Design Life-Cycle

assess.design.(don't)consume

Regina Paredes Martinez

Des 40A Section 3

Christina Cogdell

06 December 2018

Life Cycle of a Q-Tip Outline

The main purpose of a Q-tip is for the cleaning of your ear since the year 1955. The process of the Q-tip has stayed consistent over time, but as time progressed, so did the technologies used in the production of it, but the materials have stayed constant over time involving cotton balls, paper used as the body for the attachment of the cotton on each end of the stick, Methocel is used as an adhesive to maintain them in place and the last step is sterilization with chemicals such as Triclosan.

Cotton Production

The production of the cotton balls begins with the cultivation and production of the Gossypium plant, commonly known as the cotton plant. It was named after the cream-colored fluffy fibers surrounding the small cotton seeds. The Cotton plant has a general time frame in which they grow and produce after planting. In perfect conditions, the seed will germinate and emerge in about five to ten days. [1].After the plant has completed its growing process, the flower would then be ready for extraction. The small seeds in the plant need to be separated from the wool in order to isolate the cotton for its preparation and structural change. The unseeded cotton is then transformed cleaned, shaped (fibers aligned) into the cotton ball shape [2]. Although the main point of the research is of a Q-tip there are many other purposes to the plant can be used for, many important product like cotton swabs. Some of this important products are the seed of the cotton flower used for the production of oil that can be used in salads and snack foods, cosmetics, soap, candles, detergents, and paint. Cotton is also a source for cellulose products, fertilizer, fuel, automobile tire cord, pressed paper, and cardboard [3]. Once the cotton has been shaped into its desired form, the cotton balls would then be transported to a different machine where it would then be assembled to the body structure made of paper.

Making of Paper Stick

Domtar is a company that for many years has supplied companies like Q-tip for many paper purposes, for example, lollipop sticks, printing paper or even for cotton swabs[4]. The production of this material begins in a paper machine that is divided into two main components: the wet end and the dry end. The wet end begins with the formation of the paper sheets. Forming fabrics, which resembles a large mesh screen. At this point, the mesh screen is mainly composed of water. The following step is suctioning the water out of the mesh screen. The sheet is then transported to the pressing, where the paper machine removes more water out of the mesh screen and begins to modify the thickness and smoothness of the sheet. The paper is then squeezed through rolls. The paper rolls are then moved into a machine that would dry out the role completely, passing through steam-heated dryers. After is completely dry, the sheet moves to a different machine where the smoothness and thickness would be adjusted, then the paper sheet would be cut and shaped to the desired form, for the product it would be used [5]. For the purpose of a Q-tip the shape of the Paper would have to be cylindrical and long as a stick. The finished product would then be moved to the next phase, that would be the attachment of the cotton at both ends of the paper stick.

Assembly

After Q-tip has been assemble is time to hold everything in place, methocel is used as an adhesive with a biodegradable formula. Methocel cellulose is a water-soluble polymers derived from cellulose. Methocel is used as rheology modifiers, binders, film formers, it can have many variety of industrial applications including being used as an adhesives and sealants, coatings, ceramics, gelled fuels, inks, paint stripper, polymerization aid, and paper.[6]. Methocel cellulose is used as sizing in the production of papers and textiles as it protects the fibers from absorbing water or oil. Methocel is a white powder form that dissolves in cold water, forming a clear viscous solution type of gel. It is sold under a variety of trade names and is used as a thickener and can be used in foods and cosmetic products, and also as a treatment of constipation. It is not digestible nor toxic [7]. Once the cotton balls have been attached to the paper stick with the adhesive is time for sterilizations.

Sterilization

The sterilization of a cotton swab is the last step it would have to undergo through before packaging. The chemical used for sterilization is triclosan, is effective against many different bacteria, is commonly used as an antiseptic, preservative and disinfectant in health care and in many other consumer products including cosmetics, plastic materials, toys, and paints. It is also included in the surface of medical devices, plastic materials, textiles and kitchen utensils where it acts as a bactericide for extended periods of time.[8]. Although triclosan has many purposes in many different products, studies in animals have shown that using this product is associated with a decrease in levels of some thyroid hormones. But there aren't any human findings that show that is harmful, according to the FDA. there are many other studies in the process to ensure that triclosan is safe. One study is testing the long-term usage of triclosan and skin cancer in animals. Another study would be the breakdown of triclosan to other chemicals on human skin after exposure to triclosan to ultraviolet (UV) rays. At this time, neither study has been completed, but the FDA continues to test[9]. The reason why the Q-tip undergoes this process is that one of the many uses are in hospitals and it needs to be clean and not carry any other bacteria. In other words, it prevents it from spreading any unwanted bacteria.

Conclusion

The company Q-tip has made sure that all the products that they use are biodegradable. Using 100% cotton balls and biodegradable paper for the attachment of the cotton balls the chemical products that are used to sterilize are not harmful to the environment in any way[10]. One thing that I learn from the research of this project is the usage people give them. At the beginning they were meant to clean ears, but as doctors and scientists discovered the usage of them in the ears is harmful and can cause a person an infection, because the earwax is meant to protect the ear from any bacteria coming into the body, but by using a Q-tip to remove that, is preventing it from blocking that bacteria from entering your ear and therefore your body. Although Q-tips are very useful they are not meant to be used for the cleaning of an ear.

Bibliography

[1]Oosterhuis, Derrick M. Growth and development of a cotton plant. No. nitrogen nutrition. American Society of Agronomy, 2005.

http://www.cottonsjourney.com/storyofcotton/page3.asp

[2]How Products Are Made, Cotton Swab, April, 2018

http://www.madehow.com/Volume-6/Cotton.html

[3]Tharp, William Hardy. The cotton plant: How it grows and why its growth varies. No. 178. US Department of Agriculture, Agricultural Research Service, 2007.

https://sanangelo.tamu.edu/extension/agronomy/agronomy-publications/how-a-cotton-plant-grows/

[4]Cobb, James W. "Process and machinery for making paper sticks." U.S. Patent No. 3,450. 1 July. 2010.https://newsroom.domtar.com/paper-sticks-cotton-swabs-lollipops/

[5]Biermann, Christopher J. Handbook of pulping and papermaking. Elsevier, 2014.

https://newsroom.domtar.com/paper-making-101-inside-paper-making-process/

[6]Reese, Elwyn T., Ralph GH Siu, and Hillel S. Levinson. "The biological degradation of soluble cellulose derivatives and its relationship to the mechanism of cellulose hydrolysis." Journal of bacteriology 59.4 (1950): 485.

[7]Keary, C. M. "Characterization of METHOCEL cellulose ethers by aqueous SEC with multiple detectors." Carbohydrate polymers 45.3 (2001): 293-303.

[8]Schweizer, Herbert P. "Triclosan: a widely used biocide and its link to antibiotics." FEMS microbiology letters 202.1 (2001): 1-7.

https://copublications.greenfacts.org/en/triclosan/l-2/2-uses-cosmetics-disinfectant.htm

[9]Close, Menu. "Five Things You Need to Know About Triclosan and Our Microbiome."

https://www.fda.gov/ForConsumers/ConsumerUpdates/ucm205999.htm

[10]. Q tips, FAQ, October 1, 2018

Samantha Soleta

Christina Cogdell

DES40A

6 December 2018

Research Paper

Embodied Energy of Cotton Swabs

From farm to factory to a bathroom cabinet, something as small as cotton swabs are the product of a long and extensive journey. Throughout this journey, the production of such a small item actually requires a great magnitude of energy along the way. Looking into the production of the cotton swab, one can see that the embodied energy of such a simple household item is the end product of energy usage from farming, harvesting, transportation, manufacturing, and packaging to reach the cotton swabs’ final form. Understanding the amount of energy that goes into creating the cotton swab is very telling of the means of production of something one often takes for granted.

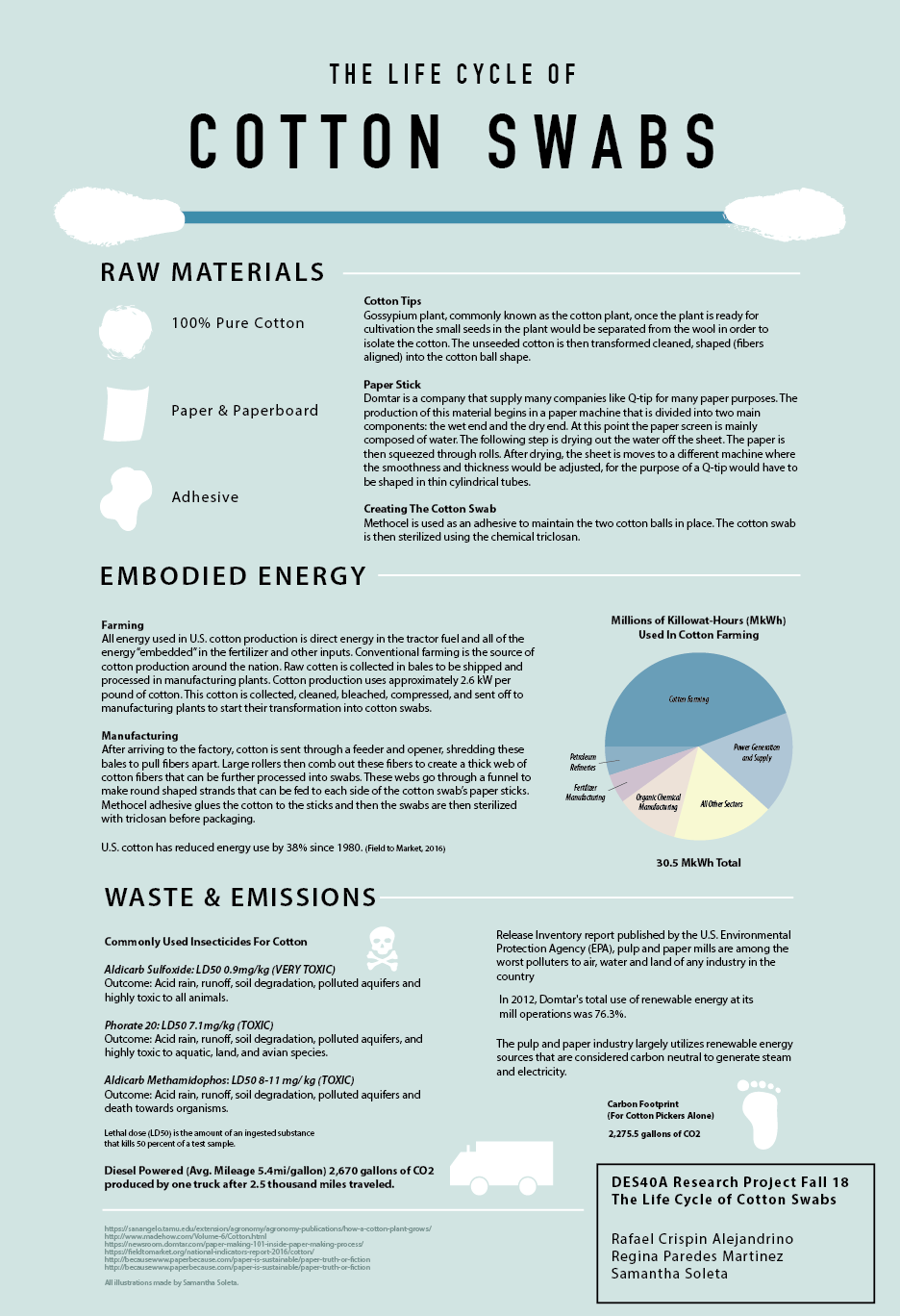

The production of the cotton swab first starts within the ground. Farming and harvesting the primary source cotton is the start of this lengthy process and also extremely costly in terms of energy, materials, and labor. The embodied energy in the production of cotton fibers is approximately 55 MJ per kg of fiber. (O Ecotextiles) It is vital to understand that both direct and indirect energy consumption occurs in this agricultural process. Noting the difference between the two highlights the different components of this process. Direct energy consumption can be seen in the use of all sorts of energy sources ranging from electricity, propane, natural gases, diesel, and renewable fuels. Whereas indirect energy consumption covers the use of products that required energy to produce; examples of indirect energy consumption include the manufacturing of fertilizers, pesticides, the use of fuel, and feedstock.

To even begin planting cotton seeds, farmers ready their fields and crops with machinery and fertilizers to produce mass amounts of cotton. “Energy makes up a significant part of operating expenditures for most crops, especially when considering indirect energy expenditures on fertilizer, because the production of fertilizer is extremely energy-intensive, requiring large amounts of natural gas.” (Energy Information Administration) Cotton farming on its own uses about 13.6 millions of kilowatt-hours (mKwH) without taking into account the production of fertilizers, power generation, organic chemical manufacturing and more. More than 250 trillion British Thermal Units (BTU) are used in distillate fuel alone while farming. About 350 trillion BTU is used in electricity and many other fuels often extend to 500 trillion BTU in farming industries like that of cotton farming. (Energy Information Administration)

An almost alarming amount of energy consumption stems in fertilizer usage. For irrigated farms, about 40 percent of all energy used is utilized in fertilization of the soil. However, non-irrigated fields can require up to 60 percent of their energy usage to go towards fertilization.

The indirect on-farm energy use (mostly the embodied energy for the purpose of manufacturing farm fertiliser chemicals and machinery for use in cotton farming) was the most significant component (average 77%), consuming on average 7.7 GJ/bale. This was followed by direct on-farm energy consumption (11%). In comparison, the direct and indirect off-farm energy consumption and soil emissions were relatively low, around 8-9% and 2-3% respectively. (Khabazz)

Through proper care of fertilizing, planting, cultivating, and harvesting cotton: the overall energy consumption has reached incredibly high numbers as they are done on such a wide scale. Taking all of these into account, cotton farming uses roughly 30.4 TJ overall.

A great deal of attention has been directed to the “energy balance” of agricultural production especially in relation to biofuel crops such as soybeans for biodiesel and corn for ethanol. The energy input considers obvious factors such as the amount of fuel used by agricultural equipment, but also includes the energy associated with the manufacturing of inputs into the system such as fertilizers and crop protection products. (Cotton Leads)

Utilizing better systems of monitoring and finding other means of fuel within farms results in much less energy consumption and therefore less emissions as well. Even with more energy conservative processes, one metric ton of cotton fiber uses on average about 19 gigajoules (GJ) ranging between 14 all the way to 35. To put that further into perspective, 1 GJ is fairly equal to the amount of energy in 7.5 gallons of gasoline. Therefore, the average GJ value per metric ton of cotton fiber would be equivalent to 142.5 gallons of gas. Taking into account the cost of gas in the south which is where the majority of American cotton farms and plantations are, it would cost nearly $400 for fuel alone to produce a metric ton of cotton fiber.

A way many farmers can monitor exactly how much energy they expend during their cultivation, the effects of tilling dictate an extremely detrimental amount energy that may be used. There are three different ways of tilling the soil. In other words, tilling essentially means the ways in which the farms disturb the soil to alter the speed of harvests. Zero tilling meaning that soil planted with cotton seeds would remain undisturbed. Minimum tillage utilizes as little disruption of the soil as possible. Finally, conventional tillage explains the traditional method of tilling and alteration of the soil to harvest. Understanding this, the comparison between energy consumption of zero tilling and conventional tilling can speak volumes in the amount of embodied energy we see throughout the cultivation of cotton. “It was found that conventional cotton farms on average consume 11.4 GJ of energy per bale, with related emissions of 0.83 tonnes CO2e/bale. This is in comparison to the values of 10.0 GJ/bale and 0.83 tonnes CO2e/bale.” (Khabazz) The difference of 1.4 GJ doesn’t seem like much but that’s nearly a million BTU difference between conventional and zero tilling.

Luckily, energy usage in cotton production has dramatically decreased over the last few decades making way for a less harmful impact on the Earth and less costs of energy consumption in the long run. Energy use has had about a 55% decrease in cotton production since the 80’s. (Field to Market)

Moving from the field to the factory, another major consumer of energy along the journey to becoming a cotton swab is transportation. Fuel is already so costly in energy and cost on the fields but the transportation of these goods can also require a hefty amount of energy consumption as well. Direct energy use is required in the transportation of the cotton bales taken from the farms. About 400 million BTU is consumed on truck transportation alone.

As these bales of cotton lint make their way to cotton swab factories, some cotton will make its way to different factories to be transformed into the cotton paper sticks that hold cotton swabs together. The most predominantly used company to create these cotton paper sticks is called Domtar. With only a small number of factories across the United States, Domtar requires a vast amount of travel to receive and ship out goods. In comparison, the 400 million BTU that is expended on transporting cotton bales for cotton swab tips would be extremely smaller than the amount of energy needed to receive, manufacture, and send cotton paper sticks.

At the tip of this journey, the thoroughly processed and many-times transported cotton is reunited once again at the factories in which cotton swabs are finally put together. Details on how much energy these factories need to run isn’t readily available information. However, one can imagine that the amount of electricity needed is an immense value. Once at the factory, bales of cotton are sent through a feeder and an opener to pull and shred the fibers apart. Large rollers then comb out these fibers, creating thick webs of cotton fiber that are passed on through a funnel. This funnel then created round strands of cotton fiber to then be woven around the cotton sticks that had traveled so far to get to that point. This is when the cotton swab reaches its final transformation before being packed off and shipped with many others.

Understanding the needs of proper sustainability, it is almost concerning to see the lack of different resources available on energy consumption past the agricultural production of these cotton products. Cotton swabs are typically made entirely from cotton, a very intensive agricultural product. Utilizing proper tillage as well as renewable resources can benefit the nation drastically as cotton production has increased while energy use has reduced by 38% since 1980 due to more efficient technologies in harvesting and ginning, as well as reduced tillage. While hundreds of trillions of BTU is being used to fuel agricultural transportation alone, there is definitely a need to further implement sustainability practices. In doing so, the production of cotton swabs can help the production of a simple household item become not only a compostable good but also a product that doesn’t take immense amounts of energy to end up in our ears.

Ultimately, the lengthy journey of the cotton swab comes to an end at some point. Thankfully, that end (for most cotton swabs) can end in compost and going back into the earth after so much energy has been used to produce it. In fact, maybe one day cotton farms could also rely on the biofuel available in cotton seeds to make for a truly sustainable cultivation of cotton and result in many more cotton swabs to come.

Works Cited

“Cotton Swab.” How Products Are Made, Advameg Inc,

www.madehow.com/Volume-4/Cotton-Swab.html.

“Energy U.S. | Cotton LEADS Sustainable Cotton Agriculture.” Cotton LEADS - Sustainable Cotton Production, cottonleads.org/sustainable-production/energy-united-states/.

“Estimating the Carbon Footprint of a Fabric.” O ECOTEXTILES, Wordpress, 31 Jan. 2012, oecotextiles.wordpress.com/2011/01/19/estimating-the-carbon-footprint-of-a-fabric/.

Daystar, Jesse, et al. “Cotton Sustainability.” BioResources, bioresources.cnr.ncsu.edu/wp-content/uploads/2016/12/BioRes_12_1_362_Daystar_BHK_Trends_USA_Cotton_Prodn_Resource_Survey_10072.pdf.

“FAQ.” Qtips, Qtips, www.qtips.com/faq/.

http://gabi-documentation-2018.gabi-software.com/xml-data/processes/8489873f-b1a0-4739-9534-54fc22ea222f.xml

Ferdman, Roberto A. “The Strange Life of Q-Tips, the Most Bizarre Thing People Buy.” The Washington Post, WP Company, 20 Jan. 2016, www.washingtonpost.com/news/wonk/wp/2016/01/20/we-have-a-q-tips-problem/?noredirect=on&utm_term=.d11dca4757e6.

Hicks, Susan. “Energy for Growing and Harvesting Crops Is a Large Component of Farm Operating Costs.” U.S. Energy Information Administration, 17 Oct. 2014, www.eia.gov/todayinenergy/detail.php?id=18431.

Johnson, James, et al. “Agricultural Outlook Forum 2018.” USDA, USDA, 23 Feb. 2018, www.usda.gov/oce/forum/2018/commodities/Cotton.pdf.

Khabazz, Borzoo G. “LIFE CYCLE ENERGY USE AND GREENHOUSE GAS EMISSIONS OF AUSTRALIAN COTTON: IMPACT OF FARMING SYSTEMS.” University of Southern Queensland, University of Southern Queensland, 2010.

Medical, Puritan. “The History and Evolution of the Swab.” Puritan Blog, Puritan Medical Products, 15 Dec. 2017, blog.puritanmedproducts.com/bid/357796/the-history-and-evolution-of-the-swab.

Melcher, Jerald R, and Debra A Speichert. Swab and Method of Manufacturing and Using It.

Moser, Rod. “Q-Tips – Weapons of Ear Destruction? « Family Webicine.” WebMD, WebMD, 13 Nov. 2006, blogs.webmd.com/all-ears/2006/11/q-tips-weapons-of-ear-destruction.html.

“Paper Sticks: The Key to Cotton Swabs and Lollipops.” Domtar, Domtar, 12 Mar. 2018, newsroom.domtar.com/paper-sticks-cotton-swabs-lollipops/.

“Sector #111920: Cotton Farming .” Eiolca, www.eiolca.net/cgi-bin/dft/display.pl?hybrid=no&first_level_sector=-1&second_level_sector=111920&newmatrix=US430CIDOC2002&key=12890365446&value=2752716255&incdemand=1&selectvect=fuels&select_button1=Run+Model.

Stein, Joel. “Something Evil in the Ear Canal.” Time, Time Inc., 26 Mar. 2001, content.time.com/time/nation/article/0,8599,105556,00.html.

“The Story of Cotton - Production.” Cotton's Journey, Cotton Journey, www.cottonsjourney.com/storyofcotton/page4.asp.

Rafael Crispin Alejandrino

Christina Cogdell

Life Cycle Paper Outline

21 November 2018

Q-tip’s Waste and Emissions .

Analyzing the growth of cotton, production of paper and the transportation have distinguishing wastes that will continue to add upound land degradation, greenhouse gases and even lower biodiversity.

Cotton, a primary resource, is the main part of a Q-tip that requires heavy duty John Deere tractors and cotton pickers to grow and harvest. These machines primary source of fuel is diesel and even though it is renewable, diesel is not sustainable due to the high consumption, According to farmdoc University of Illinois, roughly 3.7 gallons of diesel is used per acre when tilling and roughly the same for harvests. In 2017 a study made by Statista depicted that 20,545 bales of cotton were produced. If one acre produces on average 1.8 bales of cotton, according to Statista, then we know that roughly 11,413 acres were used. Since 3.7gallons of diesel is used per acre then in 2017, 42,228 gallons of diesel was used by the top ten states and if 12% of diesel byproducts is CO2, according to (Dieselnet Technology Guide, W. Addy Majewski), then that means 5,067 gallons of CO2 was produced. Along with CO2 a large quantity of water is used for cotton and even though the amount of water used varies with different regions and different styles of farming; a rough estimate of water usage to grow cotton is 7.8 megalitres/hectare or 2,060,540 gallons/2.47 acres of cotton. The amount of cotton that went to making Q-tips is unknown, but we do know more and more land is required to keep up with demand.

Our land continues to degrade around cotton crops due to their high intensive insecticide use. Common insecticides include: aldicarb sulfoxide, phorate 20 and methamidophos. Aldicarb sulfoxide, the popular choice of insecticide for cotton, can have an extremely high levels of toxicity which is measured by the LD50 value, “The LD50 value, defined as the statistically derived dose that, when administered in an acute toxicity test, is expected to cause death in 50% of the treated animals in a given period, is currently the basis for toxicologic classification of chemicals” (Environ Health Perspect. 1998 Apr; 106(Suppl 2): 497–503.). Reading at a LD50(rat) of 0.9mg/kg, aldicarb sulfoxide is a large contributor in contaminating pristine permeable soil as soon as it touches ground level dissolving within the water molecules after a week or two. The EPA has removed the insecticide from use in potato and citrus crops in 2012 and is declaring a band on aldicarb sulfoxide on all crops in 2018. Phorate 20, another commonly used chemical, has a LD50(rat) value of 7.1mg/kg a highly toxic insecticide to organisms. Fish, wildlife and bees are highly sensitive to phorate 20 and will easily kill birds and mammals if granules are not properly covered in soil when used. Ironically when it is properly covered the more the easier the toxin can penetrate the permeable soil adding to runoff causing more harm to aquatic organisms. The list continues with methamidophos LD50(bobwhite quail) value is 8-11 mg/kg which keeps on contributing to the death or severely damaged aquatic organisms. Insecticide runoff have a huge affect on our food production, polluted aquifers and even lead to dead zones at coastal areas such as the San Francisco port, Los Angeles port, all along the east coast, and the north side of the gulf of Mexico, according to (ThoughtCo What Are Dead Zones in the Ocean). On the bright side Q-tip manufactures appear to have emissions under wraps.

The waste and emissions from the actual manufacturing of Q-tips appeared to have no emissions. Cotton making machines are all electric, a secondary energy source, which on its own has traces of emissions when produced, but is not part of the Q-tips production. Little to no information was found on the companies that manufacture Q-tips besides a, How Its Made, video four years ago which can be viewed at the end of the bibliography. Despite the little to no emissions from Q-tip manufactures, paper plants have a different story.

The paper sticks for Q-tips are provided primarily by Domtar company claiming that their emissions have decreased exponentially and their renewable energy has greatly increased. Despite Domtar’s shift to renewable energy 33.7% of their energy still comes from fossil fuels burning large quantities of CO2 and CO during the paper making process. Paper plants get their primary resource from primarily pine, spruce and fir trees. According to the EPA’s 2017 Toxic Release Inventory Program paper making plants are one of the worst contributors to toxic air pollutants. Toxic chemicals released from these plants are: hydrochloric acid, toluene, methanol, chlorine dioxide and formaldehyde. Hydrochloric acid is an aggressive toxin that contributes towards acid rain where patches of dead zones on land sometimes form and organisms can no longer grow. These are mainly small grasses which kick start a habitable region and if there is no kick start then there is no ecosystem. Methanol dissolves quickly into water and remains in the atmosphere for 18 days according to the DEE ( Department of the Environment and Energy). Since methanol does not bind well to the soil’s properties it has high probability for entering groundwater. High levels of exposure lead to the death of aquatic and avian organisms. Toluene, naturally broken down by organisms, can carry several health concerns towards the public ranging from headaches to death in extreme cases. Chlorine dioxide will break apart in the atmosphere rather quickly, but lingers long enough in soil and water to have implications of toxic residue causing more aquatic organisms to be exposed to harmful toxins. The accumulation of these few dangerous gaseous chemicals only contribute to a more concentrated acidic rain affecting every aspect of our living conditions. In addition Domtar is limited to efficient transportation where the majority of their products are moved by big rigs which use up large quantities of diesel.

Diesel, which was discussed in the second paragraph, produces a small, but quantitatively large amount of CO2. Domtar, the biggest company to produce all varieties of paper including paper sticks, have only 10 locations in the U.S, which are all near the east coast. So their material has to arrive to the west coast one way or another according to Domtar’s website (Domtar Transportation and Logistics) their primary transportation, which accounts for 62%, are trucks. Big rigs have diesel engines where 12% of its byproducts when burned is CO2 gas. Big rigs have absolute rubbish mileage averaging at about 8.9 mi/gallon, according to (Popular Mechanics) when the truck is carrying near maximum capacity at around 45,000-48,000 lbs of cargo. This stressed the fact that trucks may travel up to 2 - 3 thousand miles to arrive on the west coast and with simple multiplication of 8.9gallons of diesel with the distance traveled, let's say 2.5 thousand miles for the average, we end up with 22,250 gallons of diesel used up. We use this calculation and multiply by the 12% of CO2 produce and we get a result of 2,670 gallons of CO2 produced...for one truck. Rails make up 18% of transportation where they can carry one ton of cargo 500mi on one gallon of diesel fuel according to (CSX and Wired), but produce triple amounts of nitrogen oxide than trucks. Ocean vessels make up 9% of Domtar’s transportation where the largest carrying cargo ships can produce as much CO2 as 50 million cars according to (NEW ATLAS, Environment). Intermodal transport makes up the last 11% where a variety of other sources are used. Nonetheless paper making factories such as Domatr are striving and setting new plans for a greener future through renewable sources of fuel. Forest cutting companies are now planting 4 trees for every tree cut down and semi trucks are getting more aerodynamic to increase mileage. All these factors contribute towards the waste and emissions of Q-tips.

It is uncertain how much of the cotton produced by the farms go to the production of Q-tips or how many big rigs drove thousands of miles for the transportation of Q-tips. Regardless, all these factors contribute toward waste and emissions of a Q-tips life cycle and thus the degradation of land, accumulation of greenhouse gases , and a decrease in biodiversity.

Works Cited

“Domtar.” NEWSROOM. N.p 06 June 2017. https://newsroom.domtar.com/paper-sticks-cotton-swabs-lollipops/ Accessed 28 October 30

“PAPER because.” TRUTH or FICTION. N.p n.d http://www.paperbecause.com/paper-is-sustainable/paper-truth-or-fiction Accessed 28 October 2018

“mind the trash.” Biodegradable Cotton Swabs. N.p n.d. https://mindthetrash.com/product/biodegradable-cotton-swabs/ Accessed 28 October 2018

“AMERICAN FOREST & PAPER ASSOCIATION.” Paper Recycling. N.p 2018 http://www.afandpa.org/our-industry/paper-recycling 28 October 2018

“WHIRLSTON” Cotton Picking Machine. Whirston 2003-2013 http://www.harvestermachine.com/product/Cotton-Harvester.html Accesed 29 October 2018

Citron-Fink Ronnie “care2.” Q is for Q-Tips. N.p 13 April 2010 https://www.care2.com/greenliving/q-is-for-q-tips.html Accessed 29 October 2018

“Treehugger” How many gallons of water does it take to make….Merchant Brian 24 June 2009 https://www.treehugger.com/clean-technology/how-many-gallons-of-water-does-it-take-to-make.https://www.care2.com/greenliving/q-is-for-q-tips.html Accessed 29 October 2018

“Methamidophos” -MATERIAL SAFETY DATA SHEET. ZHEJIANG RAYFULL CHEMICALS CO.,LTD http://rayfull.com/UploadFiles/PDF/201369106423.pdf Accessed 30 November 2018

“Phorate 20G” -MATERIAL SAFETY DATA SHEET. N.p n.d http://www.t3db.ca/system/msds/attachments/000/001/165/original/T3D0225.pdf?1413587636 Accessed 30 November 2018

“Comsol” Simulating Pesticide Runoff, the Effects of Aldicarb. Alexandra Foley 08 August 2013 https://www.comsol.com/blogs/simulating-pesticide-runoff-the-effects-of-aldicarb/ Accessed 30 November 2018

“Cotton Pesticides” The Deadly Chemicals in Cotton. Environmental Justice Foundation n.d https://ejfoundation.org/resources/downloads/the_deadly_chemicals_in_cotton.pdf Accessed 30 November 2018

“EHP(Environmental Health Perspectives)” Acute Oral Toxicity. E Walum 1998 https://www.ncbi.nlm.nih.gov/pmc/articles/PMC1533392/ Accessed 30 November 2018

“Colorado State University Extension” Estimating Farm Fuel Requirements. H.W Downs and R.W Hansen n.d www.waterandenergyprogress.org/library/05006.pdf Accessed 30 November 2018

“Farmdoc university of Illinois” Farm economics Facts & Opinions. N.p 19 April 2006 www.farmdoc.illinois.edu/Manage/newsletters/fefo06_07/fefo06_07.html Accessed 30 November 2018

“Statista” Leading 10 U.S states for Cotton production in 2017. N.p n.d https://www.statista.com/statistics/248776/top-10-us-states-for-cotton-production/ Accessed 30 November 2018

“DieselNet Technology Guide” What Are Diesel Emissions. W. Addy Majewski n.d https://www.dieselnet.com/tech/emi_intro.php Accessed 30 November 2018

“ABC NEWS” Murray - Darling Basin Plan: How much water is used to grow cotton? Kristy Reading 25 July 2017 https://www.abc.net.au/news/rural/2017-07-25/murray-darling-basin-plan-how-much-water-to-grow-cotton/8742234 Acccessed 30 November 2018

“Domatars” Transportation and Logistics. N.p n.d accessed 5 december 218 https://www.domtar.com/en/how-we-work/sustainability-domtar/transportation-and-logistics

“Ecology Earth” Paper Chase. Sam Martin 10 September https://www.ecology.com/2011/09/10/paper-chase/ Accessed 5 December 2018

“Youtube” How Its Made. How its made 24 December 2014 https://www.bing.com/videos/search?q=how+are+qtips+made&qs=n&sp=-1&pq=how+are+qtips+made&sc=1-18&sk=&cvid=BF0FD46A5ED74FD49D729D0258372CE7&sid=2FEC78A3BEAA6C0F07087418BFD96D6E&jsoncbid=1&ru=%2fsearch%3fq%3dhow%2520are%2520qtips%2520made%26qs%3dn%26form%3dQBRE%26sp%3d-1%26pq%3dhow%2520are%2520qtips%2520made%26sc%3d1-18%26sk%3d%26cvid%3dBF0FD46A5ED74FD49D729D0258372CE7&view=detail&mmscn=vwrc&mid=29F894D08EDB5D982D1729F894D08EDB5D982D17&FORM=WRVORC Accessed 4 December 2018