Design Life-Cycle

assess.design.(don't)consume

Coperni Air Swipe Bag Life Cycle

Audrey Patey

DES 40A

4 June 2024

Coperni Air Swipe Bag, Research Paper

The Material of Silica Aerogel in Coperni’s Air Swipe Bag

Introduction

First made public in a runway show during the Paris Fashion Week in 2024, the Coperni Air Swipe bag challenged the idea of science in relation to fashion, as well as showed how such a delicate object can be made out of a strong material. But, what exactly is this purse made out of? Lightweight, durable, and almost transparent, silica aerogel is a material mostly used by NASA for space exploration. Now, however, Coperni uses it to change the way society views textile materials. To defy most luxury purse traditions, Coperni stepped out of what is considered “normal” for most brands and created a purse out of 99% silica aerogel, an interesting nanostructure that is almost completely transparent to the human eye and considerably lightweight. Originally used in NASA technology, Coperni now begs the question whether silica aerogel can be used in more luxurious fashionable items, like their purse, by utilizing such an interesting nanomaterial that deems to be environmentally friendly and completely recyclable.

How is Silica Aerogel, the Main Material of the Air Swipe bag, Made?

Coperni’s Air Swipe bag is more than just a fashion statement, it is a scientifically innovative creation that uses several chemical mixtures, such as sodium silicate, to make a purse through an intensive process that involves aging, drying, and molding the material. Although this material has been thoroughly researched and used by scientifically important companies, like NASA, Coperni appropriates the uses of silica aerogel and turns it into a textile material, creating a one-of-a-kind bag. However, this silica gel does require quite a lot of time, cost, and work to make it perfectly clear as shown in the pictures of the AirSwipe Bag by the famous Parisian fashion company. As stated earlier, making silica aerogel requires a lengthy process, one that first starts with the mixing of chemicals. A youtube video, which demonstrates the whole procedure of making aerogel, explains how chemicals like tetramethyl orthosilicate (TMOS) and methanol or ethanol are combined with water to create a gel like material. However, it still remains rather fragile and requires a mold to make a proper shape [8]. Furthermore, a study that describes silica aerogel’s life cycle explains how, in order to avoid cracks during the drying process, the gel needs to be aged in a “pure organic solvent, usually methanol, ethanol or acetone for at least 24 h.” After the lengthy aging process, silica aerogel needs to dry in a mold under low temperature using CO2, “Here, the solvent inside the wet gel is replaced with liquid CO2 prior to drying, as it possesses a critical point closer to ambient temperature. Drying therefore takes place at ∼40 °C and ∼100 bar, making the process more viable for commercial production” [5]. Lastly, Coperni takes this method of creating silica aerogel and turns it into a stronger material worthy for a physical fashion item by adding glass. Although there is not much information found on how Coperni used glass to make a stronger silica aerogel that can “handle pressure of 4,000 times its weight and heat up to 1,200 degrees Celsius,” Coperni’s Air Swipe bag is stronger than most fragile aerogel made by scientists before [6].

Nevertheless, the formation of Coperni’s Air Swipe bags is probably the most important, but extremely difficult, step in the development of the fashion item. As mentioned before, silica aerogel needs to be dried in a mold to not only get a pleasing shape, but also avoid cracks or any sort of material failures. Thus, in order for Coperni to have formed the material in the shape of their luxurious Swipe bag, they would have needed to create a specific mold. As stated by NileRed in his youtube video, aerogel requires a mold that is non-adhesive in order to ensure a careful removal of the material when it is dry. Although information about Coperni’s specific process in making the aerogel is scarce, one could assume based on the current scientific discoveries about this material that the fashion company used some sort of non-stick mold that allowed for the aerogel to be cautiously removed. Then, from the mold, it would have been placed in a safe holder most likely made of foam to keep the silica aerogel from breaking if dropped. A briefcase of this sort can be seen on Coperni’s instagram [3,4]. Using the briefcase, it could be easily transported as well. Coperni seems to have taken the extra precautions to make sure this delicate, yet extremely durable bag, is safely transported to whichever destination it is needed at.

To conclude, this process of creating silica aerogel is extremely unique and commonly used to fabricate this material for scientific uses, but how exactly did silica aerogel enter the fashion universe, and can it be used efficiently as a material in textiles in the future?

Silica Aerogel: From NASA to Textiles

The Coperni Air Swipe bag is known to have taken inspiration from NASA’s utilization of silica aerogel, mostly gaining knowledge about how they have fabricated this material to create their own that combines glass with the gel solution. Silica aerogel was a material that was first scientifically investigated for the purpose of using it in spaceships and suits, this is because aerogel has many properties that help with certain functions that spaceships need in order to go beyond our Earth’s atmosphere. For example, according to a study that talks about NASA’s utilization of silica aerogel, aerogel is used for Hypervelocity Particle Capture, Thermal Insulation, and Cryogenic Fluid Containment. Due to its “extremely low conductivity” and “highly porous” property, silica aerogel is able to assist in these essential astronautical applications [1]. Furthermore, NASA has used silica aerogel in spacesuits for thermal insulation as well, which marks the beginning of silica aerogel as a textile material–even if it is still used for scientific purposes. One such study describes its uses in spacesuits by mentioning that “Silica aerogel's nanometer scale pore structure and its tenuous solid connections between the silica particles making up the solid structure are responsible for the low thermal conductivity of this material” [11]. These same properties have also made silica aerogel enter the world of technological textiles as a material. Some examples of how aerogel is used in this field of design include a certain blanket that is used to help protect those working in harsh conditions or, as of the present, Coperni’s Air Swipe Bag.

But why would fashion or textile designers choose such an interesting material to create clothing or accessories? An article answers this by explaining how silica aerogel is helpful in a protective blanket because of its distinctive properties. The author describes that, “the five layers laminate had good mechanical properties, and was resistant to rubbing, was water vapor permeable, hydrophobic and oleophilic material with good thermal insulation.” In other words, workers who need these specific features to protect themselves from hard conditions at work will benefit from the use of silica aerogel [9]. Additionally, silica aerogel also has the traits of being lightweight, sturdy, and flexible, which makes it a perfect material choice for Coperni’s innovative bag. However, for the fashion company, silica aerogel is much more than just a practical and sturdy material. It is a bond between science and fashion, one that may actually benefit the world of textiles due to its efficiency and low environmental impact. With that said, although aerogel has many advantages and uses, one might wonder its environmental impact and waste management as a material.

Silica Aerogel: Waste and Management

Even though silica aerogel might have a high cost for production, it is rather efficient as a material in terms of practicality and waste management due to its many uses, low environmental impact, and recyclability. Silica aerogel is a wonderful material for textiles not only because of its porous properties, but also because it is lightweight, aesthetically beautiful, and perfect for thermal regulation. However, Coperni’s Air Swipe bag isn’t really used for any of these purposes other than for the spectacle and the aesthetics. In fact, it is rather useless because “It barely has space to hold your Porsche Taycan’s keys and perhaps some Dior lipstick and a zip bag full of white pixie dust” [4]. So, if Coperni didn’t have the shared goal of practically, what is the purpose of displaying this technological creation? An interpretation could be that Coperni uses the bag to symbolize a change in the fashion industry as designers start to incorporate more environmentally friendly materials that have not been used before. The material of silica aerogel is very environmentally friendly because it is mostly made of organic substances and can be recycled easily. To give some context, silica is a chemical formula (SiO2) that is commonly found in the wild, making silica aerogel an organic and reusable material. A study that analyzed various types of aerogel determined that when creating the gel, it is important to avoid inorganic substances in order to make the material environmentally safe [9]. This could further help with the waste process of Coperni’s Air Swipe bags, leaving a low environmental footprint and encouraging more fashion designers to be environmentally cautious. However, this material is not often applied for commercial use because “the main limitation of preventing silica aerogel from commercially integrating into the aviation sector is its high cost” [1]. The same could be said for the uses of silica aerogel in textiles. Coperni is a luxurious fashion company that usually sells their Swipe Bag products at high prices around the thousands, which means this new Air Swipe purse will most likely not be available for the general public due to the management and production costs of silica aerogel. Overall, the waste and management of Coperni’s Air Swipe Bag is not much of a hassle despite the high costs, since the material it is made out of can be easily recycled by using organic substances to create the gel.

Conclusion

With the use of this lightweight, eco-friendly, and porous material, Coperni’s Air Swipe bag is a huge step forward for the fashion industry, since it is not only is utilizing more efficient materials, but also uses science to find a textile that may be better to use for the future of our world. Perhaps with this new innovation, the fashion industry will get the inspiration to use textiles that do not make a negative impact on the environment, but still have relevant functions to society.

Works Cited

[1] Bheekhun, Nadiir, et al. "Aerogels in aerospace: an overview." Advances in Materials Science and Engineering 2013 (2013), doi.org/10.1155/2013/406065.

[2] Bi, Hengchang, et al. "Carbon fiber aerogel made from raw cotton: a novel, efficient and recyclable sorbent for oils and organic solvents." Advanced Materials 25.41 (2013): 5916-5921, doi.org/10.1002/adma.201302435.

[3] Bonilla, Cortne. “Would You Buy a Bag Made of Air?” The Cut, 2024. www.thecut.com/article/coperni-air-swipe-bag.html

[4] Diaz, Jesus. “NASA used this material to catch comet dust. Now it’s being used for a luxury handbag.” Fast Company, 2024, www.fastcompany.com/91047739/nasa-used-this-material-to-catch-comet-dust-now-its-being-used-for-a-luxury-handbag

[5] Dowson, Mark, et al. "Streamlined life cycle assessment of transparent silica aerogel made by supercritical drying." Applied Energy 97 (2012): 396-404, doi.org/10.1016/j.apenergy.2011.11.047.

[6] Dreith, Ben. “Coperni unveils Air Swipe bag made out of 99 percent air.” Dezeen, 2024. www.dezeen.com/2024/03/12/coperni-air-swipe-bag-nasa-aerogel/

[7] Gurav, Jyoti L., et al. “Silica aerogel: synthesis and applications.” Journal of Nanomaterials 2010 (2010): 1-11, doi.org/10.1155/2010/409310.

[8] NileRed. “Making Aerogel.” Youtube, 2020, youtu.be/Y0HfmYBlF8g?si=0MDHuwbxBexETeBD.

[9] Pinto, Isabel, et al. “Environmental impact of the subcritical production of silica aerogels.” Journal of cleaner production 252 (2020): 119696, doi.org/10.1016/j.jclepro.2019.119696.

[10] Prevolnik, Vanja, Polona Kraner Zrim, and Tatjana Rijavec. “Textile technological properties of laminated silica aerogel blanket.” Contemporary Materials 5.1 (2014): 117-123, doi.org/10.7251/COMEN1401117P.

[11] Trevino, Luis A., et al. Aerogel-based insulation for advanced space suit. No. 2002-01-2316. SAE Technical Paper, 2002, doi.org/10.4271/2002-01-2316.

[12] Veritasium. “Worlds Lightest Solid!” Youtube, 2019, youtu.be/AeJ9q45PfD0?si=2W3-CV5G2bJLGQhV.

Arielle de Leon

DES 40A

Professor Cogdell

4 June 2024

Embodied Energy in the Production of the Coperni Air Swipe Aerogel Bag

Founded in 2013 by Sébastian Meyer and Arnaud Vaillant, and quickly making a name for their brand, Coperni is a growing modern-luxury Parisian brand. Winning ANDAM’s Creative Label Prize in 2014 to working with celebrities like Bella Hadid and Kylie Jenner, Coperni continues to evolve and create special pieces like their exclusive Airswipe bag made of NASA aerogel that caught the attention of many people during Coperni’s F/W 2024 runway show during Paris Fashion Week. The infamous Airswipe bag isn’t up for sale, hence why it’s rare. Although the founders of the brand haven’t given out much information about the production and energy used to make the bag, we know that it’s made up of NASA aerogel, so we can conclude that the forms of energy used are thermal, kinetic, mechanical, and, chemical energy because of the help from machines and personnel.

The preliminary phase of making the Coperni purse is using the material, aerogel. It is a synthetic material because of the transformation process it goes through. Aerogel comes from silica gel, for the primary material which is “silicon dioxide.” Silica can be found in stone, soil, and sand, and comes in different forms, quartz being the most common. It can be used for various things such as preserving food, documents, drying flowers, and much more. Silica is extracted from the earth by mining trucks that use kinetic energy to grab and move rocks. NASA aerogel was used to “catch stardust” and is the aerogel used to create the purse.

Scientists make the gel material by combining different chemicals. According to NASA, “They are created by combining a polymer with a solvent to form a gel, and then removing the liquid from the gel and replacing it with air. Aerogels are extremely porous and very low in density. They are solid to the touch. This translucent material is considered one of the finest insulation materials available.” In creating aerogel, you can create your own aerogel at home. There are plenty of videos online that show how to make it. You just need the right tools and materials. Since NASA hasn’t officially stated if they do or don’t use machines to make the aerogel, we can assume that they do because you will need to make a lot of aerogel to create the iconic Coperni purse, hence why it would cost a lot to produce. “Aerogel costs around $23,000 per pound to produce, which means each bag uses approximately $1,675 of aerogel. And considering Coperni’s leather Swipe bags cost $700+, I imagine this must be a VERY costly handbag.” (Berisford). The process used to make aerogel uses kinetic energy, a human adding the chemicals together, chemical energy, which are the chemical reactions produced to make the product, and mechanical energy, the machines mixing and freeze-drying the product. In order for these machines to work, they all contain power cables that help transfer energy from a source like fossil fuels, to equipment such as a mixing machine. According to an article I found, “Most power cables have a design life of between 20 to 30 years. If the cables are not fully loaded, they are expected to last beyond their design life.” (Electrotechnik). This means that power cables are reliable and can last up to two to three decades. Since they can last for quite a long time, machines that make aerogel will be able to produce more, which then leads to more use of fossil fuels and energy.

Although the bag is from the brand Coperni, the production is carried by, Ioannis Michaloudis, who is a Greek researcher and visual artist, according to Dreith. “The small bag is made from silica aerogel, is the "lightest sold [material] on planet Earth". The material – which has a chemical composition similar to gas – forms the shell of the bag, while the interior is air.” (Michaloudis). The whole aerogel bag is made up of

Aerogel distribution requires a significant amount of embodied energy. The raw materials would have to be transferred to factories, and while in the factories, the aerogel is being made into a bag. After being made, the bag will then be sent to Coperni to be shown off during the fashion weeks. To get from factories, warehouses, and shows, transportation such as boats, vehicles, and planes will be needed. This calls for a variety of energies, including chemical energy for the fossil fuels needed to power boats and vehicles, chemical and mechanical energy from fuels that move engines to power turbines, and kinetic energy for moving the product from one transport to another.

Even though the Coperni aerogel bag isn’t up for sale, the aerogel itself can be properly maintained when you’re delicate with it. “Coperni’s new Air Swipe Bag weighs only 33 grams, given that NASA’s nanomaterial silica aerogel is a highly delicate and non-fragile nanomaterial.” (Design boom). According to Dreith, “The air swipe bag has a dimension of 27 by 16 centimeters.” This is a really small bag, which can probably only carry a phone and maybe a few lip products. The aerogel bag should be handled with care, according to NASA, “Silica-based aerogels are very light, as they are about 95% porous. Silica aerogels are very useful, but they have limitations—they are very fragile.” Although aerogel is delicate, it can withstand high temperatures and heavyweight. “And not only is it light, but “it can support up to 4,000 times its own weight and withstand temperatures up to 2,200° Fahrenheit.” (Berisford). To think that NASA aerogel is fragile, but can withstand extreme temperatures and weight, it’s very clear to see that it can be maintained with proper care and use. This uses kinetic energy by the movement of human energy, using it as a bag.

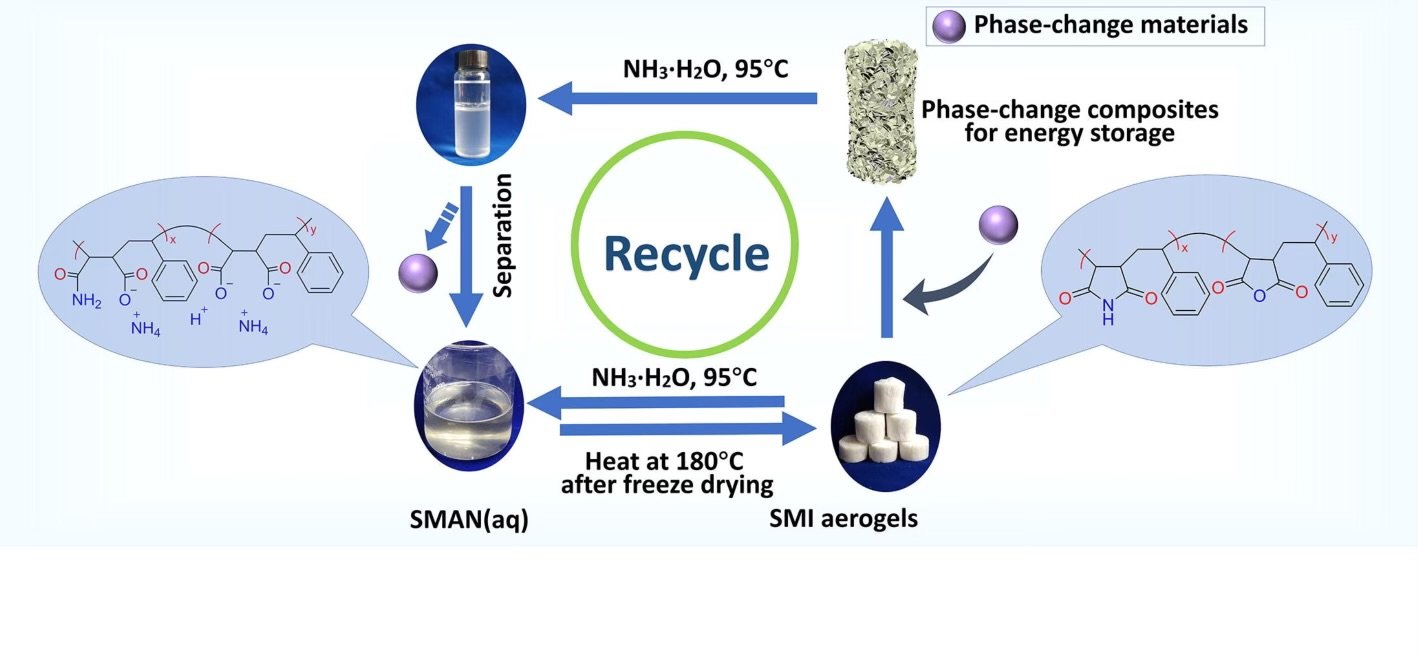

Aerogel is recyclable and is recycled by adding a chemical solution to it. “The polymer aerogel can be recycled by using aqueous solution under mild condition.” (Yao, 1). Most aerogels are non-toxic and aren’t harmful to the environment since silica is found in natural materials such as sand and rocks. The energy used to recycle aerogel is kinetic and mechanical energy. Kinetic energy is used by humans adding the solution into the aerogel and the machines use their energy to mix the solution in to renew it and start the aerogel-making process again.

Since aerogel is renewable and can be recycled, there isn’t any waste that goes into it. Coperni hasn’t put the Aerogel airswipe bags up for sale, so there shouldn’t be anyone throwing it away because no one will have it. Also, it’s a rare piece, so I’m sure no one would throw away an exclusive gem.

In conclusion, numerous steps require energy in the form of kinetics, chemicals, mechanical, and thermal to make Coperni’s iconic aerogel bag. The process of acquiring the raw materials involves using fossil fuels and the energy used in the manufacturing and transportation process adds to the total use of energy. Even though the exact amount of energy used by Coperni is not disclosed, it is clear that there is much energy put into the whole production, which we can conclude isn’t a sustainable process. Although Coperni isn’t sustainable, aerogel itself is renewable and can be made repeatedly. Aerogel is such an amazing material and it’s very impressive to see a Fashion brand show off something that has never been made nor seen before.

Works Cited

[1] “How Is Aerogel Made?” Aerogelorg RSS, www.aerogel.org/?p=4.

[2] Berisford, Jonathan. “Aerogel Handbag Is Made from the World’s Lightest Material.” Technabob, 7 Mar. 2024,

technabob.com/aerogel-handbag-is-made-from-the-worlds-lightest-material/.

[3] “Brand.” Coperni, coperniparis.com/en-us/blogs/about/brand.

[4] Camara, Sharon. “Coperni Unveils Bag Made of 99 Percent Air.” FashionUnited,

FashionUnited, 7 Mar. 2024, fashionunited.com/news/fashion/coperni-unveils-bag-made-of-99-percent-air/2024030758762.

[5] Dreith, Ben | 12 March 2024 3 comments. “Coperni Unveils Air Swipe Bag Made of 99 per Cent Air.” Dezeen, 14 Mar. 2024,

www.dezeen.com/2024/03/12/coperni-air-swipe-bag-nasa-aerogel/#:~:text=Greek%20researcher%20and%20visual%20artist,show%20during%20Paris%20Fashion%20Week.

[6] ELEK Software. “Estimating Cable Life Expectancy.” ELEK Software,

elek.com/articles/estimating-cable-life-expectancy/#:~:text=Most%20power%20cables%20have%20a,between%2020%20to%2030%20years.

[7] “Aerogel Insulation for Better Thermal Protection.” Gore,

www.gore.com/products/thermal-aerogel#:~:text=CONTACT%20US-,Aerogel%20Insulation%20Properties,1.8J%2Fg%20%C2%B0C.

[8] “The Coperni-Can Revolution: What’s behind the 99% Air Swipe Bag?: Istituto Marangoni.” ISTITUTOMARANGONI,

www.istitutomarangoni.com/en/maze35/game-changers/the-coperni-can-revolution-whats-behind-the-99-air-swipe-bag.

[9] “A Bag Made of 99 per Cent Air.” MaterialDistrict,

materialdistrict.com/article/a-bag-made-of-99-per-cent-air/#:~:text=During%20Paris%20Fashion%20Week%2C%20fashion,by%20NASA%20to%20capture%20stardust.

[10] “Aerogels: Thinner, Lighter, Stronger.” NASA, NASA, 25 July 2023,

www.nasa.gov/aeronautics/aerogels-thinner-lighter-stronger/#:~:text=They%20are%20created%20by%20combining,the%20finest%20insulation%20materials%20available.

[11] Speakman, Kimberlee. “Coperni Delivers Another Fashion Magic Trick with Bag Made of 99% Air - and the NASA Science behind It Is Wild.” Peoplemag, PEOPLE, 5 Mar. 2024,

people.com/coperni-latest-viral-bag-features-99-percent-air-nasa-technology-photos-details-8604601.

[12] 2, Upcycleluxe. “The Futuristic Sustainable Bag - Coperni Air Swipe Bag Made of 99% Air.” Upcycleluxe, Upcycleluxe, 8 Mar. 2024,

upcycleluxe.com/blogs/our-readers-digest/the-futuristic-sustainable-bag-coperni-air-swipe-bag-made-of-99-air.

[13] Yuan Yao a b, et al. “Preparation and Application of Recyclable Polymer Aerogels from Styrene-Maleic Anhydride Alternating Copolymers.” Chemical Engineering Journal, Elsevier, 14 Nov. 2022

www.sciencedirect.com/science/article/pii/S1385894722058430#:~:text=The%20aerogel%20is%20superlipophilic%2Dhydrophobic,temperature%20monitoring%20function%20was%20prepared.

[14] Recyclable picture comes from: Yuan Yao a b, et al. “Preparation and Application of Recyclable Polymer Aerogels from Styrene-Maleic Anhydride Alternating Copolymers.” Chemical Engineering Journal, Elsevier, 14 Nov. 2022

www.sciencedirect.com/science/article/pii/S1385894722058430#:~:text=The%20aerogel%20is%20superlipophilic%2Dhydrophobic,temperature%20monitoring%20function%20was%20prepared.

Carly S. Schnack

Professor Cogdell

DES 40A Energy, Materials, & Design Across time

June 4, 2024

The Air Swipe Bag; Are Aerogels Our Solution?

Waste and pollution are a main focus in current worldwide topics. With the fashion industry being among the leading industrial pollution in the world, will we ever discover a sustainable future for fashion? According to the Carbon Literacy Project in 2021, “[w]hen factoring in the entire lifecycle of a garment, from manufacturing to transportation to, ultimately, ending up in landfill, in total, 1.2 billion tonns of carbon emissions are released by the fashion industry every year” (Clark, August 2021). The global pollution of the fashion industry ranks higher than air travel. Imagine, a product composed of 98-99% air in a world where waste and pollution are major concerns. “The Air Swipe bag that made its big debut at Paris Fashion Week left many asking whether this is the solution to our disposal issues.” (DeNinno, Mar 5 2024). Aerogels used in the production of the Air Swipe bag look to be a promising solution to a goal of sustainability worthy of research dollars.

Sustainable fashion (also known as eco-fashion) is a term describing efforts within the fashion industry to reduce its environmental impacts, protect workers producing garments, and uphold animal welfare. Sustainability in fashion encompasses a wide range of factors, including cutting CO2 emissions, addressing overproduction, reducing pollution and waste, supporting biodiversity, and ensuring that garment workers are paid a fair wage and have safe working conditions. One product, the Coperni Air Swipe purse promises to succeed in the goal of sustainability. This paper will address waste and pollution from the formation to end of silica aerogels in regard to the Coperni Air Swipe purse. This covers the waste from the formation of the material from polymer and solvent; the byproducts of the process which it becomes silica aerogel; distribution of the purse and its environmental waste; any waste associated with use and upkeep; waste from the recycling process; and overall waste when the purse is thrown away.

“A product composed of 99% air seems ideal in a world where waste and pollution are major concerns. The Air Swipe bag that made its big debut at Paris Fashion Week left many asking whether this is the solution to our disposal issues.” (DeNinno, New York Post, Mar 5, 2024). A methodology termed Life Cycle Assessment (LCA) is used to determine a product’s negative environmental impact on the world. The LCA of a product and its process of production is analyzed to determine its impact from beginning to the end of its life. These “life-cycle” stages are: raw material acquisition; production; transportation; maintenance; and final disposal.

The Air Swipe purse which appears almost like a cloud is revolutionary and its usefulness is still very much in question. The Air Swipe bag is considered to be 99% pure “nothing” and 1% glass. However, the pursuit of transforming “air” into fashion is remarkable and worthy of the attempt. As stated in TechEBlog, “it could just be one giant leap for mankind, and fashion’ (Smith, Mar 7, 2024).

The material for the Air Swipe purse comes in the form of tiny silicon dioxide and sand pellets. This is the same material that NASA used on the space shuttle as well as the Mars rovers. The largest issue with aerogel production is the acquisition cost of the raw materials (R. Garrido, J. Dinis Silverstre, I. Flores-Colen, Vol. 151, pgs 537-545).

The acquisition costs will have to be reduced to make the production viable in the future. It is however expected that as production increases, the incremental costs will decrease making it competitive with conventional materials (R. Garrido, J. Dinis Silverstre, I. Flores-Colen, Vol. 151, pgs 537-545).

Aerogels are produced by extracting the liquid component of a gel through supercritical drying or freeze-drying. This allows the liquid to be slowly dried off without causing the solid matrix in the gel to collapse from capillary action, as would happen with conventional evaporation. There is very little waste associated with this process. Complex production and has not been done in large scale outside a lab. The bag is the biggest piece to ever be crafted from the nanomaterial. Aerogel is currently the lightest known solid on Earth.

The LCA of aerogels is mostly unknown because of the complexity of the production and the lack of public data. Most of the studies have been within the laboratory setting with very low volume. The market competition is this area is ratcheting up and therefore “confidentiality, while necessary for market competition, is an obstacle for LCA” (Turhan Kara, Kiyak, Colak Gunes, and Yucel).

Further impeding any analysis, Aerogels are not regulated as nanomaterials. This leads to other worries such as its safety on consumers. Specifically, exposure to consumers to fragments of aerogels, either via pulmonary or oral uptake is concerning. According to the Royal Society of Chemistry,

The risk for humans may be low, as long as the hazard potential of inhaled or swallowed aerogel beads or fragments is low as well. However, the development of appropriate methods to characterize exposure and hazard of aerogel beads is challenging because they retain properties of the nanoscale only by their internal structure. Although the inherent toxicity of most materials that can be formulated as an aerogel is low, an increased bioactivity may result from their large inner surface area, possibly fostering a high surface reactivity and/or a high dissolution. Toxicity inherent to nanostructures is not expected in general, but the hazard assessment of aerogels needs to consider the composition of inhalable or ingestible fragments, and the modulation of their potency by the large surface area. (Keller, Wiemann, Gröters, Werle, Vennemann, Landsiedel, and Wohlleben)

If its toxicity can be controlled or diminished sufficiently and the issues of raw material acquisition are solved, the remaining factors of LCA, appear positive. Since the product is so light, transportation of it leaves less carbon footprint from today’s products; the weight of the truck is light so there is less tire wear and gas use. The product does not require washing, drying, or ironing. Like glass products, the purse would not “age” or have wear and tear thereby having a longer life not requiring replacement. The fashion house Coperni told the New York Post that “nanomaterial silica aerogel is the ‘glass of the future’ and despite being ‘very delicate,’ the purse is ‘non-fragile’” (DeNinno, Mar 5, 2024). Also noteworthy, with 98% of the bag being air, landfill problems are more than substantially reduced. Moreover, if the remaining 2% is glass, this can be recycled and reused.

For the possible substantial reduction in negative environmental impact, it is worthwhile to continue funding the discovery of other uses of aerogels. The management of the tons of waste from residential, commercial and manufacturing activities that are being generated due to the growing population, urbanization and economic development, requires research and development in sustainable measures. More consumer products utilizing aerogels may change human consumption and disposal practices. Researchers are also looking into ways of addressing the issue of waste management by converting waste to aerogels including from agricultural waste, municipal solid, and industrial waste while also focusing on the fabrication, properties, and applications of such aerogels.

Widespread application of aerogels appears to still be distant. Fans of the Coperni Air Swipe Bag which debuted during Paris Fashion Week this year is at all useful; whether it “can even hold anything inside of it, to which Coperni answered, ‘It can hold an iPhone’” (DeNinno, Mar. 5, 2024). According to Tech EBlog, the bag weighs 33 grams and measures 27 x 16 x 6cm. This means that it may not be able to hold much. “One more caveat: there’s no word yet on if Coperni plans on making more than one of these bags, but if they do, just know that the material costs around $23,000 per pound.” (Smith, Mar 7, 2024).

Application of aerogels is promising especially in a world where solutions to overconsumption and waste are necessary. “Opportunities always coexist with the abovementioned challenges. We have witnessed the rapid development of aerogel fibers, and this rising field is going to expand its influence with the continuing efforts of enormous researchers” (Sheng, Liu, Hou, Jiang, Y. Li, G. Li, and Zhang, Jan 19, 2023). However, with an apparent race to obtain market share of production of products using aerogels together with the lack of regulation, caution should be advised. It is much to early to determine if aerogels may be one solution that only then causes another problem.

Bibliography

Bonilla, Cortne, “How Does the Coperni Air Swipe Bag Even Work?” The Cut.com, Mar. 7, 2024, www.thecut.com/article/coperni-air-swipe-bag.html, 23 May 2024.

Clark, Rebekah, “Fast Fashion's Carbon Footprint.” The Carbon Literacy Project, August 2021; www.carbonliteracy.com/fast-fashions-carbon-footprint/, 21 May 2024.

DeNinno, Nadine, “Purse made out of nothing but air and glass debuts at Paris Fashion Week.” New York Post, Mar 5, 2024, www.nypost.com/2024/03/05/lifestyle/purse-made-out-of-air-debuts-at-paris-fashion-week-thanks-to-nasa/, 21 May 2024.

Garrido, Dinis Silverstre, and Flores-Colen, “Economic and Energy Life Cycle Assessment of aerogel-based thermal renders.” Journal of Cleaner Production, Science Direct, May 2017, Vol. 151, pgs 537-545, doi: 10.1007/s12649-021-01627-3; 1 June 2024.

Keller, Wiemann, Gröters, Werle, Vennemann, Landsiedel, and Wohlleben, “Aerogels are not regulated as nanomaterials, but can be assessed by tiered testing and grouping strategies for nanomaterials.” Royal society of chemistry, May 19, 2021, www.sciencedirect.com › org › science, 23 May 2024.

Munasinghe, Druckman , and Dissanayake, “Corrigendum to “A systematic review of the life cycle inventory of clothing.” Journal of Cleaner Production, vol. 320 (2021) 128852; reproduced by ui.adsabs.harvard.edu/abs/2023JCPro.42238615M/abstract, 23 May 2024.

Nguyen, Do, and Goh, “Recent Progresses in Eco-Friendly Fabrication and Applications of Sustainable Aerogels from Various Waste Materials.” Waste Biomass Valorization, Nov. 2021, pubmed.ncbi.nlm.nih.gov › 34745389, 21 May 2024.

Smith, Bill, “Coperni's Air Swipe Bag is Made from Aerogel, the Same Material NASA Used on Space Shuttles.” TechEBlog, March 7, 2024, www.techeblog.com/coperni-air-swipe-bag-nasa-aerogel, 1 June 2024.

Sheng, Liu, Hou, Jiang, Y. Li, G. Li, and Zhang, “The Rising Aerogel Fibers: Status, Challenges, and Opportunities.” January 19, 2023: https://doi.org/10.1002/advs.202205762, 21 May 2024.

Turhan Kara, Kiyak, Colak Gunes, and Yucel, “Life Cycle Assessment of Aerogels: A Critical Review.” Research Gate, January 4th, 2024, www.researchgate.net/publication /377177199, 21 May 2024.