Design Life-Cycle

assess.design.(don't)consume

Xinlei Li

Christina Cogdell

Design 40A

15 March 2018

The Embodied Energy in Sanitary Pads’ Life Cycle

Starting from the average age of 12, menstruation periods join in females’ life, and they appear in patterns: most of the women have menstruation at the end of each month, while some of the women have it once every two months. Throughout the history, women have tried a lot of ways to hide the uncontrollable bloody features: ancestors tended to use animal skins, feathers, and other materials that seemed to have higher absorbing ability; in recent times, people used more cotton materials, but new problems about reusing and wasting appeared ; and now, with advanced development of factories’ systems of manufacturing process, transportation, and disposing wastes, females have more options to deal with their physiological body reactions. One of the options is to have sanitary pads. Through the complex life cycle analysis on these products, I will demonstrate the various kinds of energy that are consumed in different levels of productions.

1. Raw Material Acquisition and Manufacturing, Processing, Formulation

The main raw materials used today for sanitary pads are mainly made from cotton. With the development of technology, people invent more synthetical materials including rayon (which is often considered as artificial celluloses), non-woven fabric, paper pulp, and a combination of these materials. In many developing regions, harvesting cotton plantation requires human power (“Transportation of Cotton Cargo”); in developed countries, with advanced technology, producing cotton requires agricultural forces in forms of electricity, diesel, and other sources, which means electrical energy and thermal energy are applied (Welsh). Paper pulping mills have different consumption of energy due to different products, and it’s more common in inking industry, so it’s unsuccessful to find the exact number of energy for sanitary products. In order to acquire rayon, the producers need to cover a long process from purifying, drying, shredding, and aging (“Rayon”).

While the producers of rayon use machines, kinetic and mechanical energy is largely involved, and since the machines made nowadays require electricity to run on, electrical energy is involved as well. The manufacturing process of non-woven fabric is similar as rayon’s, which includes purifying and drying processes, and the producers use machines for some steps as well, but it requires some other complex technology’s combination: “hydroentangling, neddlepunching, thermalbonding, etc. (“Nonwoven Fabric Manufacturing Process: Air/Dry Laid and Carding”).” According to these technology, it’s obvious to figure out that the producers use thermal energy and chemical energy to master the technology. By examining hydroentangling technology, researchers from College of Textiles in NC State University demonstrate the existence of threshold energy. They also find out the relationship between jet pressure and the variable amount of energy (Zheng et al. 43). By examining neddlepunching technology, researchers discuss the elastic energy increasing from 9.7 mJ/m at 0.01 mm/s to 18.1 mN mm/mm at 1.0 mm/s according to the different fiber sliding and pulling-out process (Martinez-Hergueta et al. 64). Thermalbonding technology is basically relied on heat energy in high temperature in order to soften and melt. By transferring heat energy into mechanical energy in equipment like calendars, radiant energy appears.

2. Distribution and Transportation

Fundamentally, distribution and transportation in sanitary pads’ life circle have three transitions: from raw materials to industrial factories, from industrial factories to consumers, and from consumers to waste.

In the transition from raw materials to industrial factories, from the standpoint of global statistics, cotton is mainly exported from countries such as India, China, United States, Pakistan, Brazil, and some other places around the world (“Distribution of cotton production worldwide in 2016/2017, by country”). In these big countries with beneficial and stable resources of cotton, factories can choose local delivery with transportation ways like tractors, overloaded trucks and railroads (“Transportation of Cotton Cargo”). These vehicles require the energy from burning fuels, which is considered as a transformation from thermal energy to kinetic energy.

In the distribution from industrial factories to consumers, companies generally choose the common way like other products, which is to use ocean transport, rail transport, and air transport, and the energy required is basically the same as the vehicles required in the process from raw materials to industrial factories: any kind of energy will eventually transform into kinetic energy (Cao et al. 1). However, since the ocean transport requires water power, the new transformation from water power to kinetic energy is presented.

Lastly, there is the distribution from consumers to waste. This process is simple if people just focus on the distribution part, which is illustrated by consumers’ actions of throwing trash as other common behaviors. There are any researchers calculating the data through this process.

3. Use/Reuse/Maintenance and Recycle

In the process that consumers use the sanitary pads, absorption takes a significant role to help to collect the biological waste from women’s bodies, and the main energy included in the process is electromagnetic energy that is transformed by wave motion (“Absorption”).

Since almost all the sanitary pads that women buy for monthly use are one-time products, it’s hard to tell the reusability by simply discussing the products’ use for menstruation. However, reusable sanitary pads exist, and the material is basically the same while larger portion of cotton is added into the product. Women will use the products and wash it for many times; however, based on the more complicated process of washing and drying, their higher price, and more options like menstrual cup and tampons, the reusable sanitary pads don’t have a large market and enough analyzed data provided.

In order to maintain the sanitary pads in clean conditions, producers have used plastic wrappers and cardboards to pack the products to create non-polluted condition for sanitary pads. Since more materials are applied to sanitary pads in this maintaining process, more energy is required to make the plastic wrappers and the cardboard boxes. The energy required for making plastic wrappers is similar with rayon’s manufacture, which requires kinetic energy and electrical energy. Same kinds of energy are applied on cardboard making.

There is not any access available for manufacturers to recycle one-time used sanitary napkins: there are many things added into the products after being used, including human wastes that should be sorted as landfill. In short, there is no energy cost for recycling part. However, since the cardboard boxes are considered as a part of the products, the recycling process is possible, and a lot of energy could be saved: “recycling one ton of cardboard saves 390 kWh of energy (“Recycling Facts & Tips”).” According to the same resource, WM GI Industries have also found out the energy saved in recycling the plastic materials: “recycling one ton of plastic saves 5, 774 kWh energy.”

4. Waste Management

From the standpoint of the whole life cycle of sanitary pads, there are a lot of wastes produced from the process of acquiring raw materials to the disposal step. Since there are many kinetic energy and mechanical energy appeared for transportation and machines’ use, according to the law of energy conservation, there must be some amount of energy lost in the process, and the energy is thermal energy and kinetic energy of friction (Redish).

Additionally, there is a large amount of energy cost while people try to deal with the wastes in disposal systems. There are several common ways to dispose the waste: simply throwing away the trash in assigned trash collection or random public spaces including water area, burning, burying, and flushing down in toilets (Basu). Water power appears in the process of throwing into water areas and flushing down in toilets. However, these ways can cause pollution problems and also mechanical problems of local water system, so in the process of fixing the issues, human energy is involved. In order to burning the wastes, chemical energy and thermal energy both appear. In the process of burying, chemical and electromagnetic energy are involved to decompose the waste in the dust. In the process of burning, a large amount of thermal energy is required to ignite the cotton materials inside the products, and chemical energy appears in the process of burning biological waste and plastic wrappers accompanied with the products.

In conclusion, throughout the life cycle, the embodied energy to produce, transport, and discard as waste requires various kinds of energy, mainly composed of mechanical energy, chemical energy, and electrical energy as main ones in the whole routine.

Work Cited

Blythe, James. “Transportation of Cotton Cargo.” Skuld, 11 June 2014,

www.skuld.com/topics/cargo/general-cargo/transportation-of-cotton-cargo/.

Britannica, The Editors of Encyclopaedia. “Absorption.” Encyclopædia Britannica,

Encyclopædia Britannica, Inc., 20 July 1998, www.britannica.com/science/absorption-physics.

Cao, Dayong, et al. “Compare for Water Transport and Railway.” MARKET OUTLOOK, 19 May

2009, wenku.baidu.com/view/e54fe32f7375a417866f8f7e.html.

“Distribution of Cotton Production Worldwide in 2016/2017, by Country.” Statista, Nov. 2016,

www.statista.com/statistics/595561/distribution-of-global-cotton-production-by-country/.

“Energy Use Efficiency.” CottonInfo, www.cottoninfo.com.au/energy-use-efficiency.

Laurijssen, Jobien, et al. “Benchmarking Energy Use in the Paper Industry: a Benchmarking

Study on Process Unit Level.” Energy Efficiency, vol. 6, no. 1, 2012, pp. 49–63., doi:10.1007/s12053-012-9163-9.

MartÃnez-Hergueta, F., et al. “Deformation and Energy Dissipation Mechanisms of Needle-

Punched Nonwoven Fabrics: A Multiscale Experimental Analysis.” International Journal

of Solids and Structures, vol. 64-65, 2015, pp. 120–131., doi:10.1016/j.ijsolstr.2015.03.018.

“Nonwoven Fabric Manufacturing Process: Air/Dry Laid and Carding.” Barnhardt Purified

Cotton, 10 Mar. 2016, www.barnhardtcotton.net/blog/nonwoven-fabric-manufacturing-process-airdry-laid-and-carding/.

“Rayon.” How Products Are Made, www.madehow.com/Volume-1/Rayon.html.

“Recycling Facts & Tips.” Waste Management , WM GI Industries,

www.wm.com/location/california/ventura-county/west-hills/recycle/facts.jsp.

Redish, Joe. “Mechanical Energy Loss -- Thermal Energy.” Umdberg, PBworks, 23 Nov. 2012,

umdberg.pbworks.com/w/page/61342878/Mechanical%20energy%20loss%20-

-%20thermal%20energy.

Robinson, John R.C., et al. “Cotton Transportation and Logistics: A Dynamic System.”

Russell, S. J. Handbook of Nonwovens. CRC Press, 2007.

“Tracking Progress: Pulp and Paper.” International Energy Agency, 16 May 2017,

www.iea.org/etp/tracking2017/pulpandpaper/.

Zheng, Huabing, et al. “The Impact of Input Energy On the Performance Of Hydroentangled

Nonwoven Fabrics.” International Nonwovens Journal, 2003,

www.bing.com/cr?IG=BD5F404B1C2A487F8B847F4B2EA467DF&CID=3F8E3EF6D6436AF532463547D7EC6B4E&rd=1&h=otOHpbsJforNW_po9OoHwW1eafiMnEHAxEKUmoEejiw&v=1&r=https%3a%2f%2fwww.jeffjournal.org%2fINJ%2finj03_2%2fp34-44.pdf&p=DevEx,5062.1.

Zaira Escalante

Professor C. Cogdell

Des 40A

March 15 2018

Raw Materials in Sanitary Pads

Menstrual pads have been an essential product in the lives of women when dealing with the monthly menstruation cycles that take place. The earliest form of sanitary pads can be traced back to the early 10th century in Ancient Greece where rags were utilized by women which were commonly made up of either sheep’s wool or cotton as the main material that was used (“The History of the Sanitary Pad”). The concept of these menstrual rags were then later evolved in France when nurses created a disposable pad that they could utilize when in the battlefield during war time, which instead of being made out of sheep’s wool as in the earlier centuries, were created using wood pulp bandages, making them extremely absorbent and easy to dispose after using them (“The History of the Sanitary Pad”). Because of the nurse’s creation this idea was later adopted by commercial manufacturers, such as Johnson and Johnson among others, who began selling the product in the markets to women. During this time in the 1920s, pads were deemed as a luxury item as they were sold at quite expensive rates which could only be afforded by a select few and was viewed as an embarrassing product to have buy for many women, so they would purchase them with much discretion. Nowadays purchasing these hygiene items are not as taboo to purchase as they were in the past and easy to get a hold of, but are still hard to obtain in third world countries where these sources are not as easily available for use. These days there are a wider range of hygienic products that are offered in today’s markets for women to use during their menstrual cycle, varying from the traditional sanitary pad that was first invented, to newer “greener” alternatives such as the diva cup that women can select from with more products developing.

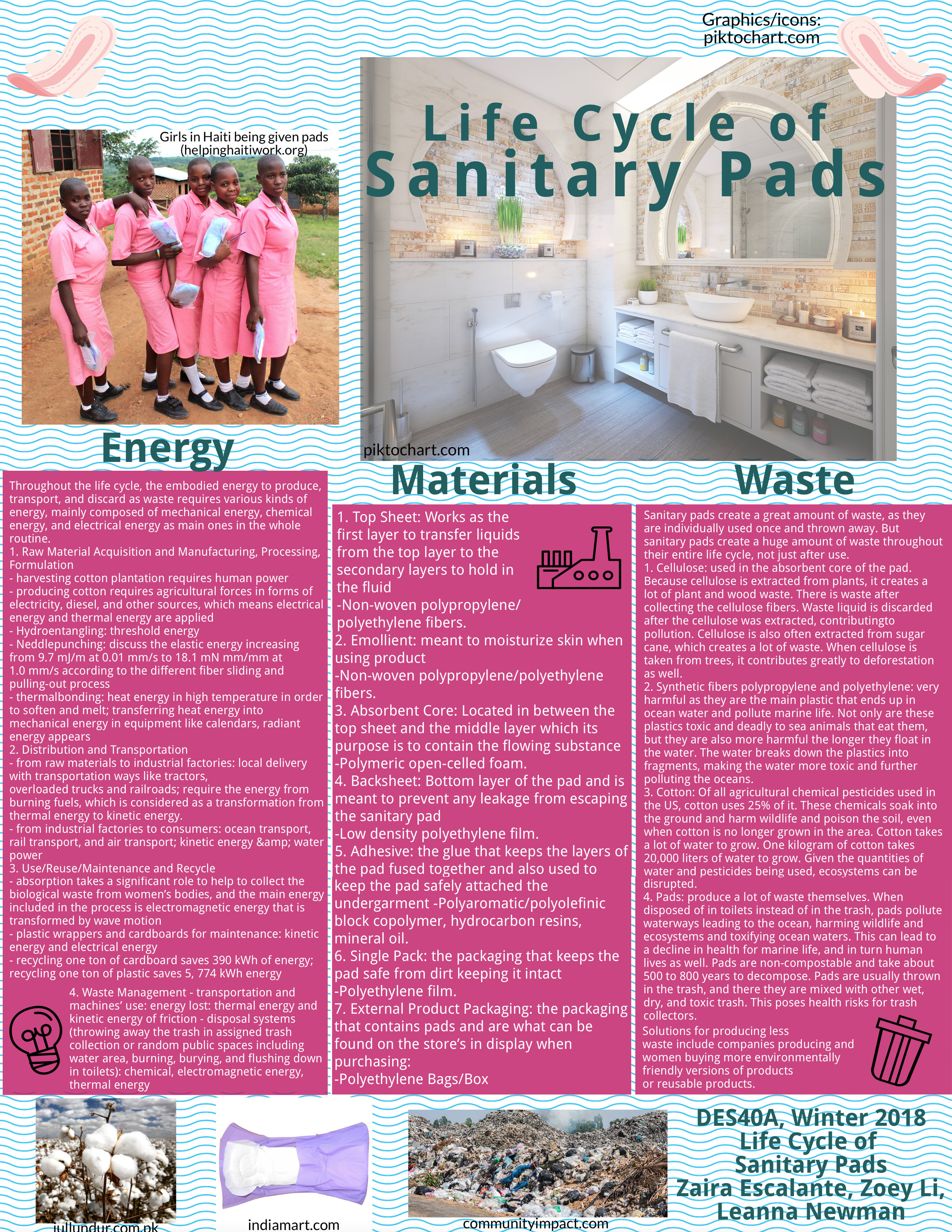

Because of the various types of the pads on the wide range of brands on the market for pads, each contains a few materials that differ from each other, but have an overall similar structure/raw materials used in each design of the pads available for buyers. The sanitary pad is composed by a series of raw materials which are distributed based on the different layers that make up the sanitary pad which includes: the topsheet, emollient, absorbent core, scent, and backsheet. The main design of a standard sanitary pad includes: the top sheet, emollient, absorbent core, backsheet and the adhesive needed to attach the pad to the undergarment. Perfume/scent is optional and varies as some sanitary pads have no fragrance and is not always present as it depends on the production of the pad product. Using scents in these hygienic products is somewhat controversial and has received backlash from the public, as it can potentially impact the natural PH of the vagina, causing imbalance and sensitivity in that area. Each one of these layers serve a different function that work together as a whole to successfully contain the menstrual fluids safe from seeping out of the structure and providing comfort for the wearer. Along with these materials that make up the sanitary pad, packaging for the product is also put into account as they also contain materials that are meant to work to preserve the product for the consumers to purchase in stores.

The first layer of a sanitary pad is the top sheet, which functions as the first layer to transfer liquids from the top layer to the secondary layers below it, to hold in the fluids that comes into contact with the material (“Natural and Sustainable Raw Materials for Sanitary Napkin”). The topsheet of the sanitary pad consists of perforated non-woven fabric of polypropylene/polyethylene fibers that serve to absorb the fluids along with cellulose that can found in this layer. Polypropylene/polyethylene fibers are produced by American Fiber Manufacturer companies such as American Synthetic Fiber among many others that are prominent in the United States. These fibers “are a product of the polymerization of propylene and ethylene gases” (American Fibers Manufacturers Association, Inc). The process to create these fibers is complex as polymerization must be performed under “controlled conditions with special catalysts that give chains with few branches” (American Fibers Manufacturers Association, Inc). Polymerization can be defined as, “any process in which relatively small molecules, called monomers, combine chemically to produce a very large chainlike or network molecule, called a polymer. The monomer molecules may be all alike, or they may represent two, three, or more different compounds” (“Polymerization”). These fibers created by these companies are meant to be comfortable and stain resistant which is ideal in the construction of the sanitary pad as fluids are coming into contact with the first layer. Asides from being found in pads, these fibers can also be found in a series of different items ranging from automotives to industrial products. Examples of this material being used in other items would include these fibers being found in seat construction, sock and other apparel along with being found in common household essentials such as carpets. The second layer of the sanitary pad is the emollient which is meant to moisturize skin when using product and provide overall hygiene benefits. The emollient is also made out of perforated non-woven fabric of polypropylene/polyethylene fibers similarly to the topsheet layer, undergoing the same process of polymerization. In addition to these fibers, the emollient is also made up of a petroleum based formulation which is typically used to soothe the skin from any potential irritation that can occur when wearing the product as it makes direct contact with the skin. Petroleum can also be found in other products that we use such as in vaseline and healing ointments meant to treat the skin.

Under the emollient layer, the absorbent core is located in between the top sheet and the middle layer which its purpose is to contain the flowing substance and where most of the fluids stay. The absorbent core is made out of polymeric open-celled foam which is created through either “extrusion include, extrusion, compression molding, injection molding, reaction injection molding, solid state method (where pressurized gas is forced into a solid polymer at room temperature followed by depressurization and heating to above its Tg) (“Polymeric Foams: An Overview”). The main producers of this growing product include Mexico, South Korea and India among many others who partake in the further developing production of polymeric foam. This polymeric foam can also be found in items such as car seat cushions

The backsheet is the bottom layer of the pad and is meant to prevent any leakage from escaping the sanitary pad. The backsheet is made out of low density polyethylene film with pigments which consists of “derived from either modifying natural gas (a methane, ethane, propane mix) or from the catalytic cracking of crude oil into gasoline” (“The Manufacture of Polyethylene”). This material was first derived from Great Britain, but is now imported to locations such as New Zealand. Other materials that are included in the production of sanitary pads include the single pack which is the packaging that keeps the pad safe from dirt keeping it intact and is made out of polyethylene film as well. The external packaging where the final product is sold in stores also requires the use of polyethylene in its production, and serves as the container to hold the sanitary pads.

The material that holds the whole product together is the adhesive, which is essentially the glue that keeps the layers of the pad fused together and is also what is used to keep the pad safely attached the undergarment. This material consists of polyaromatic/polyolefinic block copolymer, hydrocarbon resins and mineral oil. Polyaromatic block polymers are, “high molecular weight polymers having two or more distinct regions of differing properties” (“Solubilization of Polycyclic Aromatic Hydrocarbons by Poly(ethylene oxide-propylene oxide) Block Copolymer Micelles: Effects of Polymer Structure”). Hydrocarbons are defined as being, “any of a class of organic chemical compounds composed only of the elements carbon (C) and hydrogen (H)” (HydroCarbon). This material is also used in items such as explosives and in other common plastic materials.

Works Cited

A, Barman, et al. “Natural and Sustainable Raw Materials for Sanitary Napkin.” OMICS International, OMICS International, 20 July 2017, www.omicsonline.org/open-access/natural-and-sustainable-raw-materials-for-sanitary-napkin-2165-8064-1000308.php?aid=93070.

Carey, Francis A. "Hydrocarbon." Encyclopædia Britannica. Encyclopædia Britannica, Inc., 06 July 2017. Web. 08 Mar. 2018.

Hochwalt, Anne E., and Kara E. Woeller. "Safety Assessment of Sanitary Pads with a Polymeric Foam Absorbent Core." Regulatory Toxicology and Pharmacology. Academic Press, 05 Aug. 2015. Web. 03 Mar. 2018.

Hurter, Patricia N., and T. Alan Hatton. "Solubilization of Polycyclic Aromatic Hydrocarbons by Poly(ethylene Oxide-propylene Oxide) Block Copolymer Micelles: Effects of Polymer Structure." ACS Publications. N.p., 02 Mar. 1992. Web. 02 Mar. 2018.

Khemani, Kishan C. "Polymeric Foams: An Overview." N.p., 01 June 1997. Web. 24 Feb. 2018.

Kounang, Nadia. “What's in Your Pad or Tampon?” CNN, Cable News Network, 13 Nov. 2015, www.cnn.com/2015/11/13/health/whats-in-your-pad-or-tampon/index.html

Lepoutre, Priscilla. "The Manufacture of Polyethylene." Transpak Industries Ltd, n.d. Web. 01 Mar. 2018.

Roeder, Robert J. “Small Size Sanitary Napkins with Improved Absorption Capability.” Google

Patents, Google, 5 Mar. 1974, patents.google.com/patent/US3865112A/en.

Sabrina. "Sabrina." Femme International. Sabrina

https://www.femmeinternational.org/wp-content/uploads/2016/09/femmeheaderlogo340x156.png, 24 Nov. 2016. Web. 19 Feb. 2018.

Wang, Hu L., and N. J. Mills. "Modelling the Creep of Open-cell Polymer Foams." Journal of

the Mechanics and Physics of Solids. Pergamon, 10 May 1999. Web. 03 Mar. 2018.

<https://www.sciencedirect.com/science/article/pii/S0022509698001161>.

Woeller, Kara E., and Anne E. Hochwalt. "Safety Assessment of Sanitary Pads with a Polymeric

Foam Absorbent Core." Regulatory Toxicology and Pharmacology. Academic Press, 05

Aug. 2015. Web. 06 Feb. 2018.

Britannica, The Editors of Encyclopaedia. "Polymerization." Encyclopædia Britannica. Encyclopædia Britannica, Inc., 06 Apr. 2016. Web. 08 Mar. 2018.

By Kotex, U. “U By Kotex® Ingredients.” Feminine Hygiene Products for Girls – Pads, Liners,

Tampons, Wipes, www.productstewardshipatkc.com/ourbrands/consumer/kotex/1.

"Ingredients - What Goes Into Our Pads And Liners?" Live Fearless. N.p., 2018. Web. 07 Mar. 2018.

“RAW MATERIALS OF THE COMPONENTS OF HYGIENE PRODUCTS.” Consumpediamed, consumpediamed.com/wp-content/uploads/link-impactes_EN.pdf.

"Olefin." American Fiber Manufacturers Association. N.p., 2017. Web. 10 Mar. 2018.

"What's in Always Pads?" Always.com. N.p., n.d. Web. 06 Feb. 2018

Leanna Newman

DES40A

Prof. Cogdell

March 15, 2018

Waste and Pollution of Sanitary Pads

It seems obvious that sanitary pads create a great amount of waste, as they are individually used once and thrown away. But sanitary pads create a huge amount of waste throughout their entire life cycle, not just after use. Pads are from cellulose, polypropylene and polyethylene, and cotton, among other materials, each producing a different type of waste on its own. Pads decompose incredibly slowly and take up a tremendous amount of space in landfills, causing negative environmental impacts. However, new innovation is currently taking place to make sanitary pads both environmentally friendly and easily accessible for women globally.

One major ingredient in sanitary pads is cellulose (“Raw Materials Of The Components…”). According to NutrientsReview.com, cellulose is a complex carbohydrate made of glucose molecules (“What is cellulose?”). It can be extracted wood - more specifically, from cell walls in plants and trees - and is used to make fibers and fabrics (“Definition of ‘cellulose’”). It is also sometimes used in food. Cellulose is very absorbent and in pads is used to ensure better moisture transportation through the pad, and reduces the growth of bacteria within the pads (Barman). Cellulose is also used in the absorbent core of the pad instead of pure cotton, which would be more expensive (Barman). Because cellulose is extracted from plants, it creates a lot of plant and wood waste. According to one experiment on extracting cellulose from mulberry branch bark, the experimenters tried to utilize waste from mulberry farming by using the leftover bark to collect cellulose. Though this recycling process used materials more efficiently, there was also some waste after collecting the cellulose fibers. The Barman article states that during the process, waste liquid was discarded after the cellulose was extracted, contributing to pollution as the waste consists of pectin, hemicellulose and lignin, all of which hurt the environment (Liu, et. al.). Cellulose is also often extracted from sugar cane, which creates a lot of waste as there are many parts of the plant for which there is no known use. The sugar cane waste includes straw and stalks, as well as other general agricultural biomass waste (Abdel-Halim). When cellulose is taken from trees, it contributes greatly to deforestation as well, though it is usually not the only reason certain trees are cut down, as the trees can be use for multiple purposes (“Raw Materials Of The Components…”).

In addition to cellulose, the synthetic fibers polypropylene and polyethylene are also used in sanitary pads, and produce their own waste separate from pad disposal (“Raw Materials Of The Components…”). These are thermoplastic polymers (types of plastics) with various uses. Polypropylene resists many chemicals very well (“Plastics Comparison Chart”) and polyethylene is a flexible and durable material, but the two are quite similar in uses. They are used in many plastic materials, such as packaging and plastic bags (“Everything You Need…”). In sanitary pads polypropylene and polyethylene are used to neutralize odors by stopping air flow. They trap heat and stop bacteria from growing and spreading (“Women Beware: Most Feminine Hygiene…”). These plastics can be very harmful as they are the main plastic that ends up in ocean water and pollute marine life. Plastics in the ocean absorb toxic substances called PBTs. Not only are these plastics toxic and deadly to sea animals that eat them, but they are also more harmful the longer they float in the water. The water breaks down the plastics into fragments, increasing their surface areas, and therefore increasing their concentrations of PBTs the water absorbs, making the water more toxic and further polluting the oceans (“Toxicological Threats of Plastic”).

A third material used in sanitary pads is cotton, and cotton processing in and of itself is very pollutive and wasteful (“Raw Materials Of The Components…”). Cotton is a fiber extracted from cotton plants and is used mainly in the textile industry (“The Story of Cotton”). In pads, cotton makes up the top layer that touches the skin because it is skin-friendly, very absorbent, soft, and comfortable (Barman). One of its biggest drawbacks is the use of pesticides in cotton farming to keep away pests and to prevent the cotton from rotting. Of all agricultural chemical pesticides used in the US, cotton uses 25% of it. These chemicals soak into the ground and harm wildlife and poison the soil, even when cotton is no longer grown in the area. While organic cotton is grown without the use of chemical pesticides in order to reduce this problem, organic cotton cannot be produced in as large quantities as conventionally-grown cotton, which is why it is not more widely farmed (“Cotton”). Cotton is also a very “thirsty” crop and takes a lot of water to grow. According to the World Wildlife Federation, one kilogram of cotton takes 20,000 liters of water to grow. Given the quantities of water and pesticides being used, ecosystems can be disrupted, and this has already occured in the Aral Sea in Uzbekistan (“Cotton Farming”).

Aside from the individual raw materials, sanitary pads clearly produce a lot of waste themselves. When disposed of in toilets instead of in the trash, pads pollute waterways leading to the ocean, harming wildlife and ecosystems and toxifying ocean waters. This can lead to a decline in health for marine life, and in turn human lives as well (O'Rourke). Pads are non-compostable and take about 500 to 800 years to decompose (Delaney). If the components are bleached, they can take even longer. How long objects take to decompose also depends on other factors, including biological activity (amount of material-eating bacteria in the soil), oxygen levels (how dense the soil is and how deep the product is buried), and moisture levels (amount of water in the soil for certain bacteria to live). If these conditions are not ideal, breakdown can be extended (“Factors That Influence the Decomposition…”). When sitting in landfills, pads can create groundwater pollution. Each individual woman produces approximately 62,415 pounds of tampons and pad waste in her lifetime, which takes up space in landfills (O'Rourke, Rastogi). The problem of menstrual waste is especially bad in India, where 121 million women and girls use disposable sanitary pads. When pads go into sewers, landfills, fields, and bodies of water in India, it creates serious health and negative environmental impacts. According to Myles Ellege, Senior Director at RTI International, “The issue of managing menstrual waste is one that needs more attention… MHM (Menstrual Hygiene Management) is a neglected issue, and disposal is probably the most neglected topic in the MHM value chain.” All over the world, pads are usually thrown in the trash, and there they are mixed with other wet, dry, and toxic trash. This poses health risks for trash collectors. Chemicals from pads are passed between the air, water, and ground. But many women in India do not have access to places to dispose pads, so they throw them in streets and rivers, creating more pollution and health hazards (Bajeli-Datt).

There are efforts being made to reduce the amount of sanitary pad waste with methods ranging from more efficient packaging to different ways to dispose of waste, environmentally friendlier materials, and alternative types of sanitary products. A simple fix to produce less waste is for women to buy more environmentally friendly versions of products, such as sanitary pads that don’t have individual wrappers. Choosing to buy products made from organic cotton (cotton grown without pesticides) can help reduce the environmental impact of pollution from chemical pesticides and hard-to-degrade plastics. Steps could also be taken to ensure that more cotton farming companies begin to grow organic cotton rather than regular cotton. New sanitary products are also being made with fewer chemicals. Some companies say their pads and tampons are chlorine-free. This can either mean no elemental chlorine is used, or no chlorine is used at all. Both of these “chlorine-free” methods reduce the amount of dioxins released from chlorine compounds that pollute the environment, and the latter method reducing them to zero. However, if more companies converted to either method, pollution from sanitary pads would be reduced (Rastogi). There is also a patent for a product in the works that solves the problem that burnable waste and plastic waste from menstrual produces are not sorted and disposed of properly because they are not sanitary for workers to deal with. The inventor’s solution is a sanitary box, like in public bathrooms currently, that has a partition down the middle for people to sort their own products. The box can be opened and closed without touching the products inside and the bags can be removed and disposed of properly without touching the workers’ hands (Noriko). Another patent for a similar product is an opaque box in bathrooms that has different compartments for sanitary pads, toilet paper, and paper towels. A cord is attached to the bags inside that can be pulled to seal the bags, which then cannot be opened up again without being ripped (Cobos, et al). Both of these products would allow for more efficient and sanitary waste disposal. Furthermore, innovations to sanitary pads are taking shape. Alternative materials are available in place of common materials currently used. A company called Lenzing has invented a new fiber called TENCEL®Biosoft that can replace the cotton top layer of pads and that decomposes completely, reducing the amount of waste and pollution from cotton production. The new fiber is soft and comfortable. It is hydrophobic and lessens moisture and bacteria growth. For the absorbent core of the pad, three options for replacing cotton are bamboo, banana fibre, and flax spinning waste. Bamboo is better than cotton by 3-4 percent at absorbing water and reducing odor. It is naturally smooth and soft without chemicals added. Banana fiber can also be used to replace the cotton. It was developed by Sustainable Health Enterprises to made affordable sanitary products for women and girls in poorer countries. It is soft, absorbent, and environmentally friendly. Finally, the absorbent flax spinning waste from fibers used in spinning wheels may also be used as a cotton substitute because it is much cheaper (Barman). Moreover, waste can also be diminished by encouraging women to use alternative, more environmentally friendly menstrual products instead of the pad. The best option is the menstrual cup, which can be emptied, washed, and reused for multiple years. Other possible choices include machine-washable pads that can be reused. However, these options are not pleasing or ideal to many women. Most would rather throw the waste away after use and do not consider more eco-friendly options (Rastogi). This is why the sanitary waste problem remains.

Sanitary pads produce and contribute to an abundance of waste throughout their life cycle. Each material used in production individually creates waste, pollution, and harms the environment - specifically the materials cellulose, synthetic fibers polypropylene and polyethylene, and cotton are big contributors. Pads are disposed of after one use and create contaminated garbage that is improperly disposed of. Though potential solutions have been presented and created, the problem lingers now and in the near future.

Works Cited

Abdel-Halim, E S. “Chemical Modification of Cellulose Extracted from Sugarcane Bagasse: Preparation of Hydroxyethyl Cellulose.” Arabian Journal of Chemistry, Elsevier, 29 May 2013, www.sciencedirect.com/science/article/pii/S1878535213001263.

Barman, A, et al. “Natural and Sustainable Raw Materials for Sanitary Napkin.” OMICS International, OMICS International, 20 July 2017, www.omicsonline.org/open-access/natural-and-sustainable-raw-materials-for-sanitary-napkin-2165-8064-1000308.php?aid=93070.

Cobos, et al. “Receptacle System for Waste Paper, Toilet Tissue and Sanitary Napkins.” Search.library.ucdavis.edu, search.library.ucdavis.edu/primo-explore/fulldisplay?docid=TN_epo_sWO2004083046A2&context=PC&vid=01UCD_V1&lang=en_US&search_scope=everything_scope&adaptor=primo_central_multiple_fe&tab=default_tab&query=any%2Ccontains%2Cwaste%2Bof%2Bsanitary%2Bpads&mode=Basic.

“Cotton Farming.” WWF, WWF Global, wwf.panda.org/about_our_earth/about_freshwater/freshwater_problems/thirsty_crops/cotton/.

“Cotton.” How Products Are Made, www.madehow.com/Volume-6/Cotton.html.

“Definition of 'Cellulose'.” Cellulose Definition and Meaning, www.collinsdictionary.com/us/dictionary/english/cellulose.

Delaney, Paul. “How Long It Takes for Some Everyday Items to Decompose.” Down2Earth Materials, 14 Feb. 2013, www.down2earthmaterials.ie/2013/02/14/decompose/.

“Everything You Need to Know About Polyethylene (PE).” Creative Mechanisms, www.creativemechanisms.com/blog/polyethylene-pe-for-prototypes-3d-printing-and-cnc.

“Factors That Influence the Decomposition Rate of Organic Matter in the Soil.” Home Guides | SF Gate, SF Gate, homeguides.sfgate.com/factors-influence-decomposition-rate-organic-matter-soil-50156.html.

Kavita Bajeli-Datt , Kavita. “As Billions of Sanitary Pads Pollute Our Environment, India Needs to Focus on Managing Menstrual Waste.” The News Minute, IANS, 4 June 2017, www.thenewsminute.com/article/billions-sanitary-pads-pollute-our-environment-india-needs-focus-managing-menstrual-waste.

Liu, Lin, et al. “A Two-Step Chemical Process for the Extraction of Cellulose Fiber and Pectin from Mulberry Branch Bark Efficiently.” SpringerLink, Springer US, 27 May 2011, link.springer.com/article/10.1007/s10924-011-0300-x.

Noriko, Kakemizu.“Prudence Sanitary Box, Prudence Sanitary Napkin.” Espacenet - Bibliographic Data, European Patent Office, worldwide.espacenet.com/publicationDetails/biblio?FT=D&date=20080228&DB=EPODOC&locale=&CC=JP&NR=2008044784A&KC=A&ND=4.

O'Rourke, Evelyn. “Using Disposable Menstrual Products- What Are the Environmental Impacts?” Bleed With Pride!, World Press, 2 Dec. 2012, rathofeve.wordpress.com/using-disposable-menstrual-products-what-are-the-environmental-impacts/.

“Plastics Comparison Chart.” Alpha Packaging, www.alphap.com/bottle-basics/plastics-comparison-chart.php.

Rastogi, Nina. “What's the Environmental Impact of My Period?” Slate Magazine, 16 Mar. 2010, www.slate.com/articles/health_and_science/the_green_lantern/2010/03/greening_the_crimson_tide.html.

“Raw Materials of the Components of Hygiene Products.” Consumpediamed, consumpediamed.com/wp-content/uploads/link-impactes_EN.pdf.

“The Story of Cotton.” Cotton Acres, www.cottonacres.co.uk/.

“Toxicological Threats of Plastic.” EPA, Environmental Protection Agency, 19 June 2017, www.epa.gov/trash-free-waters/toxicological-threats-plastic.

“What Is Cellulose?” Nutrients Review, 4 June 2016, www.nutrientsreview.com/carbs/insoluble-fiber-cellulose.html.

“Women Beware: Most Feminine Hygiene Products Contain Toxic Ingredients.” Mercola.com, 22 May 2013, articles.mercola.com/sites/articles/archive/2013/05/22/feminine-hygiene-products.aspx.