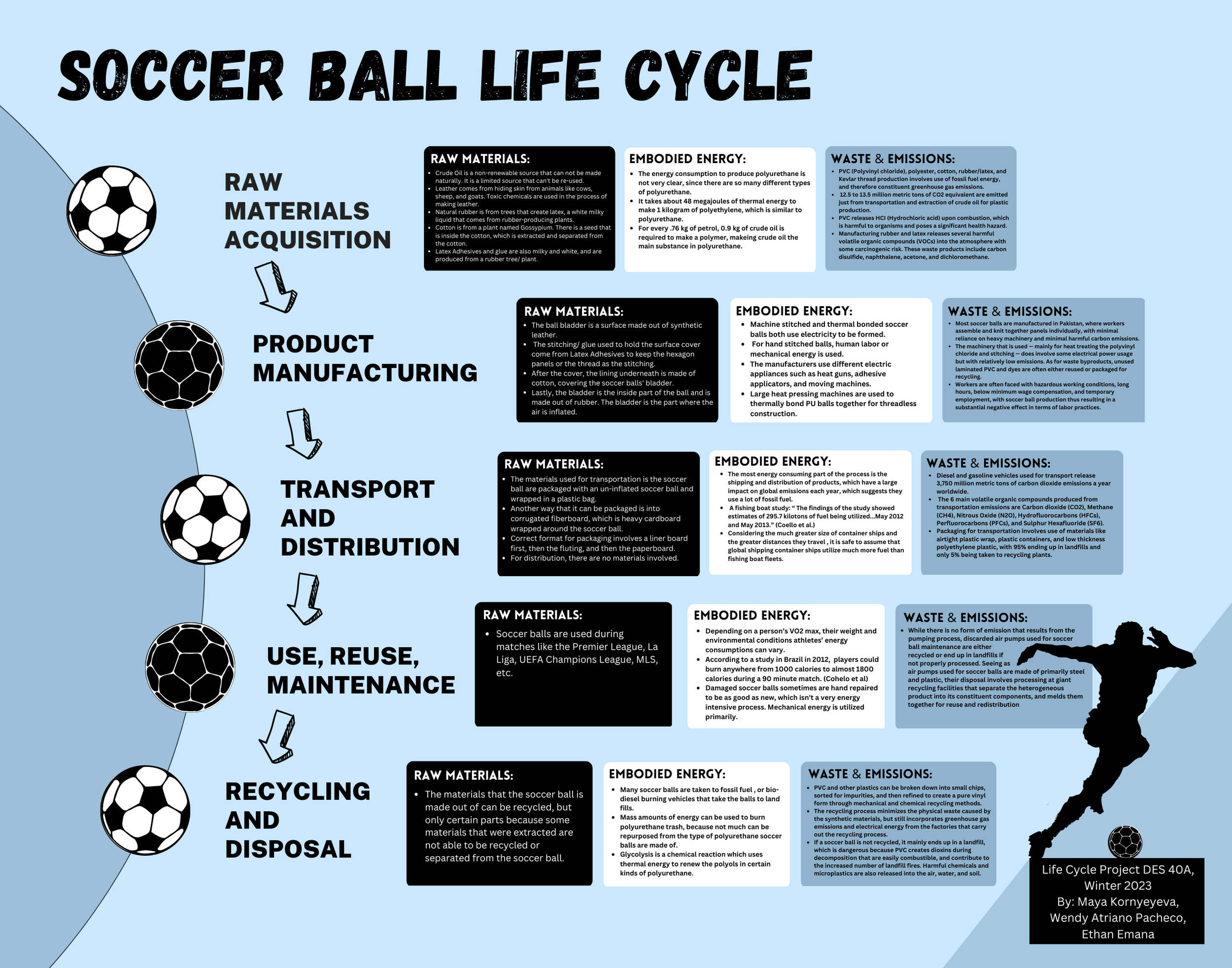

The soccer ball has materials that people make by hand or extract from nature. A soccer ball is a very popular product that people use, and there are so many soccer balls being manufactured every year for tournaments. It contains materials that most people are unaware of. The focus is on raw materials, and the product that will be researched is a soccer ball. Some specific raw materials that soccer balls are made out of are crude oil, leather, natural rubber, etc. This is important because a soccer ball is a product that is made from six different materials and is not what people would expect from a soccer ball.

The source of raw materials in a soccer ball is crude oil, which is a non-renewable source that cannot be produced naturally. It is a limited resource that can be used in products, and it can run out in the future. For example, in Investopedia by Daniel Liberto “crude oil is a raw natural resource that is extracted from the earth and refined into products such as gasoline; it is composed of hydrocarbon deposits and other organic materials that were formed from the remains of animals and plants that lived millions of years ago”. This explains that the materials being extracted have limited resources to be able to make a soccer ball. This source of crude oil is renewable and not able to be made naturally. Another material is Leather comes from the skin of animals like cows, sheep, and goats. Leather has a process like tannery that involves chemicals. Then the next step is the dyehouse, which shows the chemical properties, and when it is finished, leather is made and done. There are toxic chemicals used when making leather. For example, The Life Cycle shows “chemicals and materials that were common and recurring and identified about 48 chemicals and materials that are involved at some point in the leather tanning processes”. This explains why toxic chemicals are being used to make leather and how the material is made out of it. There are toxic bubbles in the river that are harmful to people, who are not able to use the water or drink. Natural rubber comes from trees named Brasiliensis which creates latex, which creates this milky white liquid that is from rubber-producing trees. This plant is limited to making products that need rubber. Also, another material is cotton which is from a plant named Gossypium. Where this plant grows cotton and is harvested. The progress of extracting the seed from the inside of the cotton is first taking the cotton and then finding the seed. Also to be used to plant more cotton. Latex adhesives and glue are similar and come from a rubber garden that produces latex similar to rubber. It's also milky and white, and it comes from a rubber tree and plant. The social impact of all of their raw materials, which are plant-based and renewable, means they are limited in their use in products. It can run out quickly and not have enough. There are health concerns, like the fact that the water used in leather goes into the rivers where people drink.

The product of soccer ball manufacturing is the cover, which is the surface of the soccer ball, and how it has different patterns of color. The bladder surface is made out of leather but uses fossil fuels to make the leather. For example in “The Life Cycle of a Soccer Ball” “The surface of a soccer ball is made from synthetic leather or rubber”. This explains that fossil fuels are being used to make the cover of the soccer ball. The stitching or the glue is used to hold the surface as the cover (using latex adhesives to hold the hexagonal panels) or the thread as the stitching. For example in The Life Cycle of a Soccer Ball, “some balls are stitched together using threads, while other balls use glue to hold the panels together”. This explains how soccer balls can be stitched with a thread or glued by using latex adhesives to put them together. After the surface cover is the lining and the lining is made out of cotton. The lining covers the bladder of the soccer ball. For example, The Life Cycle of a Soccer Ball shows “lining is composed of cotton that is combined with a polyester”. This explains that the lining is important because the soccer ball needs to bounce and be in good condition. Another example: “The lining of a ball plays an important role in its strength, structure, and bounce”. Also, layers of lining are placed between the cover and bladder to make sure the thickness of the ball is the same throughout the panels”. This explains that the weight of the soccer ball plays a huge part in having a good soccer ball and being able to use the soccer ball. Lastly, the bladder is the inside part of the ball and is made out of rubber. The bladder is the part where the air is inflated. For example “bladders made from natural latex rubber provide the softest feeling”. This explains that the bladder is made out of latex, which can last a long time. This is important because it shows the manufacturing of the raw materials used specifically to make a soccer ball.

The raw materials are transported to factories in Pakistan. During the process of extraction, the materials go to Sialkot, Pakistan, to make the soccer ball. The materials used for transportation are the soccer ball, which is packaged with an uninflated soccer ball and wrapped in a plastic bag. For example in the How are Soccer balls package “you’ll generally find that soccer balls that have been shipped in a deflated state will be wrapped in low-density polyethylene as a way of securing them for a customer”. This explains that when the soccer ball is made, it is deflated and wrapped in plastic so the ball is not damaged or scratched before it gets to the client. Another way that the soccer ball can be packaged is in corrugated fiberboard, meaning it is wrapped in cardboard. For example, in How are soccer Balls Packaged “fluffing is essentially an architectural design that uses curves within the confines of a given space to strengthen the structural integrity of corrugated fiberboard, which helps the material resist bending and pressure from all directions”.This explains that there is a good reason for using corrugated fiberboard to secure the ball and have no damage. When it is packaged it is safe it has the best quilty. There is a format of a liner board first, then the fluting, and then the paperboard. Another example from How are soccer ball packaged is “Futing is essentially an architectural design that uses curves within the confines of a given space to strengthen the structural integrity of corrugated fiberboard, which helps the material resist bending and pressure from all directions”.This explains the process by which the corrugated fiberboard is useful in avoiding damage to the soccer ball. For distribution, there are no materials involved.

Soccer balls are used when there are soccer matches like the Premier League, La Liga, UEFA Champions League, MLS, etc. In each tournament, soccer balls are kicked around by professional soccer players. The main one was the World Cup in Qatar, for which Bola Gemma had to produce a large number of soccer balls. After one game, it is reused for another, but it is not reused again because it was not of the highest quality when first used. Each soccer ball shows a sticker that is approved. For example, “one way to ensure quality is to look for a soccer organization's "approval" imprinted on the ball”. This explains that there can be fake soccer balls and real soccer balls that were approved for sale and are of good quality to use. The materials that the soccer ball is made out of can be recycled, but only certain parts because some materials that were extracted are not able to be recycled or separated from the soccer ball. It is important to study the environmental impact because it can show us what the soccer ball would be used for and how it would be used for a short amount of time.

The soccer ball is recycled when it is not being used anymore like being in bad condition and being donated. The pieces of the soccer ball are recycled, but the other materials can sometimes not be recycled. But it can be bad for the environment. For example “Over 40 million soccer balls are produced and must be disposed of every year by FIFA”. This explains how the FIFA brand recycles all the soccer balls they have been using. The materials used in the soccer ball cannot be recycled fully; only some parts of the soccer ball can be recycled. There is importance to the fact that sometimes recycling can be helpful, but sometimes it can be hard to reduce materials that have been used for a soccer ball. Raw materials have effects on the environment and the people making them, causing harm to society. The effect is that soccer balls are destroyed, and some parts are not able to be recycled, and only certain ones are.

The way the soccer ball is managed as waste determines whether it can be recycled, reused, or donated. For example, in “Lifecycle of a Soccer Ball” by Jansnoor Kang “The recycling program also contributes to the overall health and well-being of a community. Fewer landfills mean better property values”. This explains that soccer balls don’t always go to landfills but to recycling centers where the materials can be reused or recycled. There are also nonprofit organizations and animal rescues where animals can play with soccer balls and do some exercise. A non-profit organization can be donated to low-income communities like schools and families. For soccer balls, the waste is managed by reducing the number of balls ending up in landfills and finding solutions for the ball to be recycled. This means you should use a soccer ball as home decoration and find a recycling plant where soccer balls can be recycled as well.

This research on raw materials for a soccer ball explains all the materials that are being used to make a soccer ball and the process by which it is made. Also where the materials being extracted end up in their final phase. What I learned through this research is the importance of knowing that a product can cause so much waste. All the waste ends up in poorer countries. People need to make changes in buying certain products so that they're not buying products that are harmful to the environment.

Bibliography: Soccer Ball Production Raw Material

Liberto, Daniel, et al. “What Is Crude Oil, and Why Is It Important to Investors?” Investopedia, 23 Sept. 2022, https://www.investopedia.com/terms/c/crude-oil.asp#:~:text=Crude%20oil%20is%20a%20raw,lived%20millions%20of%20years%20ago.

Arias, Marina, and Dijk. J Peter “What Is Natural Rubber and Why Are We Searching for New Sources.?” Frontiers for Young Minds, Frontiers, 19 July. 2019, https://kids.frontiersin.org/articles/10.3389/frym.2019.00100#:~:text=Natural%20rubber%20is%20obtained%20from,contain%20rubber%20in%20their%20latex.

Islam Md Nazrul, et al. “Raw Natural Rubber Latex-Based Bio-Adhesive for the Production of Particleboard: Formulation and Optimization of Process Parameters.” RSC Advances, U.S. National Library of Medicine, 24 Aug. 2021, https://www.ncbi.nlm.nih.gov/pmc/articles/PMC9038045/.

Wolf, Nicki. “Where Can You Recycle Soccer Balls.?” Home Guides | SF Gate, SFGATE, 17 Nov. 2020, https://homeguides.sfgate.com/can-recycle-soccer-balls-79392.html

Sadykhov Sima, and Abramson Samara. “Photos Show Time-Intensive, Hands-on Process Where a Factory in Pakistan Makes Soccer Balls for the World Cup.” Insider, 13 Dec. 2020, https://www.insider.com/most-of-the-worlds-soccer-balls-are-made-in-pakistan-2022-12.

Atkin David, Chaudhry Azam, Chaudhry Shamyla, Khandelwal K. Amit , Verhoogen Eric, “Organizational Barriers to Technology Adoption: Evidence from Soccer-Ball Producers in Pakistan.”, The Quarterly Journal of Economics , pp.1101-1164, Oxford University Press, Volume 132, Issue 3, 2017 , https://doi.org/10.1093/qje/qjx010

“Global Soccer Ball Market Size By Type, By Distribution Channel.”, By Geographic Scope And Forecast, Verified Market Research, Report ID:144305, May 2021, No. of Pages 202, https://www.verifiedmarketresearch.com/product/soccer-ball-market/

Waihenya, Samuel. “What Are Soccer Balls Made of.?” (11 Materials Revealed).” Soccer Whizz, 31 Jan. 2023, https://soccerwhizz.com/what-soccer-balls-are-made-from/.

Xu, Yunyun et al. “DNA Soccer-Ball Framework Templated Liposome Formation with Precisely Regulated Nucleation Seeds.” ACS Nano 16, 7, 1 July.2022 : 11004–11010. Web. ,https://pubs.acs.org/doi/full/10.1021/acsnano.2c03575

W. Findiastuti, et al. “Comparative Assessment of Green Ball Manufacturing Alternatives Using Green Productivity Index (GPI).” IOP Conference Series: Materials Science and

Engineering, pp. 1-5, IOP Publishing, 2021,

https://iopscience.iop.org/article/10.1088/1757-899X/1125/1/012106/pdf.

Kang, Jasnoor. “Lifecycle Of A Soccer Ball.”, ArcGIS StoryMaps, Esri, 1 Feb. 2020,

https://storymaps.arcgis.com/stories/ef946b742331425fb773a2d06f6b44f0

Waihenya, Samuel. “How Are Soccer Balls Packaged. ? (Quick Read).” Soccer Whizz, 26 Jan. 2023, https://soccerwhizz.com/how-soccer-balls-are-packaged/.

EPA, Gov. “The Life Cycle of a Soccer Ball - Files.nc.gov.” The Life Cycle of a Soccer Ball, Solid Waste and Emergency Response, Nov. 2005,

https://files.nc.gov/ncdeq/ESI/lifecycle-soccerball.pdf.

Ethan Emana

Wendy Atriano Pacheco, Maya Kornyeyeva

DES 040a, A01

March 16, 2023

Embodied Energy From Cradle to Grave: Soccer Ball

Thesis Statement

Energy plays a crucial role in the production of soccer balls, by allowing the processing of polyurethane type plastics, constructing of materials into balls with different intended purposes, distribution of footballs to a global market, the usage of said balls, and the deconstruction or recycling of used soccer balls.

Sourcing Raw Material

In the early to mid 20th century, leather was the primary material that was generally used to make soccer balls, back when Skailot, Pakistan became the world's soccer ball manufacturing capital. Animal hide leather balls are no longer generally used for playing soccer, due to their excess and absorbent nature, which makes them a worse option for playing than polyurethane and thermoplastic polyurethane balls. For this reason, this paper will not focus on the energy consumption of producing leather for soccer balls.

The energy consumption to produce polyurethane (PU) is not very clear, since there are so many different types of polyurethane. The specific kind of PU used in footballs is not so well defined by the companies that produce PU and thermoplastic polyurethane (TPU) balls, nor is it defined by many scientific journals. This might be because certain companies want to keep technological superiority over other brands that make footballs or because of companies’ inability to control the exact sourcing of their materials. Considering polyurethane, that is to be expected. Supporting that, according to “Worldwide Polyurethane Markets”, in 1980 polyurethane was becoming an incredibly versatile, high in demand product, around the world. (Edwards et al) Exemplifying that there are many applications and different variations in each type of PU.

Another plastic known as polyethylene is similar to polyurethane and is a thermoplastic, meaning it can be broken down and reformed. Polyurethane can be either thermoplastic or thermoset, which is chemically formed and unable to be recycled. Although the energy consumption of polyurethane isn’t readily available, polyethylene is. So in general, plastic production, according to Bruno Gervet’s paper “THE USE OF CRUDE OIL IN PLASTIC MAKING CONTRIBUTES TO GLOBAL WARMING”, takes about 48 megajoules of thermal energy to make 1 kilogram of plastic. (4)

Resource Processing

The resources, polyurethane or thermoplastic polyurethane are made into the various parts of the balls. To make PU, at least in the US, it takes more crude oil than it does petrol to produce polyurethanes. This means that the production of polyurethane is dependent on a fuel source, petrol being that fuel source. According to Gervet, for every .76 kg of petrol, 0.9 kg of crude oil is required to make plastic. (4)

Manufacturing of the Balls

According to Jones et al, “Firms in Sialkot are using multiple technologies to produce footballs like thermal balls, machine stitched balls and hand-stitched balls.” (125). Machine stitched and thermal bonded soccer balls both use electricity to be formed. However for hand stitched balls, human labor and mechanical energy is used. The manufacturers use different electric appliances such as heat guns, adhesive applicators, and moving machines. The video from the FUSION YouTube channel adidas ball factory documenting the factory shows the process of making the balls from start to finish. (FUSION, 2014) Thermal, electric, radiant and mechanical energies are all used to make balls in Pakistan.

Shipping Post Manufacturing

Soccer balls that are shipped worldwide and are produced in Pakistan, China and other developing nations make their global journey on container ships. A study titled “An AIS-based approach to calculate atmospheric emissions from the UK fishing fleet” stated that, “ The findings of the study showed estimates of 295.7 kilotons of fuel being utilized, and 914.4 kilotons of CO2 being emitted between May 2012 and May 2013.” (Coello et al.) Considering the much greater size of container ships and the greater distances they travel , it is safe to assume that global shipping container ships utilize much more fuel than fishing boat fleets. Trucks and Trains are then used to ship the Soccer balls across land and to consumers. Transportation has the highest dependency on fossil fuels than any other portion of global emissions, with 37% of all global emissions coming from transportation. (Hussain)

Usage of Soccer Ball

Ball usage does consume energy depending if one considers the venue and the need for lighting at certain soccer matches. There is also the energy use in the form of lawn mowers and sprinkler systems to maintain real grassfields. There is the energy of vehicles used to transport the balls from playing field to home or field to field ect. These are all conditional, and can vary widely based on different factors.

The usage of the balls, in the context of actually playing football, only consumes metabolic energy in humans, or calories. Depending on a person’s VO2 max, their weight and environmental conditions athletes’ energy consumptions can vary. According to a study of the energy demands of playing football, that took place in Brazil, players could burn anywhere from 1000 kcals to almost 1800 kcals during a 90 minute match. (Cohelo et al, 2) The variation depended mostly on what position a player was filling, some positions are typically more exhaustive than others, also depending on the other team's strategy and personal player strategies.

Sometimes soccer balls do require maintenance to prolong the longevity of their usage. It was because of this phenomenon that it is said that Skailot became the football manufacturing capital of the world. According to Farah Naz and Deiter Bögenhold, in the article “Understanding Labour Processes in Global Production Networks: A Case Study of The Football Industry in Pakistan” the authors state that, “Football manufacturing in Sialkot (Pakistan) dates back to the early 1900s when Sialkot’s leather working caste began to repair and later manufacture footballs for the large British colonial military garrison in Sialkot (Nadvi et al., 2011).” (917-934) Some balls are hand repaired to be as good as new, while for other balls, the price of hand repair or any repair at all may not be worth a user's time and money. Patching could alter the performance of a ball and would not be appropriate for a match. However patching might be appropriate for a practice ball, since it is only a ball for non-competitive use and purchasing an entirely new ball might not be cost effective.

Reuse or Recycling of Soccer Balls

Soccer balls made of thermoplastic polyurethane (TPU) are easily recycled since thermoplastics are able to be melted down and recycled. Thermobonded polyurethane balls, on the other hand, are not as easy to be recycled, since thermoset polyurethane is meant to perform better under high temperatures, making it resistant to being melted down. Polyurethane from soccer balls was not defined as recycled or not, nor was there specific evidence to show that soccer balls had a specific return as another polyurethane product. It can be assumed what happens to soccer balls that are no longer in use. There are probably millions in landfills all over the globe. Garbage disposal companies use large industrial vehicles to move vast amounts of garbage to landfills and then many of the plastic items are incinerated in an industrial sized incinerator. The rigid, strong, flexible, sometimes heat resistant and water resistant plastic that soccer balls are made of can be very difficult to separate from adhesives and other parts of very mixed end-products. (Liang et al, 14220-14221) According to Liang et al, preferable forms of polyurethane are foam type materials and elastomers; the first of which can be mechanically recycled into bedding, carpet underlayings, and cushioning. (14220) Polyols can be recovered through a chemical recycling method known as Glycolysis. Polyols can be used to create new polyurethanes and when they are recovered they can still be used to create more polyurethanes. The reaction requires thermal energy, likely in the form of petrol or butane to heat the mixture. This is a way to rid ourselves of some of the waste products and reduce the demand for more fossil fuel consumption in the form of new polyurethane synthesis.

Conclusion

Energy is the catalyst in order for soccer balls to have a cradle to grave life cycle. Soccer Balls do not consume much energy in terms of their use or production. Most of the labor is manual and machinery is minimal and small scale, in countries like Pakistan and China. The game of soccer only really requires calories to play. The most energy consuming part of the process is the shipping and distribution of raw materials, and exporting of products, which have a large impact on global emissions each year.

Bibliography

1. Edwards, et al. “Worldwide Polyurethane Market.” Urethane Chemistry and Applications ACS Symposium Series, 1981. pubs.acs.org, https://pubs.acs.org/doi/pdf/10.1021/bk-1981-0172.ch001.

2. Gervet, Bruno., and Prof. Bo Nordell. “The Use Of Crude Oil in Plastic Making Contributes to Global Warming.” Department of Civil and Environmental Engineering, 2007. researchgate.net, https://www.researchgate.net/profile/Bo-Nordell/publication/266469821/links/54b296260, cf220c63cd2659f/.pdf

3. Jones, D. S, et al. “Viscoelasticity of Multi-layer Textile Reinforced Polymer Composites Used in Soccer Balls.” Journal of Materials Science, vol. 43, no.8, 2008, pp. 2833-2843. link.springer.com, https://link.springer.com/article/10.1007/s10853-008-2526-0.

4. “How The New World Cup Balls Are Made”, FUSION, June 18, 2014. youtube.com, https://www.youtube.com/watch?v=WzPZi0DxDnA

5. Coello, Jonathan, et al. “An AIS-based approach to calculate atmospheric emissions from the UK fishing fleet.” Atmospheric Environment, August, 2015. researchgate.net, DOI: 10.1016/j.atmosenv.2015.05.011

6. Muhammad, Bilal Hafiz. Supply Chain Management and Importing Footballs From Pakistan, 2016, Central Ostrobothnia University of Applied Sciences, Masters Thesis. Theseus.fi, https://www.theseus.fi/bitstream/handle/10024/111218/Bilal%20Hafiz%20Muhammad.pdf?se.

7. Coelho, Daniel Barbosa, et al. “Energy demand and heart rate evaluation at different phases during a match along an official soccer competition” RBCDH, vol. 14, no. 4, 2012. scielo.br, https://www.scielo.br/j/rbcdh/a/dVKgNqzXggGDXvp93LCNWth/?format=pdf&lang=en. DOI: doi.org/10.5007/1980-0037.2012v14n4p419

8. Naz, Farah., and Deiter Bögenhold. “Understanding Labour Processes in Global Production

Networks: A Case Study of The Football Industry in Pakistan.” Globalizations, vol. 17, no. 6, 2020, pp. 917-934. Taylor and Francis Online, DOI: doi.org/10.1080/14747731.2019.1708658

9. Nadvi, Khalid, et al. “Playing against China: global value chains and labour standards in the international sports goods industry.” Global Networks, vol. 11, no. 3, 2011, pp. 334-354. Wiley Online Library, DOI: doi.org/10.1111/j.1471-0374.2011.00329.x

10. Symington, Annabel. “One Man’s Dream Come True: Making The Official Ball for The 2014 FIFA World Cup.” GlobalPost, April 24, 2014. TheWorld.org,

11. Zaheer, Muhammad. “Knowledge on the Fingertips: A Study of Football Production in Pakistan.” Paradigms vol. 13, no. 2, pp. 122-133, 2019. researchgate.net, https://www.researchgate.net/publication/355156505. DOI: 10.24312/1991130217.

12. Liang, Chao, et al. “Material Flows of Polyurethane in the United States.” Environ. Sci. Technol., vol. 55, no. 20, pp. 14215-14224, 2021. pubs.acs.org, https://pubs.acs.org/doi/pdf/10.1021/acs.est.1c03654. DOI: pubs.acs.org/doi/pdf/10.1021/acs.est.1c03654.

Maya Kornyeyeva

Ethan Emana, Wendy Atriano Pacheco

DES 40A, Professor Cogdell

March 16, 2023

Soccer Ball Life Cycle: Waste and Emissions

Soccer is a complex sport that has brought about centuries of cooperation and competition — not only has it unified countries and fans all over the world, but it has also generated an immense economic and social impact (Campelli). However, soccer could not be possible without the soccer ball, an object of precise engineering that allows players to pass, kick, throw, and dribble with ease. Since the invention of the first vulcanized rubber soccer ball in 1855 by Charles Goodyear (Panalytical), the design has gone through dozens of iterations to produce the iconic soccer ball we use today: a sphere of stitched hexagonal and pentagonal panels. Over the course of its life cycle — from raw material acquisition, manufacturing, distribution, maintenance, recycling, and disposal — the soccer ball production process fuses a plethora of synthetic materials and fossil fuel energy to create the beloved object sport fans and players know today. However, every step of development imparts a significant carbon footprint, including waste materials that are not properly recycled and atmospheric greenhouse gas (GHG) emissions that leave an adverse impact on our environment. Beyond manufacturing and shipping emissions, soccer ball production is tainted with allegations of child labor and exploitation of workers, primarily in Pakistan (Shahid). All of these factors contribute to a concerning level of waste and emissions that affects not only the air we breathe, but also our water, soil, and labor practices.

First, let us consider the raw material acquisition process and the corresponding waste and emissions. The primary materials necessary for the soccer ball include polyvinyl chloride, cotton, polyester, butyl rubber, kevlar threading, and latex (Waihenya). The acquisition of these materials involves a plethora of chemical reactions, which transform raw chemical compounds into the rubbery, stretchy, or rigid array of plastics used in the creation of the soccer ball. PVC, or polyvinyl chloride, is the most abundant material present in the soccer ball (30% of the entire makeup, according to Waihenya), and is formed through the polymerization of the vinyl chloride monomer, which involves an exothermic reaction and the addition of heat and UV stabilizers, processing aids, plasticizers, impact/thermal modifiers, flame retardants, fillers, smoke suppressors, biocides and optional pigments for coloration (Burch). Polyvinyl chloride manufacturing is by no means a “green” process. According to the National Institute for Occupational Safety and Health (NIOSH), PVC produces hydrogen chloride (HCI) upon combustion, which is corrosive to body tissue and can cause damage to the lungs and skin if inhaled or touched. PVC also requires fossil fuels and the extraction of natural gas, which relies on drilling into the earth and results in the presence of soil pollutants and methane and carbon dioxide gas emissions. Besides PVC, soccer balls require cotton, polyester, rubber, and latex as primary materials before the start of the manufacturing process. Cotton is a natural material found in cotton plants, and is spun into fibers at large factories to produce thread, textiles, fabrics, and clothing. Polyester, on the other hand, is a largely synthetic material and thus involves a polycondensation reaction and two main materials, purified terephthalic acid and monoethylene glycol (Katz). The manufacturing process of polyester is minimally toxic (NIOSH), but does depend on factory machinery that operates with fossil fuel energy and therefore releases greenhouse gasses into the atmosphere. Rubber and latex production is a similar story, as it is originally an organic compound harvested from rubber trees in Southeast Asia and South America. After the initial collection of the rubber, this raw material is rigorously processed, air dried, and vulcanized to improve resistance and elasticity (H. Huang, et al.). Manufacturing rubber and latex release several harmful volatile organic compounds into the atmosphere with some carcinogenic risk. These waste products include carbon disulfide, naphthalene, acetone, and dichloromethane (H. Huang, et al.).

The long lasting impact of such emissions is quite drastic. Plastic production in general leaves an extremely costly environmental footprint, as its life cycle begins with oil, gas, and coal extraction and burning, which are nonrenewable sources of energy that contribute to global warming. In fact, 12.5 to 13.5 million metric tons of carbon dioxide equivalent are emitted just from transportation and extraction of crude oil for plastic production (S. Cullinane and K. Cullinane). Such large fossil fuel extraction efforts also often require land clearing, deforestation, and the general relocation of indigenous peoples and native animal species, making land unsuitable for agricultural or conservation purposes. Thus, the very basic synthetic materials required for the creation of the soccer ball actually endure a very complex, environmentally damaging process of production and acquisition, and release both harmful chemicals and a wide array of greenhouse gasses that not only pose a health hazard for living organisms, but also impart a long term threat to the stability of our global climate.

Once all of the necessary raw materials have been accounted for, it is time to look at how these materials are cut, melted, sown, and manipulated in the manufacturing process to create the soccer ball. During the manufacturing process, there are five distinct stages of development: the creation of the outer casing, inner lining, bladder, stitching, and valve (Waihenya). Each involves a different manufacturing process, and each results in a different form of emission. The outer casing and panels of the soccer ball are created from polyurethane, or polyvinyl chloride (PVC), which is the third most common synthetic plastic polymer produced in the world (Burch). This material mainly serves to protect the soccer ball from wear and tear (Waihenya), and contains 32 hexagonal and pentagonal panels that are stitched together using stainless steel kevlar or polyester threading. Next is the inner lining, made from cotton or polyester to act as a protective cushion between the inflatable bladder and the outer shell of the soccer ball. The bladder is designed from butyl, natural latex, and carbon latex for air retention, and is a heavier material that can be blown up through the silicone valve that runs from the outer casing of the soccer ball all the way through to the bladder and serves to channel air inside for expansion (Waihenya). The soccer ball manufacturing process can be adapted to both a large and a small factory setting, with a majority of soccer balls (70%) being produced in Sialkot, Pakistan by hand (Shahid). In Pakistan, a limited range of available printing, pressing, cutting, and threading technology is employed in small warehouses, where workers assemble and knit together panels individually, with minimal reliance on heavy machinery and therefore minimal harmful carbon emissions. The machinery that is used — mainly for heat treating the polyvinyl chloride and stitching — does involve some electrical power usage but with relatively low emissions. As for waste byproducts, unused laminated PVC and dyes are often either reused or packaged for recycling (David, et al.). It is important to mention a glossed over aspect of manual soccer ball production in Pakistan, namely the exploitative labor practices of workers in the industry. According to Umar Shahid, a member of the Pakistan Trade Union Defence Campaign, a worker is only compensated about 50 cents per sewn soccer ball, and the process involves very labor intensive work that relies on temporary labor– often child labor– along with hazardous factory working conditions. Additionally, many labor unions that manage to form are attacked or disbanded, making it difficult for workers to improve their situation (Shahid). Thus, in terms of waste and emissions, soccer ball manufacturing itself has a minimal output of airborne, soil, or waterborne emissions, but does involve a substantial negative effect on individuals employed in the production process in Pakistan.

After the merging of these synthetic materials into the identifiable form of the soccer ball, the final product must now be distributed all over the world to meet demand. The top importing countries include the United States, Australia, the United Kingdom, India, and Vietnam (Volza). Seeing as these countries are all vastly situated on the global map, transportation of the soccer ball includes massive greenhouse gas emissions from a wide range of ships, trains, trucks, and cargo planes. To be precise, the average path of the soccer ball includes traveling from 50 to 13,000 miles from origin, followed by another few hundred miles by rail or truck (K. Cullinane and S. Cullinane). Having arrived at its destination, crates of soccer balls are transported by trucks to a great number of venues, including professional soccer retailers, local sports stores, and Amazon warehouses. Doing a little bit of math, that adds up to a whopping 3,750 million metric tons of carbon dioxide emissions a year worldwide, with a majority coming from diesel-based road vehicles. According to The Intergovernmental Panel on Climate Change (IPCC) cited by Cullinane, the six main volatile organic compounds produced from transportation emissions are Carbon dioxide (CO2), Methane (CH4), Nitrous Oxide (N2O), Hydrofluorocarbons (HFCs), Perfluorocarbons (PFCs), and Sulphur Hexafluoride (SF6). Since most transportation methods rely on burning fossil fuels, the primary fuel used by ships and planes is petroleum-based: mainly diesel and gasoline. Both diesel and gasoline acquisition from fossil fuel burning is one of the most detrimental processes to our environment, releasing CO2 into the atmosphere and harmful chemicals like reactive nitrogen into the soil and water (Robert, et al.). Additionally, the process of extracting fossil fuels like coal, oil, and natural gas involves the vast destruction of forested land, and is responsible for the near extinction of species like the Coho Salmon, Sumatran rhino, and the orangutan. Transportation and distribution of soccer balls is perhaps the most environmentally costly step in the life cycle, due to the fact that it releases massive amounts of GHG emissions and involves plenty of plastic packaging, like airtight plastic wrap, plastic containers, and low thickness polyethylene plastic. Plastic takes up to 450 years to break down in a landfill, which is where 95% of plastic is taken when properly disposed of. Even after centuries, plastic continues to degrade into microplastics that infiltrate the soil, air, and water, and likely end up in our bodies, food, drinking water, etc (Findiastuti, et al.).

While not a very large part of the life cycle, soccer balls do require some maintenance after a period of use. Mainly, soccer balls need to maintain their spring and require constant re-inflation to achieve the desired internal pressure. In order to inflate the soccer ball, you need an air pump and a ball needle. While there is no form of emission that results from the pumping process, discarded air pumps are either recycled or end up in landfills if not properly processed. Seeing as air pumps used for soccer balls are made of primarily steel and plastic, their disposal involves processing at giant recycling facilities that separate the heterogeneous product into its constituent components, and melds them together for reuse and redistribution (Katz).

Finally, the last step of the process is recycling and disposal. After a soccer ball is no longer useful in play — due to being broken, deflated, or worn out — the user is faced with a choice of whether or not to recycle a soccer ball. The lifespan of a soccer ball is, on average, 1.5-2 years, but some soccer balls used in professional games are sometimes only used once or twice (Jasnoor). The most sustainable form of disposal for soccer balls is to be taken to a recycling facility, where the soccer ball can be properly taken apart and individual materials can be reused to create something new. PVC and other plastics can be broken down into small chips, sorted for impurities, and then refined to create a pure vinyl form (Jasnoor). There are various means for doing so, including mechanical recycling and chemical recycling. Polyester and some of its polymers are the most widely recycled plastics, since the ester bond in polyesters is susceptible to hydrolysis, methanolysis, and glycolysis that makes this compound suitable for chemical recycling. This recycling process minimizes the physical waste caused by the synthetic materials, but still incorporates greenhouse gas emissions and electrical energy from the factories that carry out the recycling process. If a soccer ball is not recycled, it mainly ends up in a landfill in the importing country. This can be dangerous, as PVC creates dioxins during decomposition that are easily combustible, and contribute to the increased number of landfill fires in the last several decades (Katz). Not recycling a soccer ball can also lead to plastics getting into the soil of the landfill, or harmful chemicals being released into the air if the soccer ball is burnt/ melted down first before being buried.

Studying and properly researching the entire span of waste and emissions created during the life cycle of a soccer ball is both eye opening and crucial to the development of more sustainable means of production. Knowing the social and environmental impact from current processing, shipping, and recycling methods can help consumers and developers in choosing a product that imparts the least negative impact on our planet, while simultaneously protecting workers’ rights. This is why the research in our project slightly differs from life cycle analysis done previously; it contains not only the wide birth of materials used to create a soccer ball, but also the embodied energy utilized throughout the entire process and all of the impacts caused by the stages of development — from cradle to grave. This allows for a more encompassing view of soccer balls as a product, not just an insignificant object bounced back and forth across a field. Ultimately, the soccer ball is responsible for a variety of GHG emissions, from carbon dioxide to reactive nitrogen oxide to methane, and results in the production of nonrecyclable polymer and polyester waste products. These forms of waste and emissions can be minimized through the application of green energy and recycling, which can help reduce the negative impacts resulting from soccer ball materials acquisition, manufacturing, and transportation can have on the world. Moreover, a more environmentally conscious approach to soccer can serve as an example of sustainability in the sports and product industries.

Bibliography: Soccer Ball Production Waste and Emissions

[1] Waihenya, Samuel. “What Are Soccer Balls Made of? (11 Materials Revealed).” Soccer Whizz, 31 Jan. 2023, https://soccerwhizz.com/what-soccer-balls-are-made-from/.

[2] Atkin, David, et al. “ORGANIZATIONAL BARRIERS TO TECHNOLOGY ADOPTION: EVIDENCE FROM SOCCER-BALL PRODUCERS IN PAKISTAN.” The Quarterly Journal of Economics, 2017, pp.1101–1164, Oxford University Press, 2017, https://www.jstor.org/stable/pdf/26372700.pdf?acceptTC=true&coverpage=false&addFooter=false.

[3] W. Findiastuti, et al. “Comparative Assessment of Green Ball Manufacturing Alternatives Using Green Productivity Index (GPI).” IOP Conference Series: Materials Science and Engineering, pp. 1-5, IOP Publishing, 2021, https://iopscience.iop.org/article/10.1088/1757-899X/1125/1/012106/pdf.

[4] Kang, Jasnoor. “Lifecycle of a Soccer Ball.” ArcGIS StoryMaps, Esri, 1 Feb. 2020, https://storymaps.arcgis.com/stories/ef946b742331425fb773a2d06f6b44f0.

[5] EPA, Gov. “The Life Cycle of a Soccer Ball - Files.nc.gov.” The Life Cycle of a Soccer Ball, Solid Waste and Emergency Response, Nov. 2005, https://files.nc.gov/ncdeq/ESI/lifecycle-soccerball.pdf.

[6] The students of KNPE 473 at Queen's University. “The Ecological Footprint of Sport.” The Ball Is in YOur Court Social Change Through and Beyond Sport, Open Library, Fall 2020, https://ecampusontario.pressbooks.pub/theballisinyourcourt/chapter/the-ecological-footprint-of-sport/.

[7] Wilby, Robert, et al. “The Impacts of Sport Emissions on Climate: Measurement, Mitigation, and Making a Difference.” Annals of The New York Academy of Sciences, Vol. 1519, No. 1, 2023, The UC Davis Libraries, 15 Nov. 2022, https://nyaspubs.onlinelibrary.wiley.com/doi/full/10.1111/nyas.14925.

[8] Cullinane, Kevin, and Sharon Cullinane. “Atmospheric Emissions from Shipping: The Need for Regulation and Approaches to Compliance.” Transport Reviews, Vol. 33, No. 4, 2014, UC Davis Libraries, 14 June 2013, https://www.tandfonline.com/doi/full/10.1080/01441647.2013.806604.

[9] Villanueva, A., and H. Wenzel. “Paper Waste – Recycling, Incineration or Landfilling? A Review of Existing Life Cycle Assessments.” Waste Management, Vol. 27, No. 8, 2007, pp. S29-S46, Science Direct, 11 Apr. 2007, https://www.sciencedirect.com/science/article/pii/S0956053X07000712.

[10] ClimateTrade. “The Carbon Footprint of Football.” ClimateTrade, 14 Sep. 2022, https://climatetrade.com/the-carbon-footprint-of-football/.

[11] Campelli, Matthew. “Quantifying the Economic and Social Impact of Football.” Sustainability Report, In Focus, 28 Jan. 2021, https://sustainabilityreport.com/2021/01/28/quantifying-the-economic-and-social-impact-of-football/.

[12] Panalytical, Malvern. “History of the Soccer Ball.” Materials Talks, Malvern Panalytical, 24 Aug. 2021, https://www.materials-talks.com/the-evolution-of-the-soccer-ball/.

[13] Volza. “Global Soccer Ball Export Import Trade Data, Buyers & Suppliers - .” Volza, Grow Global, 20 Dec. 2022, https://www.volza.com/p/soccer-ball/.

[14] Burch, Hilary. “Poly (Vinyl Chloride).” ChEBI, EMBL-EBI, 4 Aug. 2014, https://www.ebi.ac.uk/chebi/searchId.do?chebiId=53243.

[15] Katz, David A. “Science of Plastics.” Science History Institute, 20 Nov. 2019, https://www.sciencehistory.org/science-of-plastics.

[16] H. Huang, et al. “Volatile Organic Compounds Emission in the Rubber Products Manufacturing Processes.” Environmental Research, U.S. National Library of Medicine, 13 May 2022, https://pubmed.ncbi.nlm.nih.gov/35577006/#:~:text=The%20major%20species%20released%20from,o%2Dxylene%20and%20carbon%20disulfide.

[17] Shahid, Umar. “Pakistan: The Struggles of Workers Making Footballs for the FIFA World Cup.” Libcom.org, PTUDC, 25 June 2018, https://libcom.org/article/pakistan-struggles-workers-making-footballs-fifa-world-cup.