Design Life-Cycle

assess.design.(don't)consume

Alexi Espinosa

Amanda Neves, Urvi Parashar

Christina Cogdell

DES 40A

3 March 2023

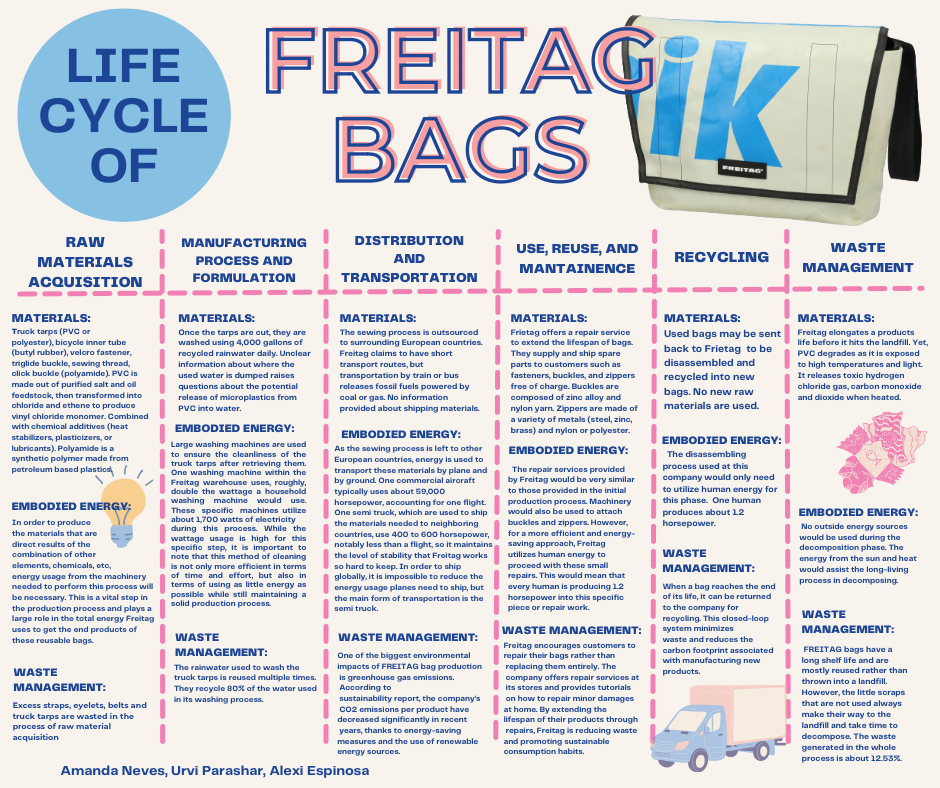

Freitag Bag Raw Materials

In recent years, rhetoric surrounding sustainability has found its way into the American lexicon. People are more aware of the environmental and social impacts of the products they consume. Similarly, companies have become increasingly conscious of the role their product plays in global fossil fuel emissions. One Swiss company by the name of Frietag has been pioneering the way in sustainable and meaningful consumption within the cycling industry for decades. Frietag creates one-of-a-kind utility bags using 87% recycled materials. It is important to study Freitag’s sustainability claims because they utilize recycled truck tarps made of PVC in the production of their bags. Polyvinyl chloride, or PVC, has been termed “the poison plastic” by green organizations looking to phase-out its usage. Despite being one of the most widely used plastics, PVC is high in chlorine based toxins and poses a multitude of environmental and human health concerns. Dioxin, one of the “dirty dozen” chemicals, is created as a byproduct. Why would a so-called sustainable company like Freitag utilize PVC as the main material in its bags? The production of PVC has a great environmental impact, however its reuse presents opportunities for improvements in circularity, energy usage, and managed waste. The raw and secondary materials necessary to the creation of a Freitag bag are PVC (salt and oil), bicycle inner tubes (butyl rubber), velcro fasteners, tri glide buckles, sewing thread, and click buckles (polyamide), polyester, and fossil fuels.

Although the materials used to produce a Freitag bag are neither organic nor compostable in nature, they are almost all recycled or recyclable. After truck tarps have been on the road for 5-8 years they are destined for disposal, with an estimated degradation period of 1,000 years awaiting them. To prolong the lifespan and utility of a heavy duty, water-proof, and durable material such as PVC, Freitag uses the tarps as the basis for their bags. PVC is composed of 57% common salt and 43% oil feedstocks (British Plastics Federation). Salt and hydrocarbon resources must first be extracted from the Earth and combined with water. The salt undergoes electrolysis, where bonded elements and compounds are separated by an electric current. The byproduct of this process is chlorine, which is then combined with ethylene. Ethylene is derived from steam cracking, a process that breaks down the hydrocarbons in oil by refining natural gas. The result is vinyl chloride monomer, or VCM. VCM is polymerised to form PVC resin, and a range of chemical additives are incorporated into the PVC to customize its mechanical properties. Freitag tests the tarps that enter its factory for plasticisers, lubricants, or unwanted constituents before transforming them into bags.

The additions that make a Frietag bag prized for its utility by cyclists and consumers alike are recycled bicycle inner tubes, velcro fasteners, buckles, and thread. These additions are noted as B-stock, materials that are rejected by distribution channels for having minor visual defects or otherwise not meeting quality standards. B-stock and recycled goods accounted for 3.58% of Freitag’s material consumption in 2021. New materials such as zips, buckles, and snap fasteners accounted for 7.73% of material consumption, while upcycled goods (used truck tarps) made up 88.69%. The recycled bike inner tubes used to line the bag are originally made from butyl rubber. Butyl rubber is a synthetic elastomer that resembles natural rubber in its elastic and durable properties. It is made by combining isobutylene and isoprene in a process called cationic vinyl polymerization, where isoprene is added to isobutylene. The product is then vulcanized, where the rubber molecules are mended together to form a single, large molecule that neither melts as it is heated or embrittles as it cools (ThomasNet).

According to Freitag, the velcro fasteners, tri glide and click buckles are all composed of polyamide. Polyamide is a synthetic polymer made from petroleum based plastics. Like polyester, polyamide is made from oil, a non-renewable energy source. When it is washed, it sheds microplastic fibers that enter waterways and oceans. Given that the material makeup of a Freitag bag lends itself to being wiped down instead of washed when cleaning is necessary, the release of microplastics is not much of an issue. However, the PVC truck tarps must also be washed before manufacturing. Freitag uses 4,000 gallons of 60% recycled rainwater to wash the tarps daily. A lack of information about where the used water is dumped raises questions about the potential release of microplastics from PVC into water or soil. Safety buckles and car seat belts are upcycled to become the straps of the bag. The straps of seat belts are made of woven polyester filament, which is derived from ethylene and is produced by melt spinning. PET plastic pellets are melted down and fed through spinnerets, or tiny holes, to form long threads that are cooled and hardened into fibers (CFDA). Buckles are made of a variety of metals such as zinc alloy or steel, or plastic such as acetal, nylon, and polypropylene.

The finishing touches of a Freitag bag are the thread used to sew the bag together and a woven label that allows Freitag aficionados to recognize one another. The large-scale replacement of natural materials for synthetic ones is illustrated in the use of nylon sewing thread. Natural fibers such as cotton and linen were once the material of choice, but the use of polyester and nylon are now ubiquitous. Polyamides derive from carbon-based chemicals found in coal and petroleum. Finally, the woven label made of polyester is attached.

The use of raw materials does not stop at the production and manufacturing of the bag. To get the materials from the producers to the Freitag factory and the bag from the production site to consumers requires fossil fuels. Transportation by truck, train, or plane for international orders necessitates the use of diesel or petroleum products such as crude oil and natural gas. The process of sewing the bag is outsourced to other European countries such as Portugal, Poland, the Czech Republic, Bulgaria, Romania, and Switzerland. The outsourcing of tasks in the production process is consistent with our modern globalized economy. Outsourcing is hard to avoid to keep labor costs cheap and product prices affordable, but often has ethical drawbacks. Frietag goes about this in the best way it can by following a Code of Conduct for its producers, which is in line with UN conventions and “regulates working conditions and social and environmental compatibility” (Freitag Impact Report 39). Frietag notes that all producers are located within 2,500 km from Zurich, which keeps transport routes short. Information about the materials used to ship products to consumers is unclear.

In line with Freitag’s journey to circularity and commitment to extending the lifespan of their products, they offer a repair and S.W.A.P service. They replace defective parts of the bag such as zippers and close rips, open seams, and holes. If the problem is simple enough for the consumer to fix the bag themself, Freitag will send spare parts such as screws, buttons, or buckles free of charge. This service avoids unnecessary fossil fuel emissions generated by shipping the product to and from the repair site. They also expanded repair sites from their headquarters in Zurich to stations in Australia, China, Singapore, Taiwan, Japan, Korea, and Thailand. For others who are looking to exchange their bag for a new-to-them product, Freitag offers a “non commercial online bag exchange platform” where consumers can register their bag and find people to swap products with. No new materials are generated in the repair and swap services besides spare parts that have already been examined. Despite their emphasis on closed cycles and recyclability, the Freitag website and Impact Report offered no information on how to recycle the bag after its use or what will happen to it when it is disposed of. Based on the previous analysis of their business model, I can assume that usable parts will be recycled to form new bags. However, the recycling of twice-used PVC tarps will most likely be up to commercial recycling facilities, if they choose to accept the PVC based on its condition. It will likely be hard to recycle due to the cocktail of harmful chemical additives incorporated into the material. If the bag is sent to the landfill, high temperature and UV light will aid in the degradation of PVC as it leaches toxic additives and releases the “dirty” chemical, dioxin. Due to the durability, pricepoint, and irreplicable nature of a Freitag bag, they are commonly sold on resale websites for a third of their original value, which is an efficient means to maintain the product’s circularity.

Though Freitag’s sustainability claims are lofty in scope, I have found them to be credible. The natural materials used in the creation of a Frietag bag are far and few, and the company chiefly relies on secondary materials that are synthetic by design. Despite this, the fact that the majority of materials are recycled and Freitag goes to great lengths to maintain sustainable practices throughout its production cycle makes the bag a conscious and meaningful investment. The high price point (ranging from $170-$330 for a messenger bag) is no small purchase for many consumers. It prevents frivolous consumption by urging people to reconsider whether the bag will be worth the investment. The long-lasting materials aided by PVC’s sturdy and waterproof properties and Fretitag’s quality craftsmanship combine to form a timeless bag. Freitag extends the functionality of the materials it uses by giving them a second lease on life for years to come. The prime issue lies in the fossil fuels used to transport products throughout Europe and internationally. Yet, in an increasingly globalized world, these factors are nearly inevitable. Frietag is exceedingly transparent about their production cycle in comparison to most companies, but further information could be provided about the disposal of rainwater, materials used for packaging and shipping, and recycling or waste management protocols. One would be hard-pressed to deny Freitag’s roots in sustainable practices and careful consumption of raw materials. Frietag’s widespread popularity among cycling buffs and urban environmentalists alike is attributed to its eco-friendly philosophy backed by tangible results.

Bibliography

“Freitag | One-off Pieces Made from Recycled Truck Tarps.” Freitag, https://www.freitag.ch/en.

“PVC: The Poison Plastic.” PVC: The Poison Plastic, 18 Aug. 2003, https://www.greenpeace.org/usa/wp-content/uploads/legacy/Global/usa/report/2009/4/pvc-the-poison-plastic.html.

Thornton, Joe. "Environmental impacts of polyvinyl chloride (PVC) building materials." Washington, DC: Healthy Building Network (2002).

British Plastics Federation. “Polyvinyl Chloride PVC.” British Plastics Federation, https://www.bpf.co.uk/plastipedia/polymers/PVC.aspx#Raw%20Materials.

“Media.freitag.ch.” Freitag Impact Report, https://media.freitag.ch/sites/default/files/freitag_impact_en.pdf.

Javith. “What Are the Contents of Tarpaulin?” Nellai Tarpaulin, 3 Feb. 2023, https://nellaitarpaulin.com/what-are-the-contents-of-tarpaulin/.

“What Is Vinyl? What Is Polyvinyl Chloride (PVC)?” Vinyl, https://www.vinylinfo.org/production/.

“Dioxins and Their Effects on Human Health.” World Health Organization, World Health Organization, https://www.who.int/news-room/fact-sheets/detail/dioxins-and-their-effects-on-human-health.

“Producing Ethylene through a More Environmentally Safe Process.” College of Engineering and Computing, https://sc.edu/study/colleges_schools/engineering_and_computing/news_events/news/2021/producing_ethylene_environmentally_safe_process.php#:~:text=Ethylene%20has%20historically%20been%20made,and%20fed%20by%20natural%20gas.

“All about Butyl Rubber - Properties, Applications, and Uses.” Thomasnet® - Product Sourcing and Supplier Discovery Platform - Find North American Manufacturers, Suppliers and Industrial Companies, https://www.thomasnet.com/articles/plastics-rubber/all-about-butyl-rubber/.

“Polyester.” CFDA, https://cfda.com/resources/materials/detail/polyester#:~:text=To%20make%20polyester%20fibers%2C%20PET,create%20fibers%20with%20different%20qualities.

Amanda Neves

Professor Christina Cogdell

DES 40A

8 March 2023

Embodied Energy of Freitag Bags

Freitag is a company that was formed within one room in an apartment, in 1993. Markus Freitag lived in a small apartment in Zurich, Switzerland with his roommate, which only cost about $300 a month. In this small area, Freitag was created. Freitag is a company that creates one of a kind utility bags using recycled materials. It is important to study Freitag’s sustainability claims because they utilize recycled truck tarps in the production process. The use of PVC has a great environmental impact, however its reuse also presents opportunities for improvements in energy use and excess waste. Their sole priority is to stay sustainable by utilizing as little energy as possible as long as the output is not harmful to the environment. Through this process, it is not only essential for the materials that are used to create the product to be considerate towards the environment, but also the energy output to reflect how important the environment is to the company. It is important to understand the amount of energy that goes into a product that is labeled as “sustainable” because it can completely counter the company’s claim. Freitag, however, does not disappoint.

Starting from the very beginning of the production process, the search for the truck tarps begins. All throughout the streets of Europe, large big rig trucks travel to find abandoned truck tarps to recycle in order for the end product to be a Freitag bag. Freitag hires 250 drivers to bring back approximately 350 tons of tarps to Nœrd, Switzerland a year (Freitag). With these large trucks, comes an extremely large amount of embodied energy. One big rig truck alone utilizes about 400 to 600 horsepower. If the trucks are driving around on, hypothetically, day-long shifts searching for these tarps, one truck alone would use approximately 3,200 to 4,800 horsepower (International Used Truck Center). This large number could be shocking to most at first glance, however it is the most sustainable and suitable method of transportation to search and carry these levels of heavy materials. Some may suggest transportation of the products by plane, however, a commercial plane uses 77% more horsepower than a semi-truck, emitting an extreme amount of energy, which is not within the sustainability goals of the company. After the searching of the tarps, human labor becomes an incredibly large portion of the embodied energy in the production process.

While the drivers pull the trucks back into the company to return the tarps, this is when human labor takes over as the largest form of embodied energy. Freitag utilizes human labor throughout the production process in order to wash, cut, shape, and photograph the products. On average, a human utilizes about 1.2 hp, or 100 watts per hour, significantly less than any form of machinery (Lecture 4). While utilizing human energy has been proven to be more sustainable overall, it is important to provide these individuals with a healthy working area and to make sure everything is safe. Freitag continues to prove that not only are they succeeding in using the minimal amount of energy possible, but they provide their workers with a large area of space to get their tasks done efficiently and safely. Even though the amount of workers who are cutting and shaping the tarps to fit the sizes of the Freitag bags is small, a large area being provided is incredibly important. As this team is using large cutting tools and moving around a lot in order to get precise measurements and straight cuts, it can be dangerous if the energy exerted is limited to a small amount of space. After the cutting of the tarps, washing is necessary in order to provide a clean slate for the products. Because the tarps are extremely large, large washing machines are needed in order to properly wash the materials used to create the bags. The washing machines in the Freitag warehouse utilize almost 4,000 gallons of filtered rainwater in order to achieve the finish they want (Freitag). After the washing process, the tarps are hung to dry, which is all done by humans working inside the large warehouse. After this process of ensuring the tarps are clean and ready to be assembled, a team of designers work to put the products together, as everyone moves onto the distribution process.

At the Freitag company, only prototype products are sold and distributed, after the production process, everything is passed on to experienced partners throughout Europe to assemble and distribute the actual finished products (Freitag). After this process, the bags are returned back to Switzerland where the final distribution happens. The individuals in the warehouse then move on to photographing the finished products, utilizing the energy created from the cameras and lighting, to be placed on the product website for all to come across. To sum up the energy usage used in the product advertising process, on average, a camera used for these types of activities uses 2 to 15 watts. Studio lighting that is used to create the perfect level of brightness in the final product photos uses about 200 watts of electricity to finalize this process. After this, comes the step of shipping out the finished products worldwide through different forms of transportation. In order to keep global shipping available to the consumers of Freitag products, aircrafts must be used to effectively transport the goods all around the world. With this taken into consideration, an aircraft uses about 59,000 horsepower per flight. With the mass production of these products, the number of flights that have to be used for transportation adds up, but gratefully, semi trucks are another huge form of transportation that Freitag uses to reduce their overall energy usage, especially towards the end of the production process as a whole. On average, as stated before, a semi truck uses 400 to 600 horsepower, the ideal sustainable form of transportation for domestic shipping. With this final step, the unbelievably sustainable and energy-reduced process of creating Freitag bags has come to an end.

Throughout this research, it is clear that Freitag focuses on not only being environmentally conscious, but also creating healthy and safe work environments for the staff they use for labor. Comparing this company to other large brands that advertise sustainability in their products, it is clear that there is no competition. If Freitag were to gain more popularity, these products would replace other reusable bag companies simply because of their care for the landscape and environment. While the price range is higher compared to others, it is more valuable due to this incredible level of environmental consciousness. Freitag is a company that is single-handedly setting an example for other companies globally, when it comes to creating effective products while still maintaining a level of sustainability and appreciating the workers that spend hundreds of hours creating the best version of these bags possible.

Bibliography

Production | Freitag. https://www.freitag.ch/en/production.

“Freitag, Keep Moving Forward like a Truck.” Labbrand, https://www.labbrand.com/brandsource/going-deeper-than-the-buzz-freitag-keep-moving-forward-like-a-truck.

How Much Horsepower Does a Semi-Truck Have? - International Used Truck ...https://www.internationalusedtrucks.com/how-much-horsepower-does-a-semi-truck-have/.

“Horsepower.” Wikipedia, Wikimedia Foundation, 11 Mar. 2023, https://en.wikipedia.org/wiki/Horsepower.

Marsh, Jacob. “How Many Watts Does a Washing Machine Use?: Energysage.” EnergySage Blog, EnergySage, 29 Nov. 2022, https://news.energysage.com/how-many-watts-does-a-washing-machine-use/.

Shiv. “What Is the CCTV Camera Power Consumption Rate: Nobroker Forum.” Real Estate Forum by NoBroker.com, 26 Feb. 2023, https://www.nobroker.in/forum/how-much-power-does-a-cctv-camera-use/.

Contributor, Guest. “An Introduction to Buying Studio Flash Lights.” Digital Photography School, 4 Aug. 2021, https://digital-photography-school.com/an-introduction-to-buying-studio-flash-lights/.

Bellocchio, Daniele, et al. “The Freitag Brothers, Inventors of the Bag Made from Used Truck Tarps, Tell Us Their Story.” LifeGate, 15 June 2020, https://www.lifegate.com/freitag-brothers-interview.

Codini, Anna. “Freitag: Recycling Strategies in Fashionable Accessories IND.” Micro & Macro Marketing, Società Editrice Il Mulino, 1 Jan. 1970, https://ideas.repec.org/a/mul/jyf1hn/doi10.1431-82871y2016i1p105-122.html.

designboom, kieron marchese I. “Freitag Introduces Lightweight Accessories Made of Recycled Plastic Bottles.” Designboom, 13 Feb. 2019, https://www.designboom.com/design/freitag-tarp-on-pet-bags-recycled-plastic-bottles-02-13-2019/.

Urvi Parashar

DES 40A

Christina Cogdell

3 March 2023

FREITAG Bag (Waste and Emission)

As the world becomes increasingly aware of the impact that human activity has on the environment, more and more individuals and companies are taking steps to reduce their waste and emissions. One company that has made significant strides in this area is Freitag Bags, a Swiss-based manufacturer of high-quality bags and accessories. One of the key ways in which Freitag Bags is working to reduce its environmental impact is through the use of sustainable materials. The company makes extensive use of recycled materials, including discarded truck tarps, bicycle inner tubes, and seat belts, all of which would otherwise end up in landfills. By repurposing these materials into stylish and functional bags, Freitag Bags is helping to reduce waste while also creating unique products that appeal to environmentally conscious consumers.Another important aspect of Freitag's approach to sustainability is minimizing resource consumption.This essay will explore the various ways in which Freitag Bags has addressed waste and emission concerns. The first subtopic of this essay will focus on material choices, where we will discuss the differences between sustainable and non-sustainable materials used in production. We will examine how Freitag Bags has chosen to use recycled materials such as discarded truck tarpaulins and seat belts instead of traditional materials like leather or synthetic fabrics. The second subtopic will delve into emissions during the production process.

Freitag bags are known for their unique design and durability, but their material choices also play a significant role in their sustainability. The brand uses a range of materials, including truck tarps, seat belts, and bicycle inner tubes, which are all repurposed from their original intended use. These materials not only give the bags their distinctive aesthetic but also contribute to reducing waste in landfills.One of the most significant aspects of Freitag bags is their use of sustainable materials. The company has always been committed to using eco-friendly and recycled materials in their products, which not only reduces waste but also minimizes emissions during production. Moreover, these materials are robust and durable, which means that they can withstand wear and tear over time, making them long-lasting products.On the other hand, non-sustainable materials such as virgin plastic or leather have a significant environmental impact due to their production process. The production of leather requires large amounts of water and energy while emitting harmful chemicals into the environment. Similarly, virgin plastic is made from petroleum-based products that contribute to greenhouse gas emissions.

In addition to using recycled materials in its products' production process, Freitag also strives to reduce its carbon footprint by implementing sustainable practices in its operations. For example, the company uses renewable energy sources such as wind turbines and solar panels at its manufacturing facilities. Additionally, it has implemented a closed-loop system where it recycles all waste generated during production.Freitag bags are made from truck tarpaulins, seat belts, and bicycle inner tubes that have been discarded or deemed unusable. These materials are sourced locally in Switzerland and collected by the company's team of "freight surfers," who scour scrapyards for high-quality tarpaulins that can be repurposed into durable bags. By using recycled materials, Freitag reduces the demand for virgin resources and prevents these materials from ending up in landfills or incinerators.However, the production of FREITAG bags still requires energy and resources, including water, electricity, and transportation.One of the biggest environmental impacts of FREITAG bag production is greenhouse gas emissions. According to FREITAG's sustainability report, the company's CO2 emissions per product have decreased significantly in recent years, thanks to energy-saving measures and the use of renewable energy sources. However, the report also acknowledges that the company's total emissions have increased due to growth in production and transportation.FREITAG bags are made in Switzerland and Portugal, and the materials used to make them are sourced from various locations around the world. This means that transportation is a significant source of emissions. FREITAG uses low-emission transportation methods whenever possible, such as rail and sea freight, but air freight is sometimes necessary for urgent orders or when transporting materials from distant locations.

Emissions in the production process of Freitag bags is a major concern for the company as they strive to minimize their environmental impact. The production process involves several stages, including cutting, washing, drying, and sewing of the materials used to make the bags. Each stage produces emissions that contribute to air pollution and climate change.One of the biggest sources of emissions in the production process is from the washing and dyeing of truck tarpaulins used to create the unique designs of Freitag bags. The washing process requires high amounts of water and energy, which results in significant greenhouse gas emissions. To address this issue, Freitag has implemented a closed-loop system that recycles 80% of water used in its washing process. This reduces water consumption significantly and minimizes wastewater discharge into rivers and oceans.Additionally, Freitag has invested in renewable energy sources such as solar panels on its factory roofs to reduce reliance on non-renewable energy sources like fossil fuels. By using renewable energy sources throughout their production chain, Freitag can drastically reduce its carbon footprint.Moreover, Freitag collaborates with suppliers who share their commitment to sustainability by sourcing eco-friendly materials such as organic cotton for lining fabrics and recycled polyester for zippers. This approach reduces both emissions from transportation and the use of non-renewable resources like petroleum-based plastics.

The use of sustainable materials also extends to the packaging used by Freitag. Instead of traditional plastic packaging, the company uses biodegradable cornstarch bags that decompose within six months when exposed to air and moisture. They do not use plastic bags or wrapping materials when shipping orders instead opt for reusing cardboard boxes from suppliers as well as biodegradable packing tape made from paper rather than adhesive plastic tape. Freitag's commitment to sustainability goes beyond just making stylish bags - it involves a whole approach towards minimizing waste and reducing emissions throughout every stage of product development. By using recycled materials and implementing eco-friendly production methods, Freitag sets an example for other companies looking to reduce their environmental impact while still delivering high-quality products.

Although the bags they make are sustainable and made from reused material, what happens to them when they are no longer functional or desired by the consumer? The company has taken a proactive approach to end-of-life waste management by implementing a circular economy model, which involves designing products with materials that can be easily recycled and reused. When a bag reaches the end of its life, it can be returned to the company for recycling. Freitag has established a system for collecting used bags from customers and processing them into new products. This closed-loop system minimizes waste and reduces the carbon footprint associated with manufacturing new products. In addition to recycling, Freitag also encourages customers to repair their bags rather than replacing them entirely. The company offers repair services at its stores and provides tutorials on how to repair minor damages at home. By extending the lifespan of their products through repairs, Freitag is reducing waste and promoting sustainable consumption habits.

In conclusion, Freitag bags have proven to be a sustainable and environmentally conscious brand that has implemented various strategies to reduce waste and emissions. The use of recycled materials in the production of bags not only reduces waste but also minimizes resource consumption. The ethical production and manufacturing practices adopted by the company ensure that their products are made under fair working conditions while minimizing environmental impacts. Freitag's commitment to minimizing resource consumption is evident in their innovative approach to repurposing materials such as used truck tarpaulins, seatbelts, and bicycle inner tubes into unique bags. This approach has helped to reduce landfill waste while creating functional products that meet the needs of customers. The company's environmental consciousness and responsibility are reflected in their efforts towards reducing emissions through initiatives such as using renewable energy sources, optimizing transportation routes, and promoting cycling as an alternative means of transport for employees. Overall, Freitag bags have set a high standard for sustainability in the fashion industry through their dedication to using sustainable materials, ethical production processes, minimizing resource consumption and reducing emissions. As consumers become more environmentally conscious, it is essential for brands to prioritize sustainability in their operations. Freitag serves as an excellent example for other companies looking to adopt sustainable practices while remaining profitable.

Bibliography

Bellocchio, Daniele, et al. “The Freitag Brothers, Inventors of the Bag Made from Used Truck Tarps, Tell Us Their Story.” LifeGate, 15 June 2020, https://www.lifegate.com/freitag-brothers-interview.

Borsi , Aurore. “Circle Lab.” Knowledge Hub, 20 Oct. 2022, https://knowledge-hub.circle-lab.com/circular-jobs-initiative.

Codini, Anna. “Freitag: Recycling Strategies in Fashionable Accessories IND.” Micro & Macro Marketing, Società Editrice Il Mulino, 1 Jan. 1970, https://ideas.repec.org/a/mul/jyf1hn/doi10.1431-82871y2016i1p105-122.html.

designboom, kieron marchese I. “Freitag Introduces Lightweight Accessories Made of Recycled Plastic Bottles.” Designboom, 13 Feb. 2019, https://www.designboom.com/design/freitag-tarp-on-pet-bags-recycled-plastic-bottles-02-13-2019/.

“Freitag | One-off Pieces Made from Recycled Truck Tarps.” FREITAG, FREITAG Lab. AG, https://www.freitag.ch/en.

Freitag. “Rpet Application Example: Freitag Launches Innovative Bag.” Petnology.com, 11 Mar. 2019, https://www.petnology.com/online/news-detail/rpet-application-example-freitag-launches-innovative-bag.

“Freitag.” FREITAG - Sustainability Rating - Good On You, July 2022, https://directory.goodonyou.eco/brand/freitag#.

Rothbarth , Frank. “FREITAG Initiates Recyclable Truck Tarp.” Freitag Initiates Recyclable Truck Tarp, Covestro, 11 July 2022, https://www.covestro.com/press/freitag-initiates-recyclable-truck-tarp/.

Supreetha. “Freitag Creates Bags and Accessories out of Recycled Tarpaulins.” DesignNuance, 19 June 2021, https://www.designnuance.com/freitag-creates-bags-and-accessories-out-of-recycled-tarpaulins/.

Xu, Jiang, and Ping Gu. “Five Principles of Waste Product Redesign under the Upcycling Concept.” Five Principles of Waste Product Redesign under the Upcycling Concept | Atlantis Press, Atlantis Press, 1 Sept. 2015, https://www.atlantis-press.com/proceedings/ifeesm-15/25841273.