Design Life-Cycle

assess.design.(don't)consume

Annabella Del Rosario

Prof. Christina Cogdell

DES 040A 006

16 March 2023

Life Cycle Analysis of TAYST Compostable Coffee Pods: Materials

I. Introduction to TAYST Compostable Coffee Pods

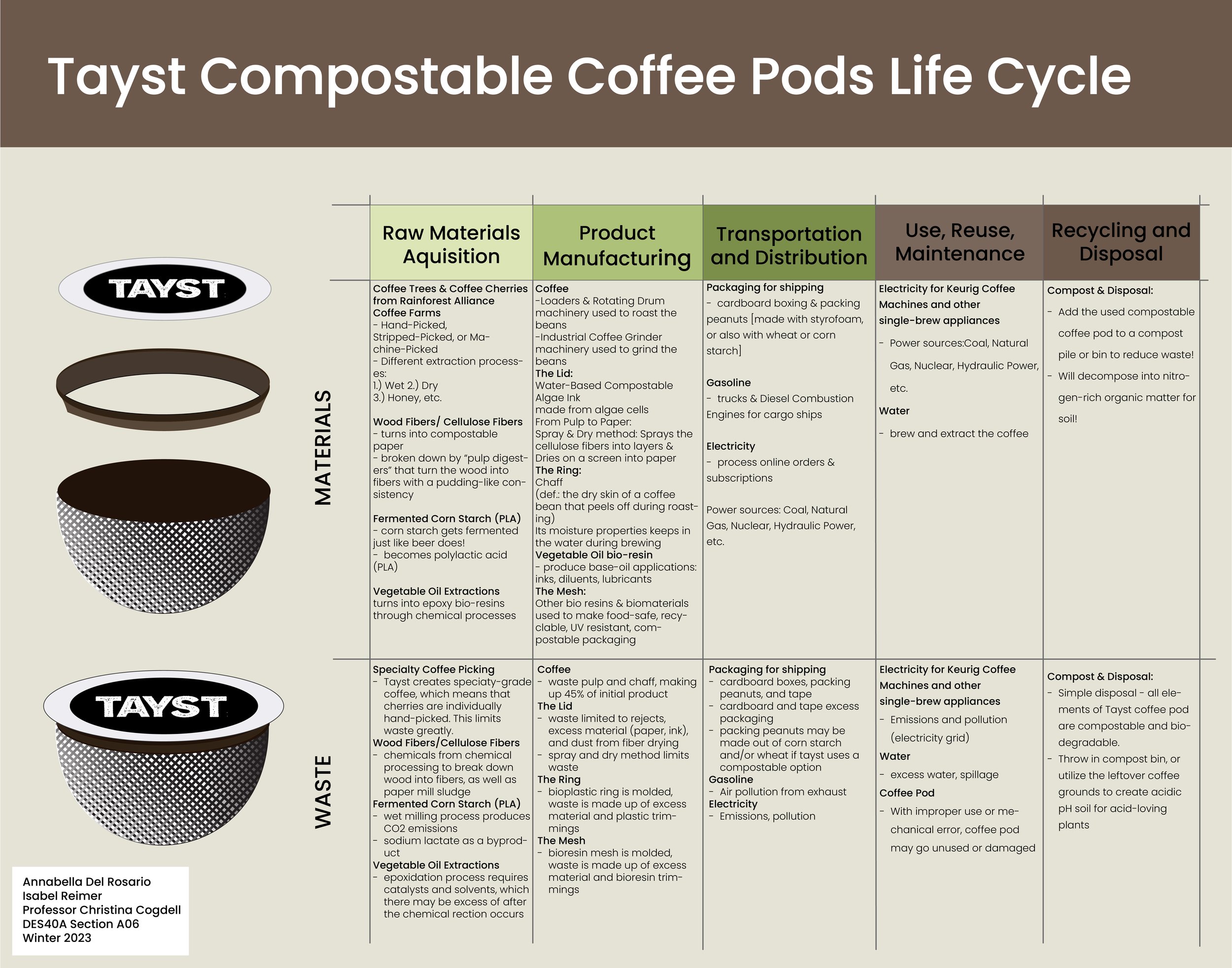

The creation, form, and design of coffee have evolved over the years from its discovery, dating all the way back to the 15th century. Since then, coffee has experienced various forms of roasts, presses, flavors, and takes on its consumption. If one is either looking for convenience, quality, or its efficient production in their cup of coffee, a product has been made to fit their standards. Specifically, the TAYST Compostable Coffee Pods add a new concept and style to what coffee production can be and become, to appeal to new consumer demographics and ideals. TAYST Coffee claims that TAYST Compostable Coffee Pods is the creation of “insanely great coffee and a single serve pod that is awesome for the planet,” that is “100% compostable… meaning they actually give back fertile nutrients to the soil as it decomposes.” (TAYST Coffee). These coffee pods not only strive for quality of taste through the variety and freshness of their coffee beans, nor the convenience from their form as a coffee pod for one to brew easily in the comfort of their own place, but also in this guideline of creating a product that is compostable in both its creation and as an end product for their consumers, which shapes their product(s) and company as “Innovation that’s changing the coffee footprint,” which again may be in line with the values of consumers’ needs or compel to their wants.

With its eco-friendly goals in mind, these TAYST Compostable Coffee Pods are made of materials that undergo many processes which are also under many categories and timelines in its manufacturing during its life cycle, in their goal to strive for its end product to be a compostable, less wasteful way to brew your coffee.

II. Raw Materials Extraction

We first must dissect the TAYST Compostable Coffee Pods’ raw materials to mark the beginning of the production and life cycle of the pod. Coffee beans start off as coffee cherries from a coffee cherry tree. Specifically, TAYST Coffee acquires its beans from its support with Rainforest Alliance farms and farmers, which aims to protect the biodiversity of their farm and forest life. These berries can either be picked via strip-picking: “stripping” the entire coffee tree of its cherries whether ripe or unripe, machine picking, or hand-picking by the Rainforest Alliance farmers. After the berries are harvested, they can undergo one of these extracting processes to separate the bean from the fruit: the dry process, washed process, the wet-hulled process, or the honey process. The result of one of these processes is our green coffee beans which will later be roasted. In regards to the pod itself, which is partly made of compostable paper, the acquisition of cellulose fibers, also called wood fibers, is through “pulp-digesters,” where wood is broken down by steam into a pudding-like consistency of cellulose fibers, along with other wood components. The fiber then gets thoroughly cleaned and screened, in preparation for it to later become paper, thus into the coffee pod. The coffee pod is also partly made up of different bio-resins and bio-materials, and one of its origins is fermented corn starch. The steps to how corn becomes fermented to become a bio-material acid are as follows: Corn is harvested, soaked, and grounded in order to separate the kernel embryo from the fiber and gluten. The kernels are mixed into a solution, which breaks it down into starch, protein, and fiber. The starch then goes through a fermentation process to turn the starched sugar into lactic acid, which greatly resembles the (fermentation) process to create beer. This now polylactic acid, known as PLA, can take the form of a spinned out fiber or film to be used for food packaging. Other bio-materials include the extraction of vegetable oils for food-safe and biodegradable epoxy resins. Vegetable oils are composed of fats and lipids and contain a high amount of unsaturated fatty acids which can be turned into epoxy fatty acids. Because of this, epoxidized vegetable oil is greatly used to combine chemicals for compounds and lubricants, and in plasticisers. In the words of the Multidisciplinary Digital Publishing Institute in their article Bio-Resin Production through Ethylene Unsaturated Carbon Using Vegetable Oils, “Vegetable oils have been widely used in various applications as raw materials because of their availability, low cost, and biodegradability.” (Latif et. al). With all of these components in mind, how will each fit together into the manufacturing of the actual, physical design of this coffee pod?

III. Product Manufacturing

With TAYST Coffee’s goal of a compostable, thus sustainable-oriented coffee pod, the composition of each of the coffee pod’s parts is made or acquired from organic materials from its raw form, which in its manufacturing phase will be transformed into each of the pod’s inner workings, along with the coffee beans itself. Aside from the actual coffee beans, it can be said that the materials used and how they are processed in each part of TAYST Compostable Coffee Pods is a substitute material or manufacturing method of that of its competitor of a regular, non-biodegradable K-cup. As broken down by TAYST Coffee, The Lid, The Ring, and The Mesh are all created to be decomposed, instead of being disposed of into a landfill. Starting with The Lid, made to seal and brand the pod, is created with compostable paper. Referring back to how the raw material of wood/cellulose fibers are created, the process of now creating it into paper to be used for packaging is through feeding the fiber into a paper-making machine. This sprays the fibers into a thin layer and onto a wide, moving wire screen, reaching sizes as long as 20 feet and speeds as fast as 60 miles per hour! The water trapped in the fibers starts to dry up, helping the fibers to bind together to form paper. Heated rollers finally press and dry the paper, where the end result is paper that can be made into any product, like paper for a TAYST Compostable Coffee Pod Lid! The Lid is also branded with water-based compostable ink, a great example of this being algae ink. Compared to regular ink that consists of carbon black and its dependency on fossil fuels, algae ink’s pigments are created from algae cells, helping to make the pods’ composting processes cleaner. Moving down towards The Ring, not only is it made up of bio-materials, but it also consists of chaff, the dried skin of coffee beans after they have been roasted (also can be called the husk). Chaff can be used as mulch in gardening to preserve the moisture of the soil, which makes it an appropriate material to be integrated into The Ring of the pod, in order for The Ring to keep the water in place for the pod during the brewing process. Adding onto the manufacturing of The Ring, as well as The Mesh is made up of bio-materials and bio-resins (as described in the previous paragraph). Biomaterials such as PLA are popular because their raw material of corn can be an abundant resource as well as a cheap crop to acquire sugar for fermentation. Some advantages and properties of PLA plastic are that it is resistant to food fats and oils, UV resistant, recyclable by grinding, and of course, compostable. Furthermore, Vegetable oil bio-resins are also readily available and require low-cost processing. After undergoing processes of chemical reactions, vegetable oils are able to produce certain base-oil applications, such as inks, diluents, plasticisers, lubricants, and food and composite materials. With their versatility, and inexpensive, bountiful accessibility, these bio-materials and bio-resins provide practical uses and qualities towards the creation of the TAYST Compostable Coffee Pods. Finally, the production of the star ingredient, the coffee beans, is through roasting the green coffee beans and afterward grinding them down. The roasting process of the green beans consists of machinery that hauls the beans onto a loader to transition them to go into what is called a rotating drum. As it spins the beans, the rotating drum allows the beans to roast evenly, with some form of heat outside the drum (fire, gas, electricity, etc) roasting the beans from all its sides and angles. After their roasting cycle, the now-roasted coffee beans are cooled off in a chamber through air or water-quenching. The coffee beans then go into an industrial coffee grinder and ground to TAYST Coffee’s ideal size for maximum taste. The TAYST Compostable Coffee Pod is now complete, and ready to be sent out to its consumers. These materials have both similarities and differences in the packaging, distribution, etc. of the coffee pods, compared to those materials of the compostable coffee pods themselves.

IV. Distribution and Transportation

The life cycle of TAYST Compostable Coffee Pods goes outside its own materials for its production and creation, and into the materials outside of the product needed to allow it to be spread to its consumers. Materials to keep in mind include ordering, more packaging, shipping and transportation, and so on. Most especially with the revolutionary age of online shopping, the materials needed to fulfill these types of internet orders may vary in the types of materials or in the amount that is needed. The first step to obtaining TAYST Compostable Coffee Pods is by purchasing them on their website. TAYST Coffee sells their products through online subscriptions and orders. On both ends for the consumer and the seller, electricity is needed to make, receive, and process these online orders. More specifically, the sources and power needed to generate this electricity can be through Coal, Natural Gases, Nuclear power, and other Renewable powers (solar, wind, etc.). Online shopping like this on electronic devices like phones, computers, and laptops takes up about 4% of household electricity use. After an order is processed, the coffee pods must be properly packaged for shipment. Typical packaging of a shipped product may include paper packaging, such as cardboard boxes and tissue paper. A packaged order also may include packing peanuts, which can be made commonly with styrofoam, or with non-synthetic materials such as wheat or cornstarch that can dissolve in water or be composted. These non-toxic and compostable packing peanuts resemble the qualities of the TAYST coffee pods in regards to the products’ goals to be less wasteful after their use. Depending on the purity of the paper packaging and whatever else is added to the packaging (stickers, tape), shipped cardboard boxes and filler paper may also be eligible to be properly composted, and if not perhaps recycled. Once an order is packaged and ready to be shipped, it will be transported to the buyer most commonly through trucks, powered by gasoline, or by international cargo ships, powered by diesel combustion engines and bunker fuel oil. In the case of the coffee pod’s transportation and distribution, these materials and sources of power are less environmentally friendly compared to the pod’s other aspects of its life cycle so far. Your TAYST Compostable Coffee Pods have made it all the way to you! You and your use of these pods will now play a role in their life cycle.

V. Use

While this part of its cycle may be short-lived compared to the long timeline beforehand to create these pods, its fast use just proves even more so how efficient the pod is at its goal of providing coffee with convenience. These coffee pods are designed for Keurig machines or K-Cup machines, also known as coffee-pod machines. Along with the coffee pod, the machine brews coffee in a single cup each time or one cup of coffee per coffee pod. The Keurig machine is run by electricity, which again can be generated by different sources of power: Coal, Natural Gasses, Nuclear power, and other Renewable powers (solar, wind, etc.). You will also need to fill the Keurig machine with water, which will be heated up to extract your coffee from the grounds in the pod. Even after your coffee is made, the job of the TAYST Compostable Coffee Pod is not completely done just yet. It will serve even more to not just consumers, but the environment in its new life cycle during its composting and decomposition.

VI. Composting and Disposal

It can be argued that this part of the pod’s life cycle can become and be recognized as a renewed life cycle in itself, creating its own new timeline beyond its coffee use and pod form. Finally being able to fulfill its purpose, the coffee pod can be disposed of in a consumer’s compost bin, composting pile, or even directly into their soil. The biodegradable, compostable materials constructing and creating the coffee pod, along with the soiled coffee grounds, will take around 90 days to decompose. The coffee pod will break down into nitrogen-rich organic material, which in turn acts as a nutrient fertilizer for the soil. The TAYST Compostable Coffee Pod has reached its full cycle, even passing beyond its original production timelines.

VII. Conclusion

TAYST Compostable Coffee Pods aim for less waste through their use of decomposing materials in the design of their pods. From creation to its finish, the pod undergoes its Raw Materials Extraction, Product Manufacturing, Distribution, Use, and Compost Disposal, with the materials used in each of its periods of production serving a specific role towards evolving or moving forward into its life cycle. While there may be more or fewer eco-friendly materials in one area of the pod’s timeline compared to other past or future production, all materials listed that are acquired and used are for the same end goal of bringing a sustainable style and value to an everyday way of easy coffee consumption. As a reminder, these materials and processes to make these pods are not reserved to just TAYST Compostable Coffee Pods, as many other manufacturers of major everyday products can learn from these pods and how they can apply these materials to their own products, making the choice of creating an overall less wasteful good. Material use like this at a greater scope can further enhance the goals that TAYST Compostable Coffee Pods have had, which is a cleaner, greener, and more sustainable planet.

Works Cited

Byrnes, Greg, and Craig Handleman. “Gourmet Coffee: 100% Biodegradable Coffee Pods.” TAYST COFFEE ROASTER, 2022, https://www.tayst.com/pages/our-coffee.

Coffee Masters Wholesale. “Harvesting of Coffee.” Harvesting of Coffee - Education | Coffee Masters, Coffee Masters Wholesale, https://www.coffeemasters.com/coffee-101/harvesting-of-coffee/.

Compound Interest. “What's Your Biodegradable Coffee Cup Made of – and How Biodegradable Is It?” Compound Interest, 26 Jun. 2019, https://www.compoundchem.com/2019/06/26/biodegradable-plastics/.

Cowley, Liné. “What Is Corn Starch Plastic? Compostable Plastic Eco World.” Eco World, 7 July 2021, https://ecoworldonline.com/what-is-corn-starch-plastic/.

Deshmukh, Sanaa and Karti Chidambaram. “Polylactide.” Polylactide - an Overview | ScienceDirect Topics, 2017, https://www.sciencedirect.com/topics/materials-science/polylactide.

EcoEnclose. “What Is the Most Sustainable Ink? (in 2022).” EcoEnclose, EcoEnclose, 7 Feb. 2022, https://www.ecoenclose.com/blog/what-is-the-most-sustainable-ink/.

Gromicko, Nick. “Electricity: Origins, Consumption and Costs.” InterNACHI®, International Association of Certified Home Inspectors, Apr. 2010, https://www.nachi.org/electricity-origin-consumption-cost.htm.

Idaho Forests Products Commission.“How Paper Is Made · Idaho Forests Products Commission.” Idaho Forests Products Commission, 23 Mar. 2022, https://www.idahoforests.org/content-item/how-paper-is-made-2/.

Kooduvalli, Komal. “Life Cycle Assessment of Compostable Coffee Pods: A US University Based Case Study.” Nature News, Nature Publishing Group, 8 June 2020, Article No. 9158 (2020). https://www.nature.com/articles/s41598-020-65058-1.

Latif, Farah Ezzah , Zurina Zainal Abidin, et. al. “Bio-Resin Production through Ethylene Unsaturated Carbon Using Vegetable Oils.” Processes, Multidisciplinary Digital Publishing Institute, 1 Jan. 2020, https://www.mdpi.com/2227-9717/8/1/48#:~:text=Thus%2C%20bio%2Dresins%20are%20resins,well%20as%20residual%20agricultural%20waste.

Murray, Martin. “The Properties of Corn Starch Packaging Material.” LiveAbout, LiveAbout, 1 Aug. 2019, https://www.liveabout.com/corn-starch-packaging-2221071.

Thomas Net. “How Are Coffee Beans Roasted and Manufactured?” How Are Coffee Beans Roasted and Manufactured?, Thomas Net, https://www.thomasnet.com/articles/other/how-is-coffee-manufactured/.

Isabel Reimer

Professor Christina Cogdell

DES 40A Section A06

16 March 2023

Tayst Compostable Coffee Pods

In the year 2020, the National Coffee Association of the United States found that 62% of Americans drink coffee every day, and that the sales of single-cup coffee brewing devices had doubled since 2015 (National Coffee Association). Single-cup brewing machines oftentimes include a ‘coffee pod’, which is a small plastic pod that holds the amount of ground coffee for one serving. The hot water from the machine runs through the pod, not unlike the brew of a traditional drip coffee. Coffee pods need to be heat resistant to the boiling water, so as to contain the ground coffee inside. The growing popularity of single-cup coffee brewing devices raises the question of sustainability. Once a consumer is done with their single serving, the coffee pod is then thrown into landfill. One solution to this issue is the biodegradable coffee pod, which caters to an eco-conscious coffee consumer demographic. One brand that has had success with the development of a biodegradable coffee pod is Tayst. The elements involved in Tayst’s biodegradable coffee pod are plastic substitutes made up of biodegradable materials, product packaging, and the coffee itself. Tayst claims to use 100% compostable paper product, a bioplastic ring that includes the use of coffee chaff, and a bio-mesh to brew coffee through (Tayst). While Tayst biodegradable coffee pods are a comparably sustainable to other options for single-serve coffee brewing at home, it is important to analyze the amount of waste that comes from each element’s acquisition, manufacturing, transportation, and maintenance.

The raw materials involved in the creation of Tayst pods are coffee, wood, and corn. Coffee is the consumable product, while wood is used in the production of paper and corn is used in the production of bioplastics. The acquisition of coffee cherries can either be mechanical or by hand, and that is based on whether a company produces commodity grade or specialty grade coffee. Tayst produces specialty grade coffee, which means the cherries are hand-selected (Guevara). This means that waste is cut down significantly, as specialty pickers choose cherries one-by-one, while commodity pickers will pick entire branches. Since specialty pickers are so selective, the waste margins decrease greatly. The second material needed to create Tayst pods is wood, in order to produce paper. The wood chips used to create the paper label on Tayst pods is collected from excess and leftover wood in the log cutting process for other products. Wood and bark that are too small or are deemed unusable for other products are converted into wood chips. Those wood chips are then put through two chemical processes. The first chemical process breaks down fiber into a sludge. The second chemical process removes resin and other liquid elements to leave only the fiber (How Paper is Made). The waste in this process is limited to the chemicals used in the breaking down of wood chips into fiber, as well as the pulp mill sludge and lime mud that results from it. The third material used to create Tayst pods is corn. Corn is used to create fermented corn starch, which then becomes polylactic acid, in order to create bioplastic (Cho). To collect polylactic acid, cornstarch must be processed through wet-milling and then heated. This converts the corn starch into dextrose. The next step is to introduce a bacteria to create lactic acid (“What is PLA”). The byproduct from this process is lactic salt, or sodium lactate. Lastly, to create the Tayst pod’s bioresin, the acquisition of processed vegetable oil is required. In order to create the bioresin, vegetable oil must go through a process called epoxidation. Epoxidation is when an oxidizing agent is added to an organic compound (A. Latif). The waste from this process would be excess catalysts and solvents left over after the epoxidation reaction.

During the manufacturing of Tayst coffee pods, the ground coffee, paper lid, bioplastic ring, and bioresin mesh are created and/or processed. Tayst’s coffee may be comparably sustainable to that of a commodity grade coffee at the acquisition level, but coffee manufacturing as a whole creates a large amount of waste. When processed, coffee waste makes up 45% of what initial product was brought in (Gemechu). This waste is made up of waste pulp and chaff. Tayst’s paper lid manufacturing involves the production of paper, ink, and finally cutting out the product into the desired dimensions. The production of paper involves the layering of cellulose fibers created in the acquisition process and the drying of that paper. Using the spray drying method, waste is limited to rejects and dust. The ink used in Tayst lids is made up of algae, which is printed on to the compostable paper. The paper must be cut into the right dimensions to be placed on to the product. The waste in this process would be excess ink and paper. The bioplastic ring is made up of polylactic acid bioplastic and chaff, a byproduct of the coffee roasting process(“What Is Coffee Chaff?”). The bioplastic is molded into the desired shape and then placed atop the bioresin mesh element. The bioresin mesh is created by molding the bioresin into a grid which will allow water through. The assumed bioplastic and bioresin waste would be rejects and excess trimmings of the materials.

During transportation, Tayst biodegradable coffee pods are packaged and shipped to individual consumers. Tayst works on a subscription model, where customers purchase directly from their website. Tayst’s packaging consists of cardboard boxes, packing peanuts, and tape. Cardboard packaging waste and tape waste would be limited to excess packaging. Tayst does not disclose whether the packing peanuts they use are biodegradable or not, but it is possible that their packing peanuts are made up of corn starch and/or wheat, and would therefore be compostable. Gasoline offgassing is another form of waste that would come from the exhaust pipe of a vehicle transporting Tayst products.

Once a Tayst biodegradable coffee pod reaches the hands of the consumer, the life of the product is short-lived. A coffee pod is used in a single-serving coffee brewing machine and then thrown into the compost bin. However, because the coffee pod is engineered to be inserted into a brewing machine, it does require electricity to be used. Without electricity, the coffee pod would not be able to be punctured while in the machine, and also would not produce a cup of coffee due to the lack of heat and water. The waste produced in this process would be excess water, spillage, or unused pod as a result of a mechanical error. Another form of waste would be pollution from a local power plant. The emissions from electricity power plants include sulfur dioxide, nitrogen dioxide, and carbon monoxide (”Electric Utilities.”).

The disposal of a Tayst biodegradable coffee pod is simple - the coffee pod is made up of biodegradable coffee grounds, paper, plastic, and resin. The consumer can put the Tayst coffee pod in the compost bin without a second thought. Alternatively, the consumer could throw this pod into an outdoor compost pile, or into solid to enrich their garden. This method would be especially effective in a part of the yard where acid-loving plants grow, as coffee grounds have a pH of between 6.5 to 6.8. Some plants that would benefit from coffee grounds in soil are beans, broccoli, tomatoes, and squash (https://www.facebook.com/marlene.affeld).

When comparing this version of a coffee pod to the other options in the market, such as the Keurig pod, Tayst coffee pods are significantly more sustainable than their counterparts. This begins with specialty hand-picking, which limits the amount of unwanted coffee cherries. This follows through to Tayst’s paper production, which utilizes a low-waste spray and dry method. Lastly, the use of technological advances in bioplastic and bioresin help to create a product that does all the same things as a regular coffee pod, but without as much damage to the environment. If coffee pods are already an essential in your life, Tayst’s biodegradable coffee pods are a good option if you are looking to make an eco-conscious switch.

Works Cited

A. Latif, Farah Ezzah, et al. “Bio-Resin Production through Ethylene Unsaturated Carbon Using Vegetable Oils.” Processes, vol. 8, no. 1, Jan. 2020, p. 48. Crossref, https://doi.org/10.3390/pr8010048.

Cho, Renee. “The Truth about Bioplastics.” State of the Planet, Columbia Climate School, 13 Dec. 2017, news.climate.columbia.edu/2017/12/13/the-truth-about-bioplastics/.

“Electric Utilities.” Www.lung.org, www.lung.org/clean-air/outdoors/what-makes-air-unhealthy/electric-utilities.

Gemechu, Getachew & Beyene, Tewodros Mulualem & Gemechu, G. (2020). The Blooming of Coffee Industry: Its Waste Problem and Utilization through Management Option: A Review. 36-46.

Guevara, Julio. “Hand-Picked vs Mechanized Coffee Harvesting.” Perfect Daily Grind, 5 July 2017, perfectdailygrind.com/2017/07/hand-picked-vs-mechanized-coffee-harvesting/.

https://www.facebook.com/marlene.affeld. “Acid-Loving Plants • Insteading.” Insteading, 26 Jan. 2019, insteading.com/blog/acid-loving-plants/.

“How Paper Is Made” · Idaho Forests Products Commission.” Www.idahoforests.org, www.idahoforests.org/content-item/how-paper-is-made-2/.

National Coffee Association. “NCA Releases 2020 National Coffee Data Trends, the “Atlas of American Coffee.”” Www.ncausa.org, 26 Mar. 2020, www.ncausa.org/Newsroom/NCA-releases-Atlas-of-American-Coffee.

“What Is Coffee Chaff?” Craft Coffee Guru, 27 Dec. 2020, www.craftcoffeeguru.com/what-is-coffee-chaff/. Accessed 15 Mar. 2023.

“What Is PLA | a Comprehensive Guide to Polylactic Acid.” Www.goodstartpackaging.com, www.goodstartpackaging.com/guide-to-pla-polylactic-acid/.