Design Life-Cycle

assess.design.(don't)consume

Abraham Gomez

Professor Christina Cogdell

DES 40A – Energy Materials & Design Across Time

16 March 2023

Mejuri’s Diamond Letter Bracelet: Raw Materials

Gold and diamond have been regarded throughout history as the most precious of materials, often used in bracelets, necklaces, or crowns, and typically reserved for those of high status. Jewelry has always been a key component in the expression of a culture, and the use of some materials like gold, diamonds, or silk was used only by royalty. As civilizations grew and toppled and societies became more connected, we find the distinction between precious metals and status become obscure as technology progressed. With the advancement of fuel sources and technology, acquiring and processing such fine materials has allowed it to extend its availability to anyone willing to pay. There is a lot of money to be made extracting these materials, and with it, conflicts between groups and environmental impacts arise. Climate change is perhaps the most important topic of this century, with ongoing debates on the approaches of extracting materials, and solutions to counteract the effects that are impacting every society, race, and religion in the world. Mejuri, a jewelry company based in San Francisco, is one whose philosophy is to mitigate the impact on the environment with materials that have, currently, 80% percent traceability. They aim to support and empower the partners with whom they work and provide a quality product made to live in that represents an expression of self. The processes behind the extraction, recycling, and acquisition of raw materials involved in Mejuri’s Diamond Letter Bracelet contribute to the sustainable practices their company’s philosophy is founded upon.

Diamond Letter Bracelet (Mejuri)

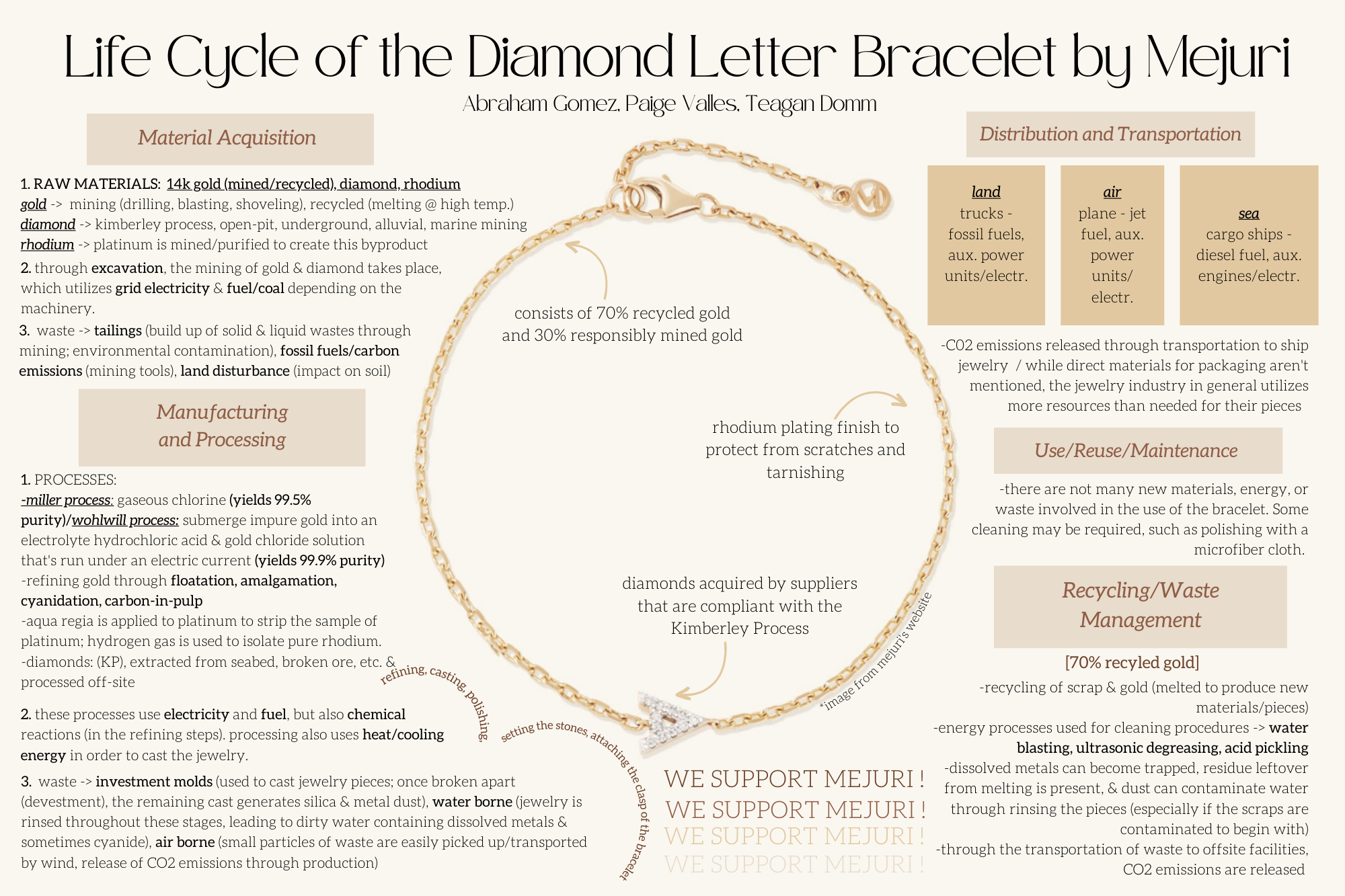

The focus of this paper will be on the raw materials incorporated in the Diamond Letter Bracelet by Mejuri. A minimalist design comprised of 14K gold (both extracted and recycled) with a rhodium plating finish, and (conflict-free) diamonds. This bracelet is sold for $300, as opposed to the estimated retail of $600.

Gold

Throughout history, civilizations have regarded gold as a symbol of high status due to its scarcity and beauty. In thinking of its value and extraction processes, it is important to be mindful of the methods used and the environmental impacts associated with them. Since the first discovery of gold, the ancient Egyptians incorporated gold in their jewelry, symbolizing royalty. As gold became discovered by other civilizations, it continued to remain a material of high value due to its beauty and utility and was typically used for jewelry, ornamentation, tools, weapons, and currency throughout human history (Reed, 2022).

Early gold mining was done through alluvial deposits and is the most environmentally friendly method of extracting gold from the earth. Alluvial gold mining is a method of washing soil and gravel with water in a pan, separating the gold particles. Alluvial deposits are found in creaks, rivers, and streams where igneous rock (rocks formed from the cooling and solidification of molten rock) has been fragmented and deposited into. Alluvial and other surface deposits do not require heavy machinery and account for about twenty percent of the world’s gold production (Gold Prospecting, Mining, and Refining). Modern gold mining techniques are done by using explosives and machines to loosen rocks containing gold. Hydraulic mining is a technique the ancient Romans invented that consists of using water to erode rock. With the advancement of technology today, this method is powerful in loosening rock, but is environmentally impactful as it clogs rivers with sediment and compromises biodiversity in the area (Norwich University Online).

Today, large-scale methods of extracting gold are being used all around the world, with China, Russia, Australia, and Canada being the top four largest producers of gold in 2022 totaling 1,190 metric tons of gold between the four (Garside, 2023). These methods consist of using heavy equipment in underground mines to break apart rocks containing gold. In the past, the rock was transported to a crusher to be grounded into dust where it would be treated with mercury to trap the gold into an amalgam (an alloy of mercury) and heated to vaporize the mercury and leave only gold. However, mercury is hazardous to humans and the environment and so an alternative method using cyanide was developed (Gold Prospecting, Mining, and Refining). Cyanidation is the process of adding diluted sodium cyanide to the crushed rock to dissolve the gold. Although much more effective, the gold continues to contain a variety of impurities and two methods for purification can be used: the Miller or Wohlwill process (Hoffmann). The Miller process utilizes gaseous chlorine that is blown into molten gold which separates the impurities and produces a 99.5 percent purity. The Wohlwill process is much more costly, requiring the producer to have gold on hand to use for the electrolyte solution where an electric current is passed through, and the impurities are dissolved into the solution or sink to the bottom of the tank. Despite the cost of this chemical purification, it produces a 99.99 percent purity of gold and is a much quicker process of extracting impurities (Hoffmann). What can be concluded from the entire process of extracting gold from the Earth is that not only is it very costly, but it presents many environmental impacts on the land and community from which it is extracted which is why Mejuri’s gold products contain only 20% newly mined gold.

Recycled Gold

As awareness grows of the impact gold mining has on the Earth, re-purposing gold jewelry is an approach Mejuri uses to offset the impacts done from production. This method is beneficial because it reduces the energy and electricity consumption associated with the extraction process. Despite the reduced energy consumption, the Miller or Wohlwill purification process is still necessary for re-casting and can be difficult depending on the gold content of the product; 10k, 14k, or 18k. These contents are usually mixed with other metals that have different melting points which can yield uncertain results (Miller-Wilson). As an environmentally ethical and sustainable organization, Mejuri follows an 80-20 approach in the manufacturing of all gold products where 80% of the gold in each product is recycled gold and 20% is responsibly mined gold. One might wonder that a 100% approach may be better suited for a company centered on sustainability, but they also understand that mining is a necessary livelihood for millions of people. The Responsible Jewellry Council is the worlds leading sustainability standard-setting organization for jewelry (Responsible Jewellry Council) and in promoting traceability and transparency, Mejuri has partnerships with RJC-certified production suppliers who embody high environmental and humane standards (Mejuri).

Rhodium

First discovered in 1803 by William Wollaston, Rhodium has been well sought after due to its effect in maintaining the quality of jewelry for a long period of time. Derived from (mainly) platinum and nickel mining, rhodium is a secondary material and byproduct of the mining and refining of these metals. After removing platinum and palladium from a sample, Wollaston was left with a reddish powder which he treated it with hydrogen gas to obtain pure rhodium (Its Elemental). Considered to be a rare and valuable precious metal due to its reflectiveness and resistance to corrosion, rhodium’s primary use is in catalytic converters because of its effectiveness in converting nitrogen oxides into harmless gases (New Age Metals Inc). Its other well-known use is as a protective coating on jewelry to prevent scratching and tarnishing. Despite needing a minimal amount to coat jewelry, the environmental impacts associated with the by-product rhodium are present. As there is no such thing as a primary rhodium mine, mining platinum is essential in isolating the by-product rhodium. This demand for rhodium presents the risks of oversupplying the platinum market, one that lacks reliable energy-generating infrastructure, which furthers the use of fossil fuels and in turn increases prices of rhodium due to emission legislation (New Age Metals Inc).

Diamond

Regarded as the most precious and rarest material on Earth, there have been many environmental and violent conflicts behind the extraction of diamonds. With its first discovery in Kimberley, South Africa through alluvial deposits along a riverbed, South Africa continues to be the world’s major producer of diamonds. Upon this discovery, Kimberley became known for its wealth of diamonds and attracted many people from around the world to mine diamonds. Now a tourist attraction, the “Big Hole” in Kimberley is a 215m deep man-made hole that was responsible for producing 95% of the world’s diamonds during the 1870s (Shimansky Diamond Jewellers South Africa). Diamond mining can be less harmful to the environment as it does not require toxic chemicals for purification such as gold yet can still cause critical environmental impacts if effective regulation and proper planning are not made. A few of those impacts that we see in South Africa today from open-pit mining are soil erosion, deforestation, entire ecosystems collapsing, and health disasters (Environmental Impact, Brilliant Earth). Alongside the environmental impacts related to diamond mining, it also fueled many civil wars; Some of which are still present in our society today. As a diamond-rich country, the lust for power and control often results in bloodshed, loss of lives, and human rights abuse. Diamonds with violent histories are often called “blood” or “conflict” diamonds and it has become urgent for consumers to demand diamonds with no association with human rights abuses and bloodshed (Blood Diamonds, Brilliant Earth). Traceability and transparency are key components in providing the highest level of sustainability, and in following this philosophy, Mejuri works with suppliers that are compliant with the Kimberley Process. Although suspicion of corruption and smuggling with the Kimberley process has caused people to question the validity of this United Nations resolution (Rhodes), it ensures that diamonds distributed to partners, like Mejuri, do not fuel conflict in countries from which they are extracted.

Environmental Impacts

Despite the common practices used for raw material extraction and the environmental impacts associated with them, Mejuri’s goal of 100% traceability is a great example of a company that is mindful of its impact. Gold mining requires a lot of energy and fuel to be used to effectively extract gold-bearing rocks, and still, the amount of gold that is eventually refined does not balance out the environmental impacts associated with extraction. The 80-20 approach is a great way of contributing to balancing the impacts associated with gold mining. With an 80% recycled gold content in all products, it avoids the use of energy and fuel required in extraction and only uses the energy associated with purification. Created with 14k gold alloy, the Mejuri Diamond Letter Bracelet is “specifically mixed to be worn every day, forever”- Mejuri. The processes with the acquisition of raw materials needed to produce gold jewelry are damaging to the environment and do not often justify the impacts caused when they have short life spans. It is known that the extraction of platinum for rhodium by-products can cause detrimental environmental impacts, yet the effectiveness in the minimal amount needed to prevent scratches and tarnishing of gold products, allowing them to be worn forever, has allowed its use to be justified. Apart from the environmental impacts associated with open-pit and underground diamond mining, diamonds have a long and violent history that needs to be recognized as well. Mejuri acknowledges that while practices around environmental protection, human rights, fair labor, and health and safety are guidelines that are core to their organization, traceability cannot always be affirmed from mine to market (Mejuri). Despite this, their partnerships with the Responsible Jewellry Council and Kimberley Process-compliant traders reflect their efforts to provide long-lasting, sustainable, and impactful jewelry for all.

In examining the environmental impacts from a life cycle perspective, the extraction and production processes required to create Mejuri’s Diamond Letter Bracelet reflect the sustainable practices the company’s philosophy is founded upon. Jewelry is an important cultural and societal symbol, and feeling good about where the materials came from is just as important as their quality of them. Mejuri embodies this in their craftmanship and philosophy, acknowledging the many problems linked to the extraction of raw materials, and the required transparency in the acquisition of such materials.

Bibliography

“Beauty and Sustainability.” Responsible Jewellery Council, 7 Mar. 2023, https://www.responsiblejewellery.com/.

“Blood Diamonds & Violence in Africa | Brilliant Earth.” Brilliant Earth, https://www.brilliantearth.com/conflict-diamond-trade/.

“Blood Diamonds | Environmental Impact - Brilliant Earth.” Brilliant Earth, https://www.brilliantearth.com/blood-diamond-environmental-impact/.

Garside, M. “Gold Production Top Countries 2022.” Statista, 3 Feb. 2023, https://www.statista.com/statistics/264628/world-mine-production-of-gold/.

“Gold Prospecting, Mining, and Refining: Gold Processes and Uses.” The Natural Sapphire Company, Education, 28 Jan. 2018, https://www.thenaturalsapphirecompany.com/education/precious-metal-mining-refining-techniques/gold-prospecting-mining-refining/.

“History of Diamonds: Shimansky.” Shimansky Diamond Jewellers South Africa, https://www.shimansky.co.za/discover/about-diamonds/history.

Hoffmann, James Edward. “Gold Processing.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., https://www.britannica.com/technology/gold-processing/Refining.

“It's Elemental.” It's Elemental - The Element Rhodium, Jlab Science Education, https://education.jlab.org/itselemental/ele045.html#:~:text=Rhodium%20was%20discovered%20by%20William,with%20a%20dark%20red%20powder.

Miller-Wilson, Kate. “How to Reuse Old Gold to Make New Jewelry Pieces.” LoveToKnow, LoveToKnow, 23 June 2021, https://jewelry.lovetoknow.com/gold-jewelry/reusing-old-gold-make-new-jewelry.

Norwich University Online. “Historical Impact of the California Gold Rush.” Norwich University Online, 2 Oct. 2017, https://online.norwich.edu/academic-programs/resources/historical-impact-of-the-california-gold-rush#:~:text=The%20Gold%20Rush%20also%20had,chemicals%20from%20the%20mining%20process.

Reed, Bridget. “Who Discovered Gold First in the World?” Acre Gold Now, 1 Mar. 2022, https://getacregold.com/blogs/news/who-discovered-gold-first-in-the-world#:~:text=They%20mined%20gold%20in%20Nubia,metals%20were%20scarce%20and%20valuable.

Rhode, David. “The Kimberley Process Is a 'Perfect Cover Story' for Blood Diamonds.” The Guardian, Guardian News and Media, 24 Mar. 2014, https://www.theguardian.com/sustainable-business/diamonds-blood-kimberley-process-mines-ethical.

“What Is Rhodium and Why Is It So Valuable.” New Age Metals Inc., 16 Sept. 2020, https://newagemetals.com/what-is-rhodium-and-why-is-it-so-valuable/.

Teagan Domm

Paige Valles and Abraham Gomez

DES 40A

Professor Cogdell

The Embodied Energy of Mejuri Jewelry

Mejuri is an emerging jewelry company which focuses on self empowerment and

sustainability. The company claims “to create true sustainability in fine jewelry we need to be able to trace the impact of our pieces from the origin of the materials all the way to their final destination: you” (Mejuri). They are changing the narrative around sustainability in the jewelry industry by stressing the importance of traceability. Traditionally, the jewelry industry has not been known for its sustainability practices. The jewelry industry has been associated with environmental degradation, human rights abuses, and unethical labor practices. For example, diamond mining has been linked to environmental destruction, child labor, and forced labor. Gold mining has been associated with pollution and toxic waste, as well as exploitation of workers in developing countries. While most of the industry uses convoluted processes in order to acquire their gold, Mejuri is focused on using mainly recycled gold. They use seventy percent recycled gold, which is a step towards sustainable jewelry production. As for the other thirty percent, that is acquired from ethical mines approved by the Responsible Jewelry Council. Though Mejuri definitely practices sustainable measures, there are still setbacks in the manufacturing process and also the distribution of their jewelry. The distribution of their jewelry uses a lot of fossil fuels and electricity. Though the distribution and manufacturing of their jewelry utilizes a considerable amount of electricity processes, Mejuri’s material acquisition process is noticeably more sustainable than the rest of the industry.

Mejuri’s materials acquisition uses processes that are less environmentally impactful compared to the rest of the jewelry industry. The use of recycled gold is definitely the most impactful, as there is considerable reduced environmental effect. The process of mining gold can be environmentally destructive, involving the removal of large amounts of earth, water use, and the use of toxic chemicals such as cyanide to extract the gold. Recycling gold reduces the need for new mining and its associated environmental impacts. The main result of recycled gold is energy conservation. The mining, refining, and transportation of new gold require significant amounts of energy, which can contribute to climate change. Recycled gold, on the other hand, requires less energy to be processed, reducing its carbon footprint. The only energy process required to refine recycled gold is melting it down to remove impurities (Saradesh et al). Comparatively, this is a considerably small amount of energy used. The use of seventy percent recycled gold cuts the fuel, energy, and environmental displacement by seventy percent. Though some may think that completely recycled gold would be optimal, the company explains why they still use thirty percent from the mines. They recognize that “mining remains a necessary livelihood for millions of people worldwide. That’s why we work with suppliers who are positively impacting mining communities by complying with the highest environmental and most humane standards” (Mejuri). They also only use gold from reputable sources who are approved by the Responsible Jewelry Council. This is another factor to consider other than environmental impacts. The rest of the jewelry industry does not take such measures for their material acquisition process, so Mejuri is comparatively sustainable.

Though the material acquisition is sustainable, the manufacturing step is harder to conserve power in. Processing and formulation of Mejuri gold jewelry requires a significant amount of energy. Between refining, alloying, casting, and finishing the jewelry, there are a lot of factors that require heat and electricity (Corti). The first step in the refining process is to crush and grind the ore into a fine powder. This process requires electricity to operate the equipment used for crushing and grinding. The next step is to extract the gold from the ore using chemicals such as cyanide, which requires energy to produce and transport. After the gold is extracted, it must be purified through smelting, which involves heating the gold to a high temperature to melt it down and separate it from impurities. Once the gold has been smelted, it must be further refined to remove any remaining impurities. The next step is alloying the metal, which typically requires a high-temperature furnace or kiln to heat the metals to their melting point. These furnaces or kilns are often powered by natural gas, electricity, propane, or oil. Once the metal is melted, it is poured into a mold, which is typically made of plaster or sand. The mold is designed to create the desired shape of the jewelry piece. After the metal is poured into the mold, it must cool and solidify. This process requires energy to remove the heat from the metal and lower its temperature to a solid state. The cooling process can be accelerated by placing the mold in a cooling chamber or quenching the metal in water (Kaspin, et. al). Polishing is a key step in finishing gold jewelry, which involves using a polishing wheel or other equipment to remove scratches and other imperfections from the surface of the metal. Polishing typically requires electricity to power the polishing equipment and to maintain the necessary speed and pressure. Electroplating is the final process used to create gold jewelry. Electroplating is a process used to apply a thin layer of metal, such as gold or rhodium, onto the surface of the jewelry to improve its appearance and durability. Electroplating involves immersing the jewelry in a plating solution and applying an electric current to the solution. This process uses one to six volts to power the electroplating equipment and to maintain the desired current and voltage.

Finally, the transportation and distribution of Mejuri jewelry uses a considerable amount of energy. Between air, land, and sea transportation, this step in the life cycle process utilizes the most energy. According to Mejuri’s website, they manufacture their jewelry in a number of locations around the world, including Canada, the United States, Italy, Thailand, and China. They also ship to two hundred different countries. Since Mejuri is a global company, the energy used in shipping the jewelry is the most intensive part of the life cycle. They use air, sea, and land transportation in order to ship their jewelry. As for air transportation, most of the jewelry is shipped on cargo planes. Cargo planes, like other jet-powered aircraft, use combustion of jet fuel to generate energy to power the engines. Cargo planes also use Auxiliary Power Units, which are small gas turbine engines that are used to power auxiliary systems such as air conditioning and electrical systems while the main engines are shut down (Aturk, 73). This helps to conserve fuel and reduce emissions during ground operations. Cargo ships are similarly powered. Cargo ships use internal combustion engines to generate power, which typically burn heavy fuel oil. They also typically have auxiliary engines and generators that are used to power various shipboard systems, which run on diesel fuel. Some energy is conserved in the Heat Recovery Steam Generator, which converts waste heat into steam that can be used to drive a turbine and generate electricity (Chopra). For the final step of transportation, trucking similarly uses combustion of fuel and Auxiliary Power Units. Truck drivers can also reduce fuel consumption and emissions by avoiding idling when the truck is parked. This can be done by using battery-powered heating and cooling systems, or by using the APU’s that run on diesel fuel or other alternative fuels.

The last two steps in the life cycle analysis do not apply as relevantly to the embodied energy focus. The use/reuse/maintenance segment would only entail the energy of the user to clasp the bracelet, unclasp it, or wipe it with a microfiber cloth to clean it. As for waste management and recycling, the user could recycle the gold. This would simply restart the life cycle of the bracelet, beginning with the recycled gold segment in material acquisition. Though Mejuri uses a considerable amount of electricity to create their jewelry, this is to be somewhat expected. It is difficult to reduce the amount of energy used in the creation of fine jewelry, given that the materials used are diamond, gold, and rhodium. This can also be said for the distribution and transportation segment. This part of the life cycle uses a considerable amount of electricity but also fossil fuel and diesel. According to the International Energy Agency (IEA), shipping accounted for around 7% of global oil demand in 2019, and is projected to account for up to 17% of global CO2 emissions by 2050 if no further action is taken to reduce emissions. So while Mejuri’s shipping is not considerably worse than the rest of the jewelry industry, they could potentially try to localize their warehouses a bit more in order to eliminate the need for as much travel. Mejuri does pull their weight in the material acquisition process however. The use of seventy percent recycled material means that the electricity used to acquire gold is considerably smaller. As for thirty percent of non recycled gold, they buy from mines “who are positively impacting mining communities by complying with the highest environmental and most humane standards” (Mejuri). In conclusion, though Mejuri does utilize harmful energy processes, that is to be expected. In order to create a product there will have to be consumption, use of energy, and waste. Mejuri is comparatively more sustainable than the rest of the jewelry industry due to their use of recycled materials in the materials acquisition stage.

Aturk, Serkan, et al. “Assessing Impacts of Introducing Ship-to-Store Service on Sales and Returns in Omnichannel Retailing: A Data Analytics Study.” Journal of Operations Management, Elsevier, 9 July 2018, https://www.sciencedirect.com/science/article/pii/S0272696318300408.

Chopra, Sunil. “The Evolution of Omni-Channel Retailing and Its Impact on Supply Chains.” Transportation Research Procedia, Elsevier, 20 Sept. 2018, https://www.sciencedirect.com/science/article/pii/S2352146518300735.

Corti, Christopher. Recovery and Refining of Gold Jewellery Scraps and Wastes. 2002, https://www.researchgate.net/profile/Christopher-Corti/publication/237462783_Recovery_and_Refining_of_Gold_Jewellery_Scraps_and_Wastes.

Haufler, Virginia. “The Kimberley Process Certification Scheme: An Innovation in Global Governance and Conflict Prevention - Journal of Business Ethics.” SpringerLink, Springer Netherlands, 4 Feb. 2010, https://link.springer.com/article/10.1007/s10551-010-0401-9.

Jakobi, Anja P. “Governing War Economies: Conflict Diamonds and the Kimberley Process.” SpringerLink, Palgrave Macmillan UK, 1 Jan. 1970, https://link.springer.com/chapter/10.1057/9781137334428_5.

“Responsible Jewellery Council Standards Guidance.” Responsible Jewelry Council, 2018, https://www.responsiblejewellery.com/wp-content/uploads/boxed_set_2009/G002_2009_RJC_Standards_Guidance.pdf.

Rudnicka, Ewa. “The Diamond Supply Chain .” Laccei, http://www.laccei.org/LACCEI2010-Peru/Papers/Papers_pdf/ACC115_Rudnicka.pdf.

Saadiah Kaspin, et. al. “Identifying Factors Leading to Gold Losses during the Fabrication Process and Assessing Its Impact on the Smes Jewellery Industry.” Turkish Journal of Computer and Mathematics Education (TURCOMAT), TURCOMAT, 2012, https://turcomat.org/index.php/turkbilmat/article/view/2707.

Saradesh, KM, and GM Vidnokamar. “Metallurgical Processes for Hardening of 22karat Gold for Light Weight and High Strength Jewelry Manufacturing.” Journal of Materials Research and Technology, Elsevier, 24 Dec. 2019, https://www.sciencedirect.com/science/article/pii/S2238785419315406.

“Small to Medium-Sized Enterprises (Smes): Uptake, Access and Impact of ...” Responsible Jewelry Council, 2018, https://www.responsiblejewellery.com/wp-content/uploads/IHEID-SME-Uptake-Access-and-Impact-of-Certification-in-the-Jewellery-Supply-Chain-2014.pdf.

Paige Valles

Abraham Gomez, Teagan Domm

DES 40A, Section A07

Professor Cogdell

The Story Behind our Jewelry; Mejuri’s Diamond Letter Bracelet & its Accumulation of Waste

Known for their variety of jewelry pieces that are advertised as both unique and sustainable, the jewelry company Mejuri has increasingly established a title for themselves. Launched in 2015 by now Co-founder and CEO, Noura Sakkijha, Mejuri’s products are created with the intention of curating an environment where the consumer feels proud/confident when wearing their pieces. There’s no doubt that this is true, but what realistically further lies behind this intention is the accumulation of waste from Mejuri’s production of pieces. Looking specifically at Mejuri’s Diamond Letter Bracelet which consists of 14k yellow gold (both mined and recycled gold), diamonds, and is labeled as one of their most gifted pieces on their site, this specific bracelets’ foundation traces back to one filled with waste (Inc, Mejuri). While all stages of Mejuri’s Diamond Letter Bracelet’s life cycle are important to note, by looking primarily at the acquisition of its materials through mining, as well as water pollution, air pollution, and environmental impacts through the manufacturing/processing of materials, the accumulation of waste is highly evident.

Seen as a prime technique to extract gold, mining sets the trajectory for waste that is to occur. Although Mejuri states that only “30% of their gold is mined” (Inc, Mejuri), this relatively small percentage leads to a substantial outcome. Engaging in mining comes with engaging in different processes; including drilling, blasting, and shoveling around the rock underground (How Gold is Made - History, Used, Parts, Procedure, Industry, Machine, Physical Characteristics). As miners dig underground and utilize a range of small explosives to remove the gold ore from the surrounding rock, not only do these mining tools/techniques produce carbon emissions, but they also lead to the build up of rock particles, thus becoming a form of solid waste that is environmentally damaging (How Gold is Made). For example, this can be seen in tailings, which are a combination of both solid and liquid wastes that result from the aftermath of mining operations (Thammaraksa). Looking deeper at these two types of waste, solid wastes contain “sulfides” that further inhabit “acid and dissolved chemical substances from particles” and liquid wastes contain “chemical additives” as well as some “toxic chemicals” such as cyanide (Thammaraksa). As a result, the more that these raw materials are extracted/processed, the more that these tailings will occur, due to the equivalency between the volume of tailings and the volume of raw materials (Thammaraksa).

Looking at mining diamonds, a similar trend of extraction and waste can also be seen. For diamonds, there are primarily four types of mining that occur; open-pit mining (removing layers of sand/rock overhead kimberlite), underground mining (tunneling through earth’s crust to reach the kimberlite pipe), alluvial mining (diamond deposits that are removed from the kimberlite source/placed in riverbeds), and marine mining (the extraction of diamonds from the seabed) (Oluleye, 12). While all of these techniques do involve mining from the kimberlite (“igneous rock in vertical structures called kimberlite pipes”, which are the source for mined diamonds), they all also include their own form of waste/environmental damage that occurs as a result (Oluleye, 9). For example, while waste during open-pit mining and underground mining is generated from the accumulation of excess “rock, sand, processed kimberlite, and soil” that are found underneath “overburden” and can additionally lead to the gas pollutant, ozone, (through dust particles), waste through the lens of alluvial mining/marine mining is seen as environmental damage in which excavation of areas take place (removing an entirety of seabed matter, having to modify the land, etc.) (Oluleye, 14, 15, 26). Relating to this act of mining disturbing different locations/land, the impact that mining diamonds has on soil quality as well is important to note. Over large areas, mining can pollute soils, in which the mining (alluvial mining specifically) can loosen the soil that is in place. As a result, this loose soil can be carried away and can end up residing in different rivers or small dams that may be located in the same area (thus contaminating these new locations as well) (Oluleye, 16). Therefore, this shows that mining (even occurring on coastal areas for example) still leads to an accumulation of waste or damage, in some shape or form.

In comparison, looking at the obtainment and processing of recycled gold, waste can also be noticed throughout the variety of steps. Stated on their website, the other 70% of gold that is used by Mejuri for their products is recycled (Inc, Mejuri). Recycled gold is the process in which gold, scraps, and in Mejuri’s case, “products that are brought back or returned” (Inc, Mejuri) are melted down at a high temperature to secure any raw materials that are needed for the production of other pieces (Guerra). While recycled gold sounds like the more sustainable approach to retrieving/processing materials in comparison to mining for them, waste still gathers. For example, throughout the stages of creating recycled gold (melting, casting, assembly, cleaning/finishing, etc.), waste can still develop (Corti, 4). From melting/casting, residues from molds are leftover along with sometimes “dirt”, as well as metal which can get trapped in the cracks during casting (Corti, 4). For the assembly and cleaning/finishing processes, filings and dust are left behind, in which they eventually build up, and lead to cleaning fluids polluted by the different substances that still remain (Corti, 4). Subsequently, this reality of recycled gold demonstrates that it is not instantly the less wasteful choice (as it may be perceived); what is instead shown is that waste can accumulate in this situation almost as easily as mining.

Once materials are acquired, the manufacturing and processing adds an additional layer of waste that revolves around water, air, and soil. With the extraction of materials soon comes the step of rinsing them. The more that pieces are rinsed, the more dirty the water becomes, filled with dissolved metals that harm the environment (“Wastewater Produced in Jewelry Manufacturing”). While some metals can be recovered through a “wastewater treatment sludge”, the majority of the metals are not, which only leads to a further build up of contaminated water waste (“Wastewater Produced in Jewelry Manufacturing”). Transitioning to when these pieces begin to cast, this involves the method of investment molds (California, State of. / “DTSC Investment Waste Produced in Jewelry Manufacturing Fact Sheet). Investment molds which contain plaster material to form the mold that shapes the jewelry, are soon broken apart to separate the mold from the actual jewelry pieces (devestment) (California, State of.). However, as a result, the investment that was used in the earlier stage of this process ends up becoming waste, which can produce silica and metal dust (California, State of.). Similar to the contaminated water mentioned above, when these dusts build up and are executed, they are just as harmful to the environment. Moving further into the production process (of diamonds specifically), air pollution is recognizable. First, because processing diamonds includes utilizing electricity and hydrocarbon energy (oil, petrol, etc.) as its two main forms of energy, what results from these two outlets is the byproduct of CO2 emissions and therefore air pollution (Oluleye, 5). To further extend this air pollution that occurs, as waste starts to pile up during this manufacturing/processing of diamonds, these “small size particles” that are present are easily picked up by the wind and released into the air just like the CO2 emissions described above (Oluleye, 16).

Transitioning to the later parts of Mejuri’s diamond letter bracelet life cycle, the amount of waste (while still present), begins to decrease. While Mejuri doesn’t exactly disclose what materials go into packaging their pieces like the diamond letter bracelet for example, we can infer that the carbon footprint of packaging materials is an issue (Sanyé-Mengual). Common materials such as plastic, cardboard, etc. that are used to package products like jewelry may be biodegradable or renewable, but overall the amount of resources that are being used are more than is needed to package a small piece of jewelry (Sanyé-Mengual). In terms of waste that develops from the transportation/distribution of the diamond letter bracelet, due to the range of fuels that are needed to transport the jewelry either by land (trucks), air (plane), or sea (cargo ships), a substantial amount of CO2 emissions are released (Sanyé-Mengual). With packages being put together to be distributed across the world to many different people, it’s important to move forward with the intention of “optimizing the volume of packaging” and “reducing the transportation requirements” for the diamond letter bracelet and other products like that in the jewelry industry (Sanyé-Mengual). Moving on, with regards to the use/reuse/maintenance of the diamond letter bracelet, there are not many new instances of waste that occur, in which during this point of my research information was very limited. However, concerning waste management, there is some waste present. In relation to what was mentioned earlier in this paragraph about the CO2 emissions that are released throughout transportation, more CO2 emissions are released as waste is transported to offsite facilities to be handled with (Oluleye, 10). In relation to this situation, while some of the waste/scraps can be recycled (as mentioned earlier), this always comes with the potential consequence of generating more waste instead of managing it, especially if the waste is truly not clean/not handled properly (Corti, 1).

In conclusion, analyzing the life cycle of Mejuri’s prized diamond letter bracelet exhibits different takeaways. While the waste of this bracelet reduces towards the end of its life cycle, its waste is highly generated throughout the beginning stages (acquisition of raw materials and the manufacturing/processing of them). It’s neither fair nor reasonable to say that based on these outcomes that Mejuri is automatically unsustainable, but is instead helpful to break down these very outcomes to determine the true nature of not only the diamond letter bracelet, but other products similar to it/other pieces that Mejuri has released. By pinpointing the stages in which the accumulation of waste is at its highest, one is able to determine where companies like Mejuri and their products are right now in terms of their materials, manufacturing, and processing, and where they could be in the future.

Bibliography

Burat, Fırat, et al. “Gold & Silver Recovery from Jewelry Waste with Combination of Physical and Physicochemical Methods.” Waste Management, vol. 89, Apr. 2019, pp. 10–20. ScienceDirect, https://doi.org/10.1016/j.wasman.2019.03.062.

California, State of. “DTSC Investment Waste Produced in Jewelry Manufacturing Fact Sheet.” Department of Toxic Substances Control, https://dtsc.ca.gov/investment-waste-produced-in-jewelry-manufacturing-fact-sheet/. Accessed 8 Feb. 2023.

Corti, Christopher. Recovery and Refining of Gold Jewellery Scraps and Wastes. Mar. 2023.

Gary Graham. Exploring Supply Chain Management In The Creative Industries. Emerald Publishing Limited, 2005. ProQuest Ebook Central, http://ebookcentral.proquest.com/lib/ucdavis/detail.action?docID=253988.

Guerra, Maria F. “On Gold Recycling. A Physicochemical Point of View.” Archaeometry, vol. 64, no. S1, 2022, pp. 134–49. Wiley Online Library, https://doi.org/10.1111/arcm.12710.

How Gold Is Made - History, Used, Parts, Procedure, Industry, Machine, Physical Characteristics. http://www.madehow.com/Volume-1/Gold.html. Accessed 22 Feb. 2023.

Inc, Mejuri. Our Jewelry Materials & Metal Types | Mejuri. https://mejuri.com/company/materials. Accessed 8 Feb. 2023.

---. Sustainability and Traceable Materials at Mejuri. https://mejuri.com/company/sustainability. Accessed 8 Feb. 2023.

Oluleye, Dr. Gbhemi. “Imperial Consultants.” Environmental Impacts of Mined Diamonds , Centre for Environmental Policy, Imperial College London , http://www.imperial-consultants.co.uk/wp-content/uploads/2021/02/Final-report-Environmental-Impacts-of-Mined-Diamonds.pdf.

Luque-Almagro, Víctor M., et al. “Biodegradation of Cyanide Wastes from Mining and Jewellery Industries.” Current Opinion in Biotechnology, vol. 38, Apr. 2016, pp. 9–13. ScienceDirect, https://doi.org/10.1016/j.copbio.2015.12.004.

Sanyé-Mengual, Esther, et al. “Eco-Design and Product Carbon Footprint Use in the Packaging Sector.” Assessment of Carbon Footprint in Different Industrial Sectors, Volume 1, edited by Subramanian Senthilkannan Muthu, Springer, 2014, pp. 221–45. Springer Link, https://doi.org/10.1007/978-981-4560-41-2_9.

Thammaraksa, Chonlawan, et al. “Corporate Environmental Assessment of a Large Jewelry Company: From a Life Cycle Assessment to Green Industry.” Journal of Cleaner Production, vol. 164, Oct. 2017, pp. 485–94. ScienceDirect, https://doi.org/10.1016/j.jclepro.2017.06.220.

“Wastewater Produced in Jewelry Manufacturing .” Dtsc.ca.gov, DTSC, Jan. 2002, https://dtsc.ca.gov/wastewater-produced-in-jewelry-manufacturing-fact-sheet/