Design Life-Cycle

assess.design.(don't)consume

Jordan Byrnes

Design 40A

Cogdell

December 1, 2016

Life Cycle of the Tentsile Stingray: Materials

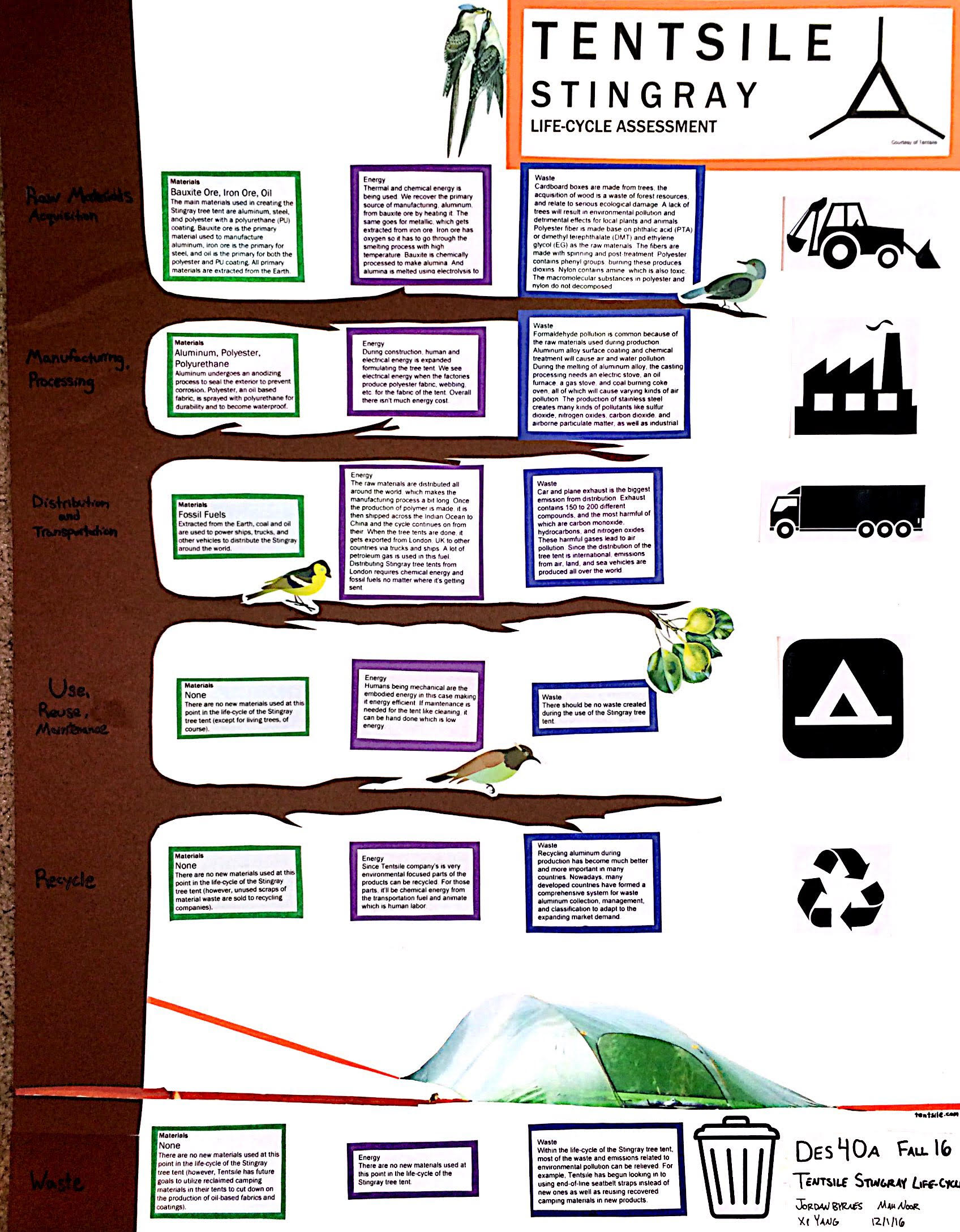

The idea behind the product is based on a child’s imagination after seeing Return of the Jedi. Suspended Ewok architecture played a crucial role in inspiring Alex Shirley-Smith to cofound Tentsile and create a product promoting the conservation of trees. Tentsile’s website has a number of articles containing information on the final materials used to make their flagship tree tent model, the Stingray. However, these articles do not specify the ecological impact made throughout the entire production of the Stingray. Primary materials must be harvested from the Earth by way of mining and drilling, each acquisition process having detrimental effects on the environment. The primary materials must then undergo further processing to become usable secondary materials. The different components are put together to create the final product but must be transported across the globe for retail sale. It is only in the product’s use and future-manufacturing intentions that care for the environment is more apparent. By analyzing the materials used throughout the entire life cycle of the Stingray tree tent, one can see if Tentsile truly prioritizes ecological wellness.

The aluminum, steel, and polyester used as final components in the Stingray have their origins as bauxite, iron ore, and oil located in the Earth. For the production of the Stingray’s aluminum frame, the process starts with the mining of bauxites, an aluminum rich material in the form of aluminum hydroxide. About 90% of global bauxite supply is found in tropical areas. After the mined bauxite is crushed and mixed with water, it is melted down to form liquid aluminum, which is poured into casts. This stock aluminum is to be used in production processes (Aluminum Production). A different kind of rock is used in creation of the steel ratcheting buckles. Once mined, iron ore is ground down and run under magnetic rollers to extract the ore. A mixture of fine grain iron ore and coal, free of impurities, is heated to yield molten iron. This becomes steel once oxygen is blown through the molten metal. The liquid steel is cast into a form and, after it cools, sent for machining into the ratcheting buckles (From Ore to Steel). While aluminum and steel are useful and versatile metals, mining for the bauxite and iron ore from which they are derived has detrimental effects on the environment. Mining devastates the regional plant life surrounding the mine by removing habitats and sources of food for local wildlife (Aluminum Extraction, Recycling, and the Environment). By removing vegetation from the mining site, animals lose necessary shelters and experience a loss of food availability. In order to reach the mining location, trees may even have to be cut down, something Tentsile has set out to defeat in their mission. Due to fewer plants rooted in the ground, soil may become weaker, leading to erosion and potential mudslides. Unlike aluminum and steel, which have to be mined for, polyester is fabric made of oil in the form of plastic fibers. After drilling for oil, which requires digging a hole thousands of meters deep to find an oil well, the oil is distilled to separate crude oil into lighter fractions. Each fraction’s molecules have different sizes and structures (How Plastic is Made). Large molecules called polymers are used to make a large variety of plastics. The polymers are processed into resins that can be used to produce finished products (Plastic). Similar to the effects of mining, drilling and extracting oil also destroy local plants and wildlife. Potential oil spills pollute waterways leading to the detriment of aquatic animal health as well as others who drink the water, humans included. Oil spilling into waterways is also devastates tree life as they depend on water, free of toxic chemicals, to live and grow. Additionally, to transport equipment and freshly tapped oil, deforestation must take place for roads to be constructed (Effects of Oil Drilling). Despite Tentsile promoting the idea that their product is to the benefit of trees, the acquisition of the primary materials used in the Stingray suggests otherwise. As with many, if not all-modern products in the consumer market, the primary materials used in the manufacturing process of the Tentsile Stingray are found in the Earth and cause harm to the surrounding environment upon extraction.

Once the primary materials are acquired, they are ready to undergo processing in order to create the more useful secondary materials. The aluminum used as framing poles for the Stingray undergoes an anodizing process to resist corrosion and abrasion. The coating is durable and does not need to be reapplied after the first processing. The entire process has four steps: cleaning, pretreating, anodizing, and sealing. Cleaning puts stock aluminum through a water-based acid bath to remove fabrication oils from the surface. Pretreating improves the final appearance of the aluminum after anodizing, which can be either a matte or shiny finish. Anodizing requires the aluminum to be submerged in a water-acid bath and used as a positive electrode as a direct current passes through. During the process, water molecules breakdown and allow for a porous layer of aluminum oxide to form on the surface of the aluminum. This layer must be sealed before being used in production of the Stingray so the aluminum is able to resist corrosion and repel stains (Aluminum Anodizing Process). Anodizing aluminum is useful because it allows for long term, reliable use of the material, especially being exposed to outdoors elements like in the Stingray. However, the process does have harmful effects on the environment. Due to the use of acidic baths during the anodizing process, evaporative fumes enter the atmosphere and cause acid rain leading to the erosion of plants, soil, and increased acidity of waterways (The Environmental Impact of Anodizing). There are also negative effects in the production of polyester fabric with a polyurethane coating, used for waterproofing the Stingray. To make polyester fabric, there must be chemical reaction between the oil-based polymers, air, water, and coal. The most common type of reaction happens within a vacuum at a high temperature, it is called polymerization. The product created by the reactants is stretched into long fibers while still hot. Once cool, these fibers are then spun into fabric and available for use in products (How Polyester is Made). Once fully formed, the polyester has become a versatile material that is does not wrinkle, is super durable, and will not fade color. The material is waterproofed using a polyurethane (PU) coating, a necessity for outdoor camping equipment like the Stingray. Manufacturing PU begins with reactant liquids, of which there are chemical alcohols and oil-based polymers, in a large tank. These are heated to the reacting temperature level where, like in polyester, polymerization occurs, and the PU coating chemically forms (Polyurethane). The coating is ready to be sprayed using a dispensing head onto materials like polyester. The major benefit of using a PU coating on camping equipment like the Stingray is that it makes the polyester cover waterproof. Even though polyester with a PU coating is a great material for camping equipment, its production has adverse effects on the environment and to the employees working with both materials. Polyester production facilities are assumed to run off of electricity, an energy source linked back to the burning of coal, causing airborne pollutants. The PU coating contains isocyanates, which can severely harm workers lungs (The Truth About Polyurethane). Even Kirk Kirchev, Tentsile’s co-inventor, has said, “I have visited those factories and found that the most polluting of all was the one that does our PU coating. Put it this way: it’s hard to breathe there,” (Kirchev, How Green is Tentsile Really?). Once the primary materials, aluminum and oil, undergo processing, they become secondary materials that are much more durable and useful for Tentsile to incorporate in their Stingray tree tent.

Once all materials are made useful through processing and the final product assembled, it must be transported to a Tentsile warehouse to be distributed to the customer. The raw materials that are utilized in the transportation of primary and secondary components as well as the finished product are assumed to be coal and/or oil. In the article How Green is Tentsile Really? by Kirk Kirchev, he is not shy about sharing how the materials and assembled product move location. He mentions the product travelling by truck and by sea. Figuring that the engines run off of fossil fuels, and not an alternate source of energy like hydrogen or wind, the extraction of coal and/or oil harms the environment in the same way as harvesting the primary materials used to create the Stingray.

Environmental cherishment can be seen in the life use, recycling, and waste management of the Stingray tent. While there are no new raw materials during the use of the Stingray tree tent, besides strong, standing trees of course, for every tree tent sold, Tentsile plants three new trees on the purchaser’s behalf via a third party company called WeForest. Since 2009, WeForest has planted almost 11 million trees in 12 different countries, 5 of which are still active. Trees planted by WeForest are grown from seeds or in nurseries and then transplanted. In 2015 alone, 277 different species were planted across all projects (WeForest Latest Annual Report). Despite the ecological impact made by the harvesting of primary materials, processing of secondary components, and global transportation, it is here where Tentsile strives to give back to the environment. In addition, Tentsile has established future goals to utilize recycled materials in their products. Ideas currently circulate about using reclaimed camping materials to cut down on oil-based fabrics and coatings. In the interim, to deal with all of the scraps of unused material cut from the fabrics the Stingray is made out of, Tentsile sells these to recycling companies (How Green is Tentsile Really?). This way, Tentsile promotes a more environmentally friendly waste management system rather than disposing of the material in a harmful way. The most environmentally friendly aspect that Tentsile provides is raising awareness among people about the conservation of trees. By utilizing Tentsile’s product, people will be able to see more value in trees and help with their protection.

After taking a closer look at the life-cycle of the Stingray tree tent from primary materials to future manufacturing goals, it has become apparent that while Tentsile designed its product with beneficial ecological intentions and hope to eventually utilize recycled components, the current extraction and processing methods of the materials used do not further environmental wellness. The harvesting of primary materials from the Earth leads to soil erosion, habitat loss, polluted waterways, and deforestation. The processing of secondary materials creates acid rain in the environment and respiratory health issues in humans. The product is transported globally utilizing vehicles that run off of fossil fuels. Even with the preceding information, Tentsile does help the environment by recycling scrap material, planting three trees for every tree tent sold, and bringing tree conservation awareness to people with their product. Tentsile does come across as an environmentally friendly company with wholesome intentions, but since analyzing the life-cycle of the Stingray, the product currently has more direct disadvantages than benefits for the environment.

Bibliography

Kirchev, Kirk. “How Green Is Tentsile Really? The Life Cycle of a Tentsile Tent.” Tentsile Tree Tents. Tentsile.com. N.p. 12 July 2015. Web. 22 Oct. 2016. <http://www.tentsile.com/blogs/news/34913412-how-green-is-tentsile-really-the-life-cycle-of-a-tentsile-tent>.

Freudenrich, Ph.D. Craig. “How Plastics Work.” How Stuff Works. HowStuffWorks.com. n.d. Web. 22 Oct. 2016. <http://science.howstuffworks.com/plastics.htm>.

“Aluminum Production.” All About Aluminum. AluminumLeader.com. N.p. n.d. Web. 22 Oct. 2016. <http://www.aluminiumleader.com/production/aluminum_production/>.

“Aluminum Anodizing Process.” Superior Metal Technologies. SuperiorMetals.us. N.p. n.d. Web. 22 Oct. 2016. <http://www.superiormetals.us/aluminum-anodizing-process.htm>.

“Polyurethane.” How Products Are Made. MadeHow.com. N.p. n.d. Web. 22 Oct. 2016. <http://www.madehow.com/Volume-6/Polyurethane.html>.

“How Plastic Is Made.” PlasticsEurope. PlasticsEurope.org. N.p. n.d. Web. 22 Oct. 2016. <http://www.plasticseurope.org/what-is-plastic/how-plastic-is-made.aspx>.

Woodford, Chris. “Nylon – The Science of Synthetic Textiles.” Explain That Stuff. ExplainThatStuff.com. N.p. 18 June 2016. Web. 22 Oct. 2016. <http://www.explainthatstuff.com/nylon.html>.

Gerard, Barbara. “How is Polyester Made?” How is Polyester Made? CraftTechInd.com. N.p. 26 Aug. 2016. Web. 22 Oct. 2016. <http://info.craftechind.com/blog/how-is-polyester-made>.

“From Ore to Steel.” ArcelorMittal. ArcelorMittal.com. N.p. n.d. Web. 22 Oct. 2016. <http://corporate.arcelormittal.com/who-we-are/from-ore-to-steel>.

“What Aluminum Extraction Really Does to the Environment.” RecycleNation. N.p., n.d. Web. 30 Oct. 2016. <http://recyclenation.com/2010/11/aluminum-extraction-recycling-environment>.

“Effects of Oil Drilling.” Rainforest Foundation US. N.p., n.d. Web 30 Oct. 2016. <http://www.rainforestfoundation.org/effects-oil-drilling-0/>.

“The Environmental Impact Of Anodizing.” The Environmental Impact Of Anodizing. N.p., n.d. Web. 30 Oct. 2016. <http://www.thomasnet.com/articles/custom-manufacturing-fabricating/anodizing-environmental>.

"The Truth about Polyurethane." The Green Guide Green Living Tips Product Reviews Buying Guides Environmental Health News and Online Stores. N.p., n.d. Web. 30 Oct. 2016. <http://www.thegreenguide.com/the-truth-about-polyurethane>.

“Latest Annual Report.” Latest Annual Report | WeForest. N.p., n.d. Web. 30 Oct. 2016. <http://www.weforest.org/newsroom/latest-annual-report>.

Mah Noor

DES 40A

Professor Cogdell

30 November 2016

The Life cycle of Stingray Tree Tent: Embodied Energy

The company Tentsile took camping to a whole new level with the invention of the Stingray Tree Tent. This tree-person tree tent has a different approach aiming towards a sheltering design, focusing on their main purpose to protect against wild animals (Tentsile Stingray). When you think of the Stingray, you think of an "alien tent" (Derek). This can reflect their adequate materials and steady use of energy. Through examining the energy used in the life- cycle of Stingray Tree Tent presents an accessible product by Tentsile that is environmentally friendly. This U.K. based company exports the tents worldwide.

The Stingray is composed of different raw materials including bauxite ore, iron ore, and oil. First off, we start with bauxite ore (not mineral) which gives us the element aluminum. This is the primary source of manufacturing. Most of the aluminum produced is from extracting bauxite (geology.com). Formed from laterite soil in wet tropical or subtropical climate, it's got a lot of silica and other soluble materials. Beginning with the Bayer Process, we put bauxite in a hot solution (hydrogen peroxide) which separates aluminum from bauxite (chemical energy). Precipitation of aluminum gets us aluminum hydroxide which has to be calcined to make alumina(geology.com). Thermal energy comes when we smelt aluminum from alumina using a different process called Hall-Heroult Process (dissolving alumina into molten bath of cryolite). Most of electrical energy (machines) is used in this process since alumina is melted using electrolysis to produce pure aluminum metal, but usually there is low electrical usage when producing aluminum. Now, the aluminum from bauxite ore is ready to be produced in the form of poles for the tent.

Iron ore used by man for over 3,000 years goes through a little less of a process than that of bauxite ore. We achieve metallic iron after heating iron ore (thermal energy). Just like bauxite ore, iron ore is the primary source for the production of world's iron and steel industries (minerals.usgs.gov). Since iron ore gets mined from 50 different countries, it's considered mechanical energy (human labor). Australia being one of the major production site for iron, hauls the ores starting from workers to machines (electrical energy) in trucks that can carry over 300 tonnes. The transportation continues on trains (over 2 kilometers long up to 25,000 tonnes), locomotives, and 250 wagons (australianminesatlas.gov.au). There are different chemical components in the ores mined today like, hematite, goethite, limonite, mixture of hydrated iron oxides, magnetite. It is then ready to be used in the materials for the tent.

Oil is used in everything and anything nowadays. Usually measured in barrels, it equals to 42 US gallons or 159 liters (dosomething.org). We get oil by drilling cutting a hole through the earth (electrical energy). This allows the air to go downward till it hits the oil. It then shoots out to towards the top of the surface. Crude oil (also known as fossil fuels) has unrefined petroleum that's made up of hydrocarbon deposits and a few other organic materials. It is used to make products like gasoline (consists of 45% of crude oil). Crude oil can be used as a binding material or a sealer for water resistant surfaces. This makes it very important for Tentsile to use in their materials because all campers want a reliable tent that can be stable during harsh weathers such as rain.

The Stingray is manufactured in London, yet there isn't much information released by the company that exclaims what machines were used for their products. It has been said that the machines to produce the tents are energy efficient because the company believes in a lively nature which consists of more trees being planted rather than cut down. We can't say for sure how efficient these machines are, but it does exclaim some of the manufacturing process that the tree tent has to go through. During construction, human and electrical energy is expanded formulating the tree tent. We see electrical energy when the factories produce polyester fabric, webbing, etc. for the fabric of the tent. The fabric gets coated with polyurethane and gets sent in a small truck. Then they (workers) cut, print logos, seam together, and pack everything in a recycled cardboard box which is mechanical energy. Overall there isn't much energy cost.

The raw materials are distributed all around the world which makes the manufacturing process a bit long. Once the production of polymer is made, it is then shipped across the Indian Ocean to China and the cycle continues on from their. When the tree tents are done, it gets exported from London, UK to other countries via trucks and ships. A lot of petroleum gas is used in this fuel. The ready tents are sent to nearby warehouses. Distributing Stingray tree tents from London requires chemical energy and fossil fuels no matter where it's getting sent.

Humans being mechanical are the embodied energy in this case making it energy efficient. Tentsile's product dwells on a great quality tent that can be very faithful when camping. If maintenance is needed for the tent like cleaning, it can be hand done which is low energy. There shouldn't be any maintenance if you follow the 4 rules : " always read the directions, be gentle with the zippers and poles, clean your tent and fly from time to time, and never storing the tent wet" (rei.com/ tent care basics instructions). This can be very beneficial to all its customers who buy it.

Since Tentsile's company is very environmental focused, parts of the products can be recycled. For those parts, it'll be chemical energy from the transportation of fuel and animate which is human labor. There wasn't much elaboration on what products can be recycled, but either way, when the tent needs to be recycled, it has to be taken to a certain destination. Humans would be the one taking to its place.

There weren't any details about the tents waste. There are no new materials used at this point to produce any kind of energy in the life- cycle of the Stingray Tree Tent.

We have discovered that energy is used at almost every part of the life cycle of the Stingray Tree Tent. If used correctly, the tent can last for quite a long time making it worth the energy that was put into it. Raw materials seems to be taking up most of the energy (electrical). Not a huge amount of energy is put into the manufacturing process because of human workers. The life- cycle of this tent can be prolonged if you choose to replace different parts of the tent that may have been broken. Overall, the Stingray Tree Tent not only lives up to their belief in the versatility of the hammock and security of the tent, but also believe in keeping trees around instead of cutting them down(can.shopify.com/ instruction manual).

Thoughts on Research

Since there is a little bit of information missing from different parts of the section like recycling and waste I failed to find out everything. Some of the dead ends occurred when I tried looking into the energy that may have been used while recycling. Human labor and mechanical energy are my two assumptions based on what I've just learned about the Stingray. Talking about recycling, I think that the rope that's used as a ladder to climb into the tree can also be reused later on. I also didn't find out the detailed information on the types of trucks being used. Just found out how much the raw materials weighed on the truck. An interesting discovery was the fact that the Tentsile website had a question box which I took advantage of to find out about the cleaning and maintenance of the tent. Based on my research, I see that Tentsile is trying to be very conscious about the outside world, yet they consume quite a lot of electricity. I personally really enjoyed choosing this product as my research point because it gave me new light to knowledge. I view things more insightfully because of this knowledge.

Citations

"All You Need To Know About Tents." All You Need To Know About Tents. N.p., n.d. Web. 01 Dec. 2016 <http://www.angelfire.com/ia3/camping/tents.htm#fourseason>.

Australia, Geoscience. "Iron Fact Sheet." Iron Ore - Mineral Fact Sheets - Australian Mines Atlas. N.p., n.d. Web. 01 Dec. 2016. <http://www.australianminesatlas.gov.au/education/fact_sheets/iron.html>.

"Basic Iron Ore Facts." Basic Iron Ore Facts. | Iron Ore: Facts. N.p., n.d. Web. 01 Dec. 2016. <http://www.ironorefacts.com/the-facts/basic-iron-ore-facts/>.

"Bauxite." Bauxite: The Principal Ore of Aluminum. N.p., n.d. Web. 01 Dec. 2016. <http://geology.com/minerals/bauxite.shtml>.

Derek. "Tentsile Stingray Tree Tent Review." The Ultimate Hang.com. N.p., n.d. Web. 30 Nov. 2016. <http://theultimatehang.com/2014/12/tentsile-stingray-tree-tent-review/>.

"11 Facts About Oil." DoSomething.org | Volunteer for Social Change. N.p., n.d. Web. 01 Dec. 2016. <https://www.dosomething.org/facts/11-facts-about-oil>.

"Energy Use for Transportation." Energy Use for Transportation - Energy Explained, Your Guide To Understanding Energy - Energy Information Administration. N.p., n.d. Web. 01 Dec. 2016.

Kirk, William S. "Iron Ore Statistics and Information." USGS Minerals Information: Iron Ore. N.p., n.d. Web. 01 Dec. 2016. <http://minerals.usgs.gov/minerals/pubs/commodity/iron_ore/>.

@REI. "How to Clean, Waterproof & Care for Your Tent." REI. N.p., n.d. Web. 01 Dec. 2016. <https://www.rei.com/learn/expert-advice/caring-tent.html>.

"Stingray Owners Manual." N.p., n.d. Web. 30 Nov. 2016. <https://cdn.shopify.com/s/files/1/0213/4326/files/Stingray_Owners_Manual_Book_OCT_2015.pdf?12423286416344298350>.

"Tentsile Stingray Tree Tent3-Person." Www.cabelas.com. N.p., n.d. Web. 01 Dec. 2016. <http://www.cabelas.com/product/Tentsile-Stingray-Tree-Tent-Person/2066975.uts>.

Xi Yang

DES 040A A01

Professor Cogdell

Dec. 1st 2016

Waste research of Textile tree tent

Nowadays, with the development of technology in the society, tree tent becomes a new popular outdoor camping accessory. It is different from the standard traditional tent, combined the regular tent and hammock together, making it much more fashion and novel. It is not installed on the ground, but hanging in the air, allows people to stay away from the damp ground, water, insects and animal disturbances. However, the limitation of it is it required to have a thick tree to play the advantages of the tent, but the designer also solved about this, it can be installed on the ground to use directly as well. To consider with the producing, processing, distribution and transportation, there are many kind of waste and emission of tree tent with its life cycle, but at the same time, most of the materials still can be maintenance, collect and recycle to solve some environment problems.

Firstly, the poles of tree tent are made by anodised aluminum alloy 7001 T6, and the roof is used with the material called tear resistant insect mesh. Its outer layer has the function to protect from fire and ultraviolet rays, so that the flysheet needs 70D PU Coated Waterproof Polyester 3000HH. Moreover, it also used stainless steel to support, and the packages are normally made by recycled cardboard boxes. Overall, in tree tents life cycle, it required bauxite and iron ore minimg, oil drilling, aluminum anodizing, polyester and polyurethane coating producing, and fossil fuels using.

As the package of the tree tent, cardboard boxes are made from the trees, and the acquisition processing is a kind of waste of forest resources, which is difficult, needs a long time to regenerate, and it also may related to serious damage to ecological balance. The lack of trees in the forest usually will result in environmental pollution, and make bad influence for animals and other plants. So that, this will cause to the environmental pollution, the waste of forest resources, the destruction of ecological balance, also water pollution and soil erosion indirectly without the protection of trees.

And then, polyester fiber is a necessary and common materials for the layers of textile tree tent. It actually is made base on phthalic acid (PTA) or dimethyl terephthalate (DMT) and ethylene glycol (EG) as the raw materials, by esterification or transesterification and polycondensation reaction of fiber-forming polymer - poly Polyethylene terephthalate (PET), and fibers made by spinning and post-treatment. As for the bad influence of these chemistry materials, since polyester contains phenyl groups, burning it may produce dioxins, while nylon containing amine, which is also toxic. And also, these macromolecular substances are hardly decomposed.

During the producing of tree tent, it usually output formaldehyde pollution because of the raw materials. Aluminum alloy surface coating and chemical treatment will cause air and water pollution. The treatment of liquid aluminum will need slag agent, refining agent and covering agent, and lead to the environmental pollution. Before the melting of aluminum alloy, the casting processing not only need the electric stove, but also need the oil furnace, gas stove and coal burning coke oven, and will cause varying kinds or degrees of air pollution.

Moreover, the production of stainless steel enterprises will fabricate many kinds of pollutants, like sulfur dioxide, nitrogen oxides (nitrogen dioxide, nitric oxide, etc.), carbon dioxide and respirable particulate matter, which is the pollution of the atmosphere. In addition, it will come with the industrial water emission, and solid emission.

As for the distribution and transportation, because of the delivery of this production, the car and plane exhaust is the biggest emission. It contains 150 to 200 different compounds and as everyone knows, the most harmful things to human bodies are carbon monoxide, hydrocarbons, nitrogen oxides, lead compounds and particulate matter. The spread of the harmful gases into the air can lead to the air and air pollution. Especially the manufacturing step is mostly done in China, so the transportation part may lead to a huge problem of emission. And then, because the delivery of the manufacturing is international, from The Middle East, via China to America, Europe and into Africa, it need substantial carton, and may related to the wood waste, and make disadvantage to the environment at the same time.

Even though it always wastes some energy and materials during the acquisition and formulation, it still can be recycled and it is extremely useful for the society. Nowadays, the recycled aluminum in the production has been developed much better and become important in many countries increasingly. Till now, many developed countries already have formed a comprehensive system of waste aluminum collection, management, classification, to adapt to the expanding market demand.

On the other side, stainless steel slag is a derivative of the steelmaking process. The use of advanced and reliable slag, steel separation technology, not only can effectively sorting slag containing chromium, nickel and other precious metals and stainless steel scrap, but also can significantly reduce the cost of steel. Moreover, at the same time, the tailings resources can also achieve resource recycling.

In addition, the tree tents also can be collected after using and then sold cut offs to small recycling company, because the materials can be decomposed and re-used to other productions in order to prove its value further.

Furthermore, the tree tent sometimes may result in some problem related to caterpillar (Malacosoma Americanum) to the trees because of human activity in the forest. And it also leads to the competitive balance problem among tree species, and made impact of host tree on forest.

To sum up, with the life cycle of tree tent, mostly the waste and emission are related to the environmental pollution, and can be relief. For example, people starts trying to using end-of-line seatbelt straps in order to protect environment, and many countries start to form a comprehensive system to work with the waste processing. During the producing of tree tent, it usually output formaldehyde pollution. And the chemical treatment of aluminum alloy always will cause air and water pollution. Moreover, the production of stainless steel enterprises will fabricate many kinds of pollutants, such as industrial water emission, solid emission and so on. After its formulation, the delivery part also will result to the wood waste of the environment. Because of the transportation of delivery of this production, the cars and planes’ emission are a unavoidable problem. Also the competitive balance problem is also an important part among tree species. But at the same time, the use of advanced and reliable slag, steel separation technology, not only can effectively sorting slag containing chromium, nickel and other precious metals and stainless steel scrap, but also can significantly reduce the cost of steel. And the recycled aluminum in the production has been developed and become important in many countries increasingly. Therefore, the tree tent as a new production nowadays, has its own advantages that is more convenient and fashion for people activity, and also has the drawback based on the waste and emission problems in the society.

Bibliography

Atwood, Margaret. The Tent. 1st ed. New York: Nan A. Talese/Doubleday, 2006. Print.

Berry, Harrison. "TENTSILE TREE TENT." Boise Weekly [Boise, Idaho] 16 July 2014: 15. Web.

Boyer, Crispin. "Tree Tent.(COOL Inventions)(Tentsile)." National Geographic Kids (2013): 5. Print.

Demo, J. J., American Society for Testing Materials. Committee A-1 on Steel, Stainless Steel, Related Alloys, and ASTM International. Structure, Constitution, and General Characteristics of Wrought Ferritic Stainless Steels : Sponsored by Committee A-1 on Steel, Stainless Steel, and Related Alloys. Philadelphia: American Society for Testing and Materials, 1977. Print. ASTM Special Technical Publication ; 619.

Eckberg, J.O., G.A. Johnson, R.E. Pain, D.L. Wyse, and G.E. Heimpel. "Spillover of Tent Caterpillar ( Malacosoma Americanum ) Herbivory onto Willow Bioenergy Crops in an Agricultural Landscape." Annals of Applied Biology 167.2 (2015): 178-85. Web.

"Handle Cardboard Boxes, Sacks with Vacuum Tube Lifter.(ProMat: SHOW PREVIEW 2013)." Modern Materials Handling 67.12 (2012): 43. Web.

Olivia Elena. "TRANSPORTATION. POLLUTION. FISCALITY." Revista Tinerilor Economişti 17 (2011): 33-40. Web.

"Polyester Fiber." (2007): 746. Web.

Smith, T.W., Axon, C.J., and Darton, R.C. "The Impact on Human Health of Car-related Air Pollution in the UK, 1995-2005." Atmospheric Environment 77 (2013): 260. Web.

Zimmer, Lori. The Art of Cardboard : Big Ideas for Creativity, Collaboration, Storytelling, and Reuse. 2015. Print.