Design Life-Cycle

assess.design.(don't)consume

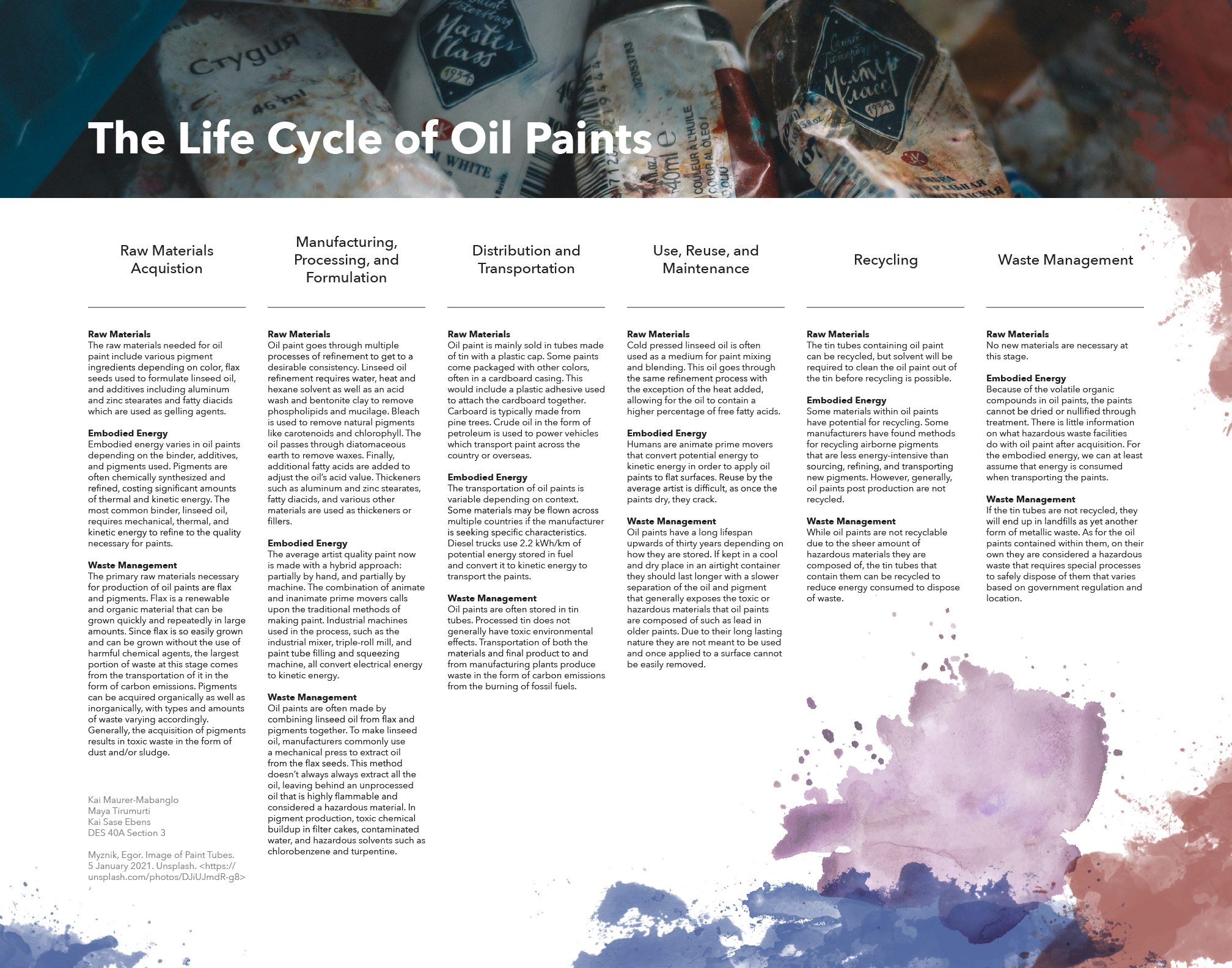

Life Cycle Assessment of Oil Paints: Raw Materials

Oil paint is widely used due to its slow drying time, which allows artists to spend more time adding to and perfecting their paintings. Its consistency allows for dilution which can help portray depth through changes in opacity. Painters can spend days or weeks working on a single piece due to the formulation of the paint. Oil paint eventually dries into a permanent and flexible film, allowing for paintings to last through centuries. This may be desirable for the conservation of an art piece; however, oil paint’s lasting ability becomes an issue when it comes to degradation, as the materials used to formulate it have been changed over time favoring toxic, synthetic materials which are hard to dispose of safely. From an environmental standpoint, innovation in oil paint formulation seems to contradict efforts at environmental conservation. Because the materials used to formulate modern oil paint are synthetic and intentionally made to last, oil paint resists degradation and causes long term environmental hazards.

The main ingredient in oil paint is pigment which is derived from various sources depending on the desired color. The highest quality oil paint can be up to 75% pigment (“Why Oil Paint Is so Expensive .”) Depending on the source of the specific pigment, the oil paint will increase in price. The price of oil paint is largely dependent upon the rarity of the pigment source, the location of the source, and the amount present in the paint formulation. Pigment is selected based on lightfastness, its ability to retain color after years of being exposed to light. Other key factors in pigment selection include heat stability, opacity and chemical interactions between different pigment formulations. The saturation and vibrancy of the paint can also vary based on the origin and amount of pigment used. Pigment stability is also a factor in preservation and degradation. Pigments such as smalt, a blue pigment derived from cobalt-containing potash glass, were used widely in Europe around the fifteenth century and have degraded over time, causing the paintings it was used in to take on a brown or green hue (Spring). Interactions with the oil binding medium can cause pigments to degrade and morph in color over time. Additionally, interactions with airborne particles that settle on the surface of a painting can alter the color of the paint over time. Pigments were once made from more natural sources but over time synthetic formulas have taken over due to convenience. An early form of tyrian purple pigment was created by extracting the glands of sea snails. It would take 12,000 snails to make 2 grams of pigment. Indian yellow was formulated using cow urine. 16th-18th century mummy brown pigment was created using dust from mummies. Extracting these natural pigments at such a large scale proved inefficient and unsustainable as it took an extreme amount of source material to create a very small amount of usable pigment output. Partly because of a lack of natural resources, pigment shifted from being collected predominantly from natural sources into being formulated more efficiently in a lab as a synthetic material. Additionally, synthetic pigment allows for a more broad spectrum of color to be achieved. Some commonly used synthetic pigments include yellow ochre, burnt umber, cadmium red hue and prussian blue, all created by treating natural compounds with various chemical solvents. While synthetically formulating pigments functions to preserve some amount of our natural environment, introducing and exposing these unnatural materials into our environment may cause more environmental degradation than mass extracting directly from natural sources. Once selected, the pigment is combined with a drying oil to achieve a superior texture.

The secondary ingredient in oil paint formulation is alkali refined linseed oil, a drying oil which produces a flexible paint surface when applied to a surface. Linseed oil starts out as flax seeds which are toasted, dried and rolled into a meal (Watson). The meal is heated and water is added to prepare it for pressing, which allows for more crude oils to be extracted as opposed to dry pressing. Because of the heat and water added, the oil must go through additional refinement after pressing to remove plant matter and impurities. Oil is refined using hexane solvent, which is separated and reclaimed for future reuse. Refinement includes additional processes to remove colorants, proteins, waxes and other impurities. Acid washing helps to remove phospholipids and mucilage contained in the oil. Alkali refining delineates the process of collecting mucilage and other impurities but it also removes free fatty acids, which are helpful in creating a more clear colored oil that will not yellow over time. Linseed oil then goes through a process of filtering and bleaching to remove natural pigments in the oil such as carotenoids and chlorophyll. Bentonite clay is treated with acid and mixed into the oil during this process to absorb impurities, then filtered out of the oil for reuse. Then, the oil is dewaxed using low-temperature winterization or by passing through diatomaceous earth. The resulting oil is given more free fatty acids to adjust the acid value. Cold pressed oils have a higher acid number, which seems to be more effective in wetting pigment, resisting yellowing and drying. Oil paint undergoes a myriad of chemical changes as it sits on canvas, mainly due to interactions between the pigment used and combined with the free fatty acids in the oil. These changes affect how the paint ages in appearance over time. Once the linseed oil is added, additive fillers and thickeners are often used to improve the texture and abilities of the paint.

Fillers and thickeners are added to manipulate the texture of the paint. This includes “aluminium and zinc stearates, added as dispersion and gelling agents” (Van Den Berg). Fatty diacids are also used in these processes, causing an oxidative reaction while drying which results in a slight color change. Fillers and thickeners are used more so during industrial processes when the machinery used to create these paint works under a set of limitations. Adding thickeners helps the oil paint become more stable, allowing more control over wetting and drying time. More expensive oil paints tend to have fewer fillers added as those buy more expensive paints expect a higher pigment percentage. Lower quality paints tend to contain less pigment and more filler. Fillers and thickeners are the final step in solidifying the formulation of an oil paint, which can then be packaged for transportation.

The industrial production and transportation of oil paint requires some new raw materials, including paint tube packaging, cardboard box and fuel for transportation. Oil paint packaging materials are more recyclable than their contents. Historically, paints were stored in a pig’s bladder sealed with string. These proved inconvenient and messy as they failed to seal properly between use. John G. Rand, a 17th century painter, invented a tin tube with a screw cap which allowed for a strong seal and for the paint to last a long time (Smithsonian). Tin allowed for paint preservation in a new way that allowed artists to explore additional colors in their paintings. The tubes are often stored in cardboard boxes for transport. These boxes are made using pulp from pine, spruce or fir trees (“How a Cardboard Box Is Made.”). A majority of European paper is made using trees from sustainable forests owned by a company that plants two trees for every one cut down. These days paper boxes are often created using recycled paper, requiring heat and water in the processes that allow the paper to be reused. Cardboard production involves the use of an adhesive as well. When transported overseas or within domestic boundaries, vehicles require fuel in the form of petroleum to transport oil paint from factory to warehouse to retail store. Gasoline includes petroleum gasoline and fuel ethanol, which contains ethanol and petroleum denaturants (“U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.”).

The innovation in oil paint formulation technique may end up hindering the environmental impacts of oil paint, since favorable long lasting quality also means the paint will take longer to degrade when discarded as well as result in hazardous waste.. Traditional means of creating oil paints with natural pigments are generally more environmentally friendly; however, as demand grows for more vibrant colors and long lasting paints, the inclusion of synthetic pigments caused oil paint to become more of an environmental hazard. The most hazardous ingredients are the synthetic pigments which can cause unwanted chemical interactions if they are not disposed of carefully. Flax seed processing includes a host of additional chemicals, but these are reused each time more linseed oil is made, making them somewhat less of an issue. Fillers and gelling agents are another reason why oil paint is increasingly hazardous. Demand for improved texture and vibrancy drives the industry to use more synthetic components. Oil paint packaging can be recycled as long as its hazardous contents are removed. Because the process of making oil paint at an industrial scale is so far from the consumer and the perception of its progression over time is that it has improved in consistency and vibrancy, it is difficult to revert back to older, more environmentally sound methods of mixing paint which result in duller, less concentrated color.

Bibliography

Bonaduce, Ilaria, et al. “New Insights into the Ageing of Linseed Oil Paint Binder: A Qualitative and Quantitative Analytical Study.” PLOS ONE, 12 Nov. 2012, https://journals.plos.org/plosone/article/authors?id=10.1371/journal.pone.0049333. Accessed 21 Oct. 2022.

HIGGITT, CATHERINE, et al. “Pigment-Medium Interactions in Oil Paint Films Containing Red Lead or Lead-Tin Yellow.” National Gallery Technical Bulletin, vol. 24, National Gallery Company Limited, 2003, pp. 75–95, http://www.jstor.org/stable/42616305.

“How a Cardboard Box Is Made.” The Manufacturer, 6 Apr. 2018, www.themanufacturer.com/articles/how-a-cardboard-box-is-made/#:~:text=A%20cardboard%20box%20is%20basically,sources%20of%20second%20hand%20paper.

“How Oil Paint Is Made.” YouTube, YouTube, 7 Apr. 2018, https://www.youtube.com/watch?v=q8Aco8V_ltk.

Magazine, Smithsonian. “Never Underestimate the Power of a Paint Tube.” Smithsonian.com, Smithsonian Institution, 1 May 2013, https://www.smithsonianmag.com/arts-culture/never-underestimate-the-power-of-a-paint-tube-36637764/.

Robertson, Sarah. “Greener Paint.” Sanctuary: Modern Green Homes, no. 16, Alternative Technology Association, 2011, pp. 71–74, http://www.jstor.org/stable/sanctuary.16.71.

SPRING, MARIKA, et al. “Investigation of Pigment-Medium Interaction Processes in Oil Paint Containing Degraded Smalt.” National Gallery Technical Bulletin, vol. 26, National Gallery Company Limited, 2005, pp. 56–70, http://www.jstor.org/stable/42616313.

“U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.” Use of Energy for Transportation - U.S. Energy Information Administration (EIA), www.eia.gov/energyexplained/use-of-energy/transportation.php.

Van den Berg, Klaas Jan, et al., eds. Issues in contemporary oil paint. New York: Springer, 2014, https://link.springer.com/content/pdf/10.1007/978-3-319-10100-2.pdf. Accessed 15 October 2021.

Watson, Greg, et al. “The Process of Alkali Refining Linseed Oil.” Just Paint, Golden Artist Colors, Inc, 24 July 2018, https://justpaint.org/the-process-of-alkali-refining-linseed-oil/. Accessed 21 October 2021.

White, Raymond, et al. “Analyses of Paint Media.” National Gallery Technical Bulletin, vol. 19, National Gallery Company Limited, 1998, pp. 74–95, http://www.jstor.org/stable/42616124.

“Why Oil Paint Is so Expensive .” Youtube, Business Insider, https://www.youtube.com/watch?v=iib_imkZ5fk.

Wurm, Daniel. “The Greening of Paint: An Eco-Paint Buyers Guide.” ReNew: Technology for a Sustainable Future, no. 136, Alternative Technology Association, 2016, pp. 74–79, https://www.jstor.org/stable/renetechsustfutu.136.74.

Life Cycle Assessment of Oil Paints: Embodied Energy

Perhaps the most commonly regarded traditional form of art is the oil painting, recognizable throughout several art movements and significant in depicting history. Oil paints themselves are a specific form of paint used in fine arts contexts as opposed to architectural ones, and they are conventionally used on flat surfaces to depict content or a message. As we shift towards a more comprehensive understanding of the processes behind the products and services around us, one begins to question the materials, energy, and waste management practices required in order for commodities to come into our individual possession. The production of oil paints has evolved from naturally sourced pigments and hand mixing locally to synthetic ingredients, mass production, and distribution. In this paper, I will review the life cycle of oil paints, describe the energy use throughout, and then come to a conclusion about the environmental impact of oil paints with the entire life cycle in mind. From the following examination, we will find that the life cycle stages of oil paints, from materials sourcing to disposal, utilize significant amounts of energy. The immense energy use in these stages contribute to the overall harsh environmental impact of oil paints.

1. Raw Materials + Energy Consumption

The secondary materials in oil paints take a considerable amount of energy to refine, making the first life cycle stage alone notable in the embodied energy of oil paints. Oil paints at their most basic form require two materials: a pigment to produce the color of the paint, and a binder to act as an adhesive or to change the viscosity of the paint.

Pigments can be categorized into bio-based pigments (primary raw material) and chemically synthesized/altered pigments (secondary raw material). A small sliver of pigments widely used in modernity are sourced from biomaterials. Producers of these pigments honor traditional methods and thus strive to reduce their energy usage (Pilcher 30). However, the majority of pigments are inorganic-colored pigments that require chemical synthesis/alteration in order to reach optimal stability, strength, and saturation of the paint. Different pigments require different processes, meaning the embodied energy in oil paints may vary due to the pigment used. For example, in order to synthesize cadmium pigments, they must be heated to 300˚C, using significant amounts of thermal energy. Cadmium sulfide (CdS) and cadmium sulfoselenide (CdS + CdSe) have notoriously excellent chemical and heat stability, making them desirable synthetic pigments. They are commonly used to make several different red, orange, and yellow paints (O’Hanlon). Another example of extensive energy use in refining pigments is the production of titanium dioxide. Titanium dioxide, which is used in several paints but is most notably used in titanium white paints, requires several chemical surface treatments to reach the quality desired (A.G. Abel 109).

The second essential material in oil paints is some form of binder or drying oil, which again, can use different amounts of energy in the refinement process depending on which binder the oil paint manufacturer uses. Linseed oil is the most commonly used binder, and its production process alone is lengthy in its energy use. Kinetic or mechanical energy is required to harvest the flaxseeds, with either human or machine prime movers. It requires thermal energy to heat the flax seeds, kinetic energy to roll them, press them, and refine the oil, and electrical energy to power the machines that do the work (Watson).

What we’ve discussed above are the minimal energy requirements to chemically alter the minimum amounts of materials in oil paints. Realistically, one can assume that most oil paints utilize several additives along with pigments and binders. Additives can be adulterants, modifiers, stabilizers, or driers that alter the characteristics of the paint, whether that’s viscosity, opacity, etc. One common additive in oil paints is silica, which can change the texture, absorbency, and physical characteristics of the paint (“Materials Information”). Silica, also known as “industrial sand or gravel” or “silica sand”, is typically mined using open pit or dredge mining techniques with a set of standard mining equipment, which uses mechanical energy to operate (“Silica Statistics and Information”). After mining, there is an extensive refining process, with the degree of which the silica is refined depending on its ultimate use. Multiple methods may be used, with some examples being gravitational separation, magnetized separation, or washing the sand with a trommel scrubber (“How to Process Silica Sand”). Much like the other materials, the various machinery needed to purify silica contributes to the overall mechanical energy used just in the materials stage of the life cycle of oil paints.

2. Product Manufacturing + Energy Consumption

Many brands pride themselves on the craftsmanship of oil paints, harkening upon the historical craft and specialization of hand-making oil paints. The average artist quality paint now is made with a hybrid approach: partially by hand, and partially by machine. As we know from lecture, the average human can produce approximately 100 watts. Workers at Gamblin Artists’ Oil Colors manually assist many of the factory machines; they disperse pigment into industrial mixers using hand shovels, scrape paint into triple-roll mills, and place empty tubes into a paint tube filling and sealing machine (“How Oil Paints are Made”). Although difficult to find exact energy outputs of the above factory machines, one study wrote that a double-roll mill used 500 watts per second to roll 3kg of a medium viscosity malt, amounting to 1,800 kilowatts an hour (Smejtkova and Vaculik). This gives us an extremely abstract, relatively inaccurate point of comparison to the triple-roll mill used to smooth oil paints. Qualitatively, in comparison to the energy output of humans, we can assume that industrial machinery requires significant amounts of electrical energy to consistently run for hours at a time. These machines then exert mechanical and kinetic energy in order to produce oil paints.

3. Transportation + Energy Consumption

Because we’re not focusing on one specific brand, the transportation life cycle stage is extremely variable depending on context. Hypothetically, let’s imagine you’re an Art Studio major at UC Davis, and you purchase a beginning painting kit. The beginning painting kit has a range of Gamblin artists’ colors oil paints in it. Since the Gamblin factory is in Portland, OR, (“How Oil Paint is Made”) you have to (at the minimum) account for the chemical and kinetic energy used by a truck to transport the paints from Portland, OR to Davis, CA. Potentially, the paints might travel from the manufacturer to a distributor, then from the distributor to the student store, meaning the transportation energy consumption could be higher. On top of the transportation of the paints themselves, you also have to account for the transportation of the materials to the manufacturers. Some pigments which must be chemically altered or mined may even need to be flown across large distances if the manufacturer is specific about the quality of the pigments. In order for these vehicles to travel, fuel stores mechanical energy as potential energy, which then is transformed into kinetic energy. For some rough quantitative estimation, diesel trucks use 2.2 to 3.3 kilowatt-hours per kilometer (Kaufmann and Moynihan). Returning to our minimum distance travelled example, 2.2 kilowatt-hours per kilometer for the 920 kilometers between Portland and Davis adds up to 2024 kilowatt-hours. Multiplying by the 8.75 hour long drive leaves you with 17,710 kilowatts to make the drive. Again, that’s an unreliable estimate, and it is the minimum energy cost given the specific hypothetical context.

4. Use, Reuse, and Recycling + Energy Consumption

For the use, reuse, and maintenance stage of the life cycle, oil paints have a brief description with little large-scale energy use. Humans are animate prime movers, and we conventionally use brushes or palette knives to apply paint to canvases. Paints generally cannot be reused by the average person once they have dried onto the surface that they were painted on, as they have hardened and will crack if flexed (“Materials Information”). Some pigments that contain iron are hypothetically indefinitely recyclable with specialized methods. This would, of course, require some energy consumption, but comparably less than sourcing a new material (Pilcher 30). It’s worth noting that reuse differs from recycling, and some materials within oil paints have potential for recycling. Although the embodied energy of oil paints thus far has been bleak, and the cradle-to-grave nature of the product is grim, there have been some possibilities for ways in which we can reduce waste by using varying byproducts to synthesize pigments. For example, the brand Gamblin uses a filtration system in their factories that collects powdered pigment. The combination of several hues then creates a gray pigment, which is then processed into an oil paint and is sold seasonally (“How Oil Paint Is Made”). Utilizing the airborne extraneous pigments both protects Gamblin’s workers from inhaling potentially hazardous compounds and reduces energy costs of needing to source and transport a new pigment to make gray paints. Another instance of recycling in the oil paint industry is a coal mine in Brazil that processes their drainage treatment sludge into paint pigments. While the processing and refinement of the waste into brown pigment consumes great amounts of thermal and electric energy, the process is beneficial in that it diverts waste from its path to instant disposal (Marcello et al.).

5. Waste Disposal + Energy Use

Because of the volatile organic compounds (VOCs) in oil paints and solvents (used while painting in order to alter the opacity and viscosity of paint), the two together are especially combustible and highly flammable. If improperly disposed of, the VOCs can seep into the ground, contaminating local water sources (“2021 Paint Waste”). This results in oil paints’ classification as hazardous waste, entering an alternate disposal process.

Hazardous waste is often produced as a byproduct of technological manufacturing processes. In the case of oil paints, it is the individual’s responsibility to transport leftover paints to a hazardous waste disposal facility, consuming more energy. Hazardous waste facilities might enact one of three processes: recycling, disposal, or treatment (“Learn the Basics”). Oil paints, because of their VOCs, cannot be dried or treated to nullify the contents of the paint (“2021 Paint Waste”). Interestingly enough, I couldn’t find anything about what hazardous waste facilities actually do with the oil paints, which leads me to believe that they’re either being stored somehow, or they’re being destroyed in a harmful way. Regardless, it is safe to assume that any sort of processing done at the facility requires some amount of energy from human/animate prime movers and machinery/inanimate prime movers.

6. Conclusion

After assessing five distinct stages in the life cycle of oil paints, one can conclude that there is significant energy use in each stage alone. Combined, the embodied energy in oil paints is a hefty amount. Unfortunately, this doesn’t come as much of a surprise. Many of the products we use today, oil paints included, have higher embodied energy levels because of the energy needed to alter synthetics, power machinery in mass production practices, and dispose of/hide the inorganic waste after use.

Oil paints’ overall environmental impact, considering energy consumption, is concerning to say the least. By design, oil paints are meant to last as long as possible. As we discussed in the materials section, processing and refinement occurs partially so that the paints retain their vibrancy and stability over time. This results in the use of volatile organic compounds and petroleum-based materials, making disposal complex and expensive.

Much like the way we addressed the Energy Civilization Equation in lecture, we have to challenge the way we approach the life cycle of oil paints because we will soon no longer have a choice. With the depletion of fossil fuel resources and the ever-looming threat of climate change, recent developments in sustainable materials sourcing present hope in the paint industry. Despite steps in the right direction, many compromises will have to be made in the rest of the life cycle of oil paints to meet the sustainability needs of the future. (Pilcher 36)

Works Cited

A.G. Abel. Paint and Surface Coatings (Second Edition). Woodhead Publishing, 1999. https://doi.org/10.1533/9781855737006.91.

Coles, David. “Inside the Painstaking Process of Making High-Quality Oil Paint.” Artsy. 3 December 2018. https://www.artsy.net/article/artsy-editorial-inside-painstaking-process-making-high-quality-oil-paint. Accessed 21 October 2021.

“How Oil Paint Is Made”. Youtube, uploaded by Art Insider, 7 April 2018, https://www.youtube.com/watch?v=q8Aco8V_ltk.

“How to Process Silica Sand?” JXSC Machine, 16 May 2018, https://www.jxscmachine.com/new/how-to-process-silica-sand/.

“MATERIALS INFORMATION and TECHNICAL RESOURCE for ARTISTS – Paint Mediums and Additives.” Arts Conservation University of Delaware, https://www.artcons.udel.edu/mitra/Documents/MITRA_Mediums_and_Additives.pdf. Accessed 21 October 2021.

Kaufmann, Johannes, and Qayyah Moynihan. “Electric Trucks like the Tesla Semi Are 'Pointless Both Economically and Ecologically,' According to a Vehicle-Tech Expert.” INSIDER, 3 Apr. 2019, https://www.businessinsider.com/this-expert-says-tesla-semi-is-economically-and-ecologically-pointless-2019-2?utm_source=copy-link&utm_medium=referral&utm_content=topbar.

“Learn the Basics of Hazardous Waste.” United States Environmental Protection Agency, https://www.epa.gov/hw/learn-basics-hazardous-waste.

O’Hanlon, George. “Cadmium Colors–It Began with Medicine”. Natural Pigments. Web. 28 April 2018, https://www.naturalpigments.com/artist-materials/cadmium-colors/. Accessed 11 Nov 2021.

Pilcher, George R. “Sustainability in the Paints and Coatings Industry: Far More than Just a ‘Good Idea’”. Coatings Tech: 8th Annual Green Coatings & Sustainability Issue. AmericanCoatings Association. 2021, pp. 26-37. https://www.coatingstech-digital.org/coatingstech/may_2021/MobilePagedArticle.action?articleId=1687919&app=false#articleId1687919

R.R. Marcello, S. Galato, M. Peterson, H.G. Riella, A.M. Bernardin. Inorganic pigments made from the recycling of coal mine drainage treatment sludge. Journal of Environmental Management. Volume 88, Issue 4, 2008. https://doi.org/10.1016/j.jenvman.2007.07.005.

Robertson, Sarah. “Greener Paint.” Sanctuary: Modern Green Homes, no. 16, Alternative Technology Association, 2011, pp. 71–74, http://www.jstor.org/stable/sanctuary.16.71.

“Silica Statistics and Information.” National Minerals Information Center, https://www.usgs.gov/centers/nmic/silica-statistics-and-information.

Smejtkova, A. Vaculik, P. “Comparison of power consumption of a two-roll mill and a disc mill.” Eesti Maaülikool: Estonian University of Life Sciences. 2018. http://dx.doi.org/10.15159/ar.18.017. Accessed 21 October 2021.

Van den Berg, Klaas Jan, et al., eds. Issues in contemporary oil paint. New York: Springer, 2014, https://link.springer.com/content/pdf/10.1007/978-3-319-10100-2.pdf. Accessed 15 October 2021.

Watson, Greg, et al. “The Process of Alkali Refining Linseed Oil.” Just Paint, Golden Artist Colors, Inc, 24 July 2018, https://justpaint.org/the-process-of-alkali-refining-linseed-oil/. Accessed 21 October 2021.

White, Raymond, et al. “Analyses of Paint Media.” National Gallery Technical Bulletin, vol. 19, National Gallery Company Limited, 1998, pp. 74–95, http://www.jstor.org/stable/42616124.

Wilson, Peter, and Petar Johnson. “MANAGING AND UNDERSTANDING THE ENVIRONMENTAL IMPACTS OF ARCHITECTURAL COATINGS.” Environment Design Guide, Royal Australian Institute of Architects, 2003, pp. 1–8, http://www.jstor.org/stable/26148401.

“2021 Paint Waste Disposal Guide.” ACT enviro, https://www.actenviro.com/paint-waste-disposal-management/.

Kai Maurer-Mabanglo

Life Cycle Assessment of Oil Paints: Waste and Pollution

Oil paints are an extremely popular form of paint commonly used in artistic applications due to their lengthy lifespan and slow drying time. Rather than having the majority of the waste produced in one particular piece of the life cycle, oil paints result in waste at almost every stage of the life cycle, those being acquisition of raw materials, manufacturing and processing, distribution and transportation, and waste management. From residual fungicide to evaporated sulfuric acid to aluminum scrap to carbon emissions, oil paints create waste at every step with every material some way or another.

The first step in the lifecycle of oil paints comes during the acquisition of materials with the main forms of waste being leftover strobilurin fungicide, carbon emissions from agricultural machinery, and sulfuric acid. While they are not the definitive ingredients to oil paints, they are used in a large portion of the oil paints one may see today on the shelves of any art store. Of course, their acquisition isn't without waste for both flax and pigments. Starting with Flax, there are many unique properties of flax that influence its harvesting method and therefore the types and amounts of waste produced. Flax is particularly susceptible to a fungal disease known as Pasmo, making fungicide an important part of a successful harvest. One of the most popular fungicides among flax producers are strobilurin fungicides (flaxadmin), which end up being a form of waste as well by seeping into the soil and water that the flax grows in. Waste from fungicides like strobilurins are known to cause ecological damage by seeping into water sources and have been shown to affect the function of mitochondria in Zebrafish contaminated by toxic fungicide water, ultimately impairing locomotion and motor control. (Li). Flax also has some other unique properties that generally reduce the amount of waste produced through its growth and harvest. One example of these unique properties is its watering needs (or lack thereof); without a drought present, flax does not need irrigation to grow, reducing the amount of water waste and spread of contaminated water due to fungicides (Richter). Additionally, flax does not require special fertilizers such as phosphorus fertilizers, making their waste less harmful in comparison to other crops (Kandel). Another result of bug’s disinterest in flax is that the crops do not require tilling, requiring less tractors in operation resulting in fewer carbon emissions from the burning of fossil fuels (Kandel). Even so, agricultural tractors and combines are still needed to harvest flax. It is known that at this stage carbon emissions from tractors take the cake for the largest amount of waste produced (Gemtos), lack of documentation of fuel consumptions and emission output from farmers make it difficult to glean the exact amounts of waste produced as well as their individual environmental impact (Russell). On the pigment side of production, there are many different types of pigments used as primary materials with different properties, but by far the most used in oil paints are inorganic pigments. While organic pigments often produce less harmful waste, they are more expensive to obtain and produce. Probably the most common pigment used in oil paints is titanium oxide, a non toxic and inorganic pigment (“Inorganic pigments vs. organic pigments”). To acquire this material, producers use ilmenite and sulfuric acid with the sulfate method to extract iron sulfate pentahydrate by separating the iron content from the rest of the chemical compound (“Inorganic pigments vs. organic pigments”). Sulfuric acid is extremely toxic and is a large part of the waste used in this process. As waste, sulfuric acid generally takes the form of droplets in the atmosphere that can contaminate snow, rain, clouds, bodies of water. Environmental damages to animals from sulfuric acid include burns and irritation, commonly harming the skin and lungs. Sulfuric acid waste deals the most damage to plants in the environment by changing the pH content of the soil, ultimately killing the plants within that soil and preventing future growth (“Sulfuric Acid”). With both pigment in the form of titanium oxide as well as raw flax for linseed oil, the producer is ready to start manufacturing oil paints in the wake of strobilurin fungicide, carbon emissions, and sulfuric acid waste.

The next stage of the step in the oil paint lifecycle is the manufacturing and processing phase, another stage with ample waste from chemical agents, residual flax matter, and carbon emissions alike. First, the flax seeds must be processed and turned into linseed oil to be mixed in with the pigment. This process starts with the heating and drying of the seeds in large industrial batch furnaces which produce waste in the forms of carbon emissions either by the burning of fossil fuels or electricity that is created through other sources whether they be water, solar, coal, or nuclear powered, all determining the type and amount of waste produced (“Alternative control techniques document— nox ... - US EPA”). The next step where waste is created is in the use of hexane, a chemical used for chemical solvent extraction (Watson). First, large vats of the flax seeds are covered with hexane. When the hexane evaporates, the linseed oil is conveniently left behind for collection. Hexane in particular is used during this process because of how waste produced in the form of evaporated hexane is non-toxic and does not have damaging effects on the environment after being evaporated into the atmosphere. Even if directly consumed by a human, unless consumed in large amounts, hexane should only act as a laxative (“Why is Hexane used for Extraction?”). Evaporated hexane isn’t the only form of waste from the flax to linseed oil process, as the residual organic material from the flax seed that ends up being separated from the oil turns out to be highly flammable and a dangerous hazard if not disposed of properly (“Linseed oil production technology”). The next step in the production of oil paints is bringing the linseed oil together with the pigment. Both ingredients are added into an industrial paint mixer and then put through a triple roll mill (Coles). The resulting paste is then filtered, where many of the previously mentioned wastes and impurities ranging from chemical solvents to additional dyes are built up and collected into a filter cake, one of the largest forms of waste produced at this stage (Rabelo). The other main source of waste from this process comes in the form of gaseous emissions. As noted by Tanzer - Grouner, “Oil paints contribute ~90% of the I/VOC emissions and SOA formation, even though it only accounts for ~20% of paint usage” (Tanzer-Gruener), giving them a very high waste to product ratio compared to other paints.

The transportation and distribution step in the life cycle of oil paints continues on with multiple different types of waste, ranging from aluminum scrap to freight transport vehicle emissions. Oil paint is generally packaged in metal tubes, with modern tubes being made out of aluminum due to its cheap price and its strength (Brooks). These tubes are created by heating up molding aluminum industrial furnaces and cut down to size with other machines. The result is waste in the forms of scrap metal and carbon emissions from fossil fuels burned (“Tube Council”). Fortunately for the environment, waste in the form of scrap aluminum is easily recyclable. Additionally, recycling aluminum diverts from the extremely negative environmental cost of ore mining along with the waste that produces (Husband). Apart from the tube, the newly packaged oil paints also have to be transported from the factories and production plants to consumers, a process that isn’t without its fair share of waste. In this transportation process, the waste that's in the form of carbon emissions due to the burning of fossil fuels. Since transportation of the finished product isn't location specific, there are varying methods of transport to get to wherever the consumer may be. Some examples of transport vehicles used are trucks, planes, and cargo vessels among others. Trucks are one of the most common modes of transportation with a larger footprint per unit of product (Brown). While not specifically tied to oil paints only, carbon emissions from freight make up 30 percent of all carbon emissions from transportation and 7 percent of all carbon emissions. Not only that, but these numbers are predicted to increase as time goes on due to larger and larger amounts of freight (International Transport Forum). Like every other stage of oil paint’s life cycle before distribution and transportation, there is waste. This time, it happens to take the form of scrap aluminum from the packaging and carbon emissions from burning fossil fuels.

Since oil paints cannot be recycled, the final step in their life cycle is waste management. Unfortunately there is little to no information on how oil paints are actually disposed of within a waste plant. Due to oil paint toxicity being reliant on the oils and pigments included in the production phase of the life cycle, there are many different potential types of waste that must be treated during the waste management process. For example, there are specific types of oil paints that include lead in them that must be treated a special way within a disposal plant, even if the exact methods of disposal are not shared to the public (Kelley). Fortunately, oil paints have a very long lifespan in comparison to other paints that can last upwards of thirty years if stored in the right conditions, meaning that they turn to unusable waste at a slower rate than other types of paint (Beth).

Rather than having the majority of the waste produced in one particular piece of the life cycle, oil paints result in waste at almost every stage of the life cycle, those being acquisition of raw materials, manufacturing and processing, distribution and transportation, and waste management.

Bibliography

Saft, R.J. Life cycle assessment of a pyrolysis/gasification plant for hazardous paint waste. Int J Life Cycle Assess 12, 230 (2007). https://doi.org/10.1065/lca2007.05.332

Robertson, Sarah. “Greener Paint.” Sanctuary: Modern Green Homes, no. 16, Alternative Technology Association, 2011, pp. 71–74, https://www.jstor.org/stable/sanctuary.16.71

HIGGITT, CATHERINE, et al. “Pigment-Medium Interactions in Oil Paint Films Containing Red Lead or Lead-Tin Yellow.” National Gallery Technical Bulletin, vol. 24, National Gallery Company Limited, 2003, pp. 75–95, http://www.jstor.org/stable/42616305.

Wurm, Daniel. “The Greening of Paint: An Eco-Paint Buyers Guide.” ReNew: Technology for a Sustainable Future, no. 136, Alternative Technology Association, 2016, pp. 74–79, https://www.jstor.org/stable/renetechsustfutu.136.74.

Sözen S., Duba S., Uzun Ozsahin D., Aslanova F., Gökçekuş H., Orhon D. (2021) Evaluation and Optimization of the Treatment Scheme for the Paint Industry Effluents Using Multi-criteria Decision Theory. In: Uzun Ozsahin D., Gökçekuş H., Uzun B., LaMoreaux J. (eds) Application of Multi-Criteria Decision Analysis in Environmental and Civil Engineering. Professional Practice in Earth Sciences. Springer, Cham. https://doi.org/10.1007/978-3-030-64765-0_19

Wilson, Peter, and Petar Johnson. “MANAGING AND UNDERSTANDING THE ENVIRONMENTAL IMPACTS OF ARCHITECTURAL COATINGS.” Environment Design Guide, Royal Australian Institute of Architects, 2003, pp. 1–8,http://www.jstor.org/stable/26148401.

White, Raymond, et al. “Analyses of Paint Media.” National Gallery Technical Bulletin, vol. 19, National Gallery Company Limited, 1998, pp. 74–95, http://www.jstor.org/stable/42616124.

Watson, Greg, et al. “The Process of Alkali Refining Linseed Oil.” Just Paint, Golden Artist Colors, Inc, 24 July 2018, https://justpaint.org/the-process-of-alkali-refining-linseed-oil/. Accessed 21 October 2021.

Van den Berg, Klaas Jan, et al., eds. Issues in contemporary oil paint. New York: Springer, 2014,https://link.springer.com/content/pdf/10.1007/978-3-319-10100-2.pdf. Accessed 15 October 2021.

Smejtkova, A. Vaculik, P. “Comparison of power consumption of a two-roll mill and a disc mill.” Eesti Maaülikool: Estonian University of Life Sciences. 2018. http://dx.doi.org/10.15159/ar.18.017.

“Alternative Control Techniques Document— Nox ... - US EPA.” EPA, EPA, Sept. 1993, https://www3.epa.gov/ttncatc1/dir1/procheat.pdf.

Beth “When Good Art Materials Go Bad.” Redbubble Blog, 3 Apr. 2019, https://blog.redbubble.com/2014/09/when-do-art-materials-expire/.

Brooks, Kimberly. “What's next for Artist Paint Tubes?” The Art Treehouse, 27 Apr. 2019, https://arttreehouse.com/artstore/whats-next-for-artist-paint-tubes/.

Brown, Tyson. “Transportation and Climate Change.” National Geographic Society, 11 Aug. 2020, https://www.nationalgeographic.org/media/transportation-and-climate-change/.

Coles, David. “Inside the Painstaking Process of Making High-Quality Oil Paint.” Artsy, Artsy Inc., 3 Dec. 2018,https://www.artsy.net/article/artsy-editorial-inside-painstaking-process-making-high-quali ty-oil-paint.

“Flax Tips: July Tips: Disease and Insect Monitoring.” Flax Council Of Canada, Flax Council Of Canada, 18 July 2017, https://flaxcouncil.ca/tips_article/flax-tips-july-tips-disease-and-insect-monitoring/.

Gemtos, T. A. “Tractor Engine and Gas Emissions.” ResearchGate, University of Thessaly, Oct. 2008,

https://www.researchgate.net/profile/T-Gemtos/publication/266181082_Tractor_engine_a nd_gas_emissions/links/5b043b340f7e9be94bdb92d5/Tractor-engine-and-gas-emissions. pdf.

Husband, Tom. “Aluminum Recycling.” American Chemical Society, Apr. 2012, https://www.acs.org/content/acs/en/education/resources/highschool/chemmatters/past-iss ues/archive-2011-2012/aluminum-recycling.html.

“Inorganic Pigments vs. Organic Pigments.” Brenntag, Brenntag North America, https://www.brenntag.com/en-us/industries/coatings-construction/inorganic-organic-pigm ents/.

International Transport Forum. International Transport Forum, International Transport Forum, London, 2021.

Kelley, Brian. “The Great Lead White Shortage.” Painting Perceptions, 1 Jan. 2012, https://paintingperceptions.com/the-great-lead-white-shortage/.

Li, Xiao Y, et al. “Relative Comparison of Strobilurin Fungicides at Environmental Levels: Focus on Mitochondrial Function and Larval Activity in Early Staged Zebrafish (Danio Rerio).” Meta, Meta, 7 Feb. 2021, https://www.meta.org/papers/relative-comparison-of-strobilurin-fungicides-at/33548355.

“Linseed Oil Production Technology.” Linseed/Flaxseed Oil Production Technology and Equipment Required, ABC Machinery, 2021, http://www.bestoilmillplant.com/linseed-oil-production-technology.html.

Rabelo, Sarita Cândida. “Industrial Waste Recovery.” Filter Cake - an Overview, 2015, https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/filter-cake.

Richter, Conrad. “Fibre Flax Planting and Processing.” Richters Herbs - Medicinal, Culinary, Aromatic - Plants & Seeds, Otto Richter and Sons, 10 June 2020, https://www.richters.com/show.cgi?page=InfoSheets%2Fd2701.html.

Russell, Stephen. “Everything You Need to Know about Agricultural Emissions.” World Resources Institute, World Resources Institute, 29 May 2014, https://www.wri.org/insights/everything-you-need-know-about-agricultural-emissions.

“Sulfiric Acid.” National Pollutant Inventory, Australian Department of Agriculture, 22 Feb. 2019, http://www.npi.gov.au/resource/sulfuric-acid.

Tanzer-Gruener, Rebecca, et al. “Watching Paint Dry: I/VOC Emissions from Architectural Coatings and Their Impact on Soa Formation.” ChemRxiv, 13 Aug. 2021, https://chemrxiv.org/engage/chemrxiv/article-details/611517c418911d5deedf0c61.

Tube Council. “How Aluminum Tubes Are Made.” The Tube Council, 6 Feb. 2020, http://tube.org/how-aluminum-tubes-are-made/.

Watson, Greg, et al. “The Process of Alkali Refining Linseed Oil.” Just Paint, Golden Artist Colors, Inc., 11 Feb. 2021, https://justpaint.org/the-process-of-alkali-refining-linseed-oil/.

“Why Is Hexane Used for Extraction?” EcoLink, Industrial Degreasers /Wp-Content/Uploads/2017/09/New_Ecolink_Logo-32.Png, 21 May 2020, https://ecolink.com/info/why-is-hexane-used-for-extraction/.